A coil turning frame with a positioning control device

A positioning control and stand-up technology, which is applied in the manufacture of inductors/transformers/magnets, electrical components, circuits, etc., can solve problems such as coil dumping, and achieve the effect of turning over smoothly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings, which are explanations rather than limitations of the present invention.

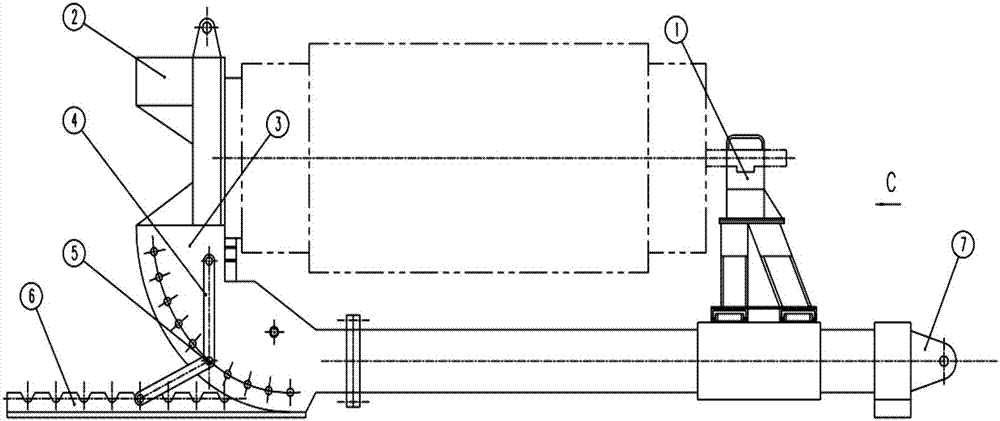

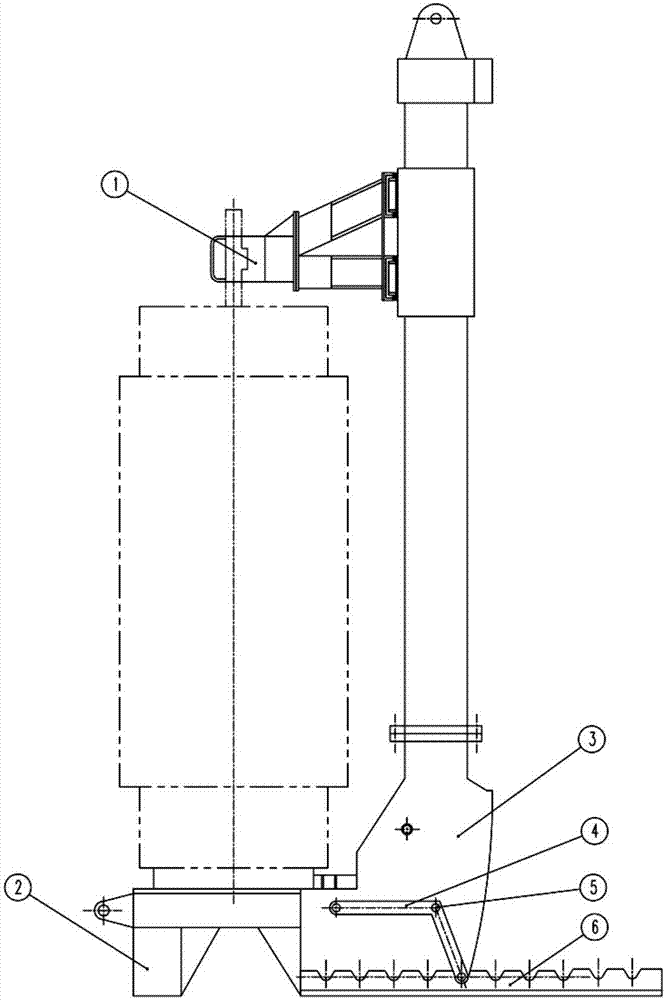

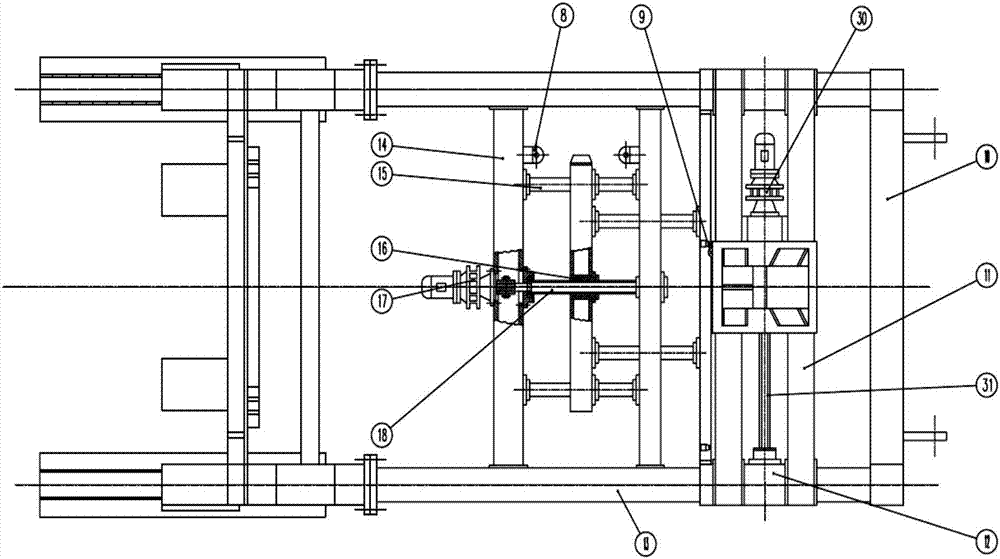

[0028] Such as Figure 1 to Figure 5 As shown, a coil turning stand with a positioning control device of the present invention includes a movable support seat 1, a foot pad 2, a turning mechanism 3, a support foot 4, a shaft circlip 5, a seat 6, a hanging climber 7, and a travel switch 8. Iron stopper 9, connecting beam 10, lateral guide rail 11, first slider 12, upward guide rail 13, beam 14, light rod 15, copper sleeve 16, first cycloid reducer 17, first wire Bar 18, ring 19, first parallel iron 20, second parallel iron 21, handle 22, semicircular ring 23, latch 24, screw rod 25, nut 26, cotter pin 27, cover 28, second slide block 29, the first Two cycloid reducers 30 and a second lead screw 31. The two semi-circular rings 23 on the movable support base 1 are detachably connected thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com