Nano SiO2 grinding material polishing fluid for electronic glass

A polishing liquid and abrasive technology, which is applied to grinding/polishing equipment, polishing compositions containing abrasives, polishing compositions, etc., can solve the problems of large roughness, high viscosity of polishing liquid, serious adsorption, etc. Foaming and defoaming power, chemical enhancement, surface tension reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Preparation of 1425g nano-SiO of electronic glass 2 Abrasive polishing fluid.

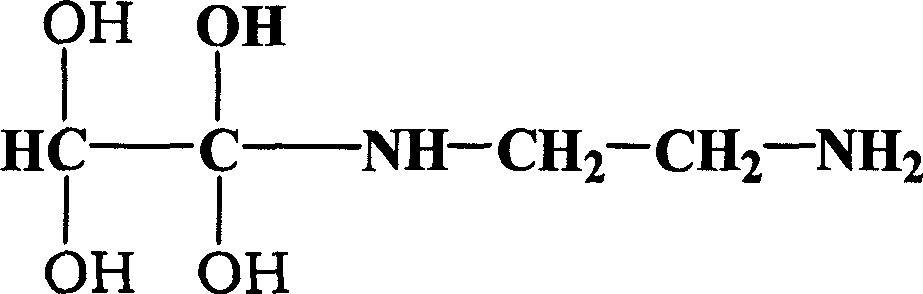

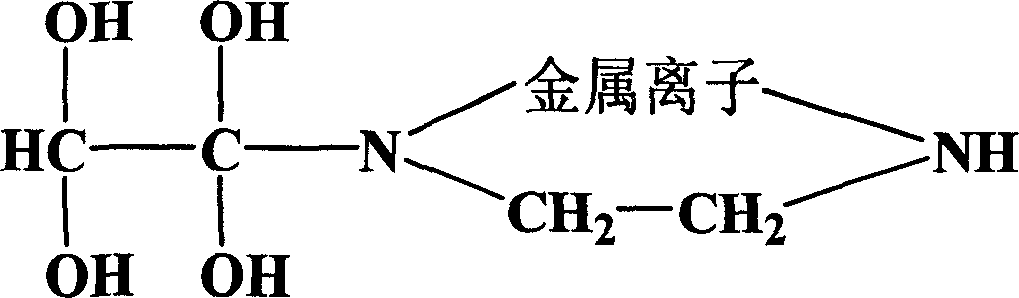

[0047] To 1000g 45wt% SiO with 40nm particle size and dispersion degree of ±10.0nm 2 Add 40gJFC, 40gFA / O type I active agent to the hydrosol solution and stir and mix evenly; and add 30g tetrahydroxyethylethylenediamine to the above mixture before polishing and stir evenly; then dilute 15gKOH with 300g deionized water Add it to the above mixed solution and stir evenly; the pH value of the prepared polishing solution is 10.5-13.5.

Embodiment 2

[0049] Preparation of 1355g nano-SiO of electronic glass 2 Abrasive polishing fluid.

[0050] 35wt% SiO to 1000g 50nm particle size 2 Add 45gJFC, 50gFA / O type I active agent to the hydrosol solution and stir and mix evenly; and add 50g triethanolamine to the above mixed solution before polishing and stir evenly; then dilute 10gKOH with 200g deionized water and add to the above mixed solution , stir evenly; the pH value of the prepared polishing solution is 10.5-13.5.

Embodiment 3

[0052] Preparation of 1555g nano-SiO of electronic glass 2 Abrasive polishing fluid.

[0053] 50wt% SiO to 1000g 40nm particle size 2 Add 35gJFC, 60gFA / O type I active agent to the hydrosol solution and stir and mix evenly; and add 40g dihydroxyethylethylenediamine to the above mixture before polishing and stir evenly; then dilute 20gKOH with 400g deionized water Add it to the above mixed solution and stir evenly; the pH value of the prepared polishing solution is 10.5-13.5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com