3D printing method for building heat preservation and sound insulation wall

A 3D printing, building insulation technology, applied in the processing of building materials, insulation, construction, etc., can solve the technical update and progress needs of unfavorable green construction, space utilization, high material loss rate, increased cost, process time, etc. problems, to achieve the effect of saving construction procedures, improving construction accuracy, and improving space utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

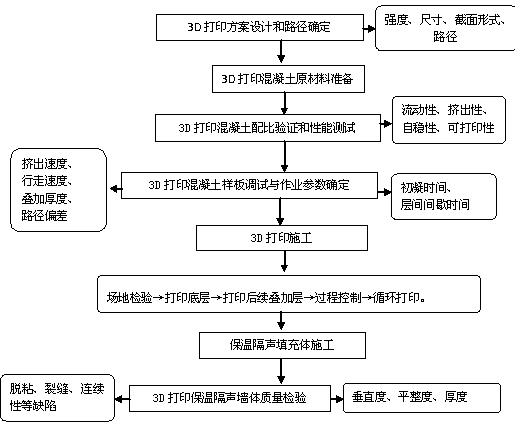

[0033] Combine below figure 1 -- image 3 , taking a multi-storey concrete structure house as an example, the construction of indoor partition walls and internal partition walls is completed by using the method of 3D printing building thermal insulation and sound insulation walls. The height of the standard structural floor is 3.0m, the net height of the wall is 2.5m, and the thickness of the wall is 120-200mm. The maximum length of the wall in the implementation case is 4.8m.

[0034] The main steps to implement are as follows:

[0035] Step 1: 3D printing wall scheme design and path determination, combined with architectural, structural, hydropower, and facility construction drawings, divide the scope of 3D printing, build models through BIM information, determine the printing path map, and formulate the 3D printing operation technical plan.

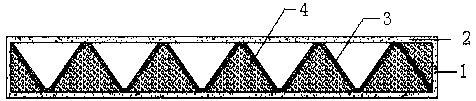

[0036] In the implementation case, the design of the wall scheme is shown in the attached figure 2 , the wall scheme design inclu...

Embodiment 2

[0060] Combine below figure 1 , Figure 4 , Figure 5 , taking a multi-storey concrete structure house as an example, the construction of indoor partition walls and internal partition walls is completed by using the method of 3D printing building thermal insulation and sound insulation walls. The height of the structural floor is 4.5m, the net height of the wall is 3.8m, the thickness of the wall is 190mm, and the maximum length of the wall in the implementation case is 3.9m.

[0061] In the implementation case, the design of the wall scheme is shown in the attached Figure 4 , The thickness of the wall section is 190mm, the square hole, the wall volume opening rate is between 25% and 65%, the thickness of the outer wall 1 and 2 is ≥ 25mm, and the thickness of the support 3 in the wall is ≥ 50mm.

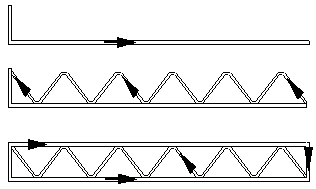

[0062] In the implementation case, the path trajectory of the wall is shown in the attached Figure 5 . Each layer of printing is composed of "concave" and "convex" combined pr...

Embodiment 3

[0065] Combine below figure 1 , Figure 6 , taking a multi-storey concrete shear wall structure as an example, the wall body built by masonry later has a section thickness of 120-150mm, and there are linear, arc, and broken line types. The height of the structural floor is 3.3m, the net height of the wall is 2.8m, and the length of the wall in the implementation case is 900-2600mm. The method of 3D printing building thermal insulation and sound insulation walls is used to complete the construction of indoor partition walls and internal partition walls.

[0066] In the implementation case, the design of the wall scheme is shown in the attached Figure 6 , The thickness of the wall section is 150mm, the oval hole, the opening rate of the wall volume is between 35% and 50%, the thickness of the outer wall of the wall is ≥25mm, and the thickness of the support inside the wall is ≥25mm.

[0067] In the implementation case, the path trajectory of the wall is shown in the attached...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com