High-performance triangular-strand steel wire rope

A technology of triangular strands and steel wire ropes, which is used in textiles, papermaking, textile cables, etc., can solve the problems of short service life of ordinary steel wire ropes, affecting work efficiency and safety, and uneven force on steel wire ropes. Cost of use, effect of preventing shelling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

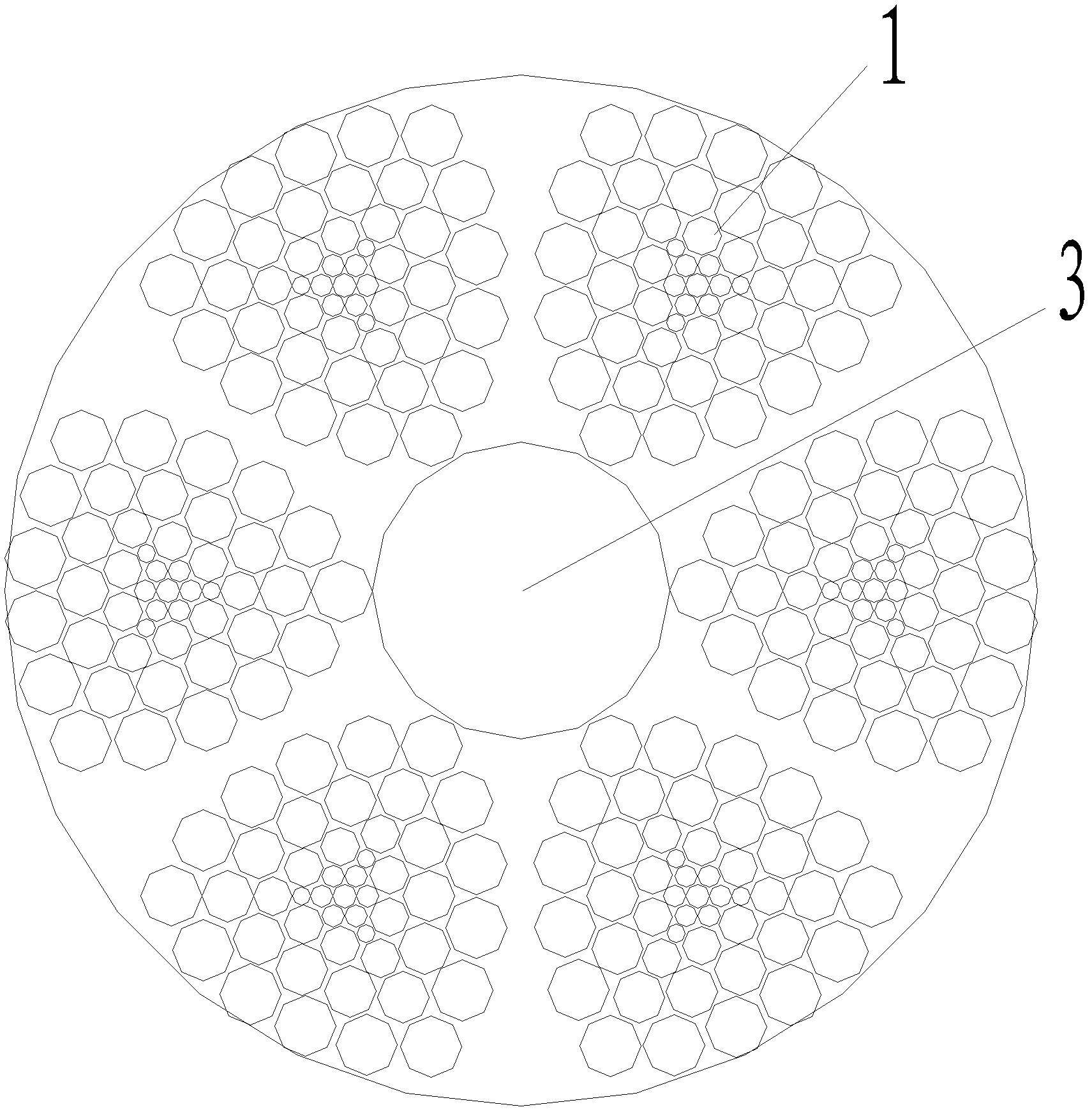

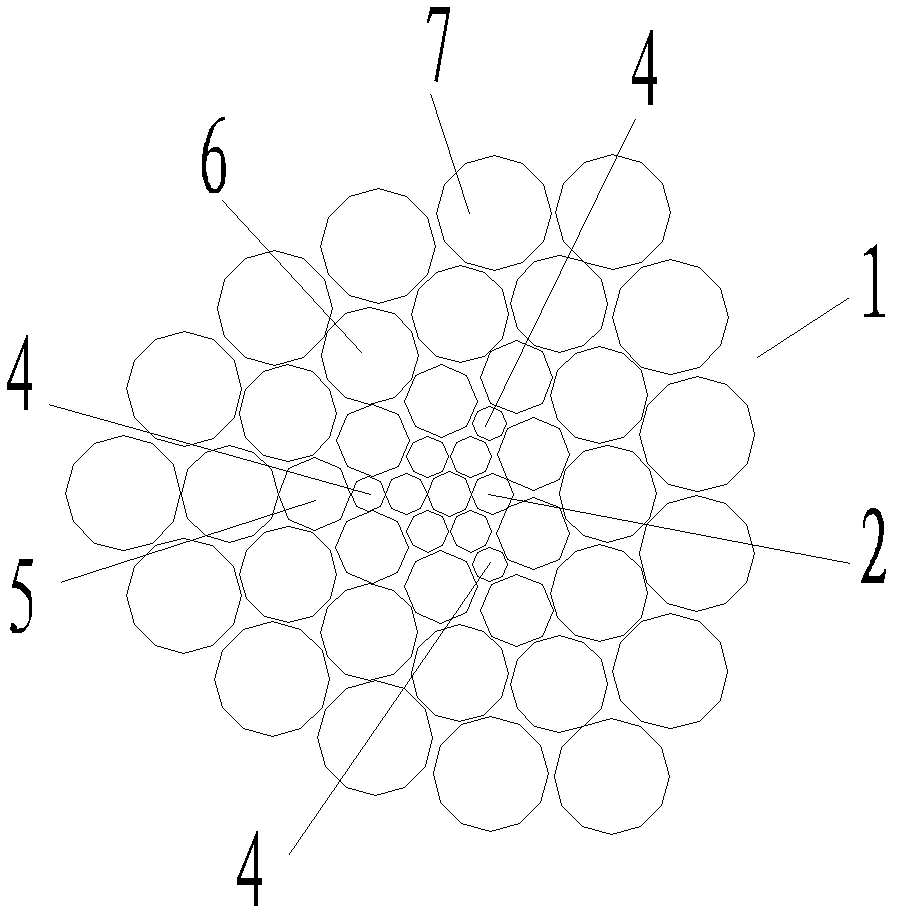

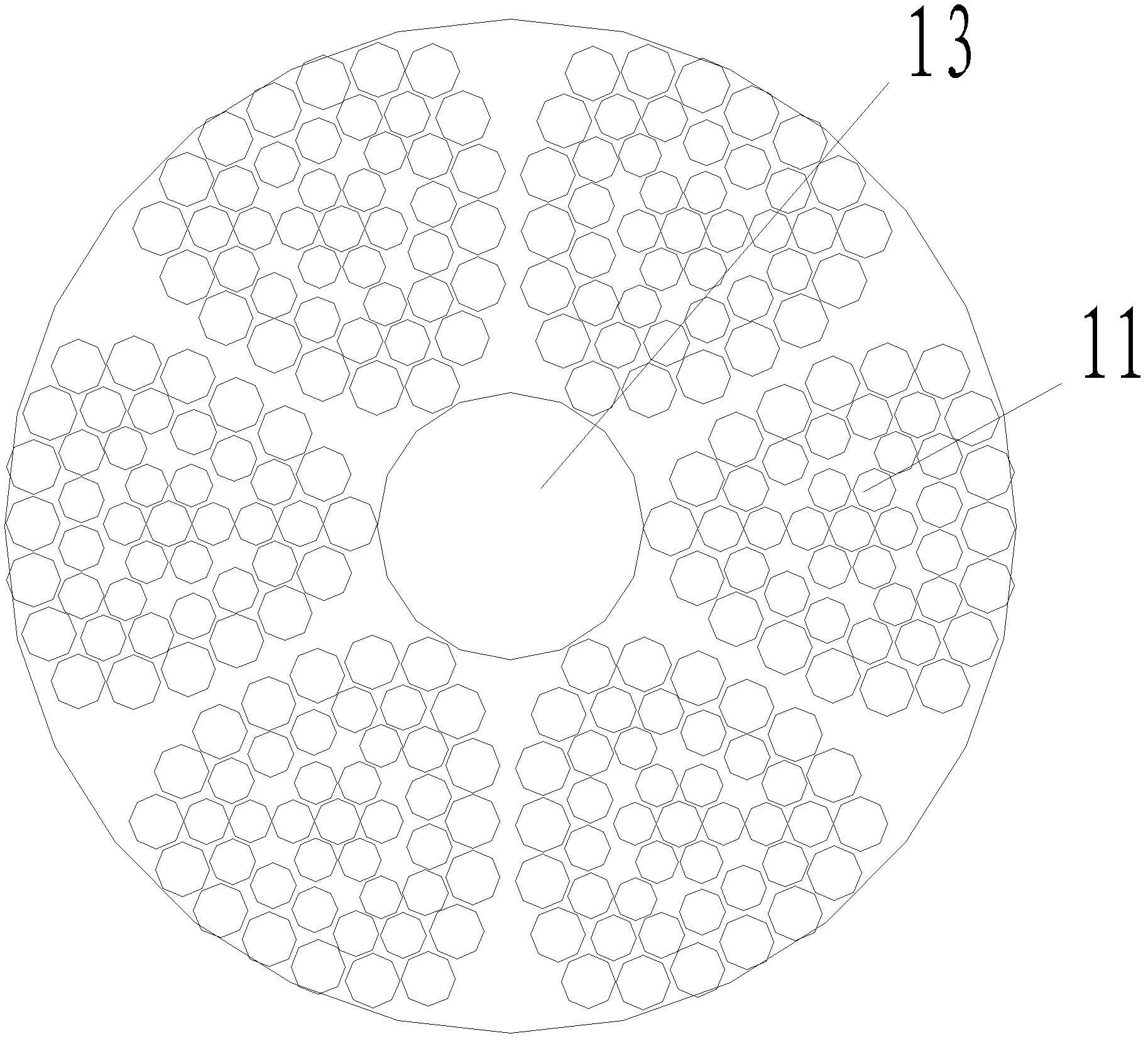

[0015] as attached figure 1 , 2 Shown is a high-performance triangular-strand steel wire rope of the present invention, comprising 6 strands 1 and a rope core 3; the 6 strands 1 are uniformly twisted on the periphery of the rope core 3; each strand 1 is connected with The rope cores 3 are tangent; the six rope strands 1 are arranged at an angle of 60°; the shape of the rope strands 1 and the rope strands 1 is roughly triangular; it includes a strand core 2, a central steel wire 4, and an inner steel wire 5 , middle layer steel wire 6, outer layer steel wire 7; described strand core 2 is the round steel wire strand that is formed by a plurality of steel wires; Described center steel wire 4 has 3, is arranged on strand core 2 periphery and is arranged by 120 ° equal divisions, cooperates The strand core 2 forms a triangular shape; the inner layer steel wire 5 wraps the strand core 2 and the central steel wire 4; the middle layer steel wire 6 is twisted around the inner layer s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com