Method for carrying out bonding epitaxial wafer and silicon wafer by indium (In)

An epitaxial wafer and silicon wafer technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problem of not being able to be widely used, save chemicals and equipment utilization, low melting point of indium, and reduce losses. The effect of matching defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

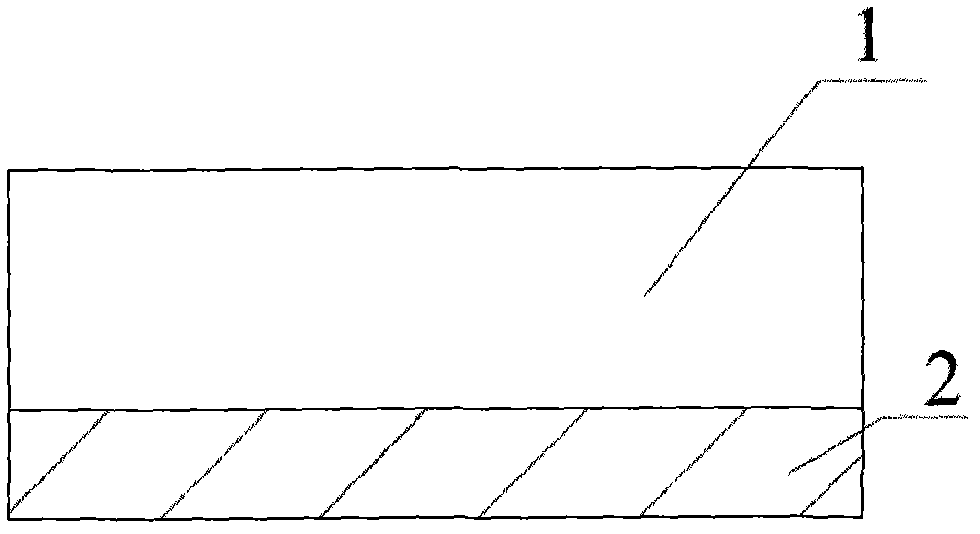

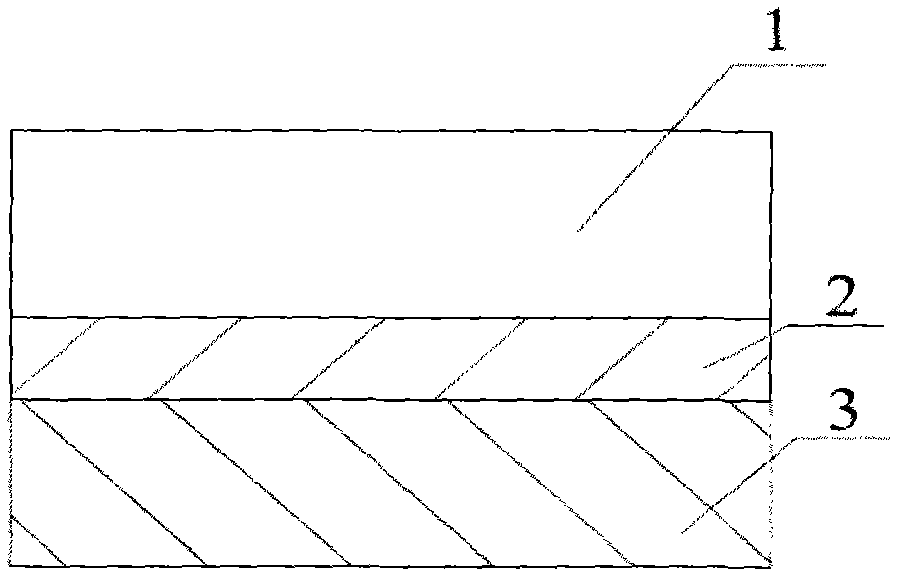

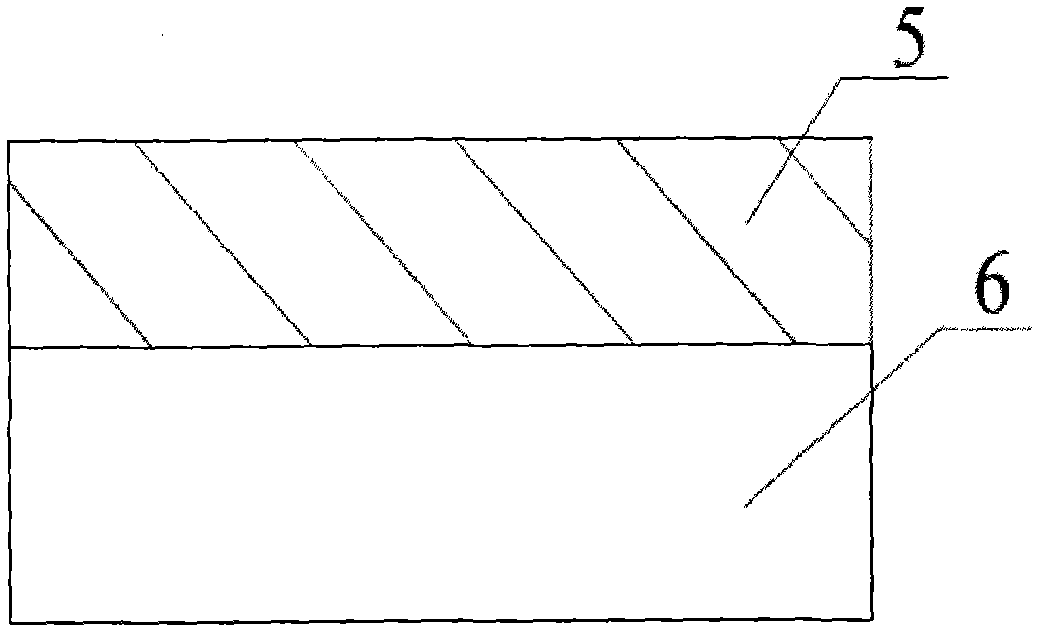

[0019] A kind of method that indium (In) carries out epitaxial wafer / silicon wafer bonding, has mirror layer (such as figure 1 The epitaxial wafer (shown in 2) (such as figure 1 As shown in 1) evaporated gold (Au) layer (such as figure 2 shown in 3), and then the mirror-polished silicon wafer (such as image 3 Shown in 6) the surface is soaked in the mixed solution (sulfuric acid, hydrogen peroxide, water) of 55 ℃ for 30 seconds, the ratio of the mixed solution can be sulfuric acid: hydrogen peroxide: water = 5: 1: 1, then rinse with deionized water, and put It is placed in a drying machine to dry, and a gold layer of a certain thickness is evaporated in an electron beam evaporation table (such as image 3 5) and indium (In) layer (such as Figure 4 shown), and then two opposite indium (In) layers are placed in the middle, put into the bonding machine (bonding) through the thermocompression bonding method, the thermocompression bonding pressure is 500KG, and the bonding te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com