Method for cleaning surface of magnesium aluminum alloy subjected to chemically mechanical polishing

A magnesium-aluminum alloy and chemical mechanical technology, which is applied in the field of surface cleaning after chemical mechanical polishing of magnesium aluminum alloy, can solve problems such as uneven fog on the wafer surface, uneven distribution of polishing liquid, and reduced precision of devices, and achieve consistent temperature distribution , Improving perfection and good temperature consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

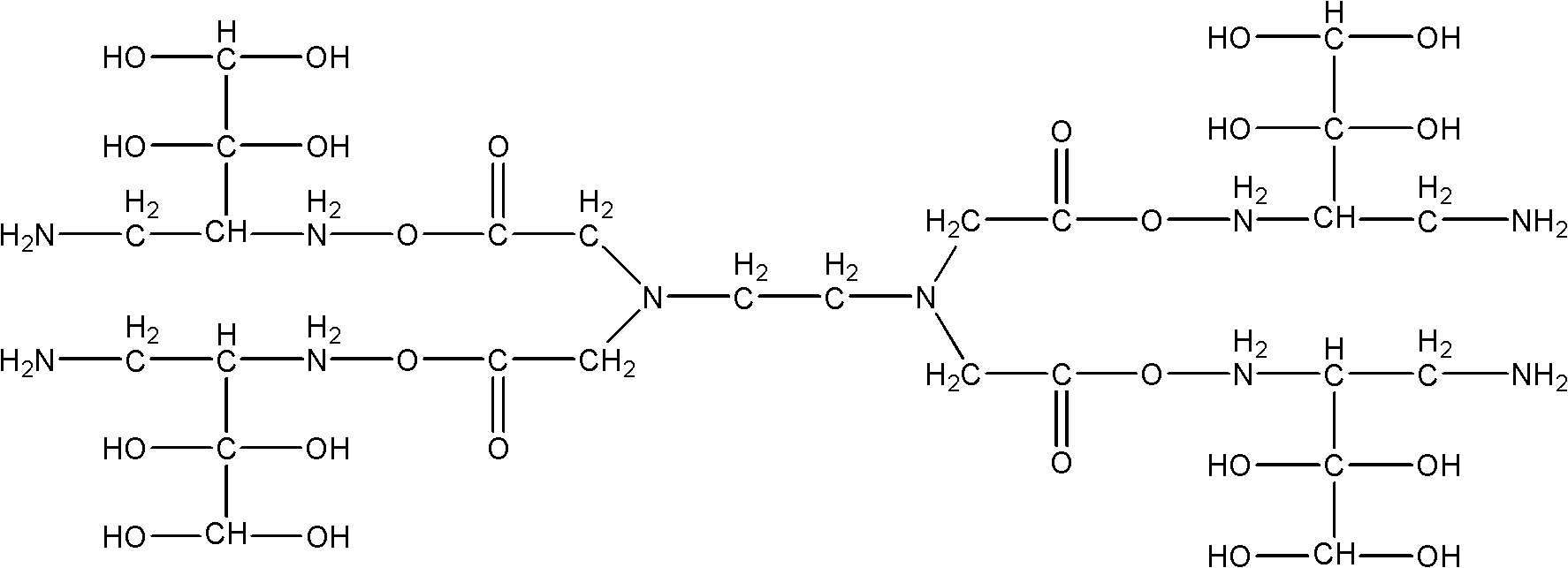

Image

Examples

Embodiment 1

[0024] (1) Get the ultrapure water 3645g that resistance is more than 18MΩ, put into 100g of FA / O Type I surfactant and 50g of FA / O chelating agent while stirring.

[0025] (2) Weighing 5g of phenylacryltriazole is diluted with 200g of ultrapure water with a resistance of 18MΩ or more and poured into the liquid of step (1) while stirring, to obtain a magnesium-aluminum alloy water-soluble surface cleaning solution after stirring evenly.

[0026] (3) Use the water-soluble surface cleaning solution obtained in step (2) to immediately polish and clean the magnesium-aluminum alloy material after alkaline chemical mechanical polishing for 2 minutes under the condition of zero pressure (self-weight pressure) at a flow rate of 1000ml / min.

[0027] (4) Rinse the magnesium-aluminum alloy material cleaned in step (3) for 30 seconds with ultrapure water with a resistance of more than 18MΩ under zero pressure (self-weight pressure) and a flow rate of 1000ml / min, and obtain the magnesium-al...

Embodiment 2

[0029] (1) Take 3400g of ultrapure water with a resistance of more than 18MΩ, and put in 100g of JFC and 50g of FA / O chelating agent while stirring.

[0030] (2) 250g of hexamethylenetetramine is diluted with 200g of ultrapure water with a resistance of 18MΩ or more and poured into the liquid of step (1) while stirring, and the magnesium-aluminum alloy water-soluble surface cleaning solution is obtained after stirring.

[0031] (3) Using the water-soluble surface cleaning solution obtained in step (2), use the flow rate of 4000ml / min to immediately polish and clean the magnesium-aluminum alloy material after alkaline chemical mechanical polishing for 30s under the condition of 0.01 atmospheric pressure (excluding self-weight pressure) .

[0032] (4) Rinse the magnesium-aluminum alloy material cleaned in step (3) for 30 seconds with ultra-pure water with a resistance of more than 18MΩ under the condition of zero pressure (self-weight pressure) and a flow rate of 4000ml / min, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com