Fishhook forming machine

A forming machine and forming mechanism technology, applied in the direction of fishhooks, fishing, applications, etc., can solve the problems of forming fishhooks bruised, slow working process, and easy wear of screw rods, so as to achieve consistent size of fishhooks and improve production efficiency , The effect of uniform material body length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

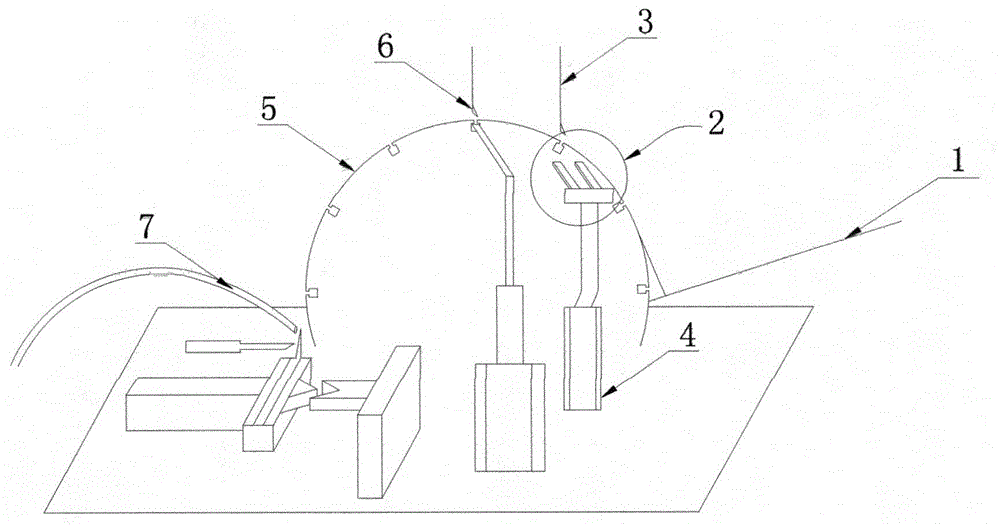

[0020] Such as figure 1 As shown, a fishhook forming machine includes a transmission mechanism, a feeding mechanism, a tail forming mechanism, a barb cutting mechanism, a hook mechanism, and a stripping mechanism, wherein an additional device is provided between the feeding mechanism and the tail forming mechanism for determining the fishhook. The length of the hook forming base material is short and the fixed length mechanism 2 that can cut the excess length; the stripping mechanism includes an air gun 7 that cooperates with the hook mechanism, that is, the air gun 7 sprays air after the fishhook is formed at the hook mechanism, and the effect of the air flow is used to make The formed fishhook is disengaged from the hook mechanism.

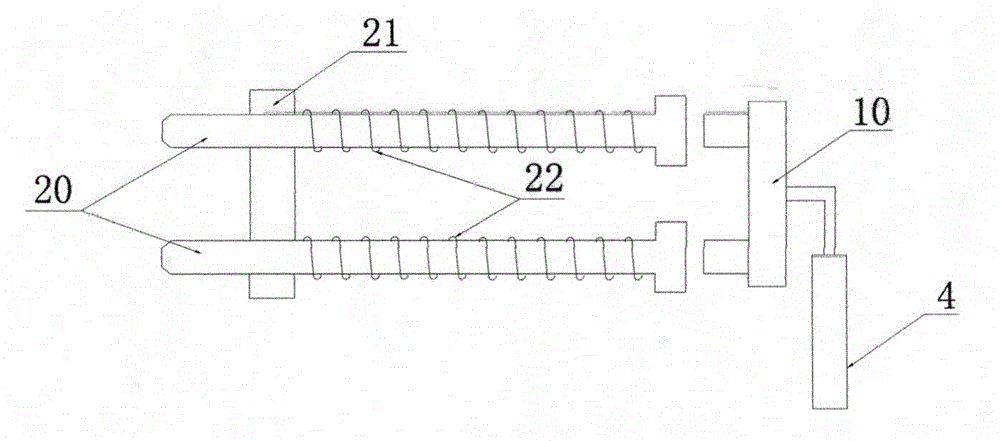

[0021] Fixed length and short mechanism 2 comprises a pusher 10 that is connected with rocking cylinder 4, and the movable rod 20 corresponding to pusher 10, movable rod 20 is connected with a support member 21 and passes this support member 21,...

Embodiment 2

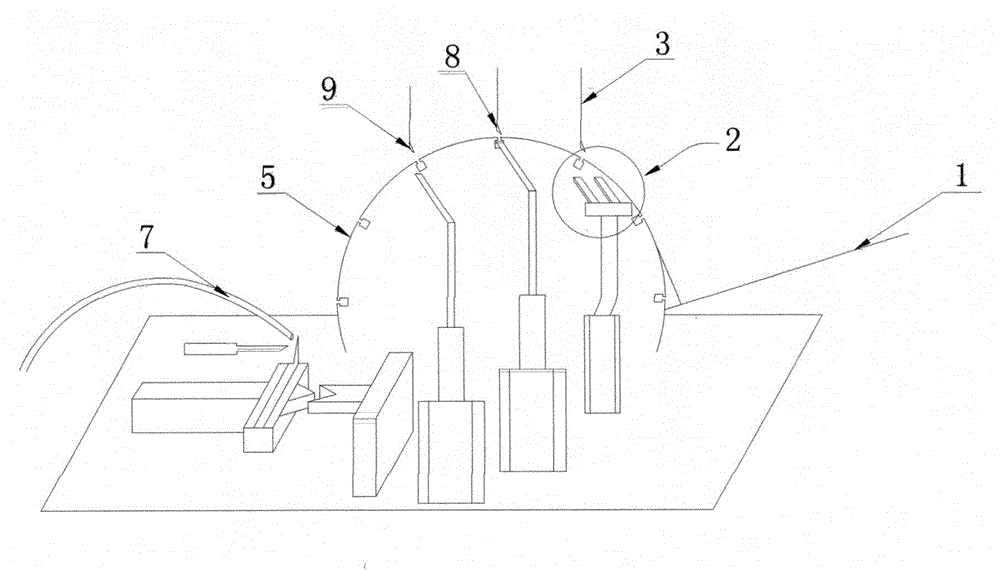

[0026] This embodiment is similar in structure and principle to the above-mentioned embodiment 1, the difference is that the tail forming mechanism includes a first pressing piece 8 for forming the tail into a half-circle shape and a second pressing piece 9 for forming a half-circle-shaped tail into a loop .

[0027] As can be seen from the above description, a fixed-length mechanism for determining the length of the fishhook forming base material and cutting the excess length is additionally provided between the feeding mechanism and the tail forming mechanism in the present invention. The fixed length and short mechanism can automatically cut according to the length of the required material body determined by the model of the fishhook to be produced, which improves the production efficiency, ensures the uniform length of the material body, and the size of the fishhook after production is consistent; the stripping mechanism includes a The air gun matched with the hook mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com