Reinforcing method for 3D printing reinforced masonry shear wall

A 3D printing and reinforced masonry technology, which is applied in the processing of walls, building materials, and building components, can solve the problems of large labor consumption, improve construction efficiency, facilitate the industrialization of construction, and simplify the construction process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

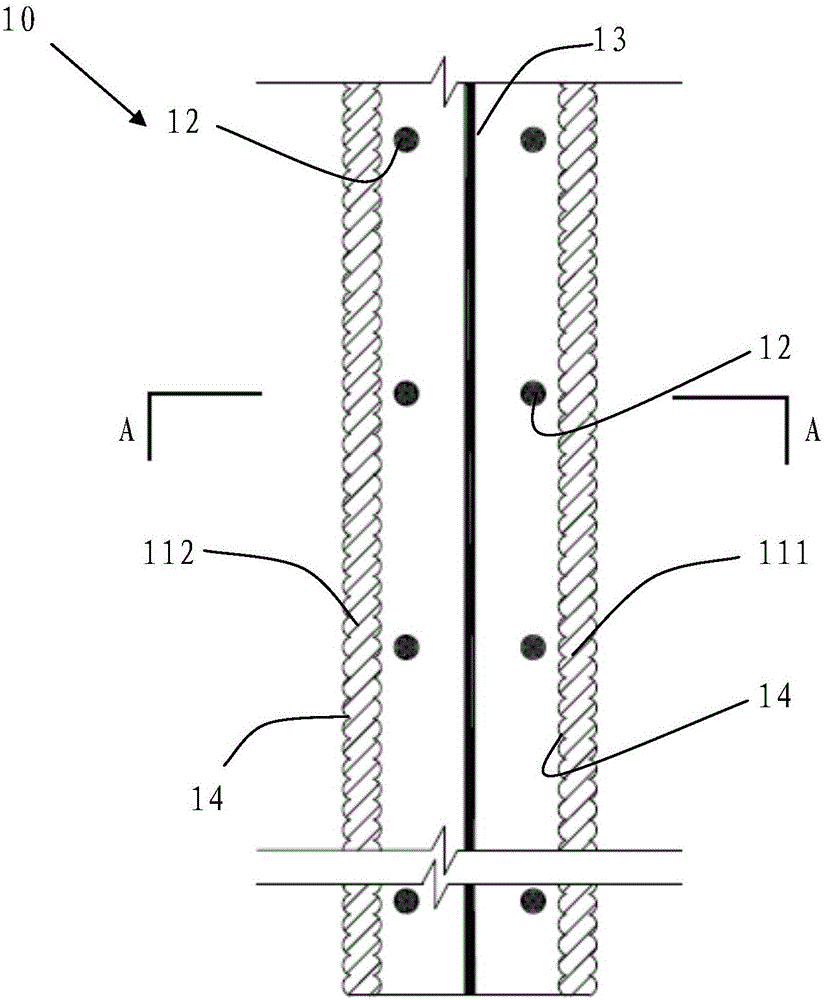

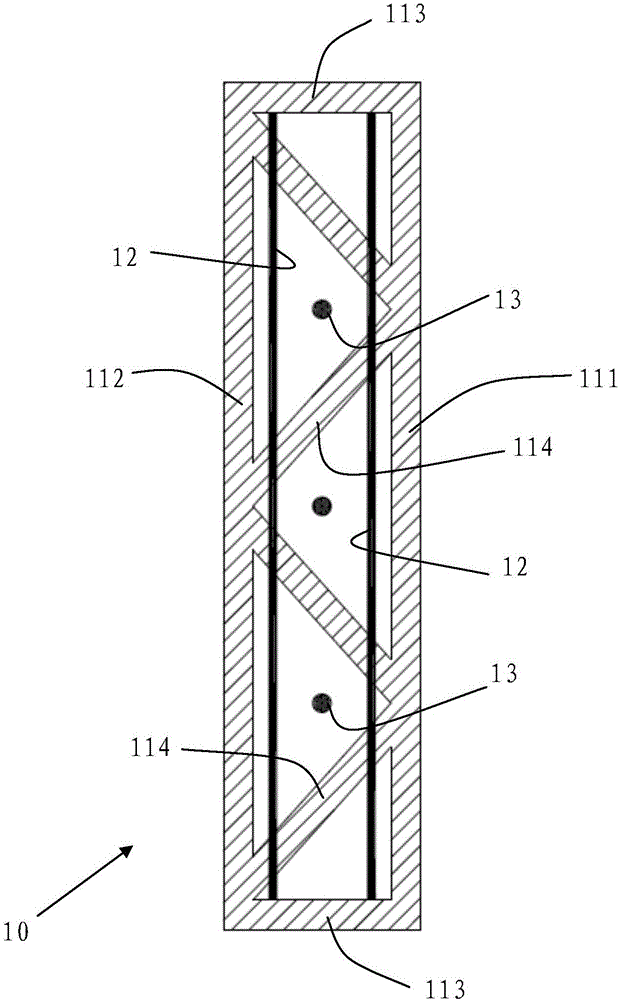

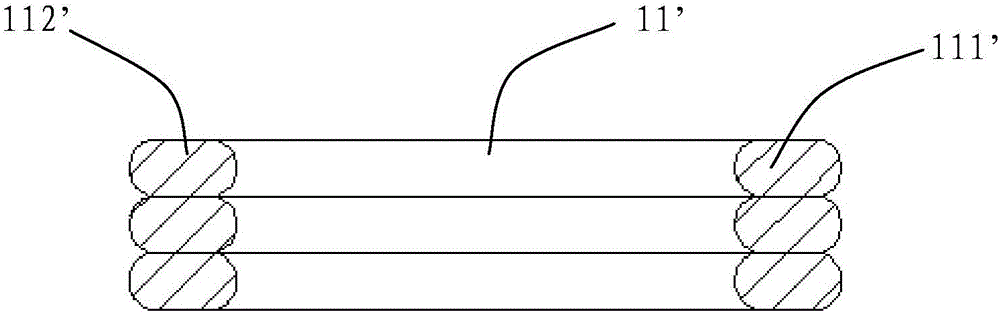

[0028] see first figure 1 As shown, it is a 3D printed reinforced masonry shear wall structure 10 made by adopting a 3D printed reinforced masonry shear wall reinforcement method of the present invention. The 3D printed reinforced masonry shear wall structure 10 is mainly It consists of a plurality of stacked masonry shells, transverse steel bars 12 and vertical steel bars 13 of reinforced masonry shear walls, and concrete poured in the masonry shells (concrete is not poured in the figure). Cooperate figure 2 As shown, the masonry shell is a rectangular shell, and its shape is adapted to the shear wall. The two side shell surfaces 113 on both sides of the two shell surfaces 112, the first shell surface 111 and the second shell surface 112 are parallel to each other, and there are multiple oblique supports further connected between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com