A method of 3D printing building thermal insulation and sound insulation wall

A technology of 3D printing and building thermal insulation, applied in the processing of building materials, thermal insulation, construction, etc., can solve the unfavorable green construction technology update and progress needs, space utilization, high material loss rate, increased cost, process time, etc. problems, to achieve the effect of saving construction procedures, improving construction accuracy, and improving space utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

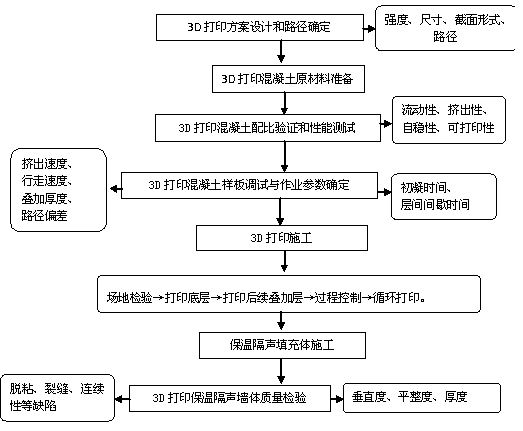

[0033] Combine below figure 1 - image 3 , Taking a multi-story concrete structure house as an example, the method of 3D printing building insulation and sound insulation wall is used to complete the construction of indoor partition walls and internal partition walls. The standard structural layer height is 3.0m, the wall height is 2.5m, and the wall thickness is 120-200mm. The maximum length of the wall in the implementation case is 4.8m.

[0034] The main steps of implementation are as follows:

[0035] Step 1: 3D printing wall scheme design and path determination, combining construction, structure, water and electricity, facility construction drawings, dividing the scope of 3D printing, building a model through BIM information, determining the printing path diagram, and formulating the 3D printing operation technical plan.

[0036] In the implementation case, the wall scheme design is attached figure 2 , The wall design includes:

[0037] (1) The strength of the wall is determined...

Embodiment 2

[0060] Combine below figure 1 , Figure 4 , Figure 5 , Take a multi-story concrete structure house as an example, adopt 3D printing method of building insulation and sound insulation wall to complete the construction of indoor partition walls and internal partition walls. The height of the structural layer is 4.5m, the net height of the wall is 3.8m, and the wall thickness is 190mm. The maximum length of the wall in the implementation case is 3.9m.

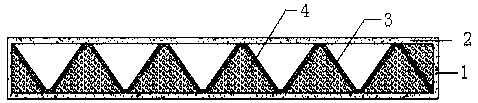

[0061] In the implementation case, the wall scheme design is attached Figure 4 , Wall section thickness is 190mm, square hole, wall volume opening rate is between 25%-65%, wall outer wall 1, 2 thickness ≥ 25mm, wall support 3 thickness ≥ 50mm.

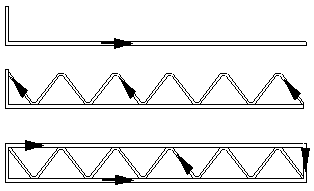

[0062] In the implementation case, see the attachment for the path of the wall Figure 5 . Each layer is printed by a combination of "concave" and "convex" printing to form a trajectory. Concave and convex combination, circular printing, can form single-row holes, double-row holes and other ...

Embodiment 3

[0065] Combine below figure 1 , Image 6 Take a multi-layer concrete shear wall structure as an example. The post-masonry wall has a cross-section thickness of 120-150mm, with straight, curved, and broken line types. The height of the structural layer is 3.3m, the net height of the wall is 2.8m, and the length of the wall in the implementation case is 900-2600mm. The method of 3D printing building insulation and sound insulation wall is used to complete the construction of indoor partition walls and internal partition walls.

[0066] In the implementation case, the wall scheme design is attached Image 6 , Wall section thickness is 150mm, elliptical hole, wall volume opening rate is between 35%-50%, wall thickness ≥25mm, wall support thickness ≥25mm.

[0067] In the implementation case, see the attachment for the path of the wall Image 6 . Each layer is printed in the form of "inverted S" or "sine wave" and "cosine wave" to form a trajectory. The printed cavity is filled with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com