Patents

Literature

92 results about "High voltage cathode" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

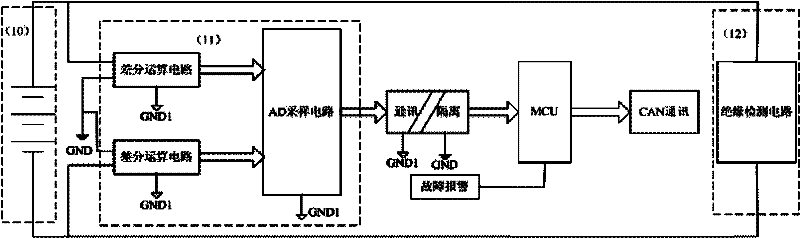

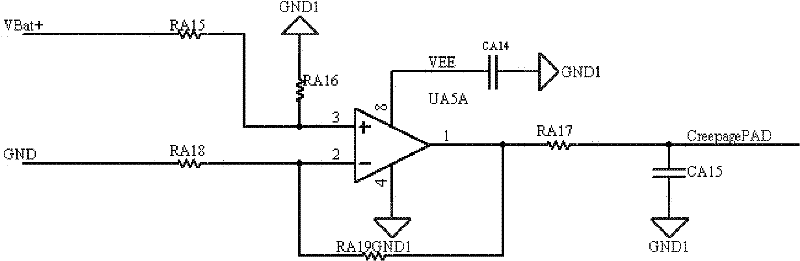

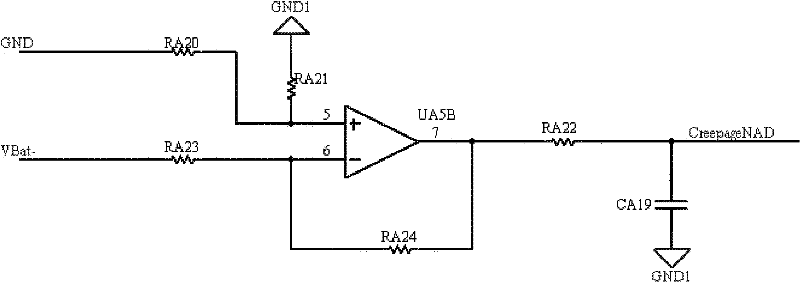

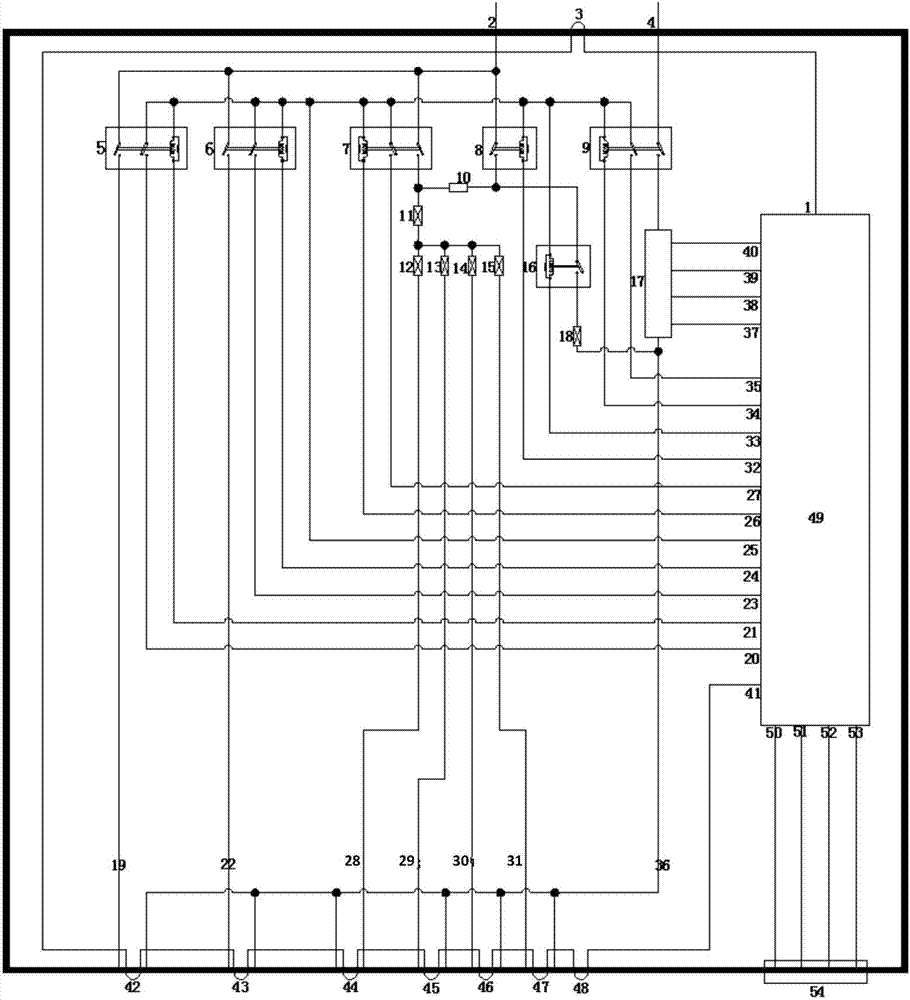

Insulating detection system and method of power battery for electric automobile

InactiveCN102508038AReal-time monitoring of running statusEnsure safetyResistance/reactance/impedenceElectrical testingNew energyElectrical battery

The invention provides an insulating detection system and method of a power battery for an electric automobile, which can be used for detecting insulting resistance values of a high-voltage anode and a high-voltage cathode of a power storage battery to an automobile body ground. The system is applicable to a high-voltage insulating detection device of a new-energy electric automobile and comprises a high-voltage subsystem, an AD (Analog to Digital) sampling subsystem, an isolation subsystem, a communication subsystem and a fault alarming subsystem. According to the insulating detection system provided by the invention, through respectively connecting different resistors with a positive ground and a negative ground of the power battery in parallel, resistance values of insulating resistors can be calculated through collecting the voltages which are not merged into the resistors and the voltages which are merged into the resistors; the resistance values are output to a whole automobile controller through a communication module, and operation states of high-voltage circuits of the electric automobile are controlled, so that the safety of people and the electric automobile is ensured.

Owner:上海恒动汽车电池有限公司

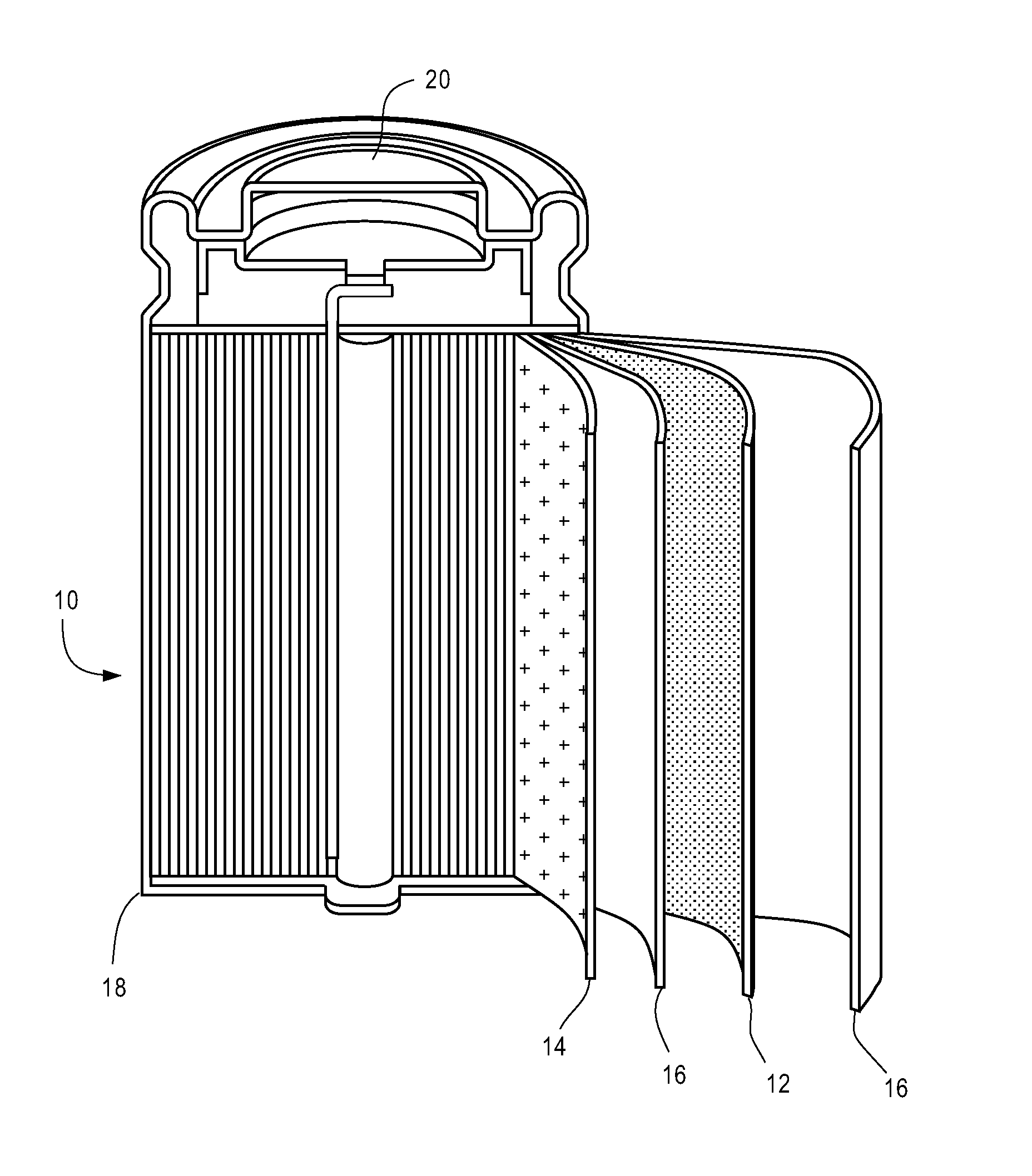

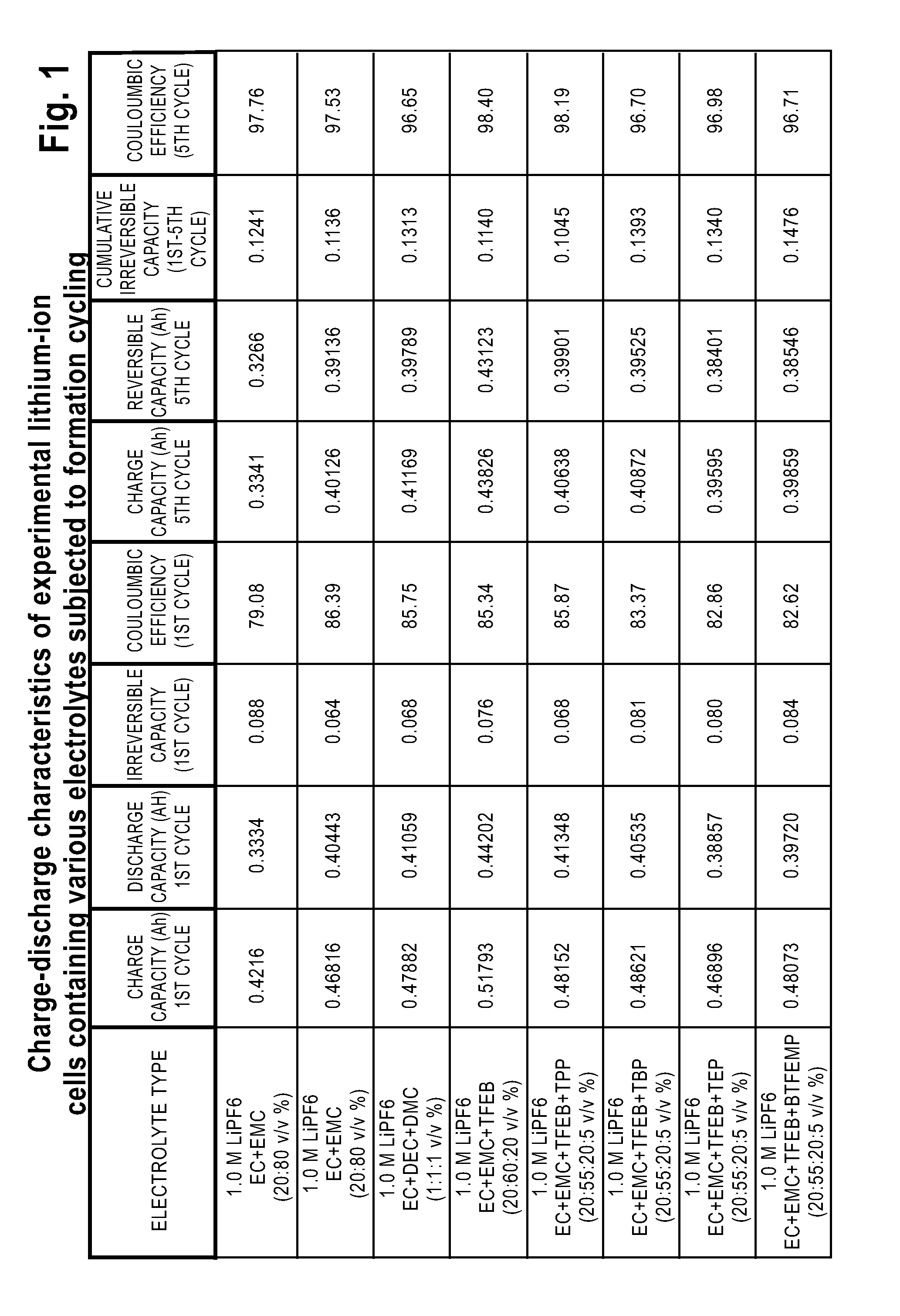

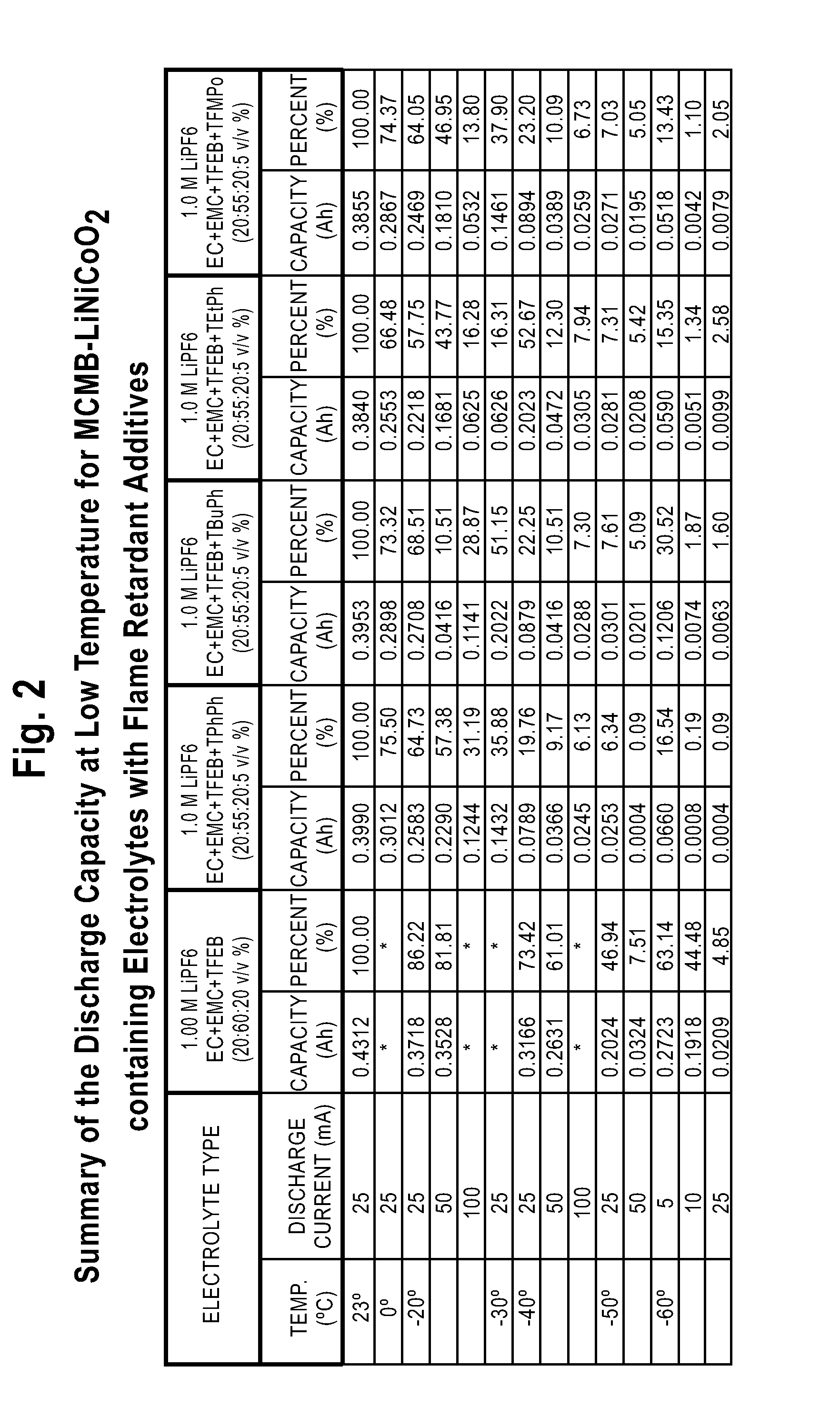

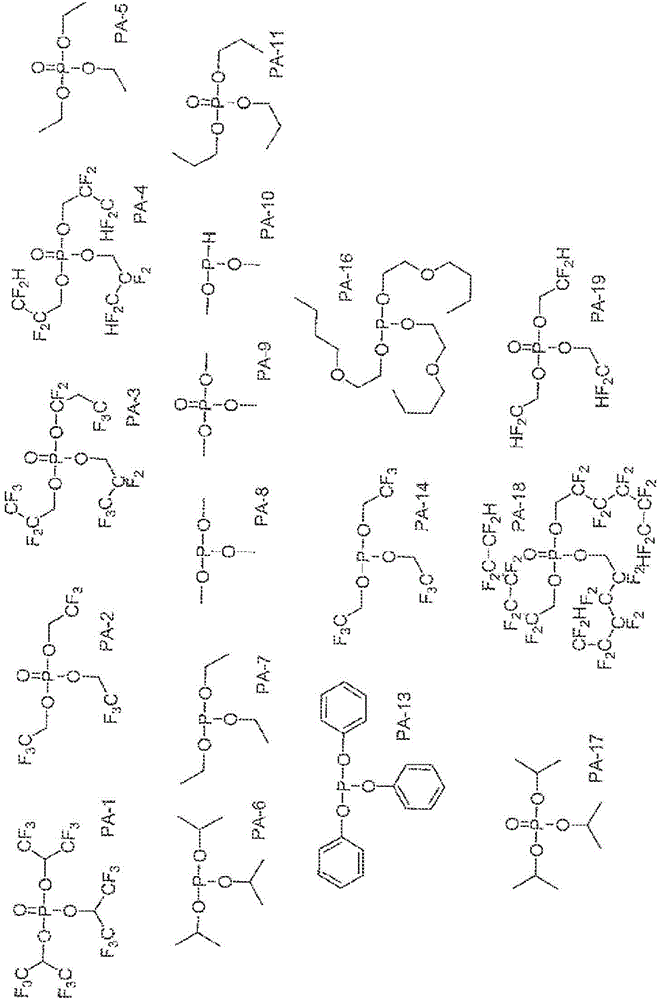

Lithium-Ion Electrolytes With Improved Safety Tolerance To High Voltage Systems

ActiveUS20120141883A1Improved safety toleranceExcellent rate performanceOrganic electrolyte cellsLi-accumulatorsMethyl carbonateHigh voltage cathode

The invention discloses various embodiments of electrolytes for use in lithium-ion batteries, the electrolytes having improved safety and the ability to operate with high capacity anodes and high voltage cathodes. In one embodiment there is provided an electrolyte for use in a lithium-ion battery comprising an anode and a high voltage cathode. The electrolyte has a mixture of a cyclic carbonate of ethylene carbonate (EC) or mono-fluoroethylene carbonate (FEC) co-solvent, ethyl methyl carbonate (EMC), a flame retardant additive, a lithium salt, and an electrolyte additive that improves compatibility and performance of the lithium-ion battery with a high voltage cathode. The lithium-ion battery is charged to a voltage in a range of from about 2.0 V (Volts) to about 5.0 V (Volts).

Owner:UNIV OF SOUTHERN CALIFORNIA +1

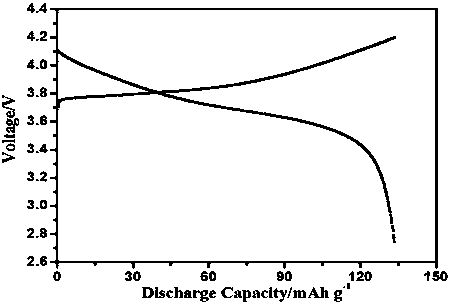

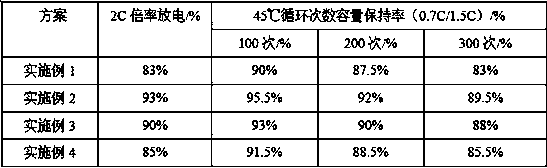

High-voltage cathode material for lithium ion battery and preparation method thereof

ActiveCN104022280ADissolution controlIncrease working voltageCell electrodesSecondary cellsHigh energySodium-ion battery

The invention discloses a high-voltage cathode material for a lithium ion battery. The high-voltage cathode material is a clad material, the core material has the general formula of [LiaNibCocMdO2]; the shell material has the general formula of [LipNixCoyMnzO2]; the cathode material of the lithium ion secondary battery has the general formula of[LiaNibCocMdO2] [LipNixCoyMnzO2]; the content of the core material is 50-99.5wt%, the content of the shell material is 0.05-50wt%. The preparation method comprises the steps of preparing the core material; preparing the precursor [NixCoyMnz (OH)2] of the shell material; cladding; and carrying out sintering twice or many times. According to high-voltage cathode material disclosed by the invention, advantages of Ni and Co elements can be given a full play, the high-voltage cathode material has the advantages of high operation voltage and high energy density as well as excellent high-temperature cycle performance and the dissolution amount of Co can be controlled well.

Owner:NANTONG RESHINE NEW MATERIAL

Lithium ion battery and cathode material thereof

ActiveCN102544481AImprove stabilityIncrease energy densityCell electrodesSecondary cellsPhysical chemistryHigh voltage cathode

The invention provides a lithium ion battery cathode material, which is applicable to high charge cut-off voltage conditions, and consists of two active substances of LiCoO2 and Li (Ni xCoyMn1-x-y) O2, wherein x is not smaller than 0.3 and is not larger than 0.8, y is not smaller than 0.1 and is not larger than 0.4, and x plus y is not smaller than 0.6 and is not larger than 0.9; both the LiCoO2 and the Li(NixCoyMn1-x-y) O2 are doped with an element M body phase and undergone surface coating of oxide M'Ox, wherein M is at least one of Mg, Ti, Al, Zr, B, La, Ce and Y; M' is at least one of Al, Ti, Mg, Zr, B2, Si and Fe; and the energy density of a lithium ion battery can be obviously improved after using the high voltage cathode material, and the cathode material has the advantages of excellent cycling performance, lower high temperature expansion and the like. In addition, the invention further discloses a lithium ion battery which comprises the cathode material.

Owner:DONGGUAN AMPEREX TECH

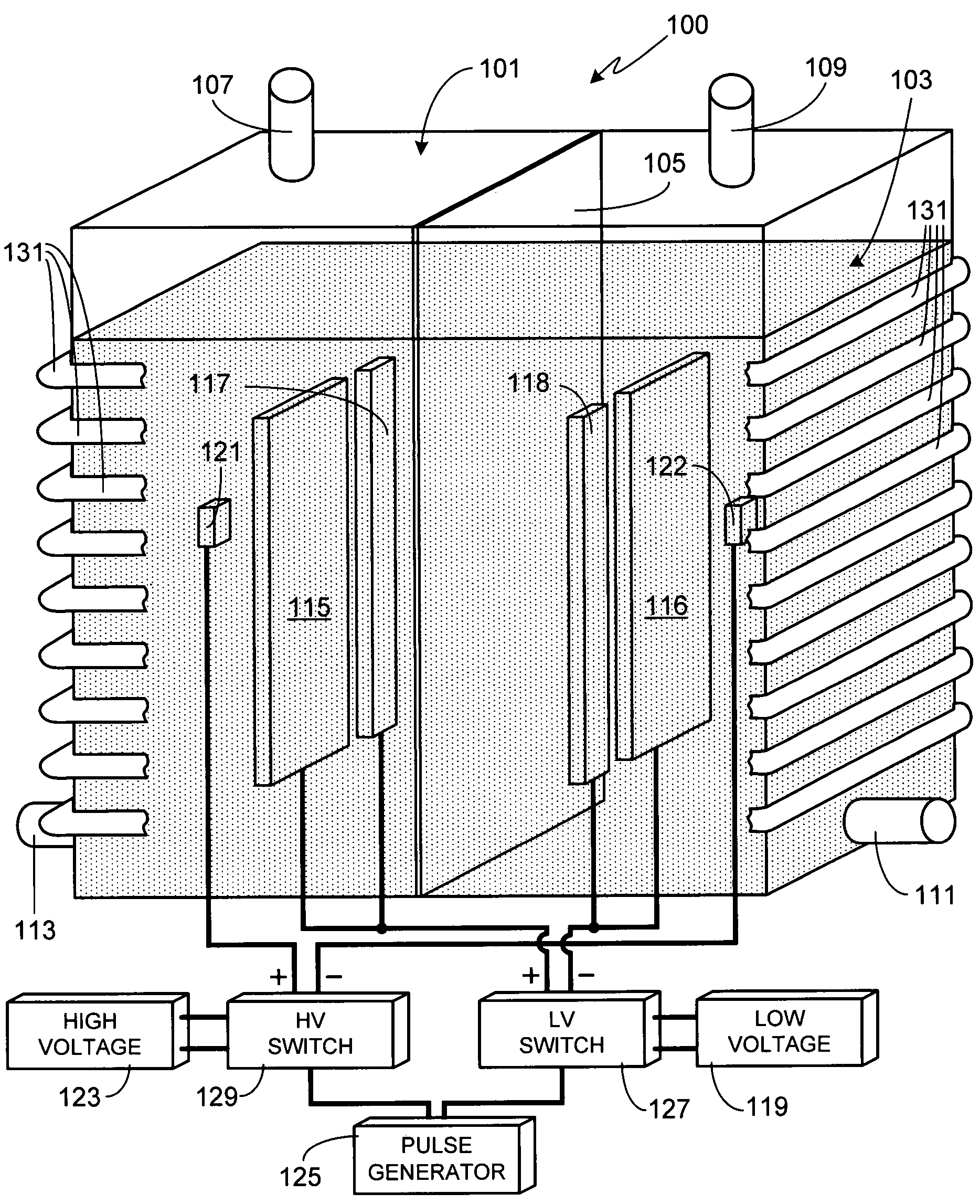

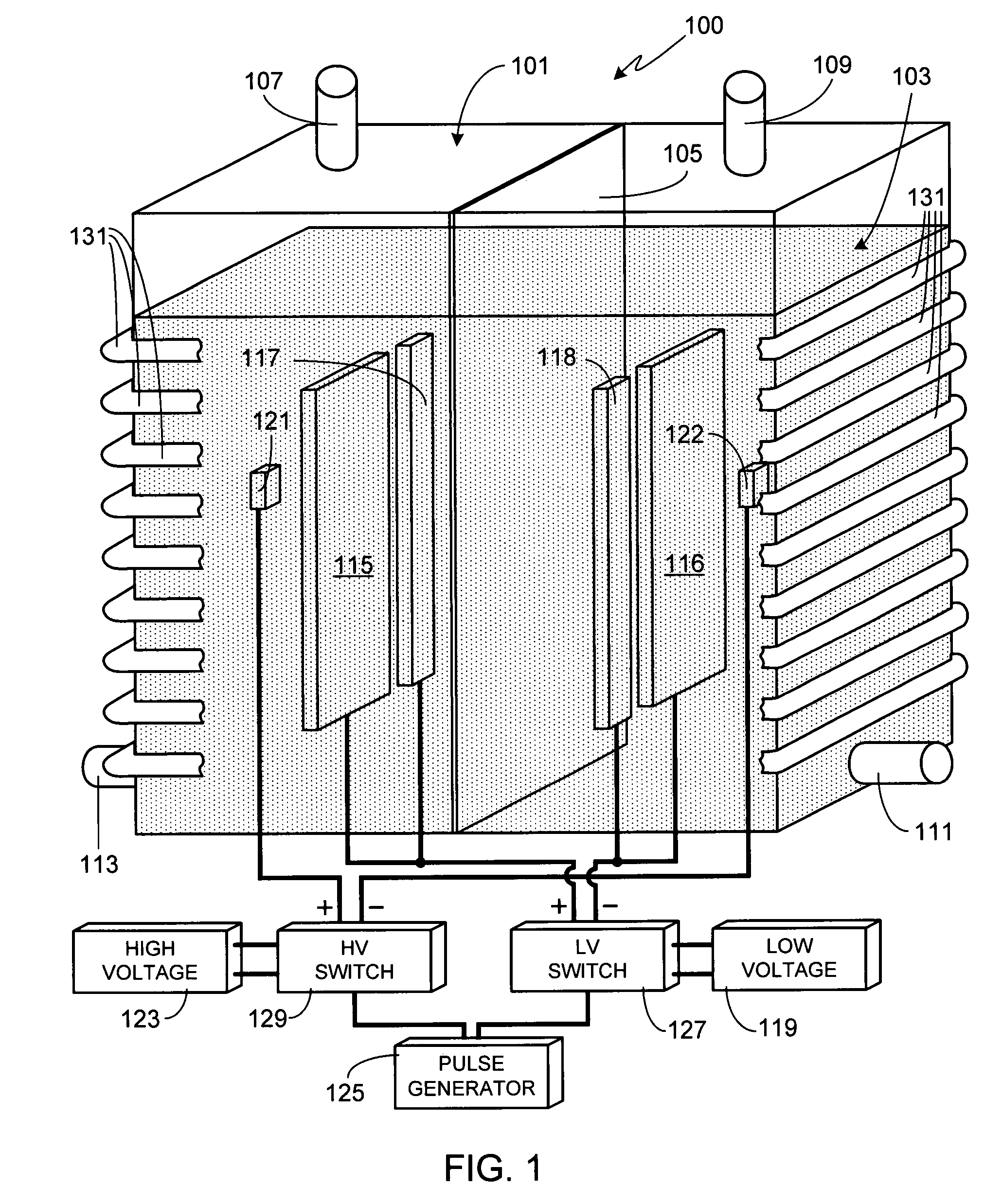

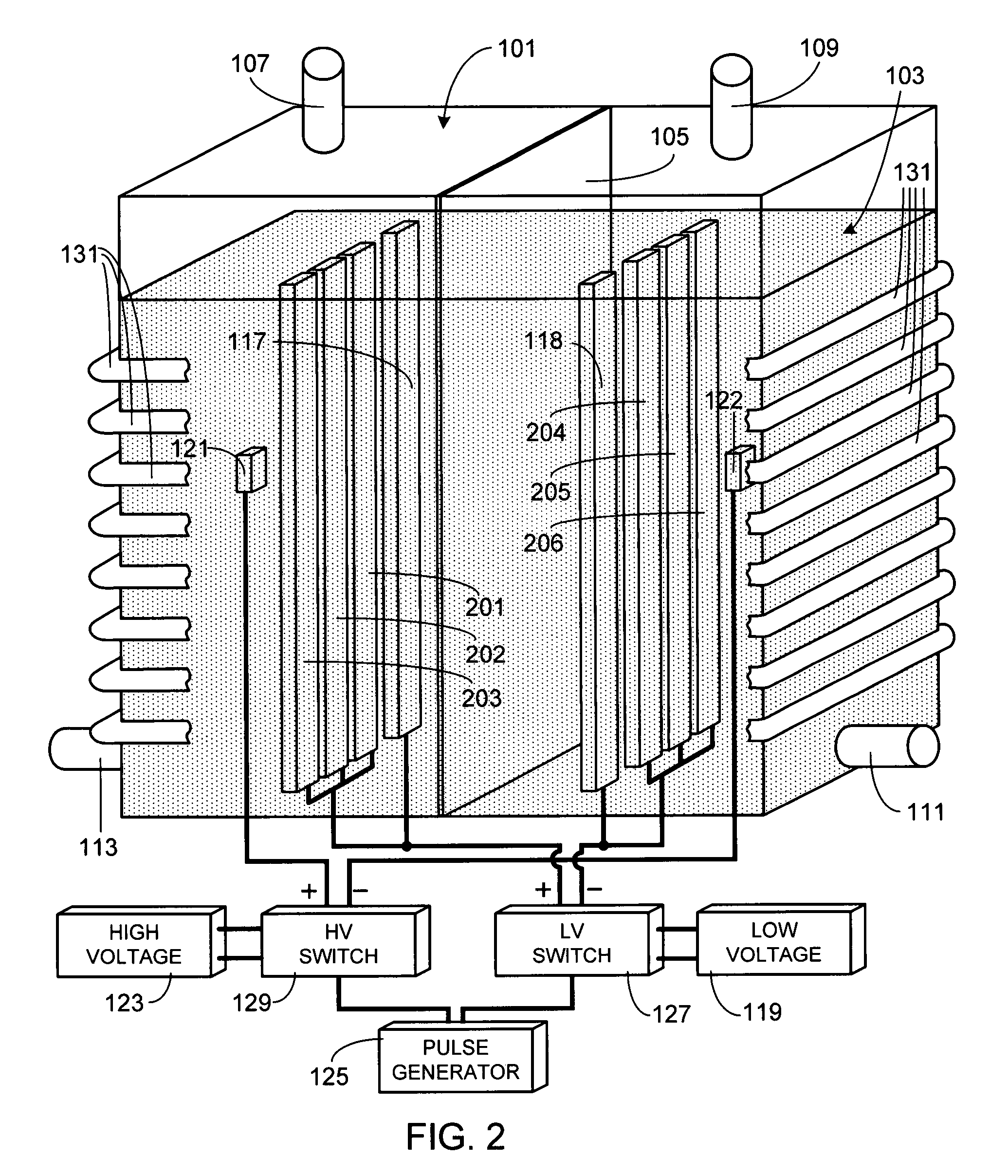

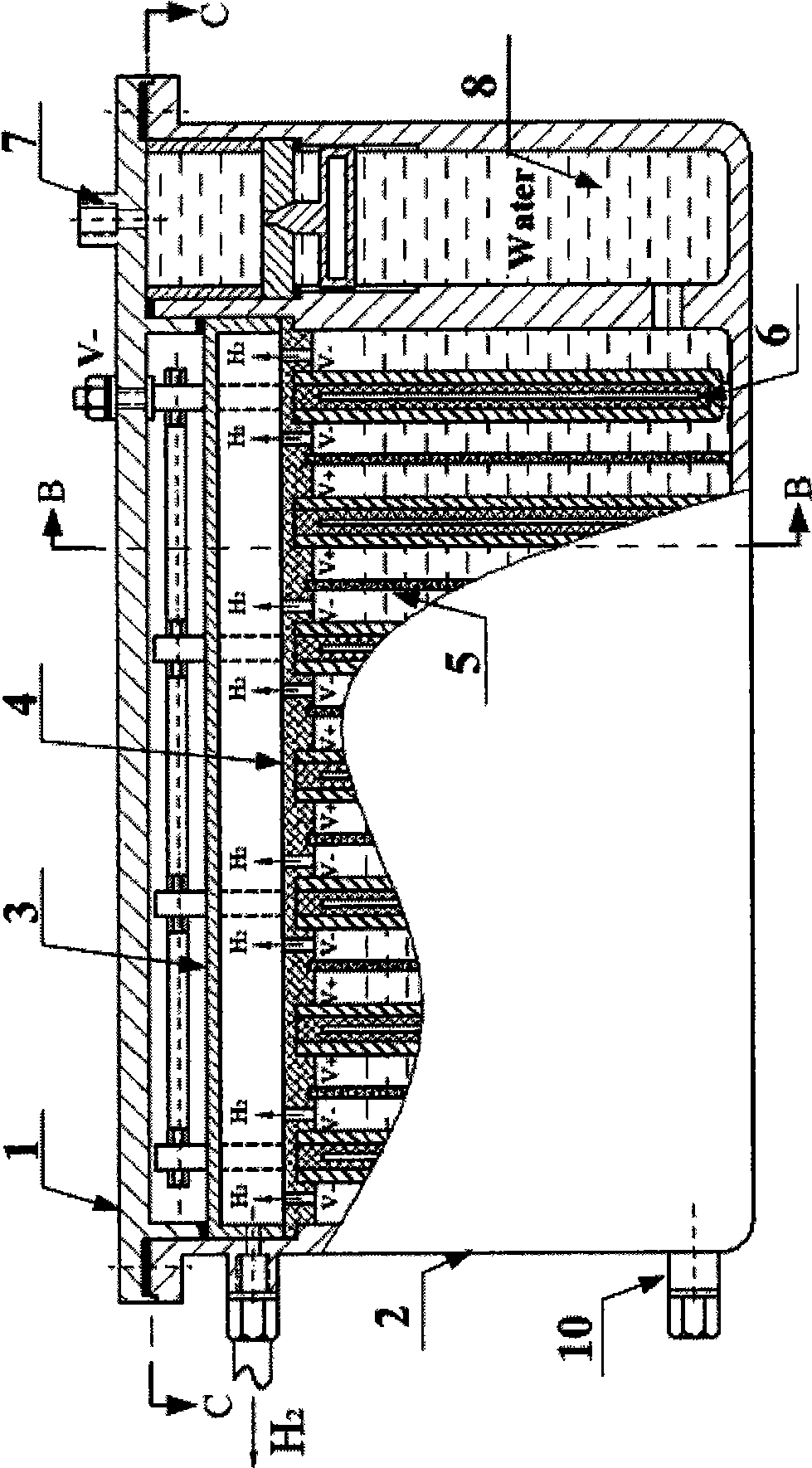

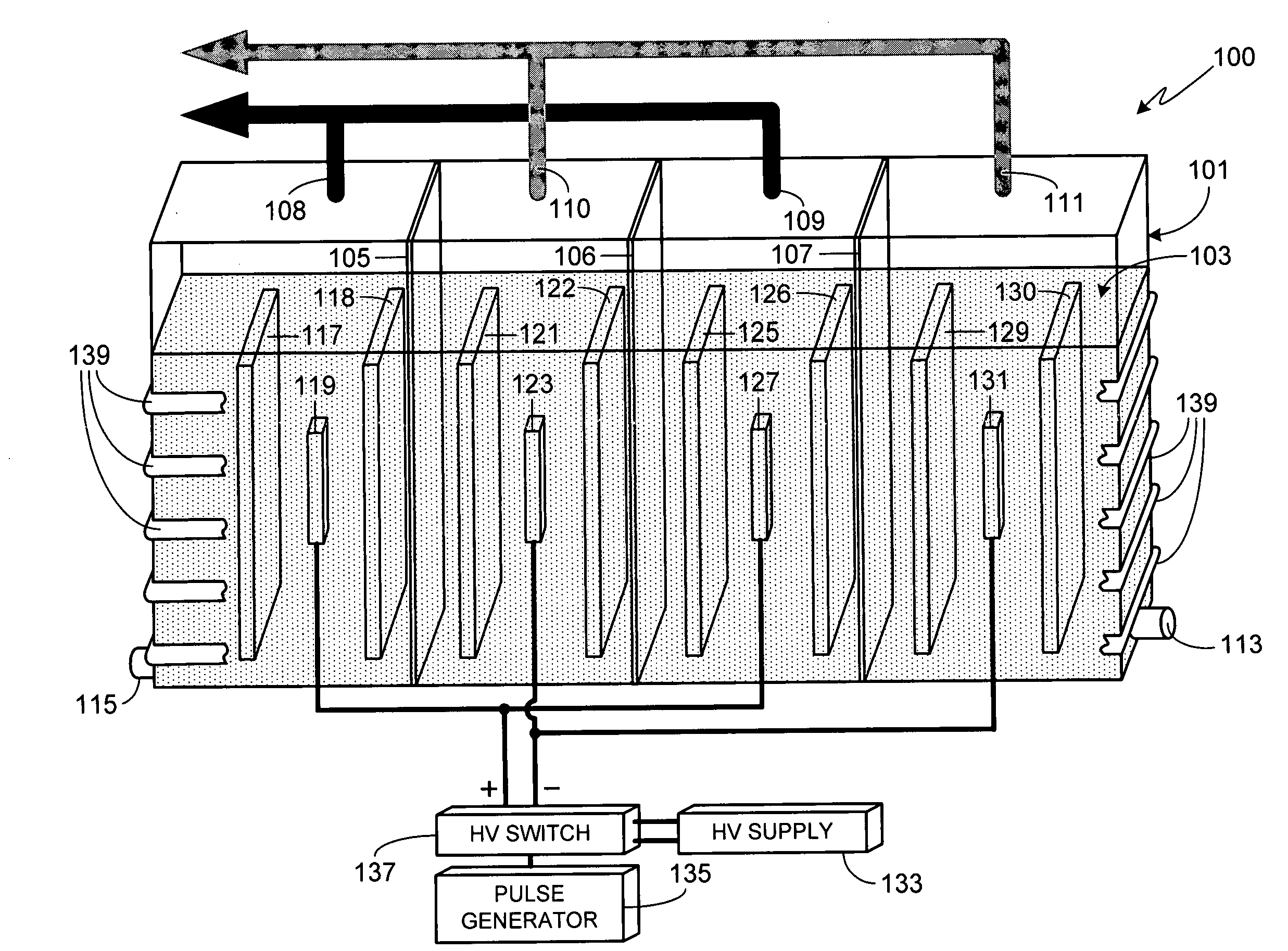

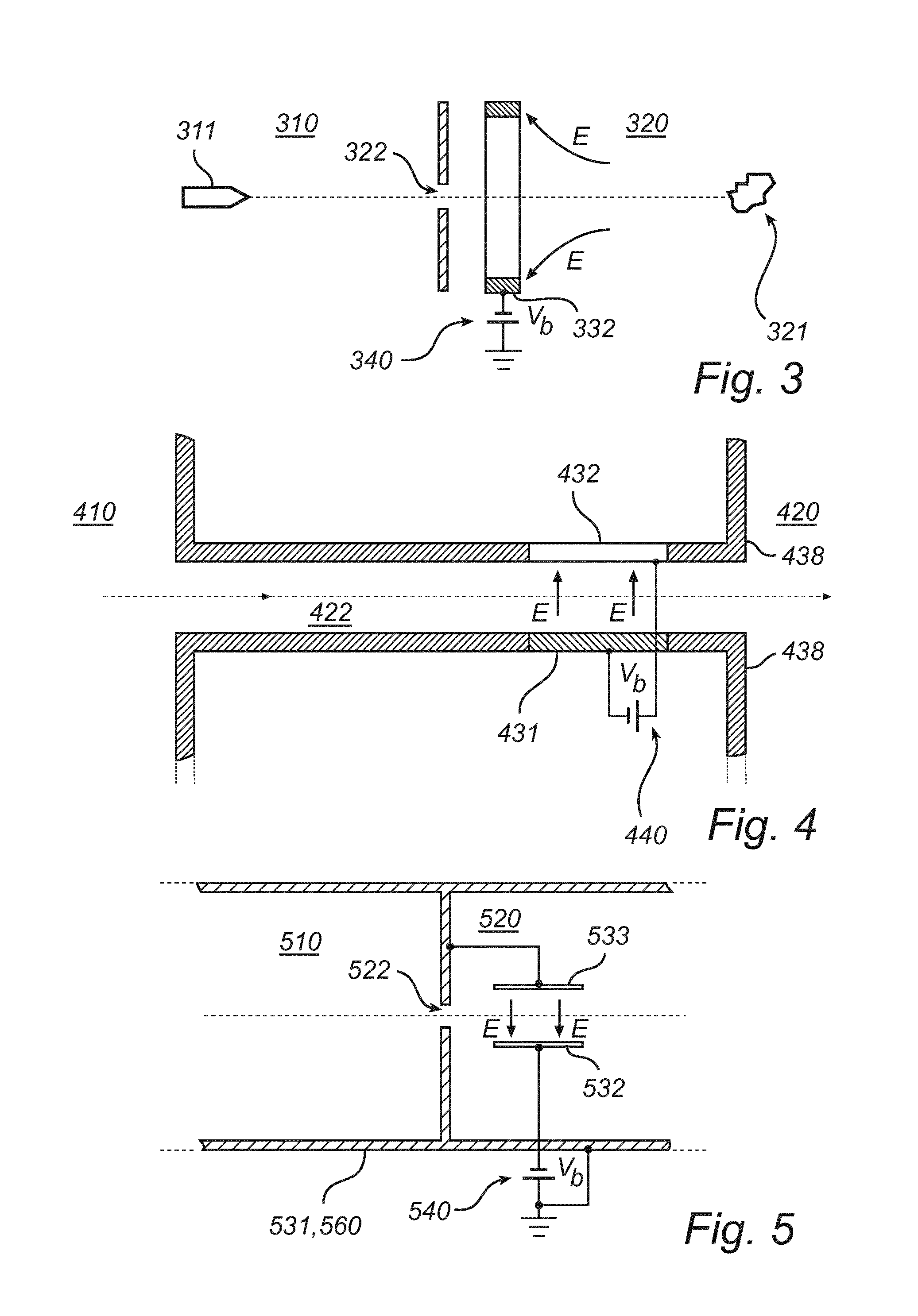

Multi-cell dual voltage electrolysis apparatus and method of using same

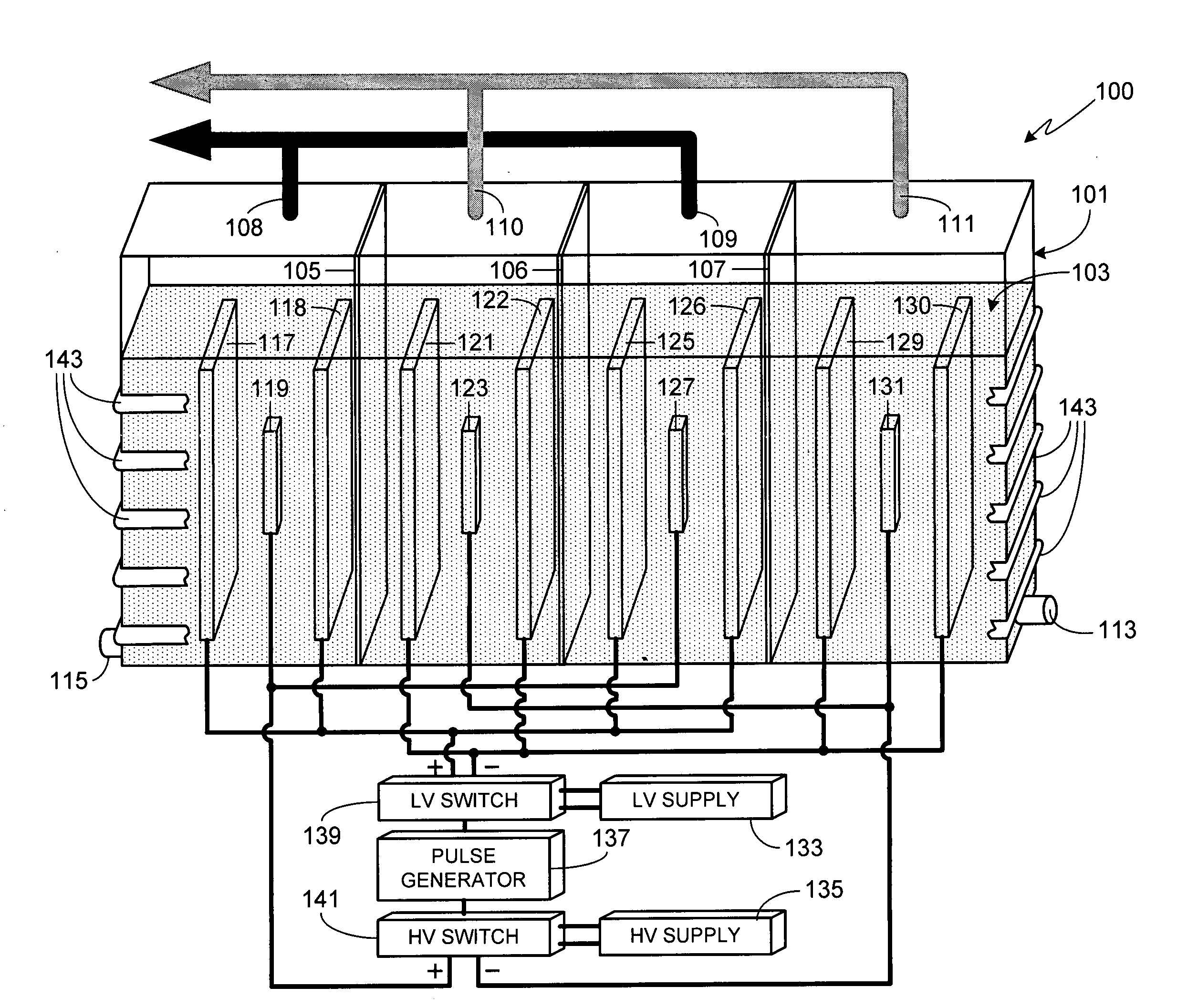

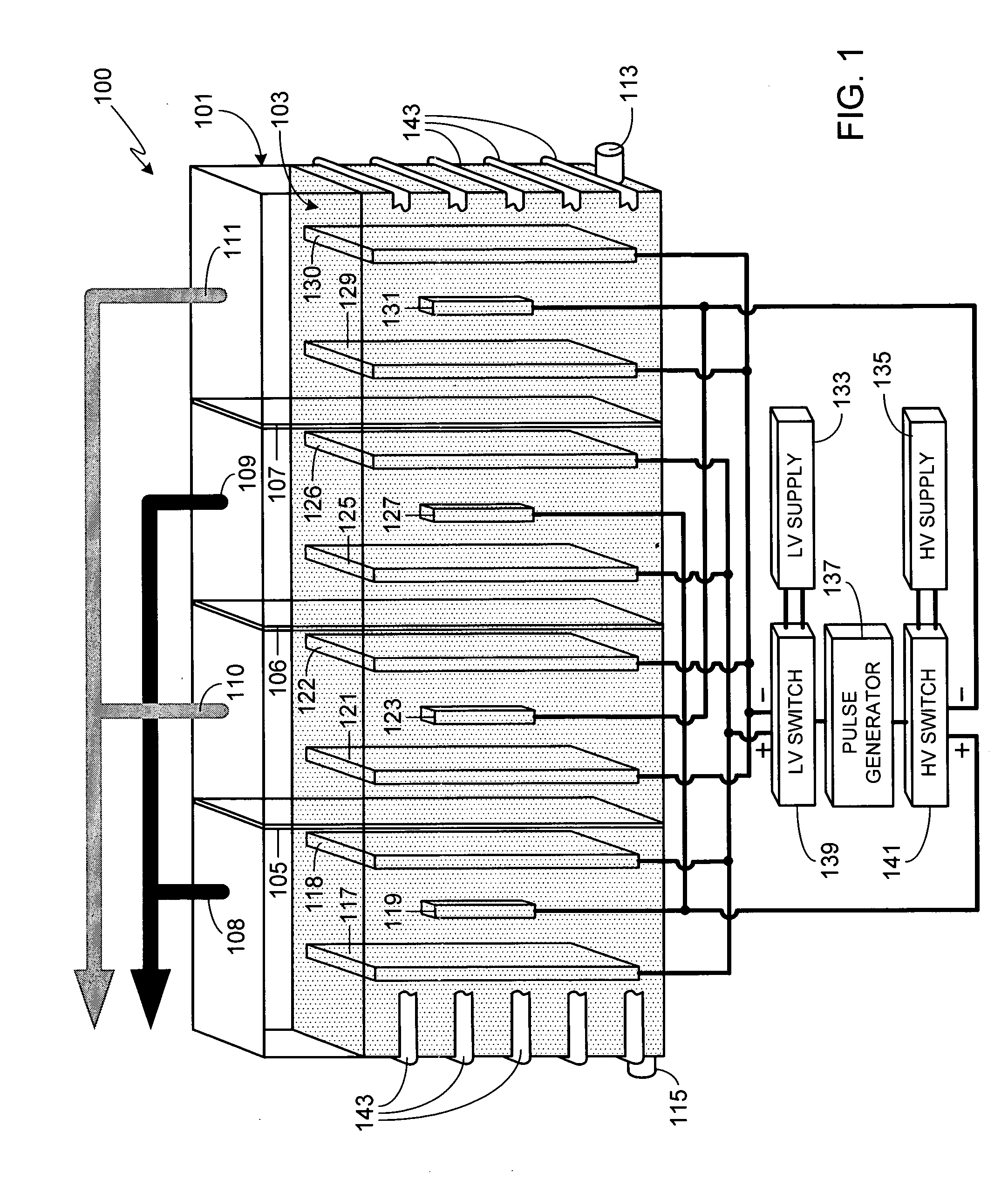

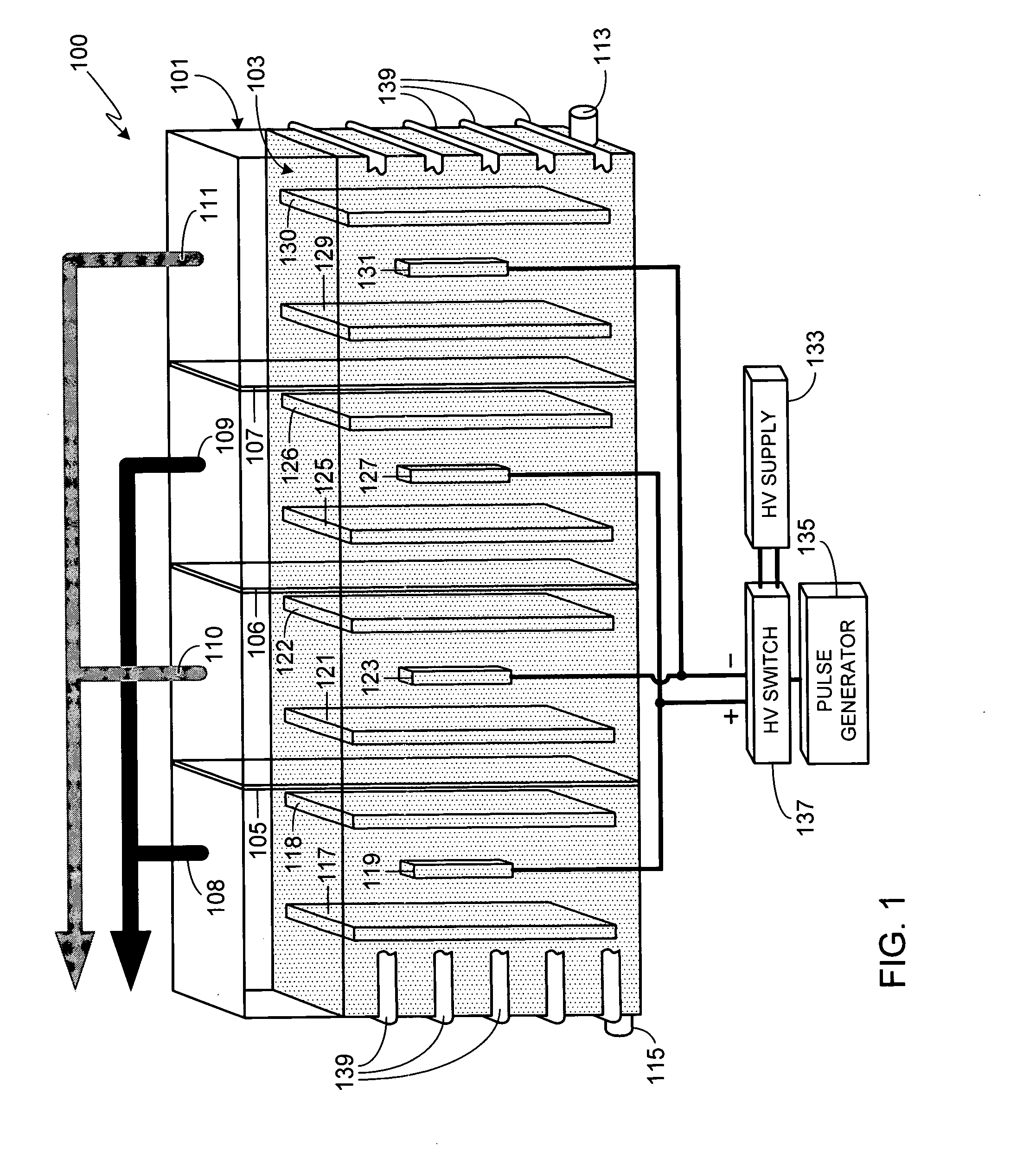

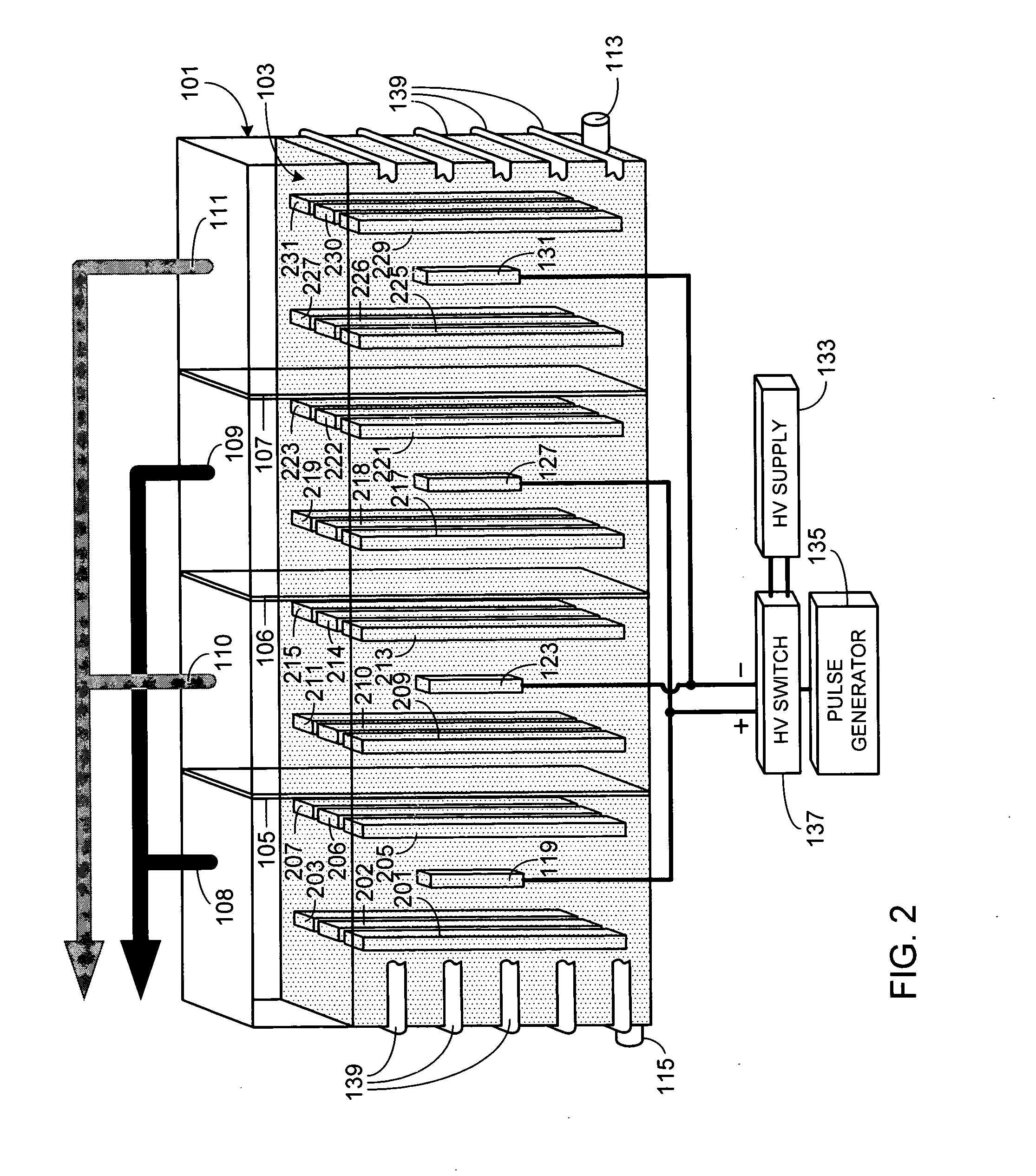

A method and apparatus for achieving high output efficiency from an electrolysis system (100) using a plurality of electrolysis cells all located within a single electrolysis tank (101) is provided. Each individual electrolysis cell includes a membrane (105-107), a plurality of low voltage electrodes comprised of at least a first and second anode (117 / 118; 125 / 126) and at least a first and second cathode (121 / 122; 129 / 130), and a plurality of high voltage electrodes comprised of at least an anode (119; 127) and a cathode (123; 131). Within each cell, the high voltage anode is interposed between the first and second low voltage anodes and the high voltage cathode is interposed between the first and second low voltage cathodes. The low voltage applied to the low voltage electrodes and the high voltage applied to the high voltage electrodes is pulsed with the pulses occurring simultaneously.

Owner:KUZO HLDG

High voltage cathode material for Li-ion batteries

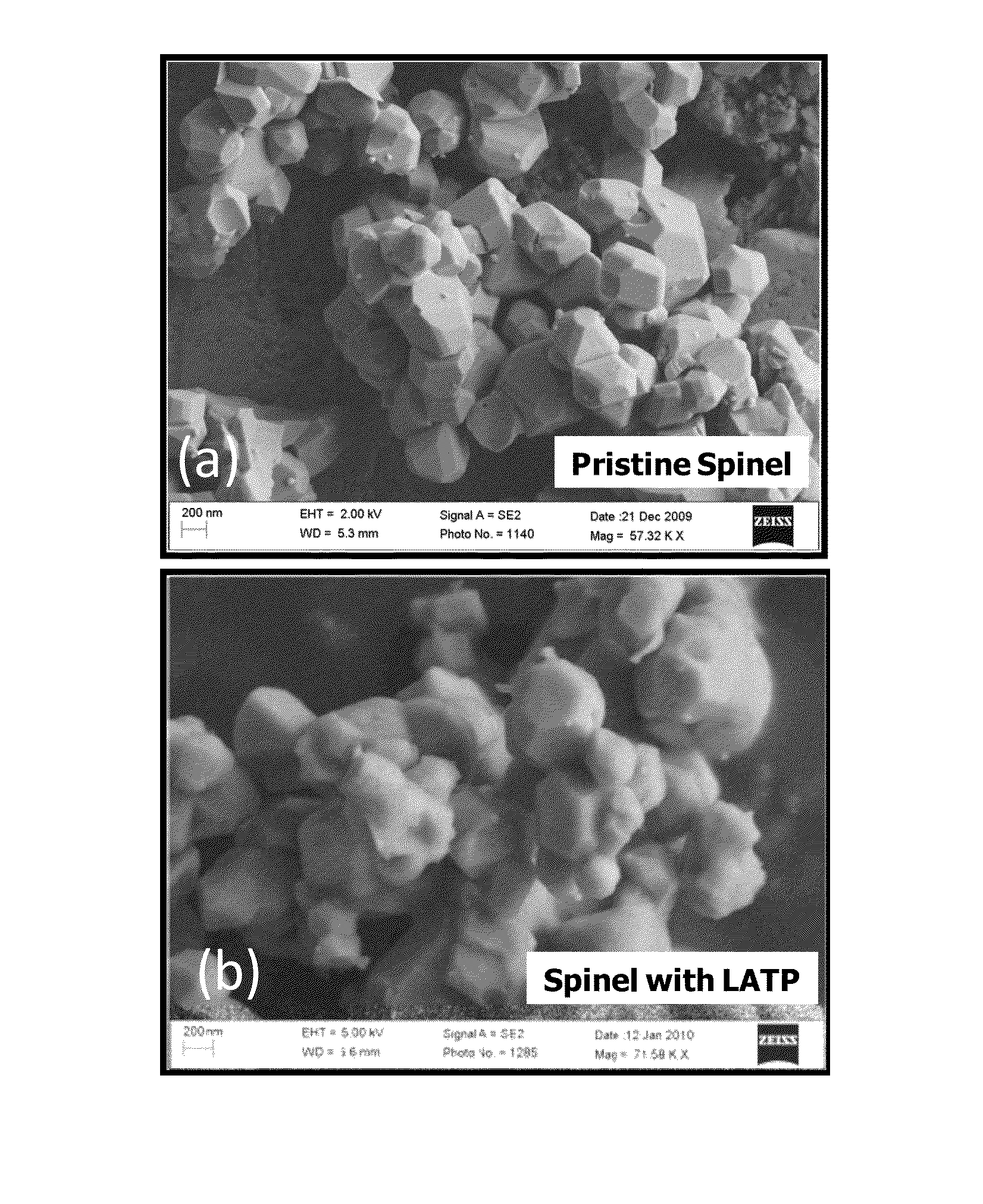

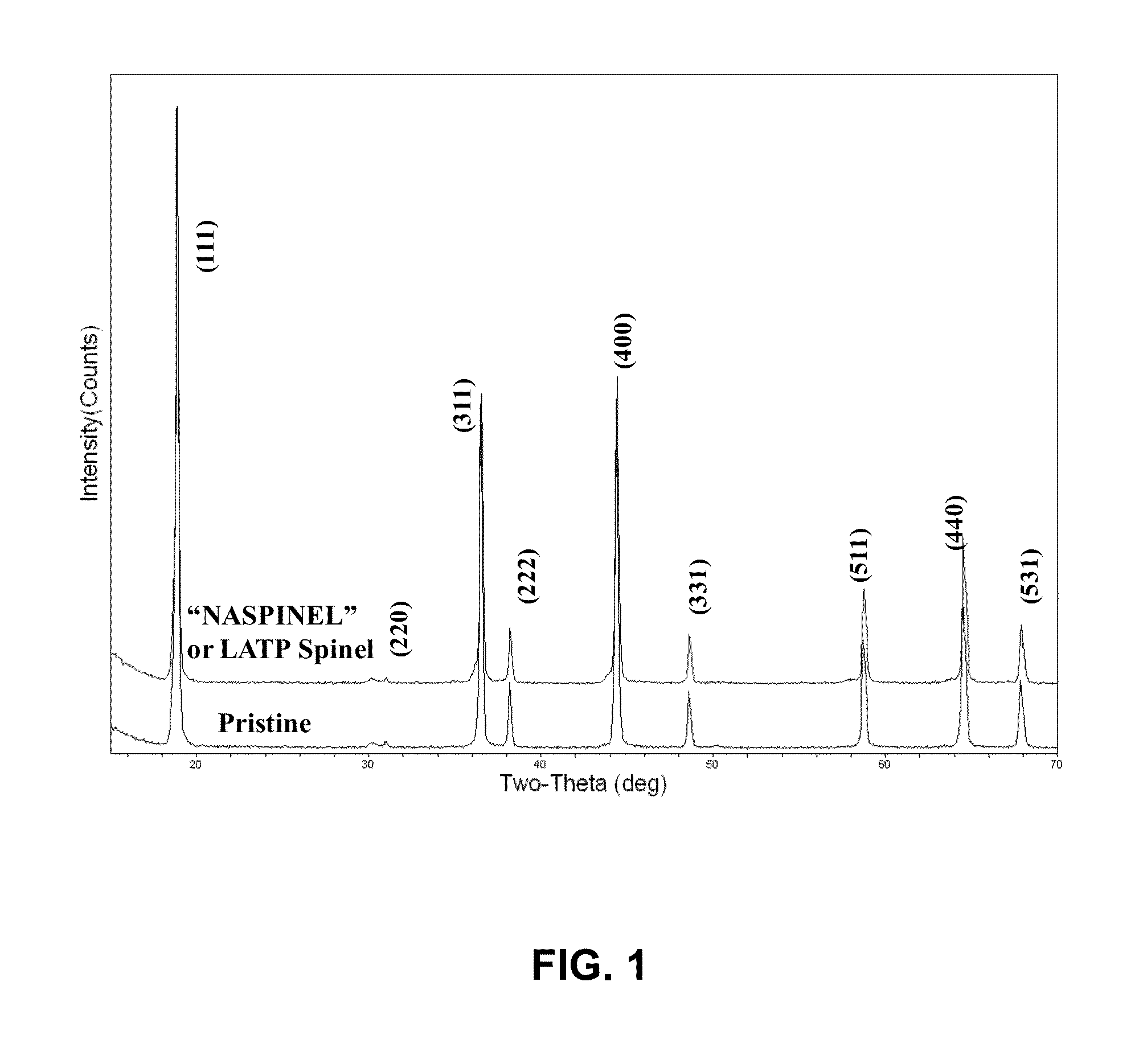

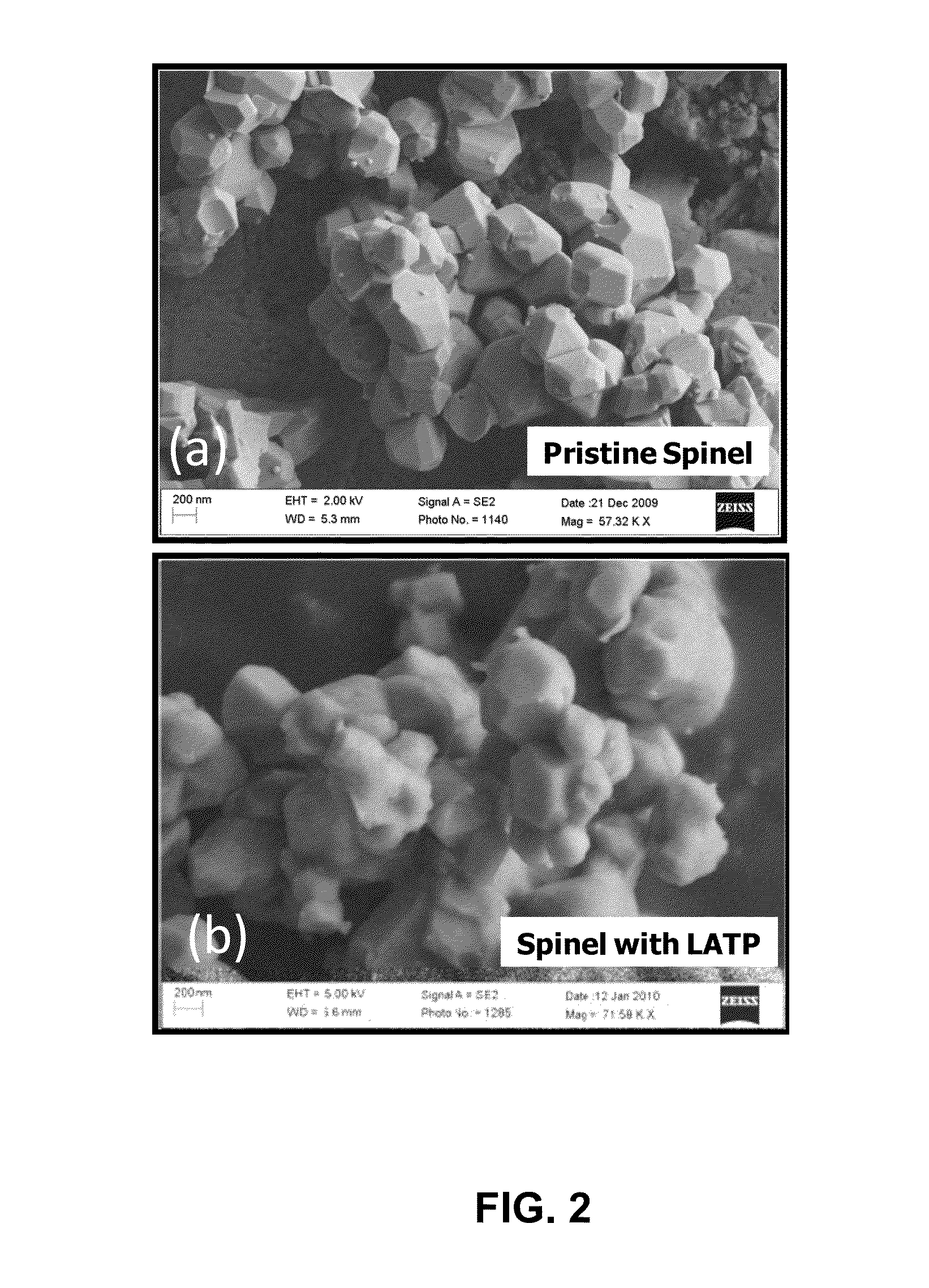

InactiveUS8906553B1PhosphatesPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesCrystal structureSpinel

A cathode electrode material for use in rechargeable Li-ion batteries, based on the integration of two Li-based materials of NASICON- and Spinel-type structures, is described in the present invention. The structure and composition of the cathode can be described by a core material and a surface coating surrounding the core material, wherein the core of the cathode particle is of the formula LiMn2-xNixO4−δ (0.5≦x≦0 & 0≦δ≦1) and having a spinel crystal structure, the surface coating is of the formula Li1+xMxTi2-x(PO4)3 (M: is a trivalent cation, 0.5≧x≧0) having a NASICON-type crystal structure.

Owner:NORTHERN ENG IND PLC

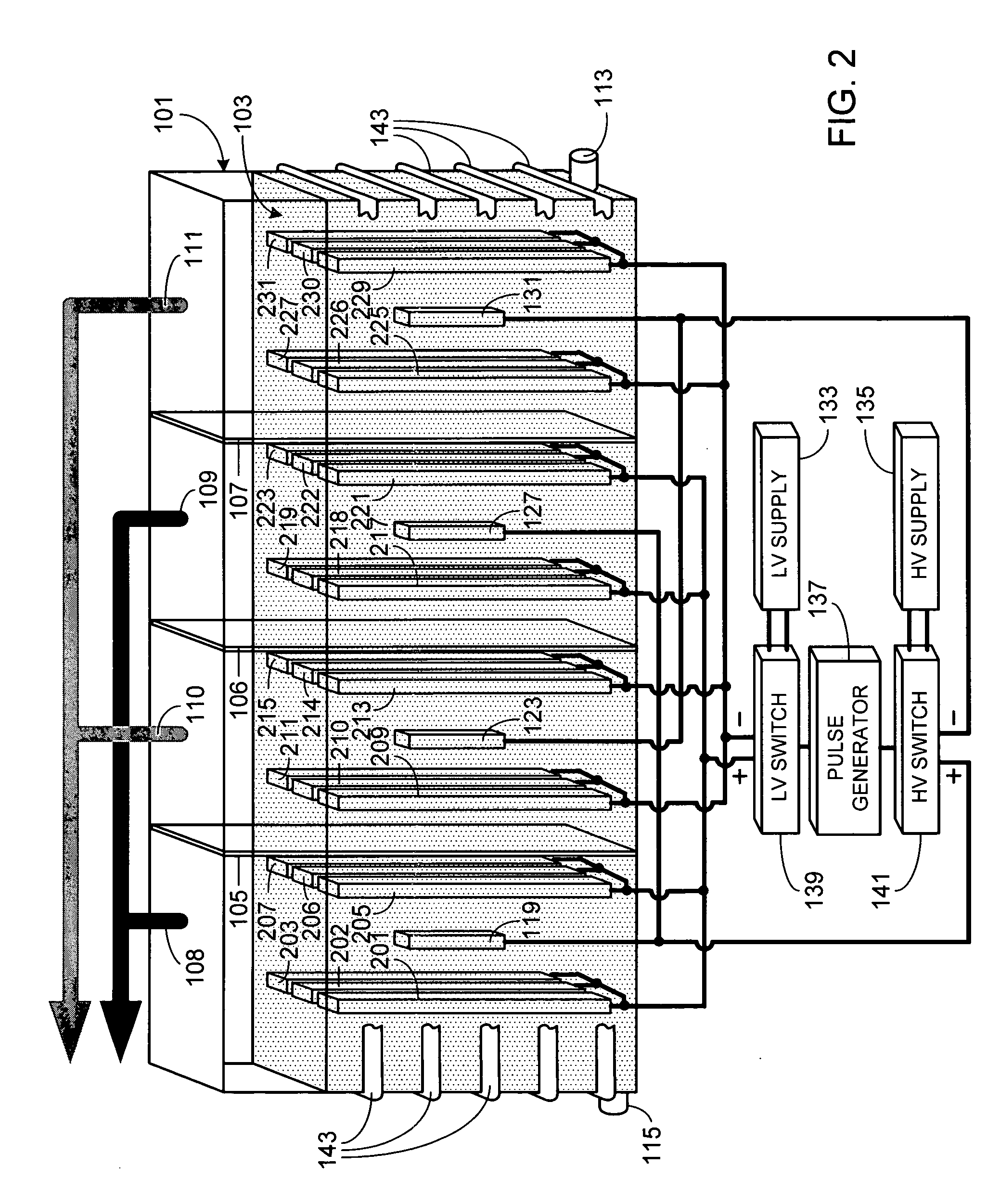

Method of using an electrolysis apparatus with a pulsed, dual voltage, multi-composition electrode assembly

A method of operating an electrolysis system (100) to achieve high hydrogen output flow rates is provided. At least three types of electrodes are positioned within an electrolysis tank (101), the three types including at least one pair of low voltage electrodes (115 / 117) comprised of a first material, at least one pair of low voltage electrodes (117 / 118) comprised of a second material different from the first material, and at least one pair of high voltage electrodes (121 / 122). The low voltage and high voltage cathode electrodes are positioned within one region of the tank (101) while the low voltage and high voltage anode electrodes are positioned within the second region of the tank (101), the two regions separated by a membrane (105). The tank (101) is filled with an electrolyte containing water (103). The power supplied to the low and high voltage electrodes is simultaneously pulsed.

Owner:KUZO HLDG

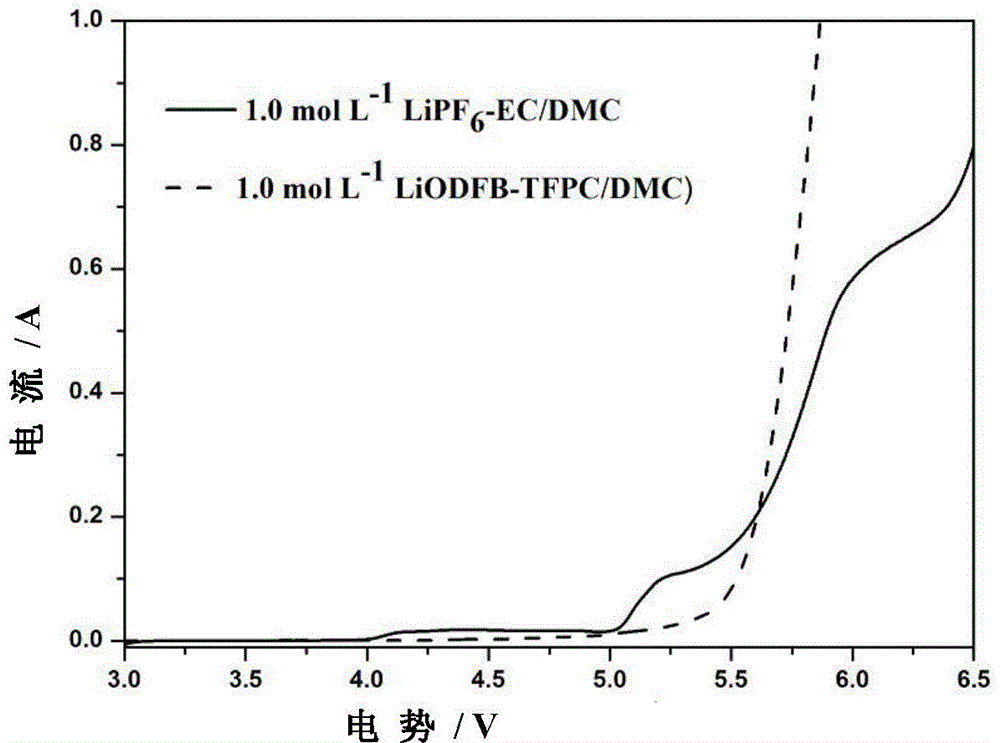

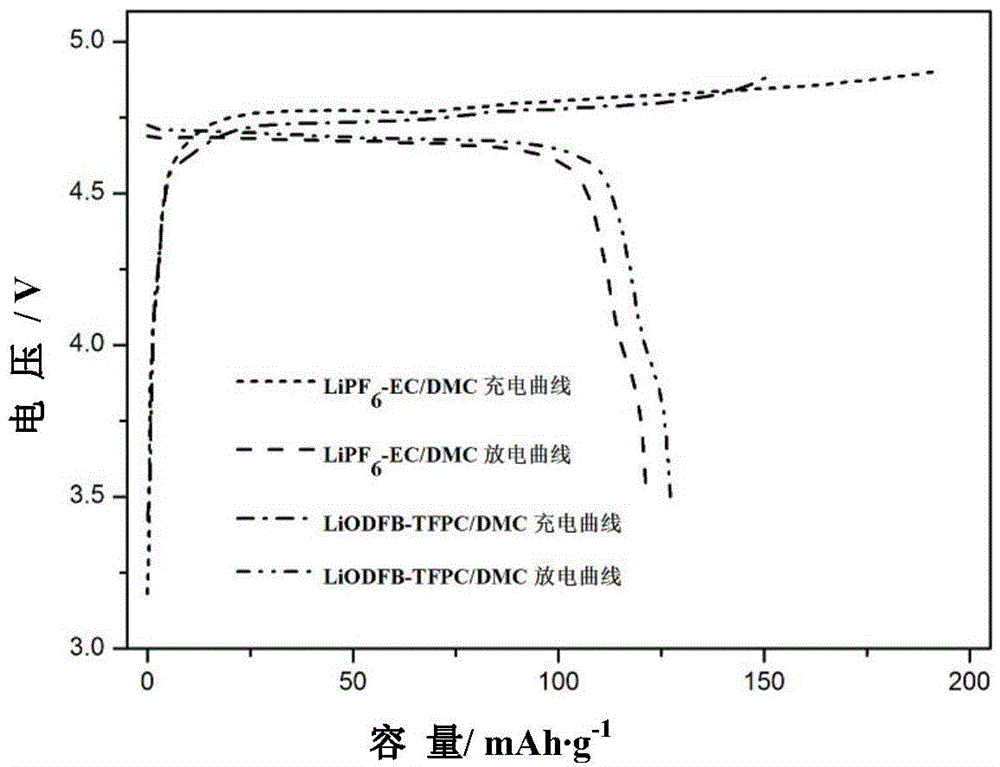

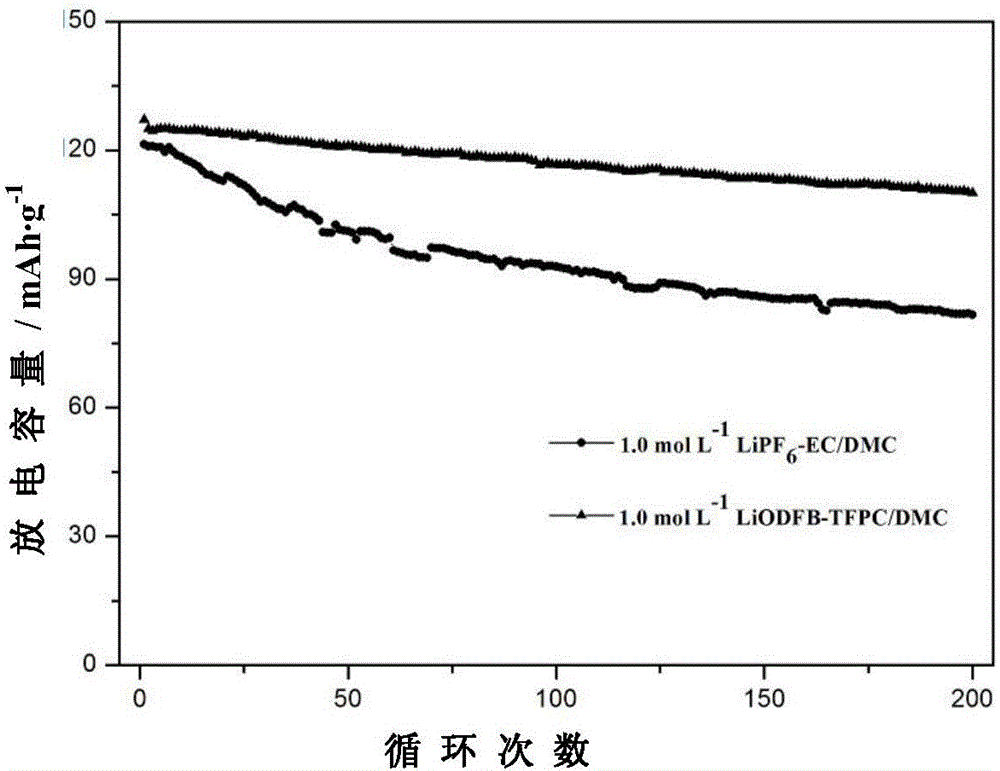

High-voltage electrolyte for lithium ion battery

InactiveCN104934638ARaise the oxidation potentialFlame retardantSecondary cellsElectrolytesOrganic solventElectrical battery

The invention discloses a high-voltage electrolyte for a lithium ion battery. The high-voltage electrolyte comprises lithium difluoro(oxalato)borate and an organic solvent, wherein the organic solvent is a mixed solution of a fluorinated solvent and a carbonic ester solvent; the concentration of the lithium difluoro(oxalato)borate in the high-voltage electrolyte for the lithium ion battery is 0.5-2.0mol / L; and the volume percentage of the fluorinated solvent in the organic solvent is 20-90 percent. The high-voltage electrolyte for the lithium ion battery provided by the invention has a high oxidation potential, and very high compatibility with high-voltage cathode materials.

Owner:ZHANGJIAGANG HUASHENG CHEM CO LTD +1

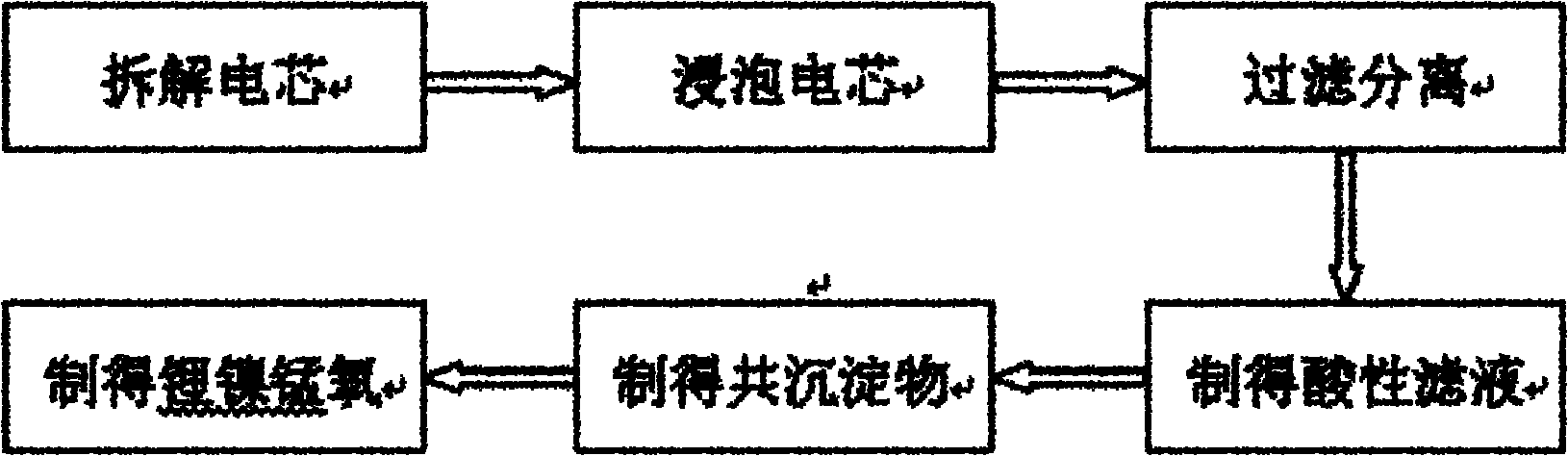

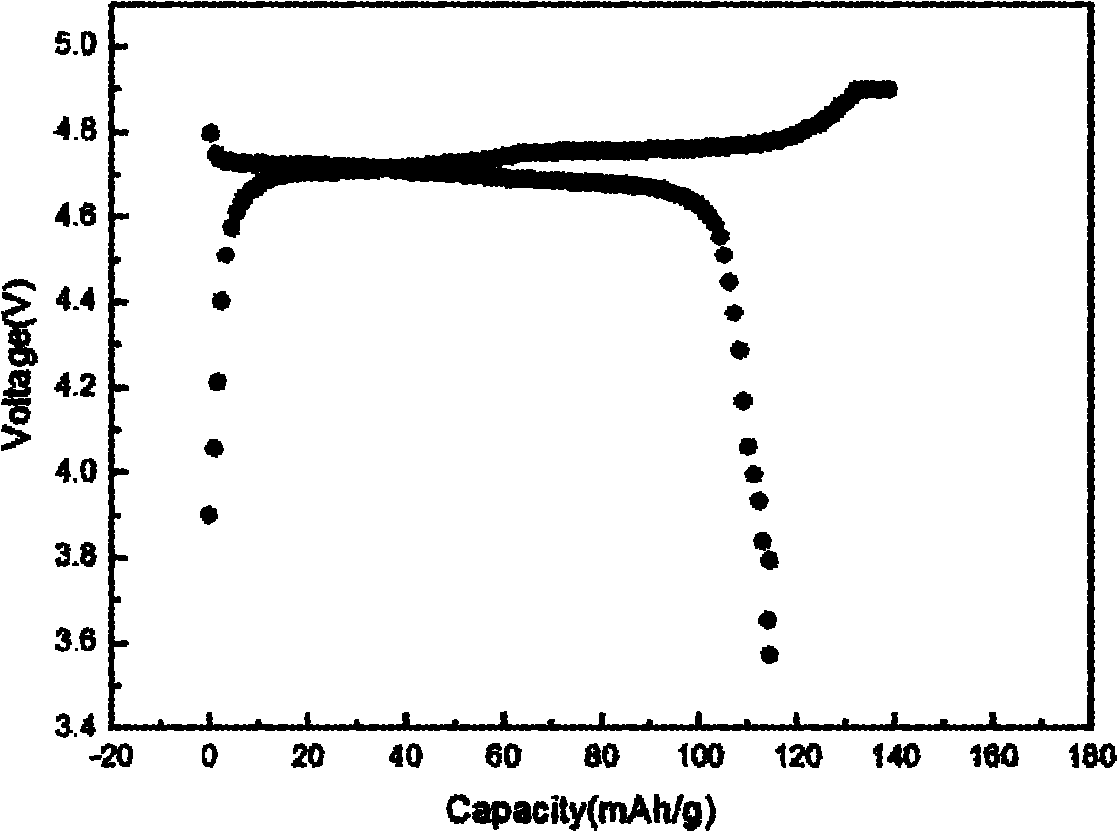

Method for preparing high-voltage cathode material lithium-nickel-manganese-oxygen battery

The invention discloses a method for preparing a high-voltage cathode material lithium-nickel-manganese-oxygen battery. The method comprises a plurality of steps of: dismantling an electric core, immersing the electric core, filtering and separating, preparing acidic filtrate, preparing coprecipiate, and preparing a lithium-nickel-manganese-oxygen battery. The method has the advantages that: 1, comprehensive recycling of Mn, Ni, Li, Al and Cu in waste and old LiMnO batteries, lithium nickel batteries and lithium nickel-manganese batteries is realized, Mn or Ni and Li elements are not needed to be separated, and the new good-performance high-voltage cathode material lithium-nickel-manganese-oxygen battery is synthesized directly; 2, the process is simple, the method is suitable for mass processing, the cost is low, the obtained battery has an impressive market prospect, and the additional value is high; and 3, the recycling rate of manganese and nickel metal in the battery is over 96 percent, and the recycling rate of lithium carbonate is 78 percent.

Owner:CHERY AUTOMOBILE CO LTD

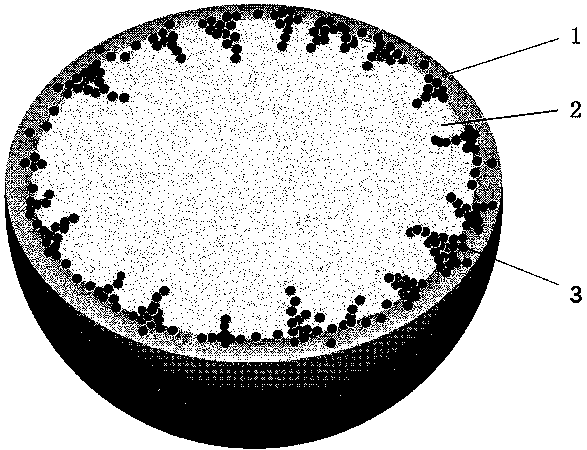

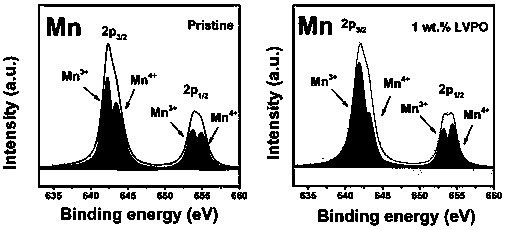

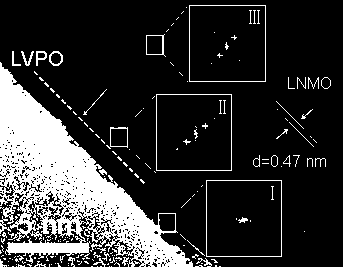

Battery cathode coating structure material with pinning effect and preparation method thereof

ActiveCN109888226AAchieve the effect of integrated double modificationPlay a protective roleCell electrodesSecondary cellsHigh voltage cathodeLithium-ion battery

The invention discloses a battery cathode coating structure material with a pinning effect and a preparation method thereof. A coating layer is formed on a surface of a lithium ion battery cathode material. The coating layer is metal compound of lithium. Metal cations in the coating layer form a metal cation gradient doped solid solution buffer structure on an interface of the coating layer and the cathode material. The solid solution buffer structure has a nail similar shape. A nail cap is formed in the coating layer. A nail point extends into the cathode material. The solid solution buffer structure and the coating layer are calcined in an inert atmosphere, and one-step generation is realized. According to the cathode coating structure with the pinning effect provided by the invention, through calcining in the inert atmosphere, surface oxygen defects of a high voltage cathode material LNMO are increased, the metal cations in the coating layer are enabled to diffuse and enter into thesurface detects of the cathode material in a coating process, so the pinning effect is achieved, and surface coating and surface doping integrated double modification of the high voltage cathode material of the lithium ion battery is realized.

Owner:HENAN UNIVERSITY

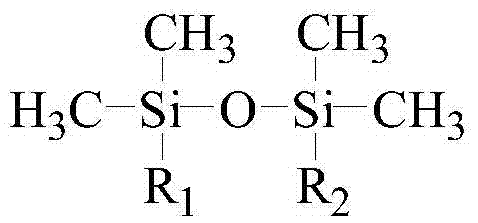

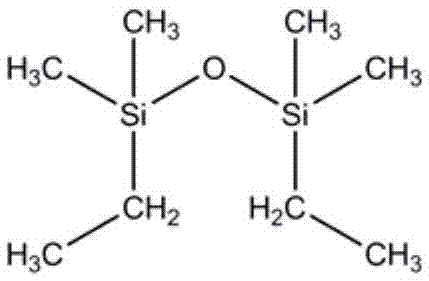

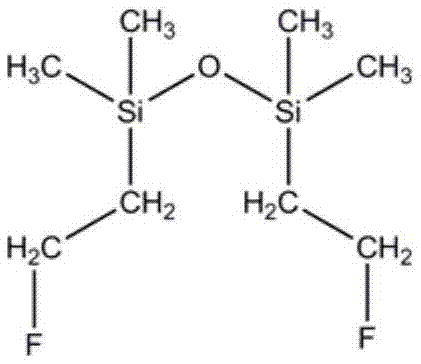

Siloxane derivative electrolyte for lithium-ion battery and high-voltage lithium-ion battery

InactiveCN105449278AGood physical and chemical stabilityIncrease energy densitySecondary cellsDecompositionHigh pressure

The invention discloses a siloxane derivative electrolyte for a lithium-ion battery and a high-voltage lithium-ion battery. The electrolyte comprises a siloxane derivative additive. The siloxane derivative additive has a relatively high oxidation potential and is matched with a high-voltage cathode material; the energy density of the lithium-ion battery added with the siloxane derivative additive is improved; and meanwhile, the siloxane derivative additive can form stable interfacial films on the surfaces of a positive electrode and a negative electrode of the lithium-ion battery, suppress the reaction activity of the electrode surfaces, reduce oxidative decomposition of the electrolyte and effectively suppress flatulence, so that the cycle performance of the lithium-ion battery under a normal voltage and a high voltage is improved; and the service lifetime of the lithium-ion battery under the normal voltage and the high voltage is prolonged.

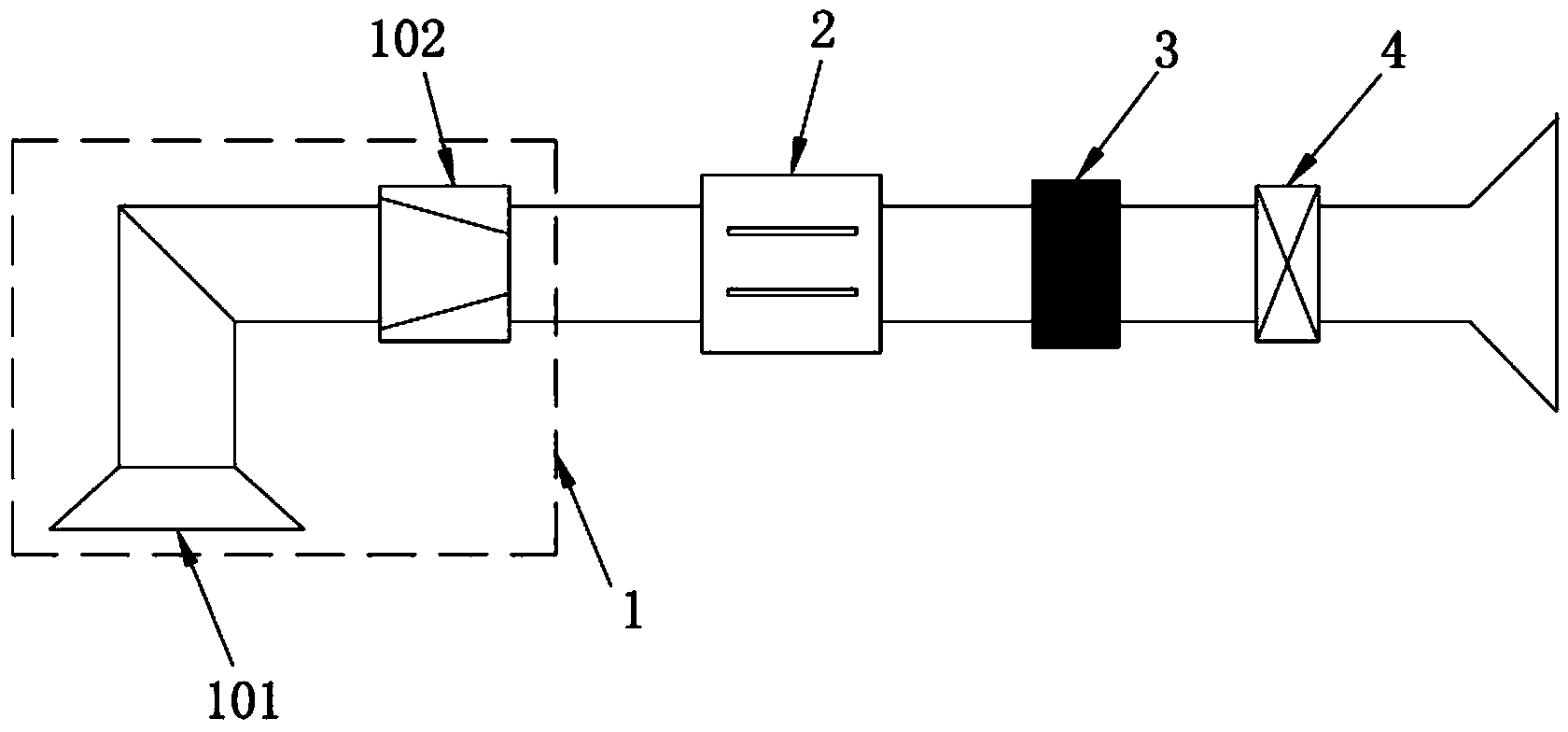

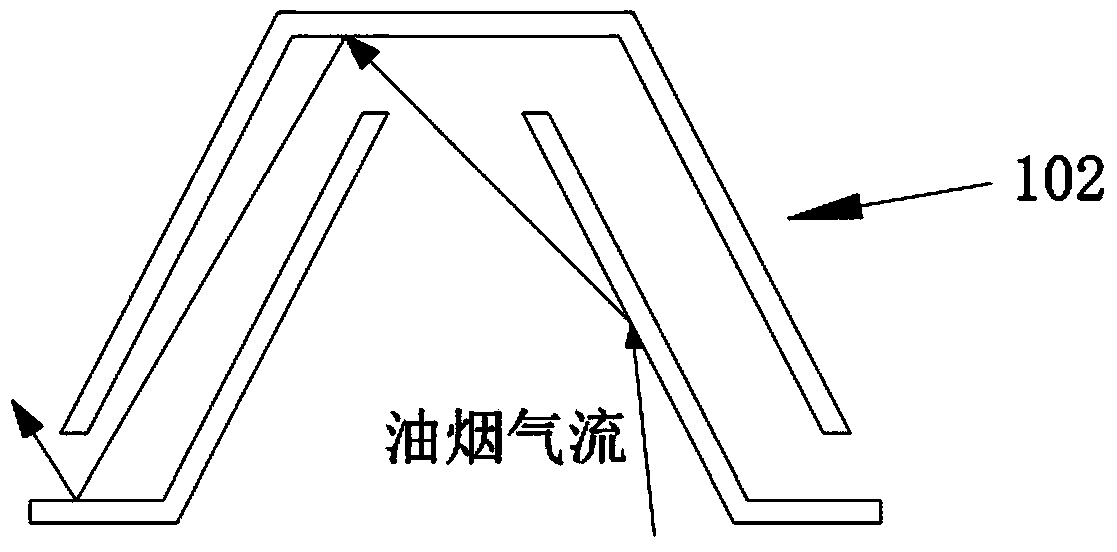

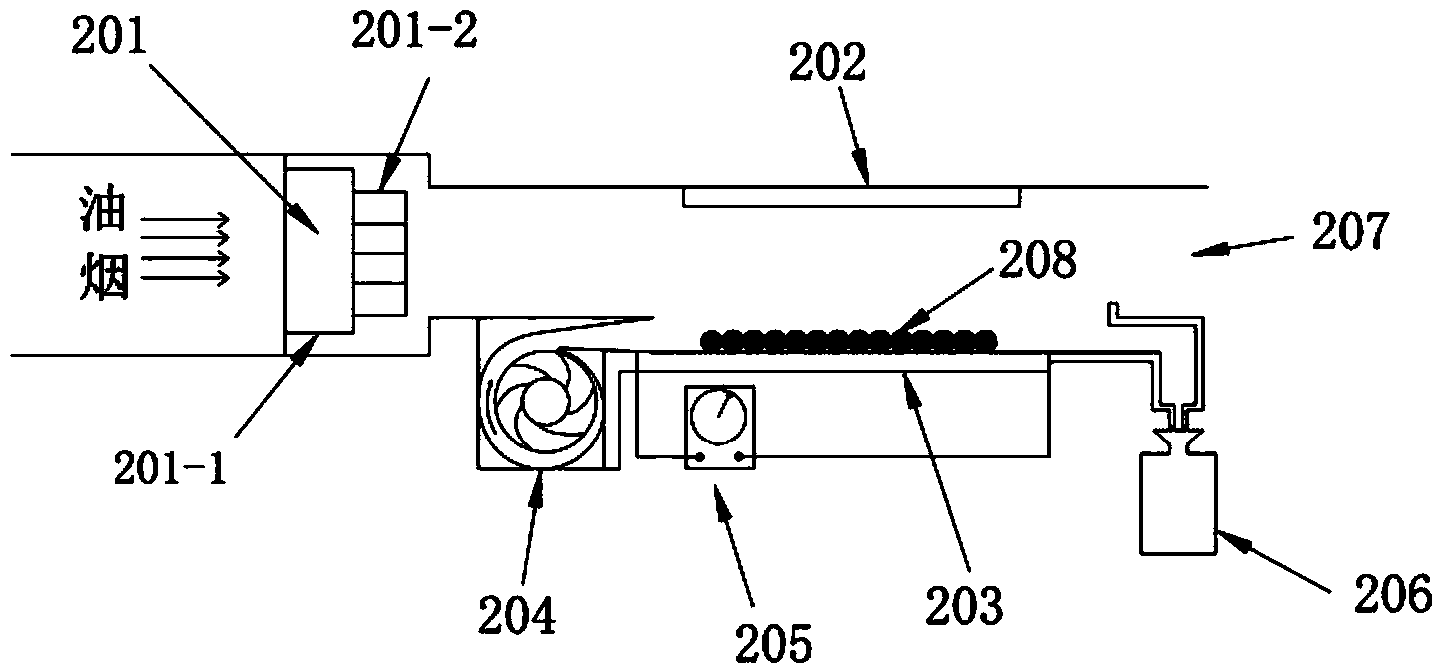

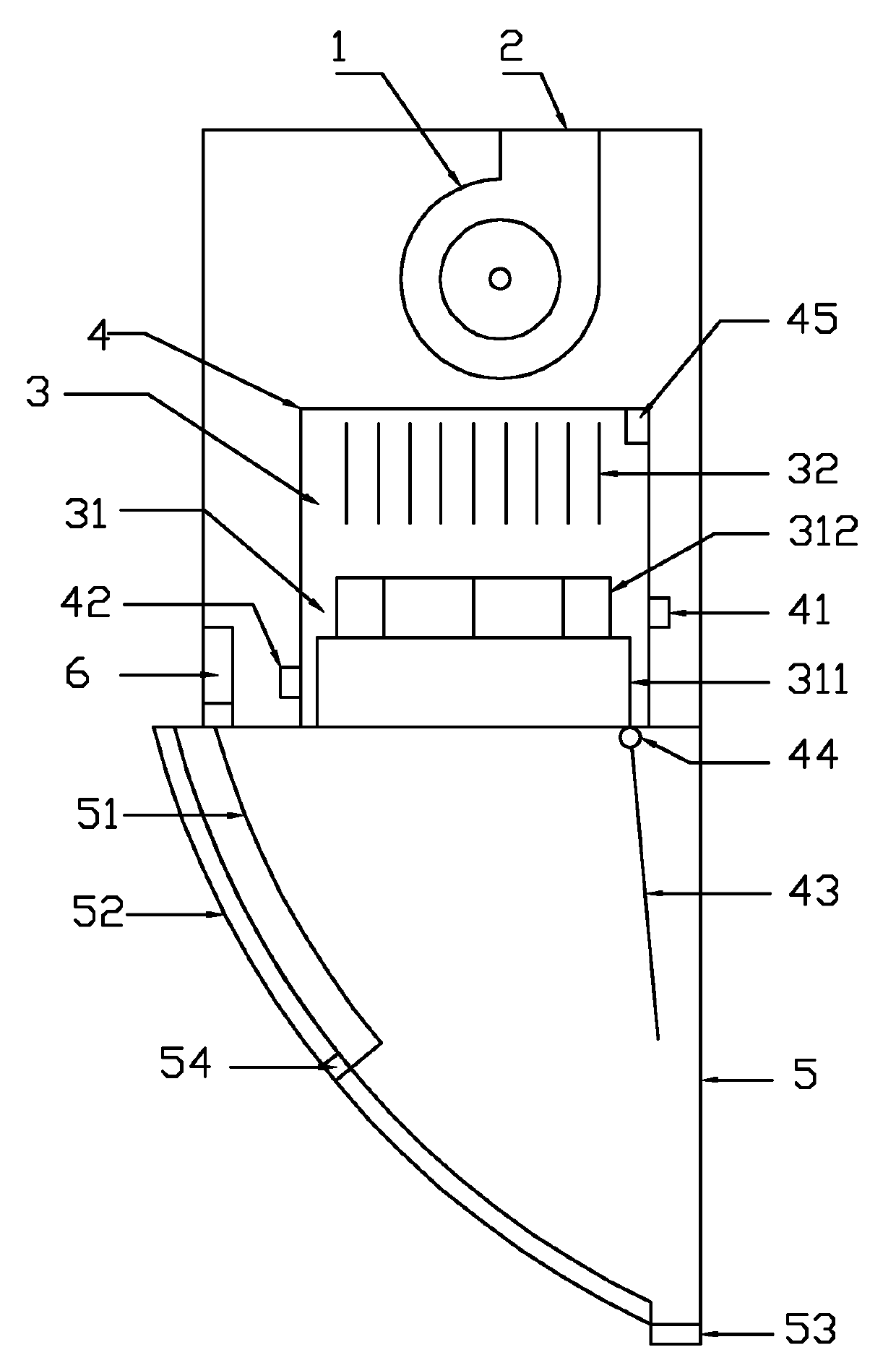

Centralized cooking oil fume treating and recycling system

InactiveCN104006432AAvoid cloggingRealize secondary useDomestic stoves or rangesLighting and heating apparatusHigh voltage cathodeHigh pressure

The invention discloses a centralized cooking oil fume treating and recycling system which comprises an early-stage pretreatment unit, an electrostatic purification oil removal unit with a pump oil removal function, a later-stage air purification unit and an exhaust fan, wherein the early-stage pretreatment unit, the electrostatic purification oil removal unit, the later-stage air purification unit and the exhaust fan are sequentially connected through pipelines along the oil fume running direction; the electrostatic purification oil removal unit comprises a high voltage electric field generating area, a high voltage cathode electrode, a high voltage anode electrode, an oil pump, a hydraulic pressure gauge and a detachable collection container; the high voltage electric field generating area is formed in an oil fume inlet of the electrostatic purification oil removal unit; the high voltage cathode electrode and the high voltage anode electrode are vertically opposite to each other; the high voltage anode electrode is connected with the hydraulic pressure gauge, and oil on the high voltage anode electrode can be discharged into the collection container through the oil pump along the pipeline. Energy in the waste oil fume is utilized to the greatest degree when an electrostatic treatment device is not required to be detached, so that the device is simplified, and the aims of energy conservation and environment friendliness are achieved.

Owner:SOUTH CHINA UNIV OF TECH

Alkyl silicyl lithium battery polymer electrolyte resistant to high voltage, preparation method and application thereof in all-solid-state lithium battery

ActiveCN108242563AGood compatibilityExcellent long cycle performanceElectrolytesLi-accumulatorsAll solid statePolymer electrolytes

The invention relates to an alkyl silicyl lithium battery polymer electrolyte resistant to high voltage, a preparation method and application of the electrolyte in a lithium battery. The electrolyte comprises alkyl silicyl polymers, lithium salt, a porous supporting material and additives. Experiments show that the alkyl silicyl polymer electrolyte material has good film forming property and the mechanical strength is 0.5-300MPa; an electrochemical window of the electrolyte material is higher than 4.3V, and the electrolyte material has good compatibility with a high voltage cathode material; ionic conductivity at room temperature is 1*10<-5>S*cm<-1>-10<-3> S*cm<-1>, and a battery assembled by adopting the electrolyte material has excellent long cycle performance. The alkyl silicyl lithiumbattery polymer provided by the invention can be taken as a high-voltage-resistant electrolyte material. The invention also provides a preparation method of the polymer electrolyte and electrochemicalproperties of an all-solid-state lithium battery assembled by adopting the electrolyte provided by the invention.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

Electromobile and high-voltage power distribution box

The invention discloses an electromobile and a high-voltage power distribution box. The high-voltage power distribution box comprises a controller, a high-voltage anode contactor, a high-voltage cathode contactor, a high-voltage pre-charging contactor, a pre-charging resistor, a high-voltage input end connector clip, a high-voltage part connector clip and a high-voltage interlocking line. The high-voltage power distribution box completes basic power source distribution and current protection; on one hand, the controller is arranged inside the high-voltage power distribution box, so that only several necessary lines such as a communication bus, a controller ground line and a power source line are needed for connection with the outside, and higher safety is realized; on the other hand, the high-voltage power distribution box is provided with the high-voltage interlocking line which is connected with the high-voltage input end connector clip and the high-voltage part connector clip, and once one connector clip is loose or off, the controller controls all contactors to be off, so that safety of the high-voltage power distribution box is further improved.

Owner:BEIJING CHANGAN AUTOMOBILE ENG TECH RES +1

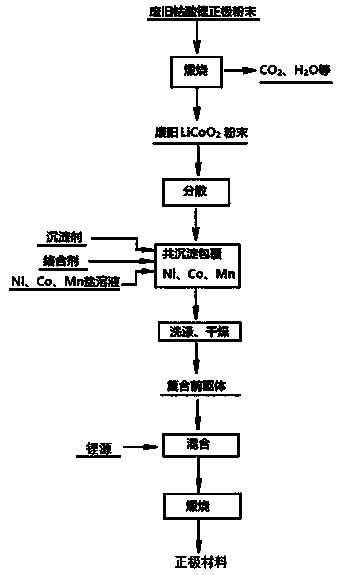

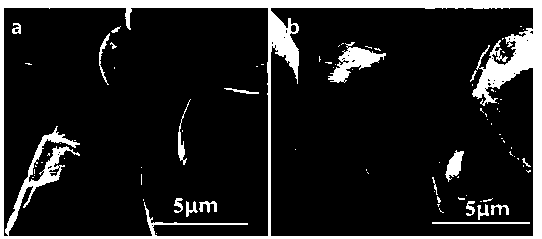

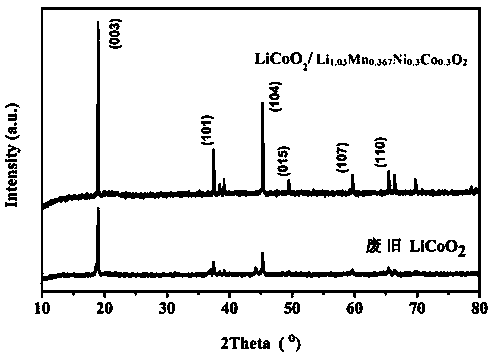

A method for preparing a high-voltage cathode material by using a waste lithium cobalt oxide battery

ActiveCN109119711AEfficient Green RestorationEfficient value-added utilizationCell electrodesWaste accumulators reclaimingNickel saltManganese

The invention discloses a method for preparing a high-voltage cathode material by using a waste lithium cobalt oxide battery. The stripped cathode material of the waste lithium cobalt oxide battery iscleaned, calcined and the content of cobalt and lithium in the cathode material is detected. According to the stoichiometric ratio of lithium-rich manganese solid solution, nickel salt, cobalt salt and manganese salt are prepared into mixed salt solution of nickel salt, cobalt salt and manganese salt, and then a complexing agent solution I, complexing agent solution II and precipitating agent solution are prepared respectively; adding a complexing agent solution II as a base liquid into the reaction kettle and adding the calcined waste lithium cobaltate material, the Ni-Co-Mn mixed salt solution, the complexing agent solution I and the precipitating agent solution are respectively added to carry out a precipitation reaction, the pH value, the concentration of the complexing agent, reaction temperature and reaction time are controlled, filtering, cleaning and drying are performed to obtain a composite precursor, and the composite precursor is mixed with a lithium source and calcined tocool to room temperature to obtain the cathode electrode material; and the material prepared by the invention has high crystallinity, high structural stability and good high voltage charge-dischargecycle stability.

Owner:江西九鼎动力新能源科技有限公司

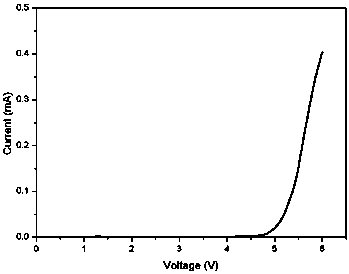

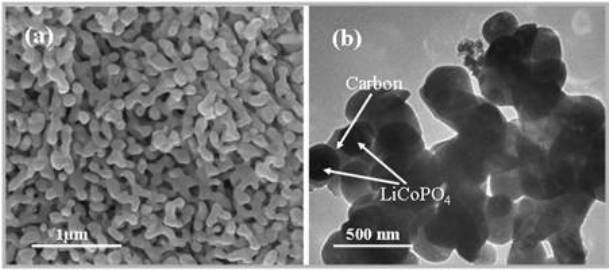

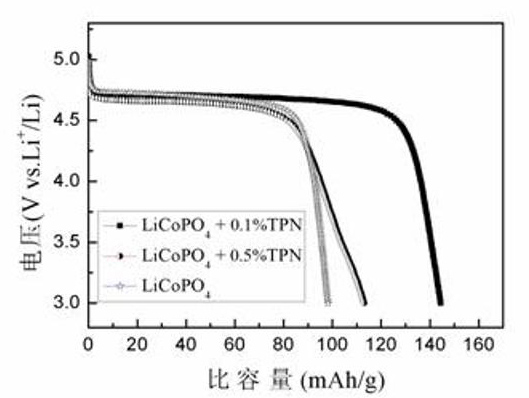

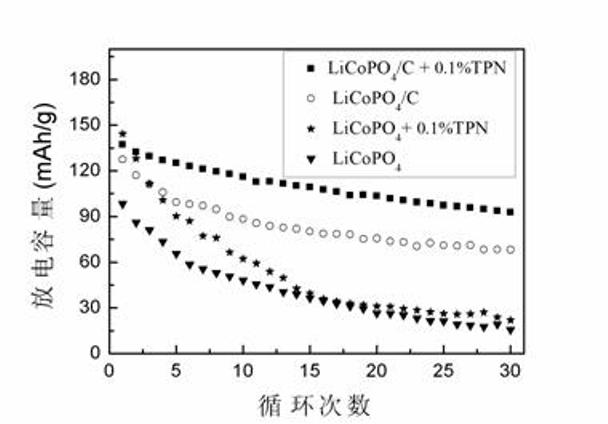

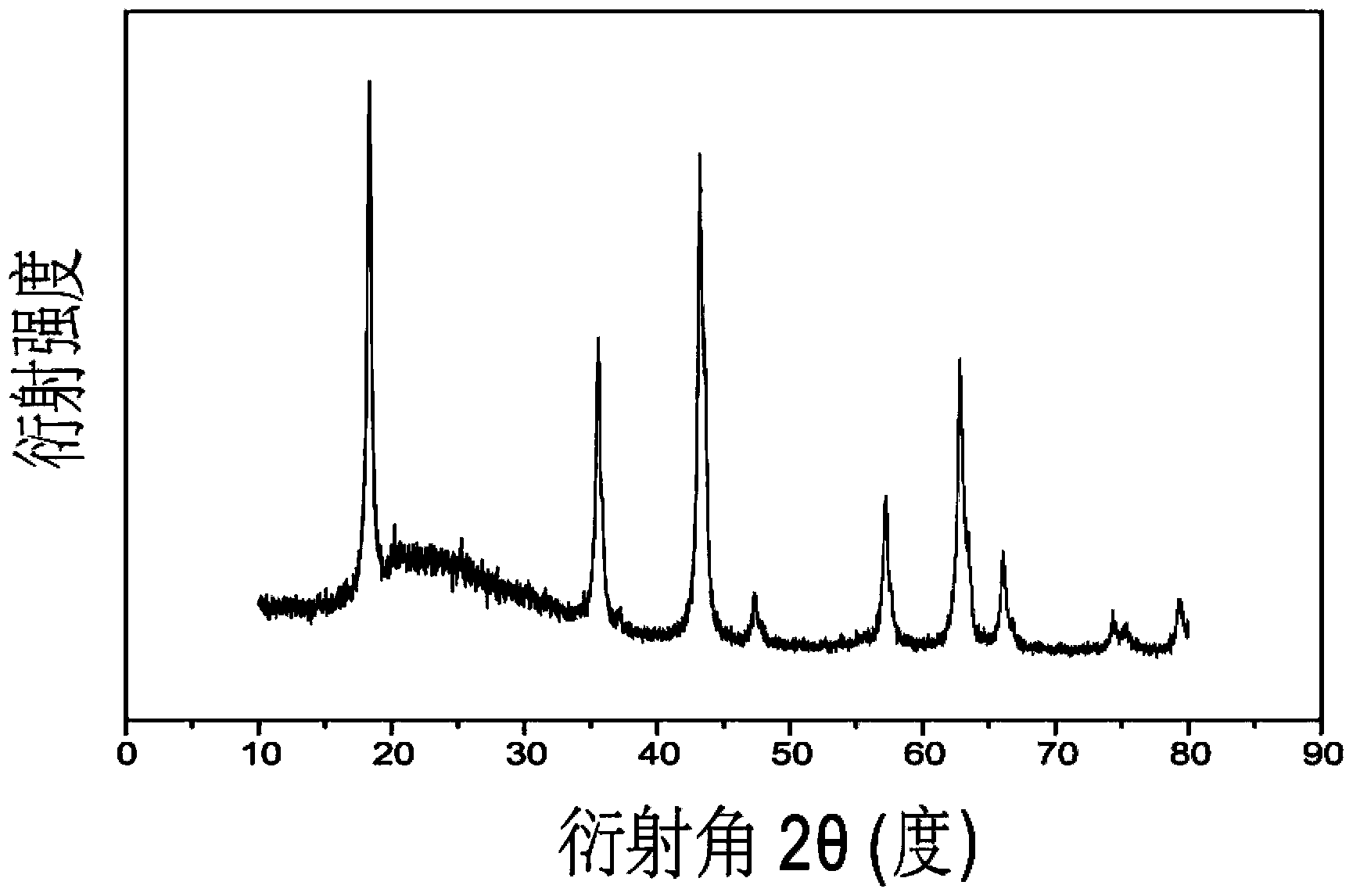

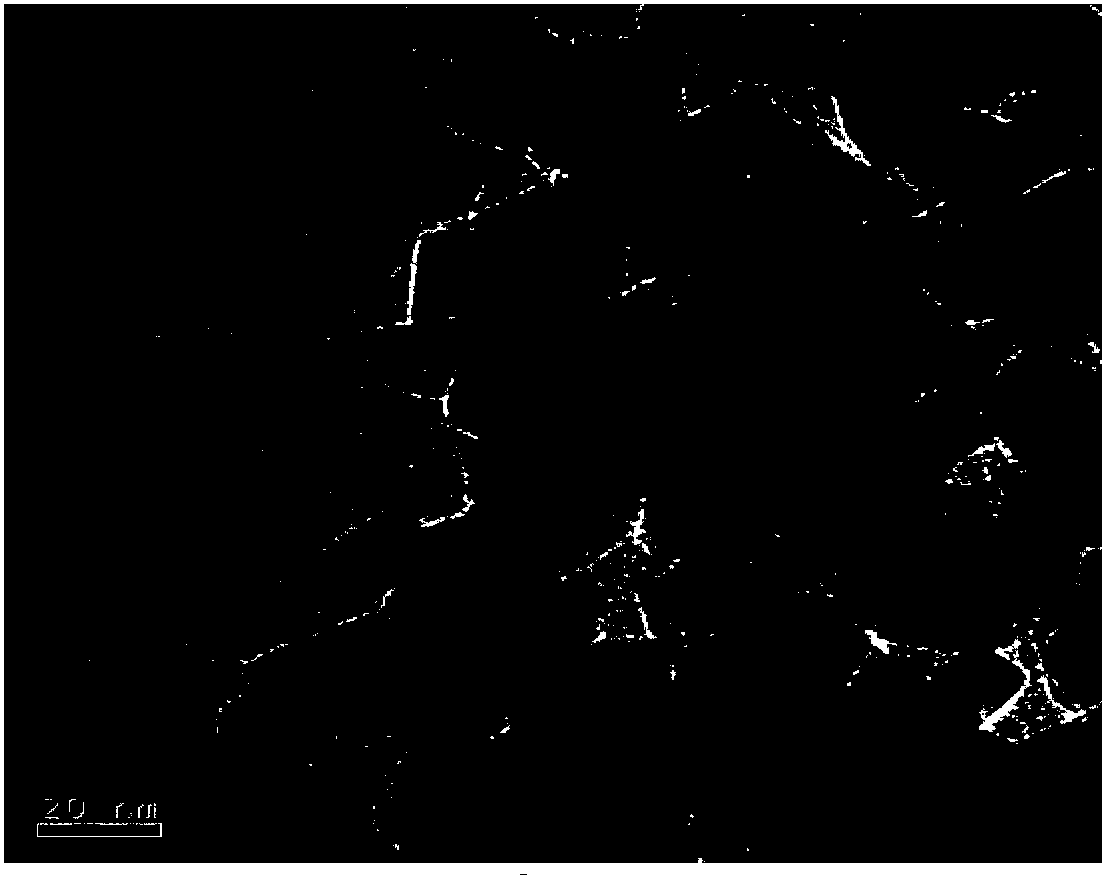

Preparation method of high-voltage lithium-ion battery

InactiveCN102024989AImprove conductivityRestrict growthCell electrodesFinal product manufactureFuranHigh voltage cathode

The invention relates to a preparation method of a high-voltage lithium-ion battery. The lithium-ion battery is assembled and prepared by using a conventional method, a cathode material is a carbon-coated cathode composite material LiCoPO4 / C, an anode material is lithium or carbon, an electrolyte is a conventional organic electrolyte added with an additive which is one of thiophene, biphenyl and furan or the combination of more than two in any proportions, and the additive consumption is 0.05-2 percent by weight of the conventional organic electrolyte. The invention has the advantages that (1) a uniform conductive film can be formed on the particle surface of a material by coating carbon on the high-voltage cathode material to benefit the embedment and the separation of lithium ions, and (2) the action of additives, such as the thiophene, and the like, ensures the stability of the electrolyte component. The method has simple process, is easy for industrialization, greatly improves the electrochemical performance of the ion battery by modifying the cathode material and optimizing the electrolyte and has wide application prospects in the field of the lithium-ion battery of a power type.

Owner:NANKAI UNIV +1

Magnesium secondary battery anode material and application thereof

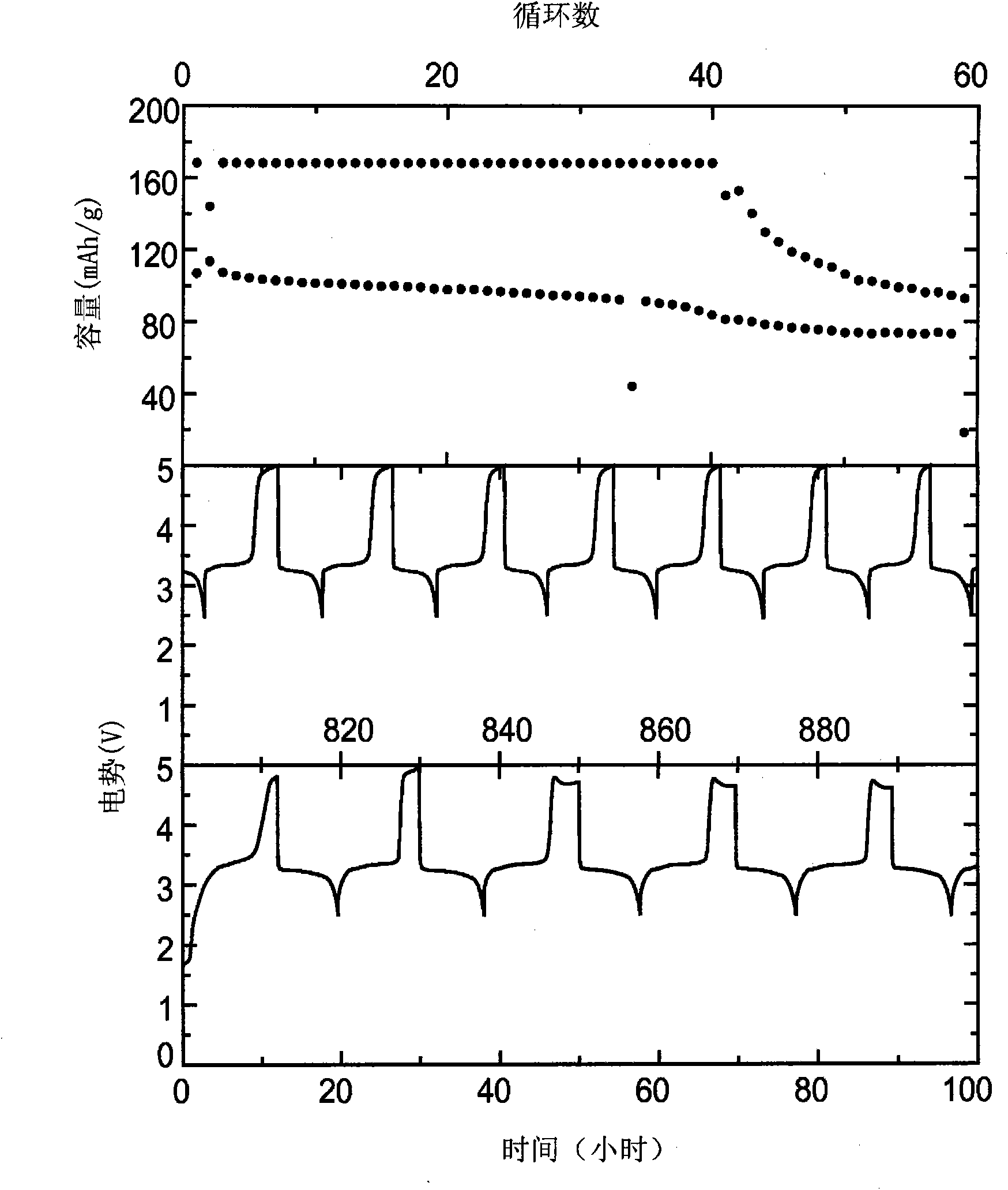

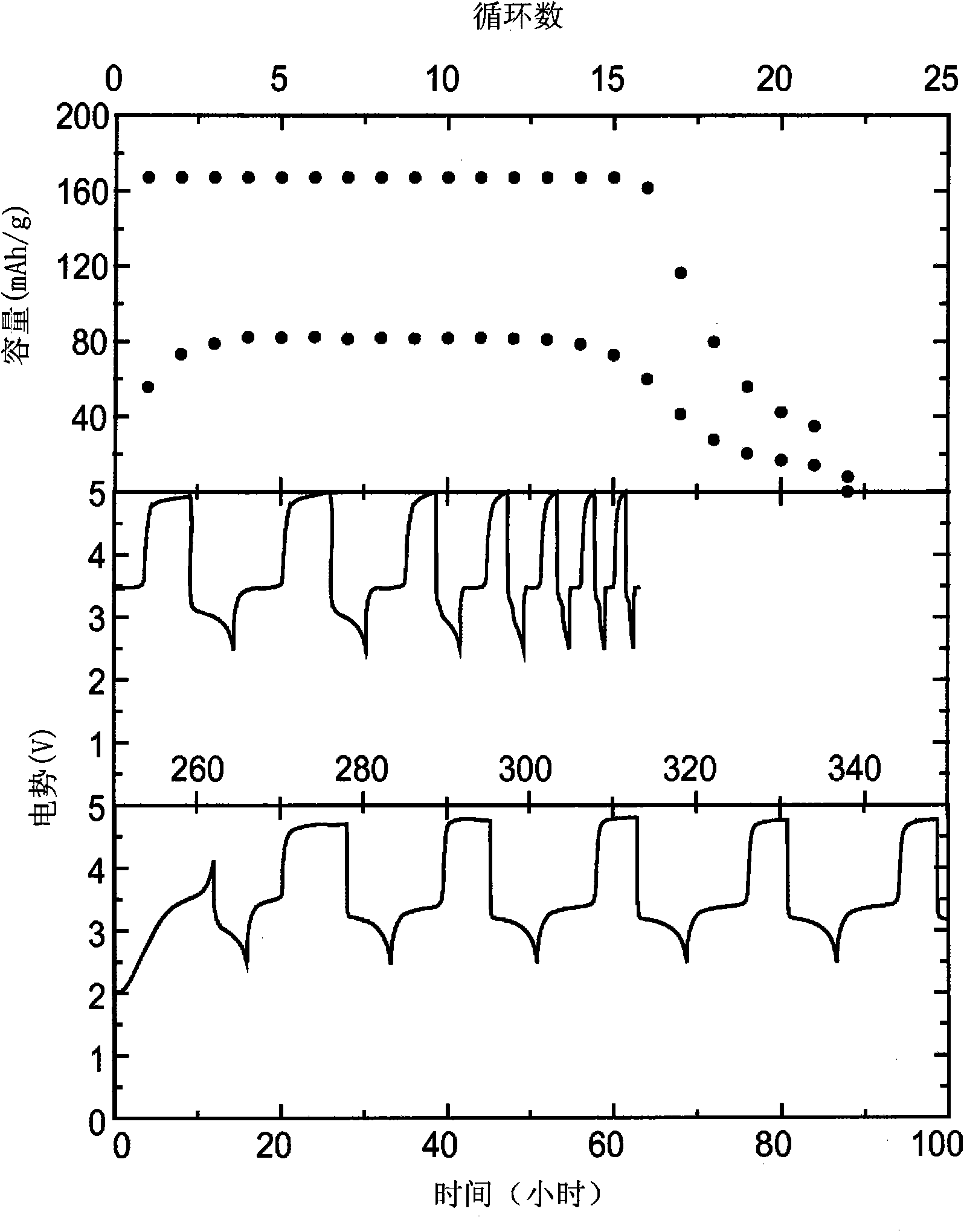

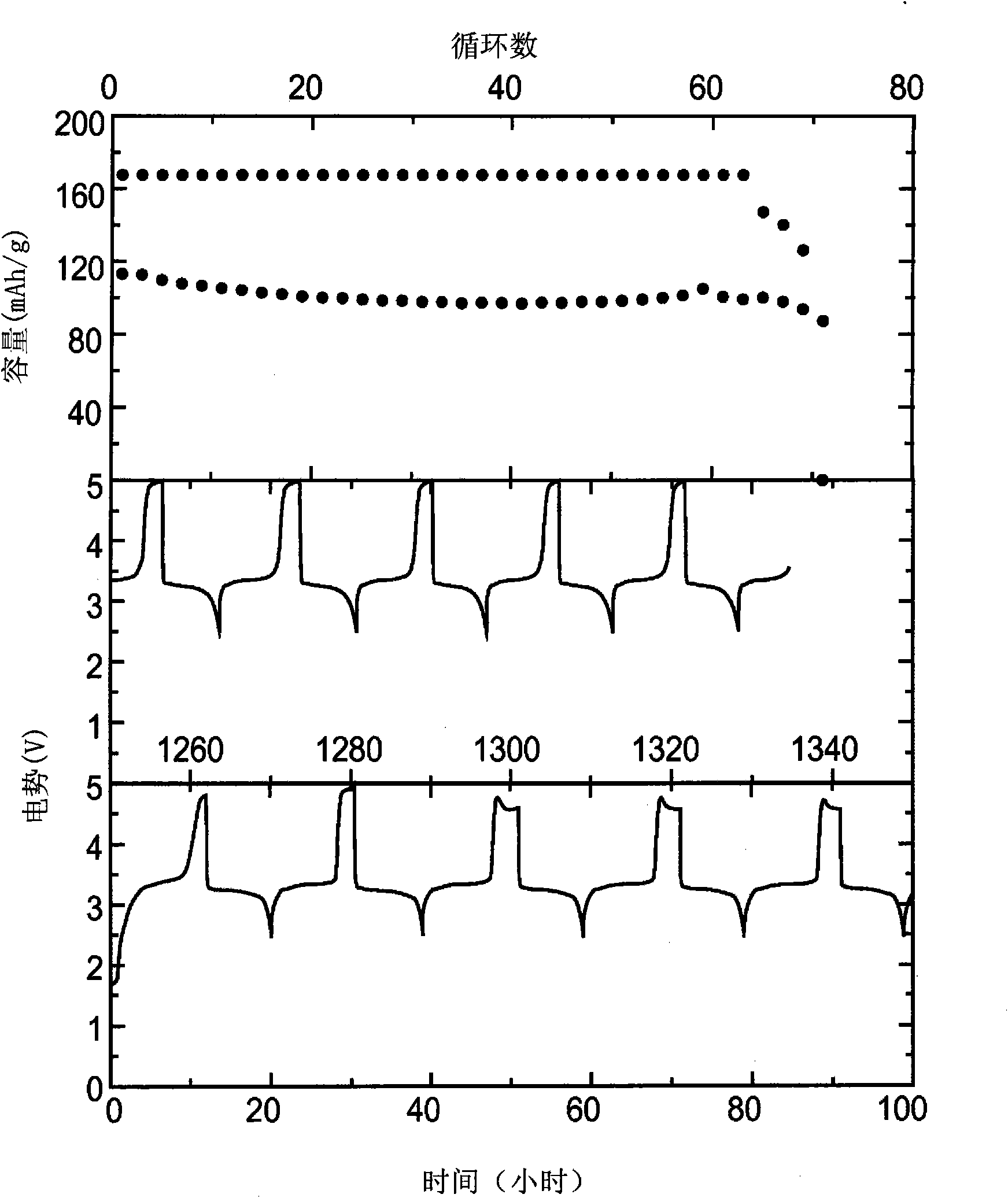

ActiveCN103367735ASimple methodRaw materials are easy to getCell electrodesSecondary cellsCharge dischargeHigh voltage cathode

The invention discloses a magnesium secondary battery anode material and an application thereof in a magnesium secondary battery. The magnesium secondary battery anode material exists in a form of particles with specific dimension. When being applied to the magnesium secondary battery, the magnesium secondary battery anode material has high charge-discharge capacity and good cycling stability. The metal magnesium is replaced by the magnesium secondary battery anode material, so that a condition is provided for creatively applying a simple ion salt / organic electrolytic liquid system into the magnesium secondary battery, and the development of high-voltage cathode material and the magnesium secondary all-battery is possible.

Owner:INST OF CHEM CHINESE ACAD OF SCI

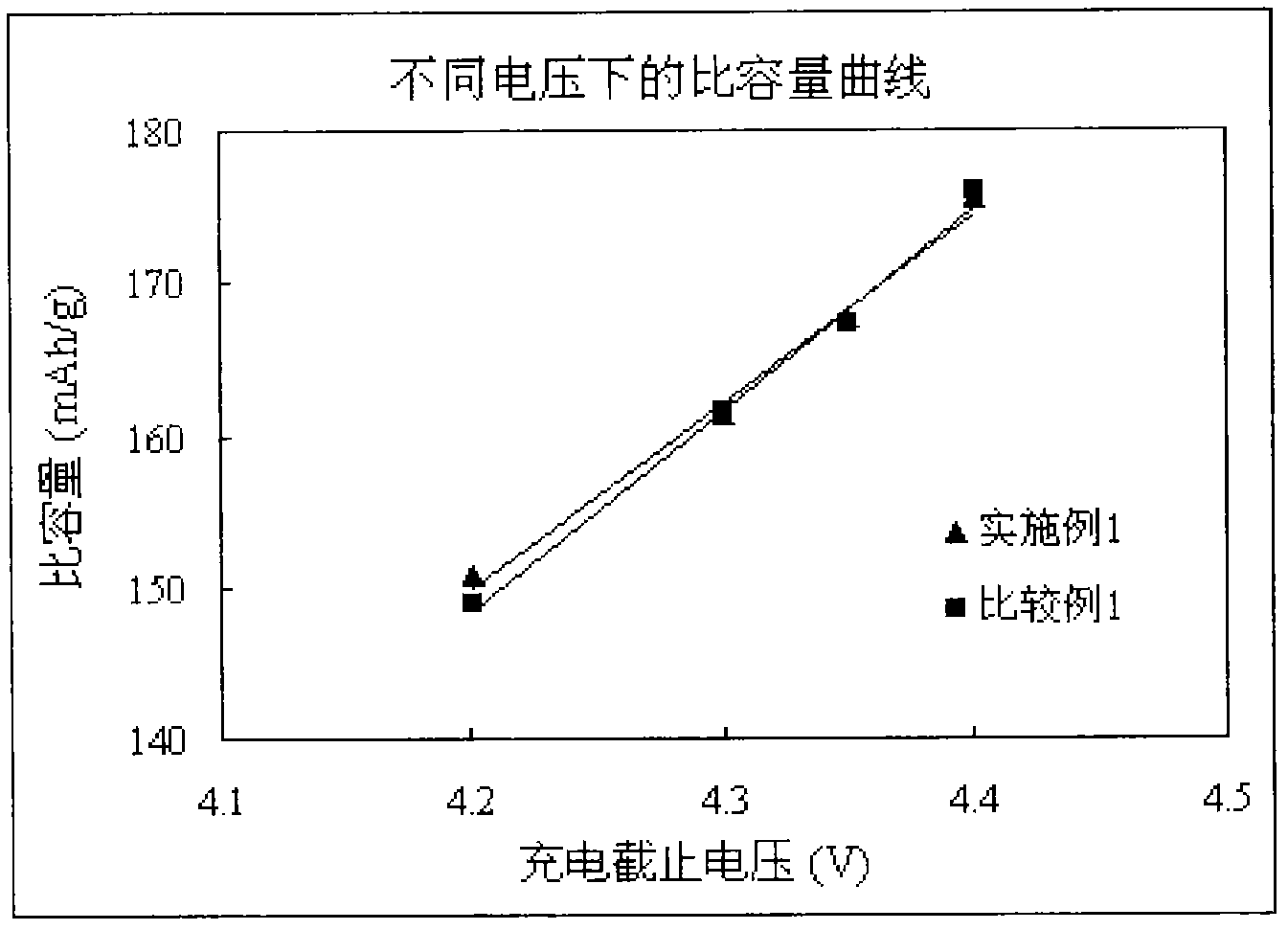

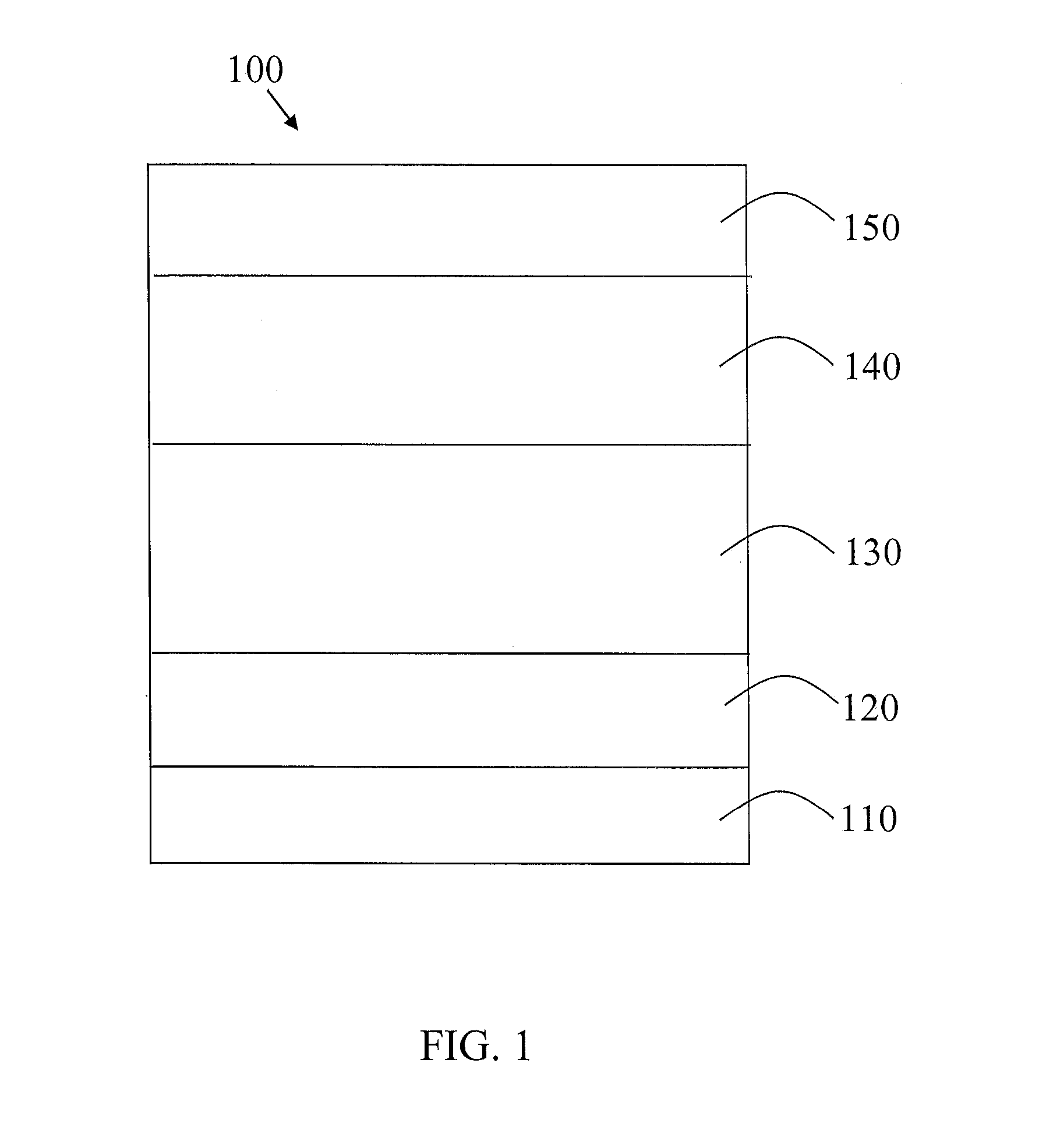

Preparation method of a lithium ion battery for improving the comprehensive performance of a high-voltage cathode material

InactiveCN109256523AHigh solid contentImprove conductivityElectrode rolling/calenderingFinal product manufactureSodium-ion batterySlurry

The invention relates to a preparation method of a lithium ion battery for improving the comprehensive performance of a high-voltage cathode material, belonging to the technical field of lithium ion battery preparation. The method comprises the following steps: coating a layer of positive electrode slurry A with the thickness of 5um to 25um on the positive electrode current collector to form an electrically conductive coating; The specific configuration method of the positive electrode slurry A comprises the following steps: firstly, a conductive agent and a binder are added, and finally, a positive electrode main material is added, and the positive electrode main material is added in 2 to 5 times on average; After the positive electrode slurry A is coated, a layer of positive electrode slurry B with the thickness of 150-200um is coated, and after the coating is completed, the positive electrode slurry B can be sorted according to the conventional production process; The invention hasthe advantages that the slurry dispersibility of the first coating layer is good, the surface resistance of the positive electrode sheet is small, and the positive electrode polarization can be improved; the slurry solid content of the second coating layer is large, and the machining performance of the positive electrode sheet can be improved, so as to improve the discharge performance and the cycle performance of the high-voltage positive electrode material battery at a high current rate.

Owner:ZHUHAI COSMX BATTERY CO LTD

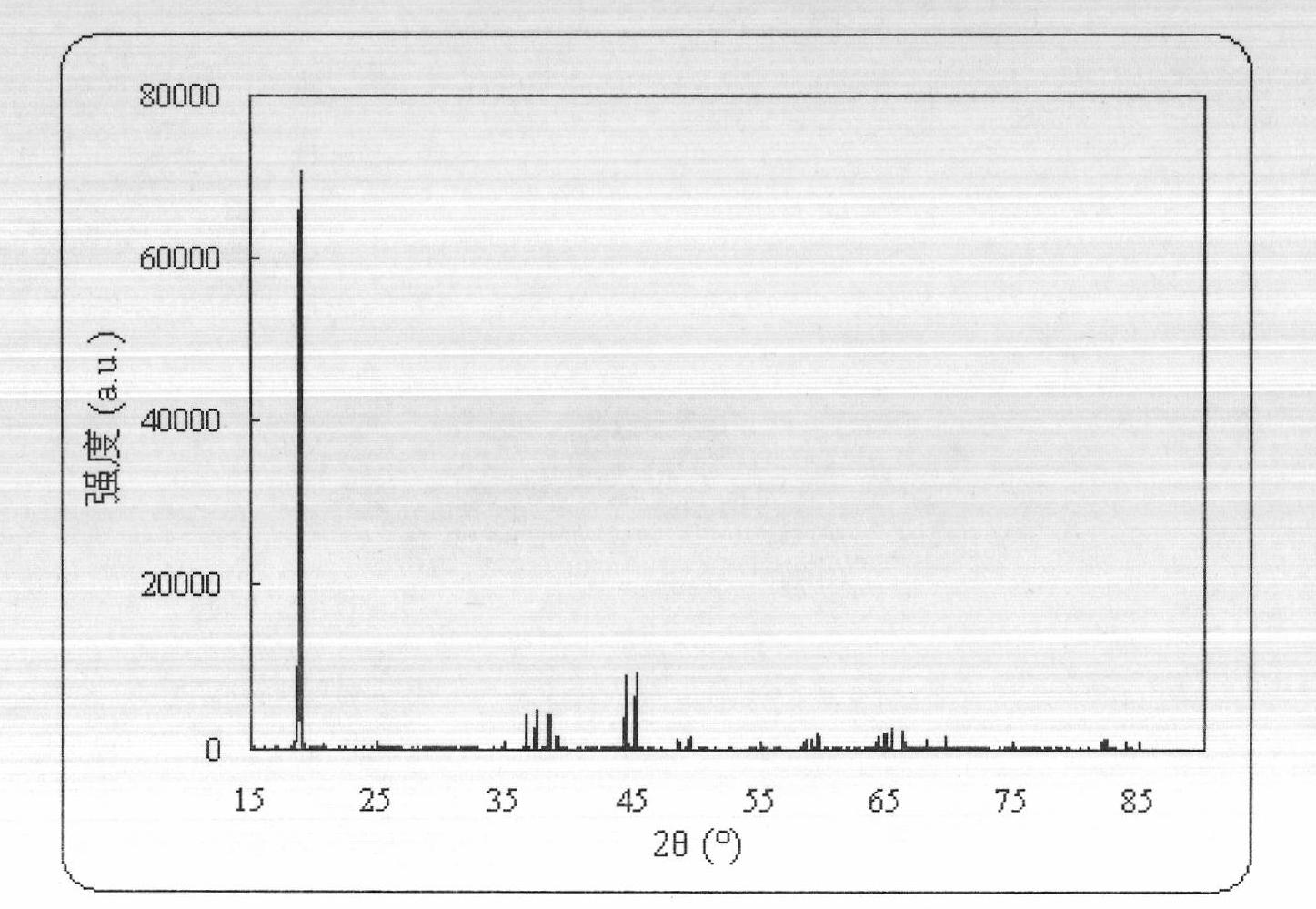

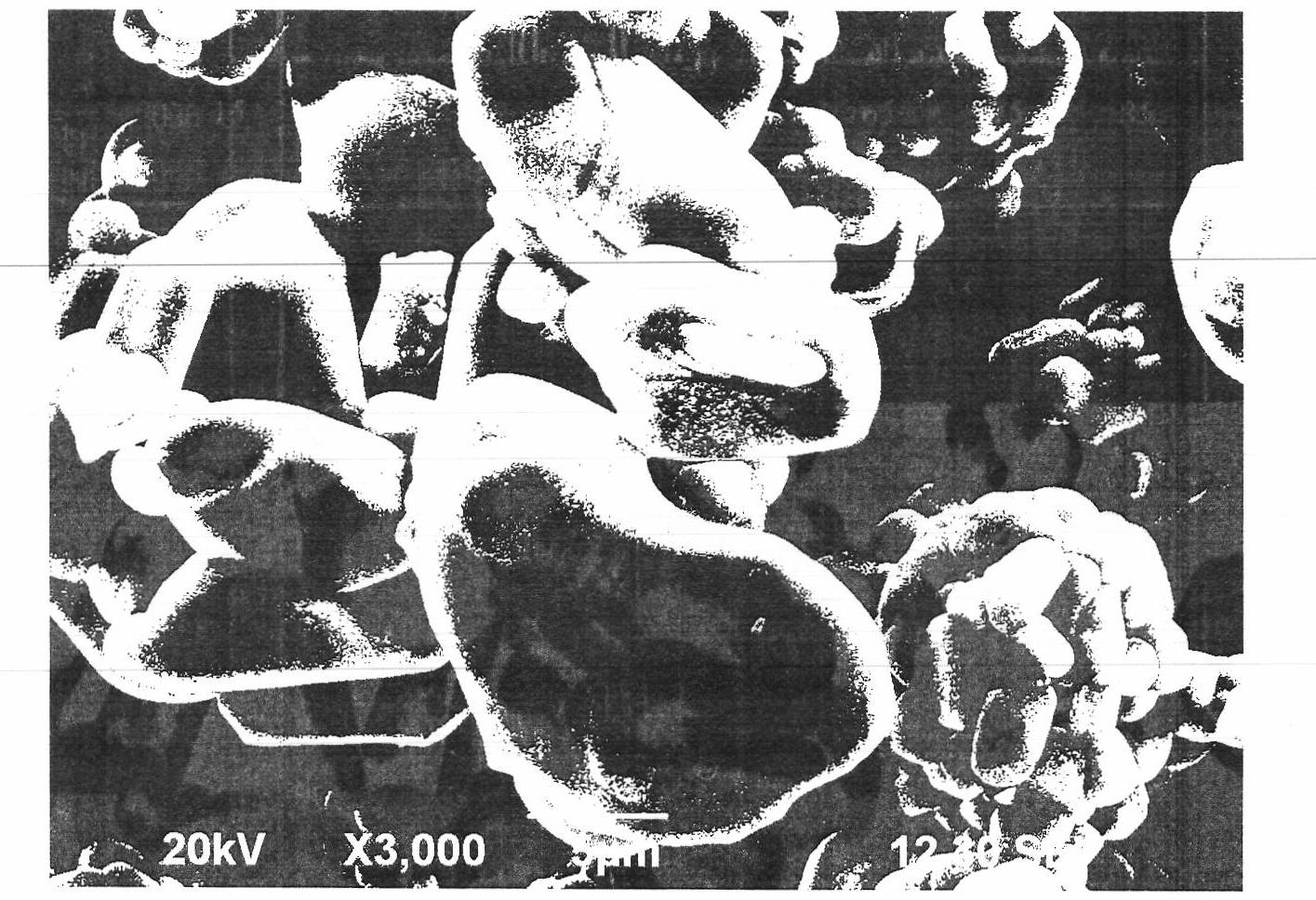

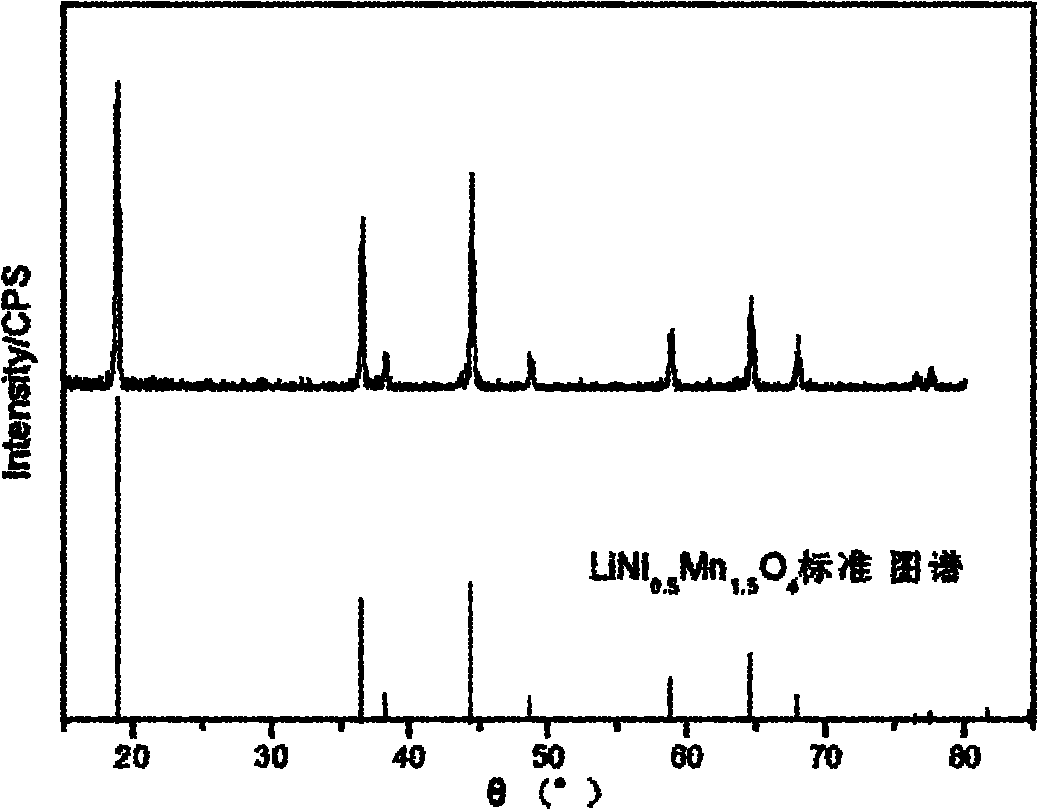

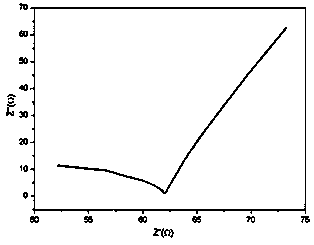

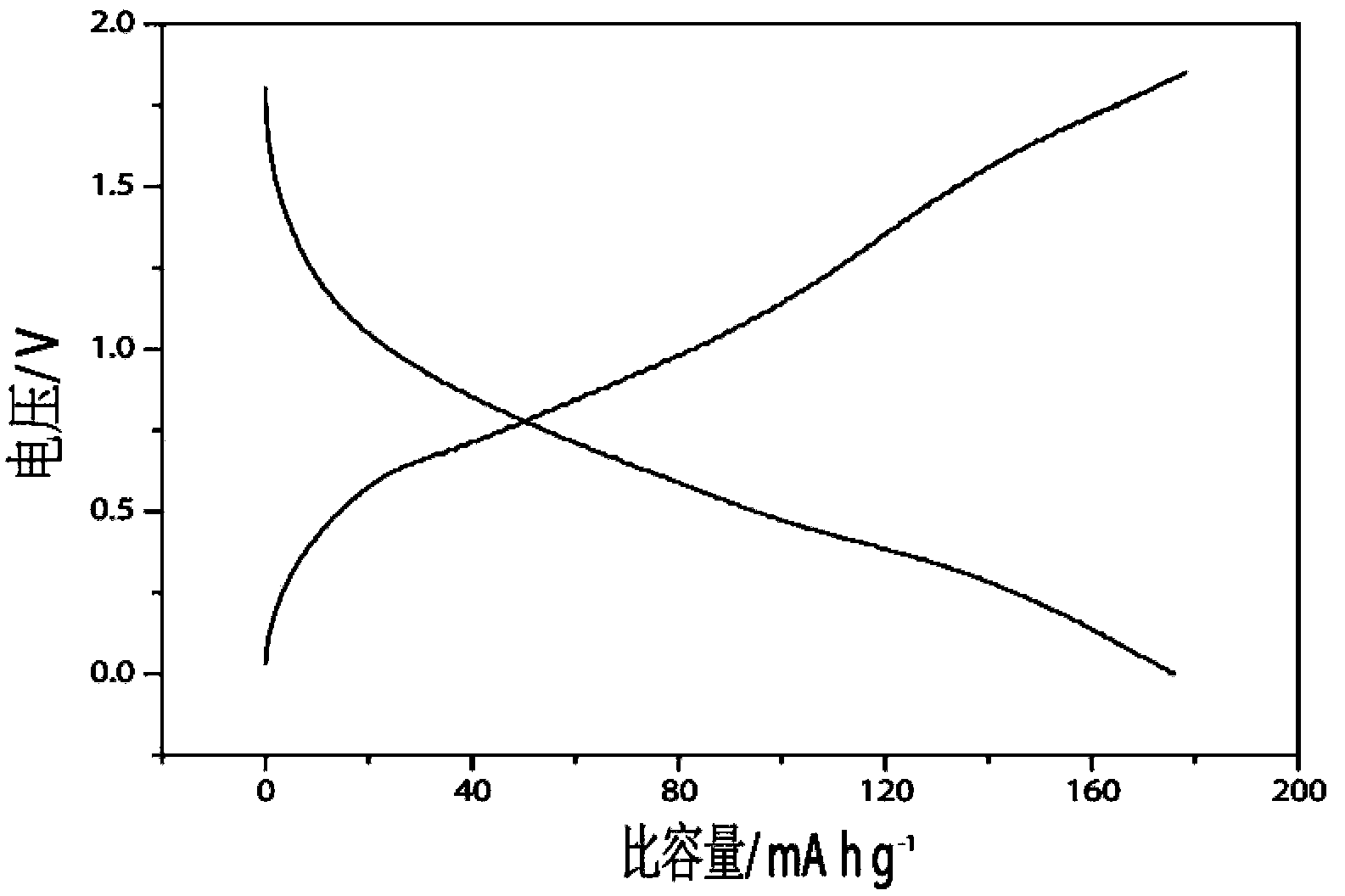

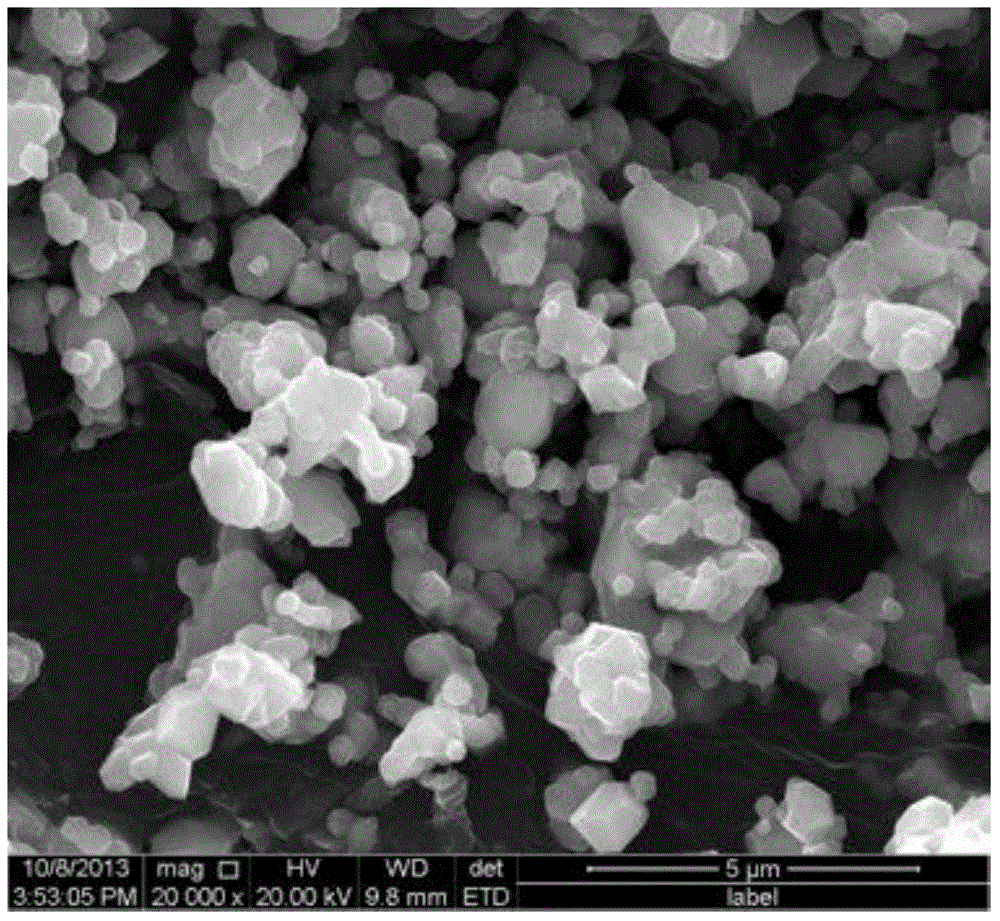

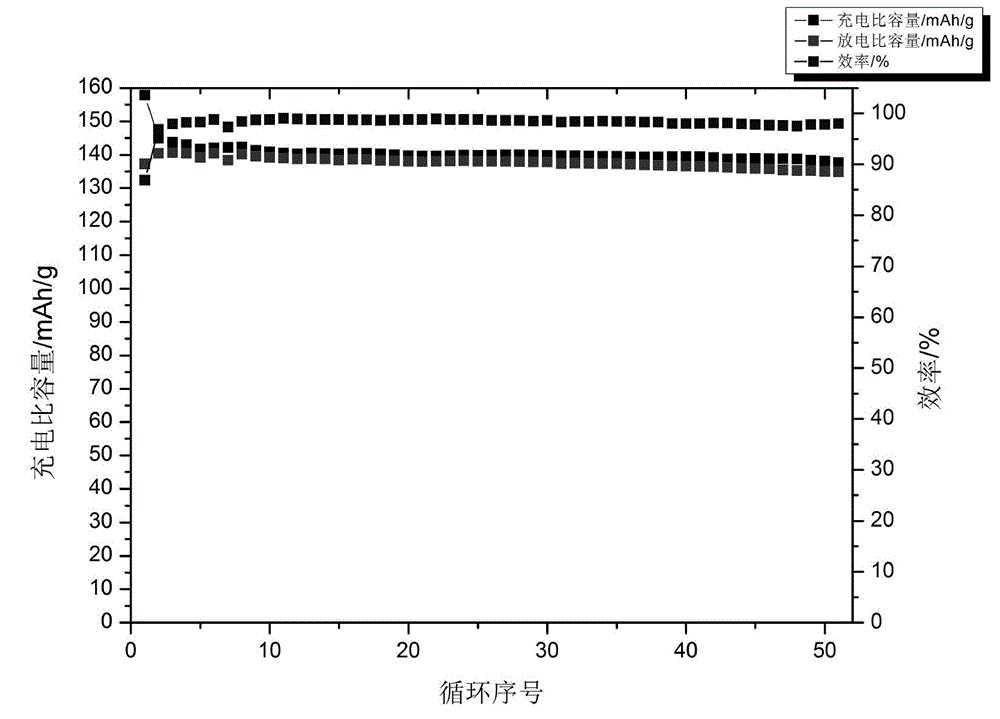

Preparation method of lithium ion battery high-voltage cathode material lithium nickel manganese composite oxide

ActiveCN103825014AStandard spinel structureImprove cycle stabilityCell electrodesSecondary cellsManganeseHigh voltage cathode

The invention relates to a preparation method of lithium ion battery high-voltage cathode material lithium nickel manganese composite oxide, and belongs to the technical field of a manufacturing process of chemical electrode materials. A dispersing agent PEG400 serves as a carrier which a material clings to for uniform dispersion in the synthesis process of the material so as to control the appearance of particles, and the final active material is obtained by removing the dispersing agent PEG400 by a pyrolysis method. The experiment indicates that the material synthesizes by the method has a standard spinel structure, improves the cycling stability and the rate performance and has a certain popularization value.

Owner:中冶瑞木新能源科技有限公司 +1

Redox shuttles for high voltage cathodes

InactiveCN101990721AImproved performance characteristicsHigh initial capacityCell electrodesLi-accumulatorsRedoxHigh voltage cathode

Overcharge protection is provided for rechargeable electrochemical lithium-ion cells. The electrolyte in the provided cells contains a cyclable redox shuttle molecule that can operate in cells with high voltage cathode materials.

Owner:3M INNOVATIVE PROPERTIES CO +1

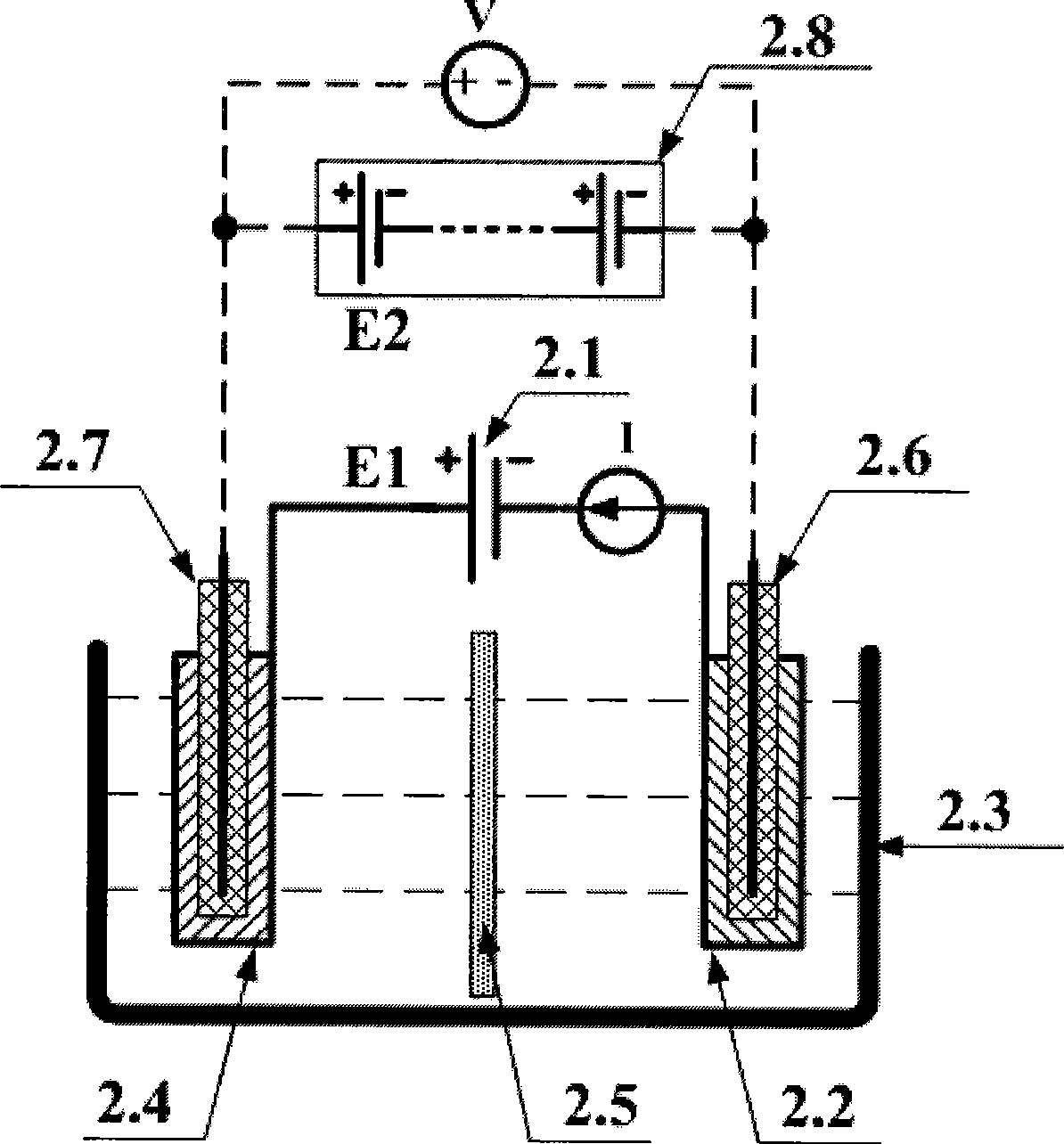

Constant current electrolytic cell in stable strong electric field and electrolysis device thereof

The invention relates to a constant current electrolytic cell in a stable strong electric field. The electrolytic cell is filled with electrolyte, and provided with a low-voltage cathode plate and a low-voltage anode plate connected with a low-voltage direct current supply respectively; a partition board or an ion exchange membrane is arranged between the cathode plate and the anode plate; the electrolytic cell is characterized in that the electrolytic cell is also provided with a high-voltage power supply system, and the high-voltage power supply system is connected with a high-voltage cathode plate and a high-voltage anode plate respectively; the high-voltage cathode plate and the low-voltage cathode plate form a composite cathode plate; the outer surface of the high-voltage cathode plate in the composite cathode plate is provided with an insulating layer to electrically insulate the high-voltage cathode plate and the low-voltage cathode plate, the high-voltage cathode plate and the electrolyte; and the outer surface of the high-voltage anode plate is provided with an insulating layer to electrically insulate the high-voltage anode plate and the low-voltage anode plate, the high-voltage anode plate and the electrolyte. The electrolytic cell can improve the work efficiency of the electrolysis process, can reduce heat loss therein, and has higher electrolysis efficiency in particular in electrolytic analysis of weak electrolyte.

Owner:郭建国 +1

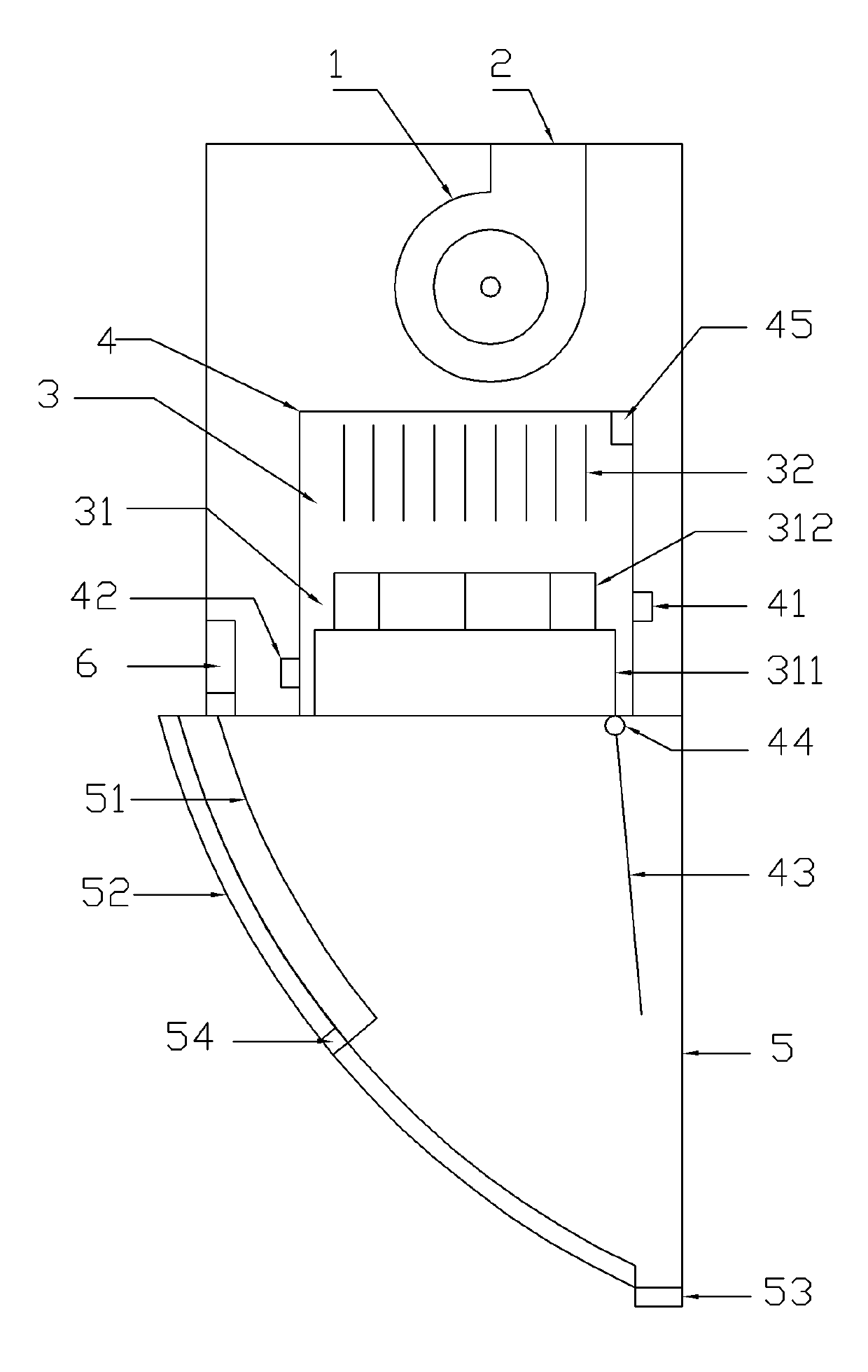

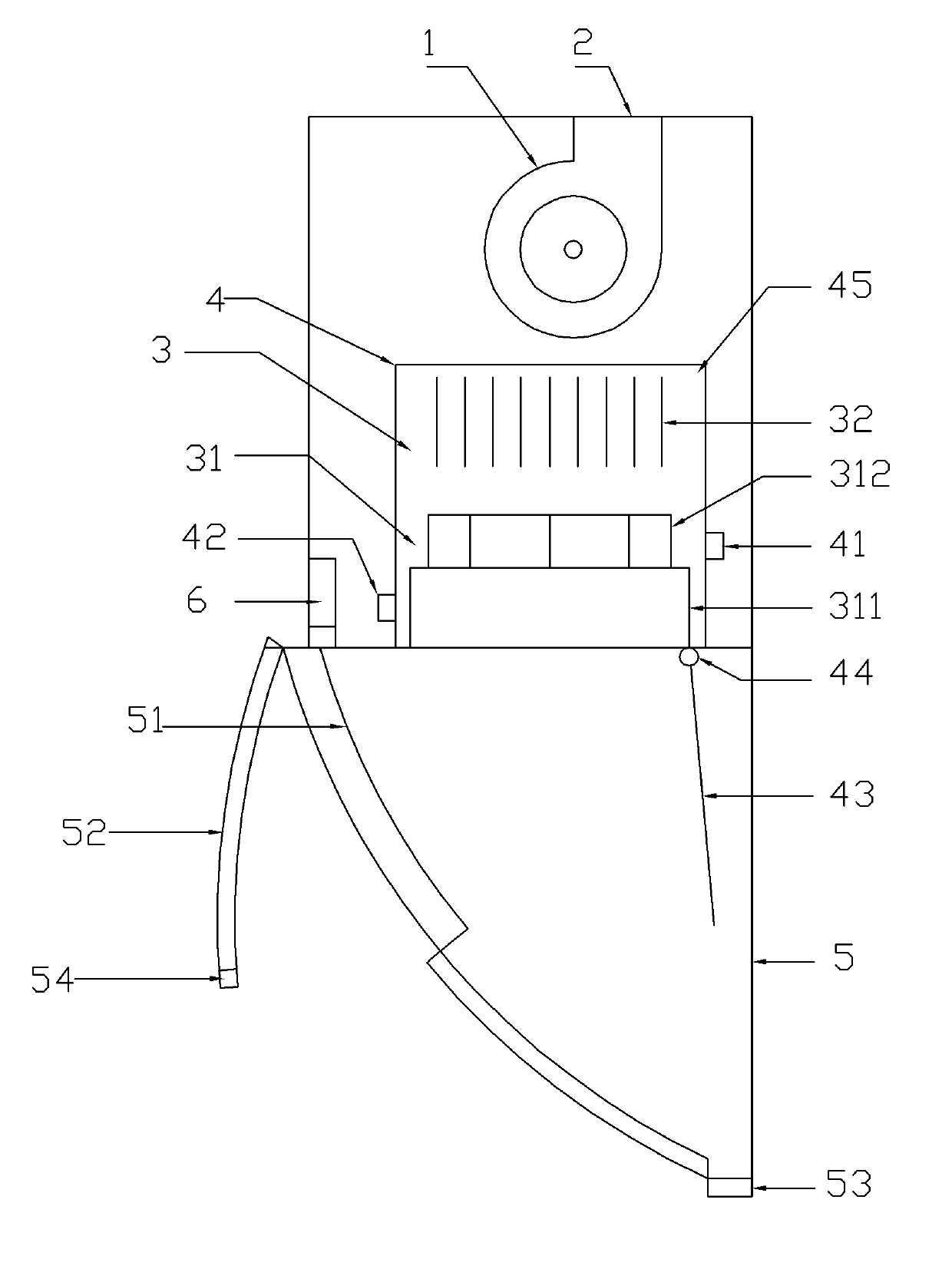

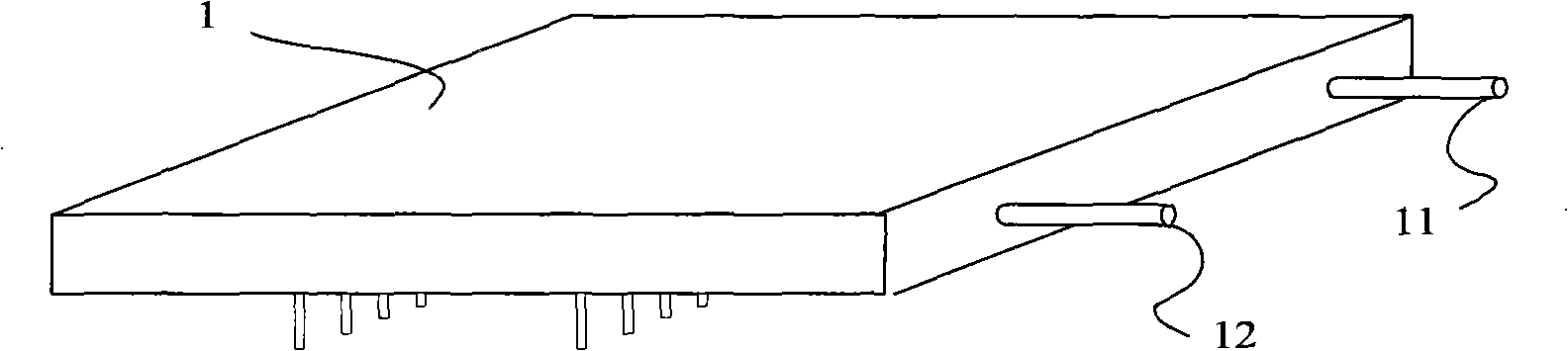

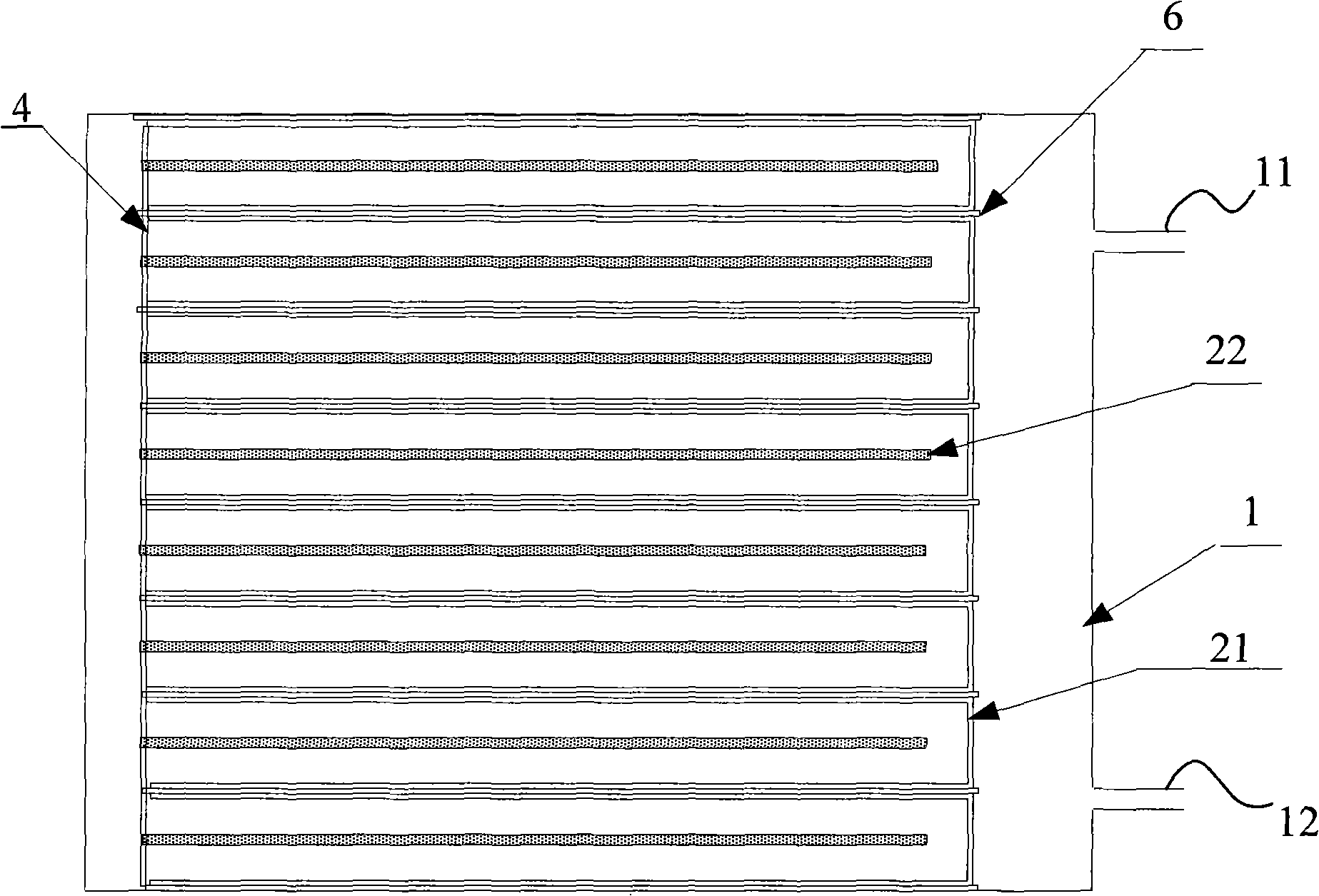

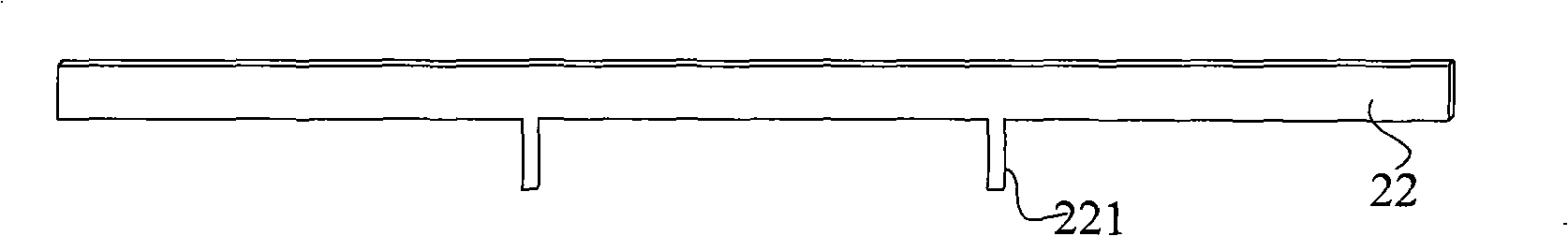

Oil smoke purifying machine free of being dismounted for cleaning

InactiveCN102434903AEfficient purificationReduce pollutionCombination devicesDomestic stoves or rangesElectricityHigh voltage cathode

The invention discloses an oil smoke purifying machine free of being dismounted for cleaning. The oil smoke purifying machine comprises a fan and an air outlet as well as an electric purifier, wherein the electric purifier is used for polarizing oil smoke and adsorbing the oil smoke through high-voltage cathode and anode, and is arranged in a water tank capable of being sealed and cleaned by soaking. By using the electric purifier to effectively purity oil smoke and peculiar smell, the air pollution is reduced, and environment is protected; and the electric purifier is arranged in the water tank capable of being sealed, the components in the water tank can be cleaned by heating and soaking after water and washing solution are added to the water tank, the washing effect is good, cleanness and hygiene are guaranteed, operation is facilitated, and the service life of the purifying machine is prolonged.

Owner:GUANGDONG DESU TECH

High-energy X-ray industrial CT ionization detector

InactiveCN101526623AIncrease conversion rateReduce manufacturing costX/gamma/cosmic radiation measurmentLattenSignal processing circuits

The invention provides a high-energy X-ray industrial CT ionization detector, which can overcome the defects of scintillator detectors and is suitable for radiation detection of a high-energy X-ray industrial CT system. The detector comprises seal housing which is filled with working gases and is provided with a plurality of ionization chamber units; the ionization chamber unit is elongated and comprises a U-shaped ionization chamber wall and a latten; a receiving terminal of the X-ray on the latten is fixedly arranged at an open end of the U-shaped ionization chamber wall via an insulation sheet; the other end of the latten is arranged in the ionization chamber and spread along the length direction of the ionization chamber; the latten, with thickness less than or equal to 0.3mm, is manufactured by high-density metals with high atomic number or the alloy of the metals; a coat on which secondary electrons are easily generated covers the external surface of the latten; the U-shaped ionization chamber wall is connected with a signal processing circuit as a collector; the latten is connected with a high-voltage cathode and a high-voltage power supply as a radiation converter.

Owner:CHONGQING UNIV

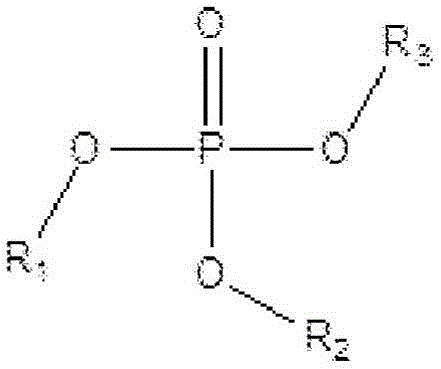

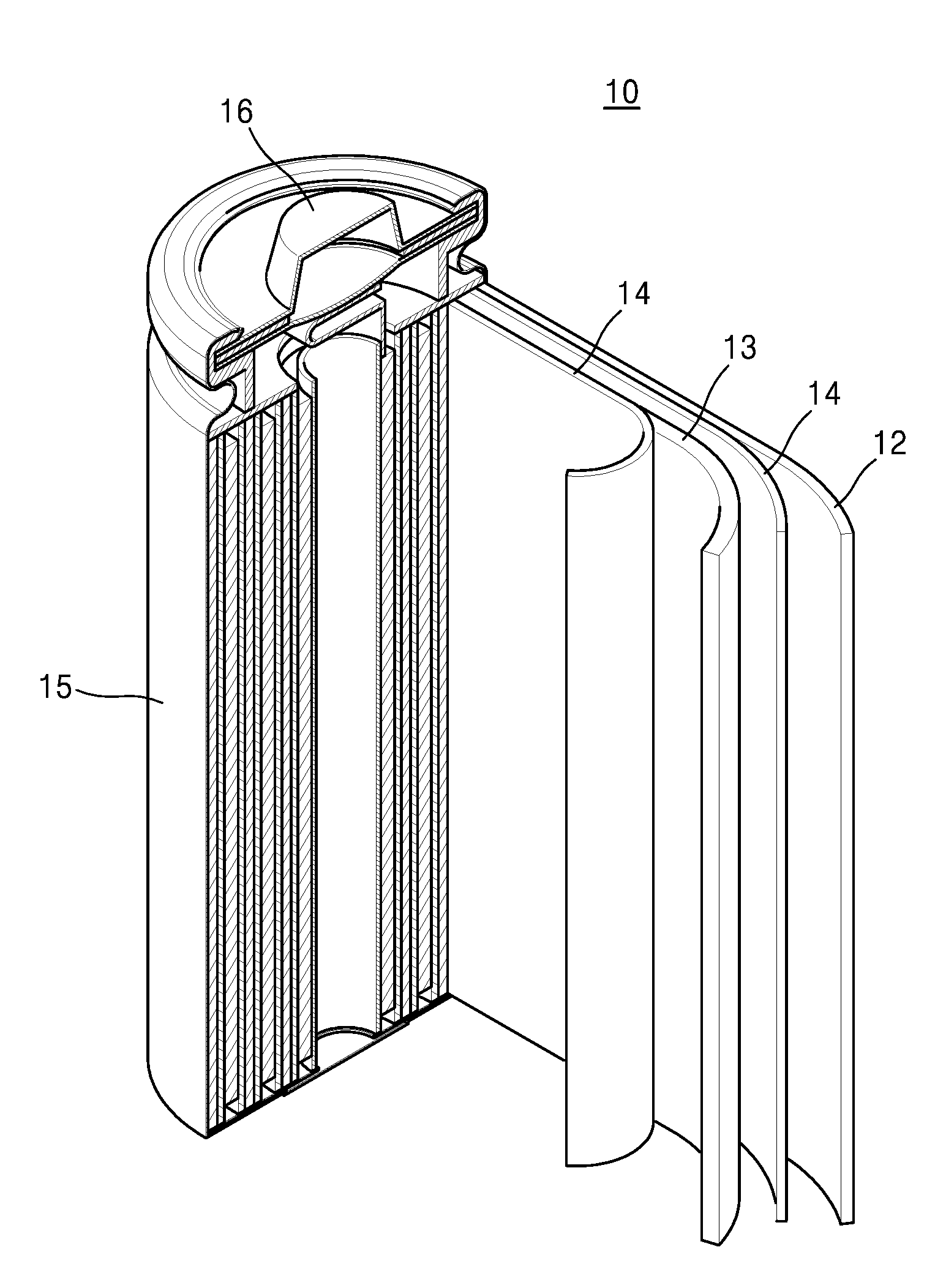

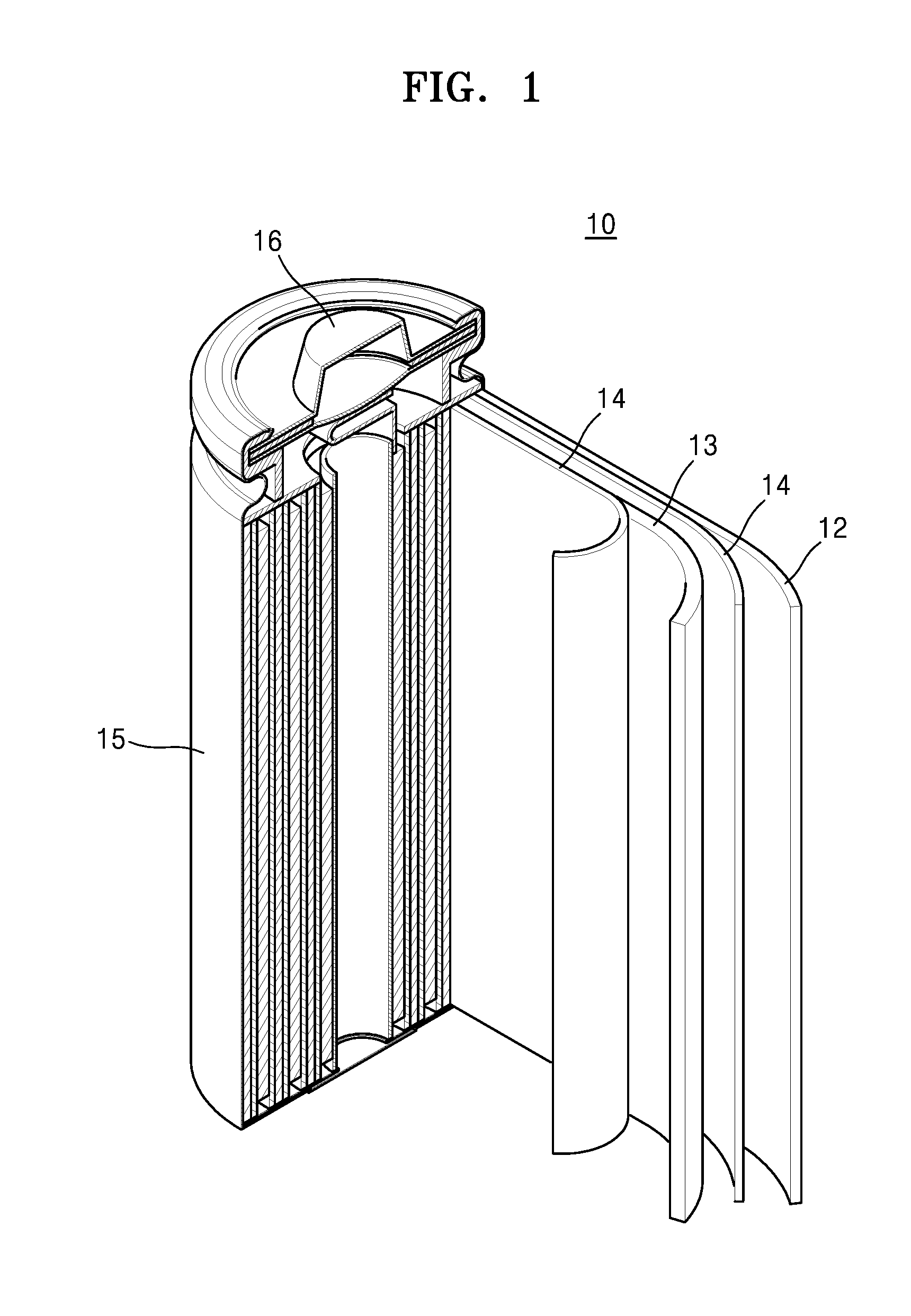

Lithium secondary battery

A lithium secondary battery including: a cathode including a high-voltage cathode active material; an anode; and an electrolyte disposed between the cathode and the anode, wherein the high-voltage cathode active material has a charge cut-off voltage of about 4.2 Volts or greater with respect to a lithium (Li) counter electrode, and wherein the electrolyte includes an organic fluorinated ether compound represented by Formula 1, an organic solvent, and a lithium salt:R1—O—CFnH2-n—R2 Formula 1wherein, in Formula 1, R1 is a C1-C10 alkyl group, a C3-C10 cycloalkyl group, a C1-C10 fluorinated alkyl group, or a C3-C10 fluorinated cycloalkyl group; R2 is hydrogen, fluorine, a C1-C10 alkyl group, a C3-C10 cycloalkyl group, a C1-C10 fluorinated alkyl group, or a C3-C10 fluorinated cycloalkyl group; and n is 1 or 2.

Owner:SAMSUNG ELECTRONICS CO LTD +1

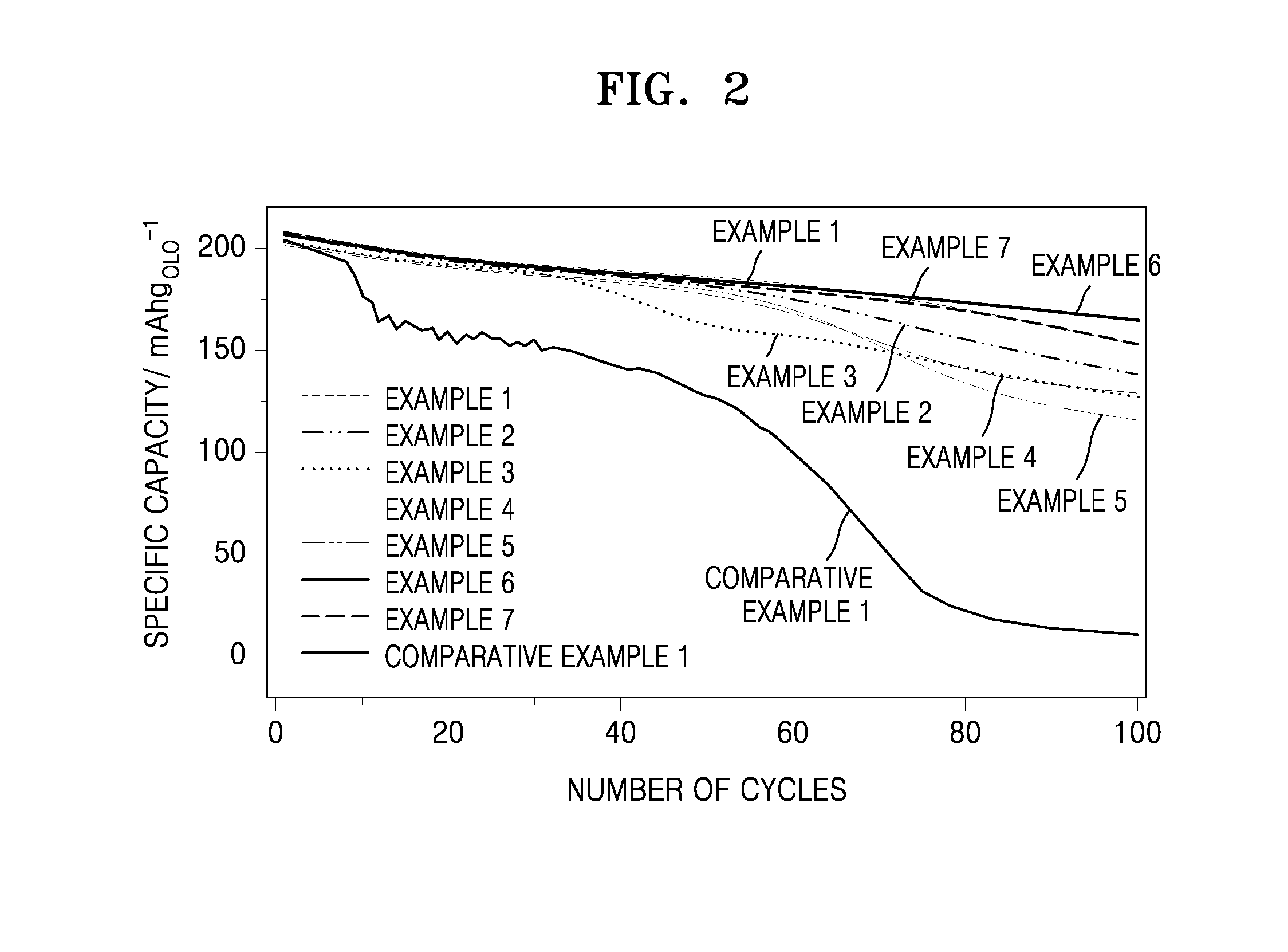

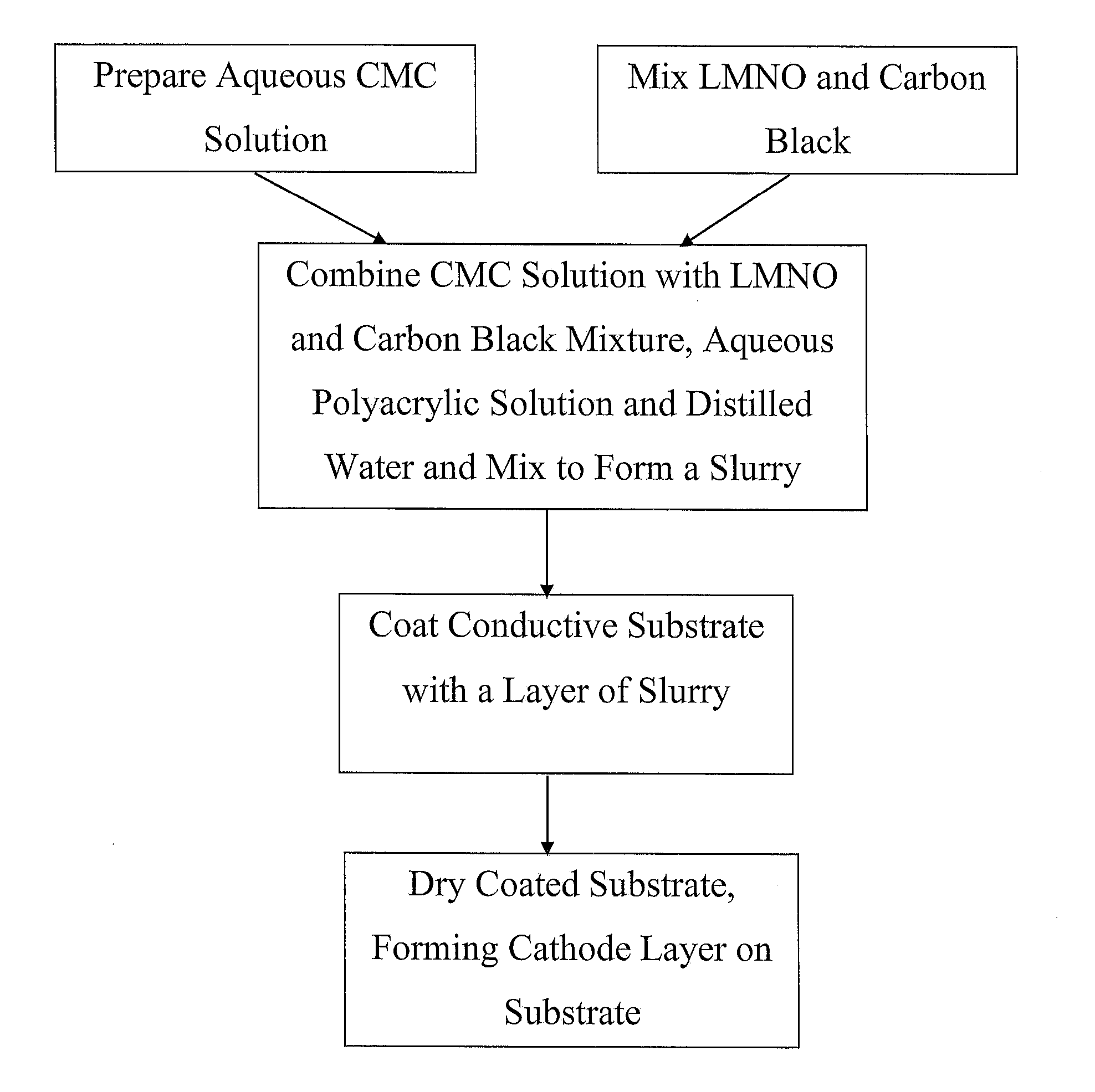

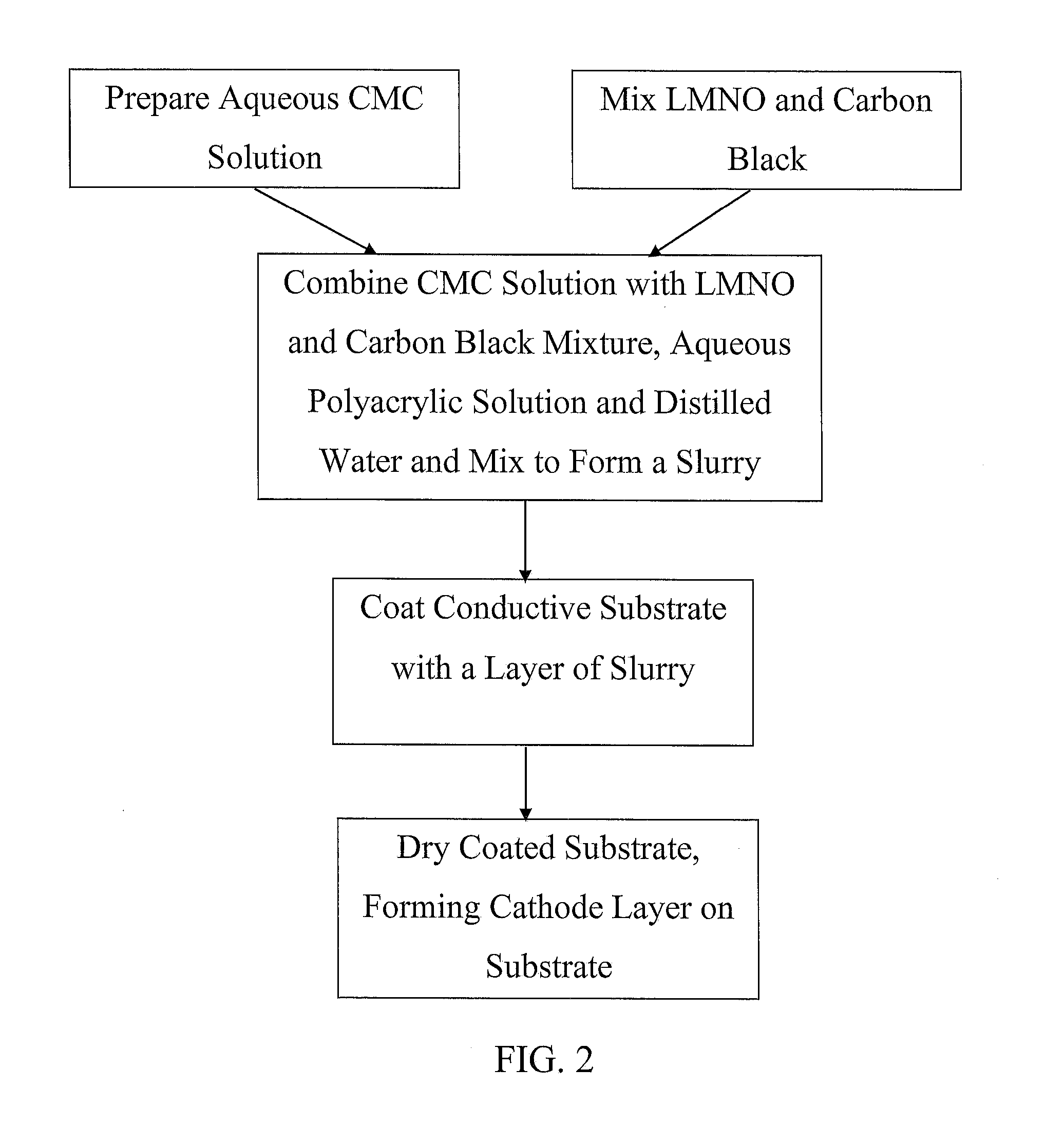

Water-based binder for high voltage cathode material for Li-ion battery

ActiveUS9331331B1Avoid insufficient thicknessImprove film qualityCoatingsSpecial surfacesWater basedSlurry

The present invention generally relates to using water-based binders for high voltage cathode materials, such as LMNO (spinel LiNi0.5Mn1.5O4), in Li-ion batteries. An example of a water compatible polymer binder according to some embodiments of the present invention is a combination of CMC (carboxymethylcellulose) and a second water compatible polymer that produce coatings of adequate thickness and loading (mAh / cm2). A method of forming a cathode for a Li-ion battery may include: preparing an aqueous solution of CMC; mixing together LMNO and carbon black; combining the LMNO and carbon black mixture with the CMC solution, an aqueous polyacrylic solution and distilled water, and mixing to form a slurry; coating a conductive substrate with the slurry; and drying the coated substrate, forming a cathode layer on the substrate. Furthermore, this invention describes a cathode for Li-ion batteries and tools for carrying out the above method.

Owner:APPLIED MATERIALS INC

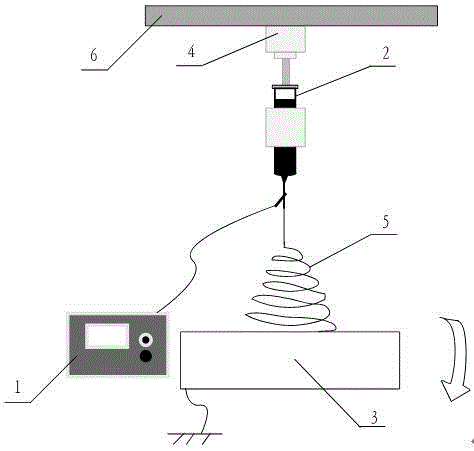

Method for preparing direct alcohol fuel cell graphene-based anode electro-catalyst

InactiveCN106784894AEasy to assembleSimplified powder structureCell electrodesAlcohol fuelEngineering

The invention discloses a method for preparing a direct alcohol fuel cell graphene-based anode electro-catalyst. The method comprises the steps of sucking an electro-spinning solution into an injector, and performing electrostatic spinning, wherein the tip of the injector is connected with the anode of a direct-current high voltage power supply; and placing a rotary collecting plate connected with a direct-current high voltage cathode at a position 10-20 cm away from the vertical direction of the tip, applying 0-50 kV voltage, propelling the injector at the speed of 0.002-0.01 mm / s, and ejecting the electro-spinning solution from the tip of the injector under the actions of the high voltage electric field and self gravity of the solution to form a Taylor cone and arrive at the rotary collecting plate to form an anode electro-catalyst membrane, wherein the temperature in the electrostatic spinning process is 30-50 DEG C. The anode catalyst prepared by the method for preparing a direct alcohol fuel cell graphene-based anode electro-catalyst is of a membrane-like structure and distributed uniformly, simultaneously, the traditional powdery structure is simplified, the step of preparing a catalyst layer by complex coating in the traditional process is simplified, the anode catalyst has obvious advantages in comparison with the conventional fuel cell anode catalyst, and assembly of cells is simplified.

Owner:NANTONG UNIVERSITY

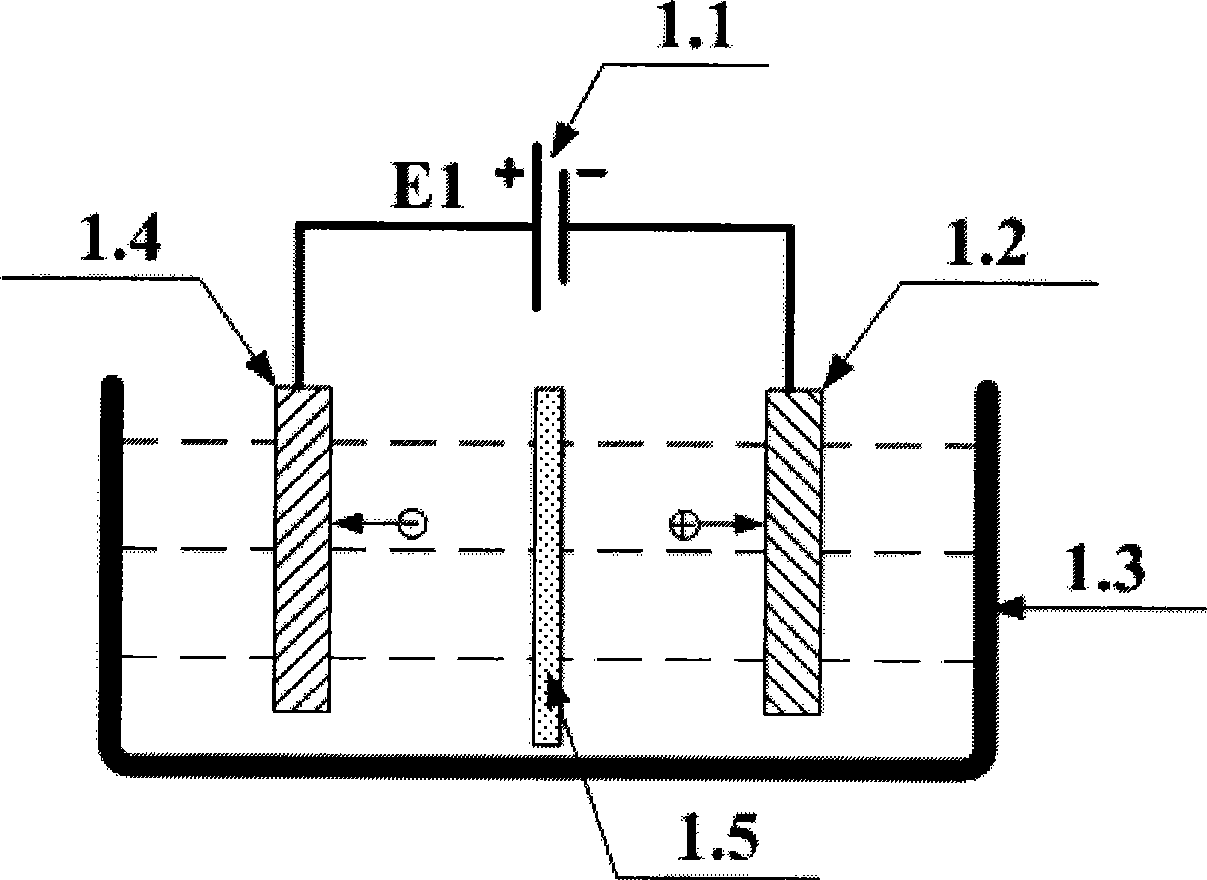

Multi-cell single voltage electrolysis apparatus and method of using same

InactiveUS20080296169A1Improve output efficiencyCellsPhotography auxillary processesElectrolysisElectrical battery

A method and apparatus for achieving high output efficiency from an electrolysis system (100) using a plurality of electrolysis cells all located within a single electrolysis tank (101) is provided. Each individual electrolysis cell includes a membrane (105-107), a plurality of metal members comprised of at least a first and second metal member (117 / 118; 125 / 126) and at least a third and fourth metal member (121 / 122; 129 / 130), and a plurality of high voltage electrodes comprised of at least an anode (119; 127) and a cathode (123; 131). Within each cell, the high voltage anode is interposed between the first and second metal members and the high voltage cathode is interposed between the third and fourth metal members. The high voltage applied to the high voltage electrodes is pulsed.

Owner:KUZO HLDG

Limiting migration of target material

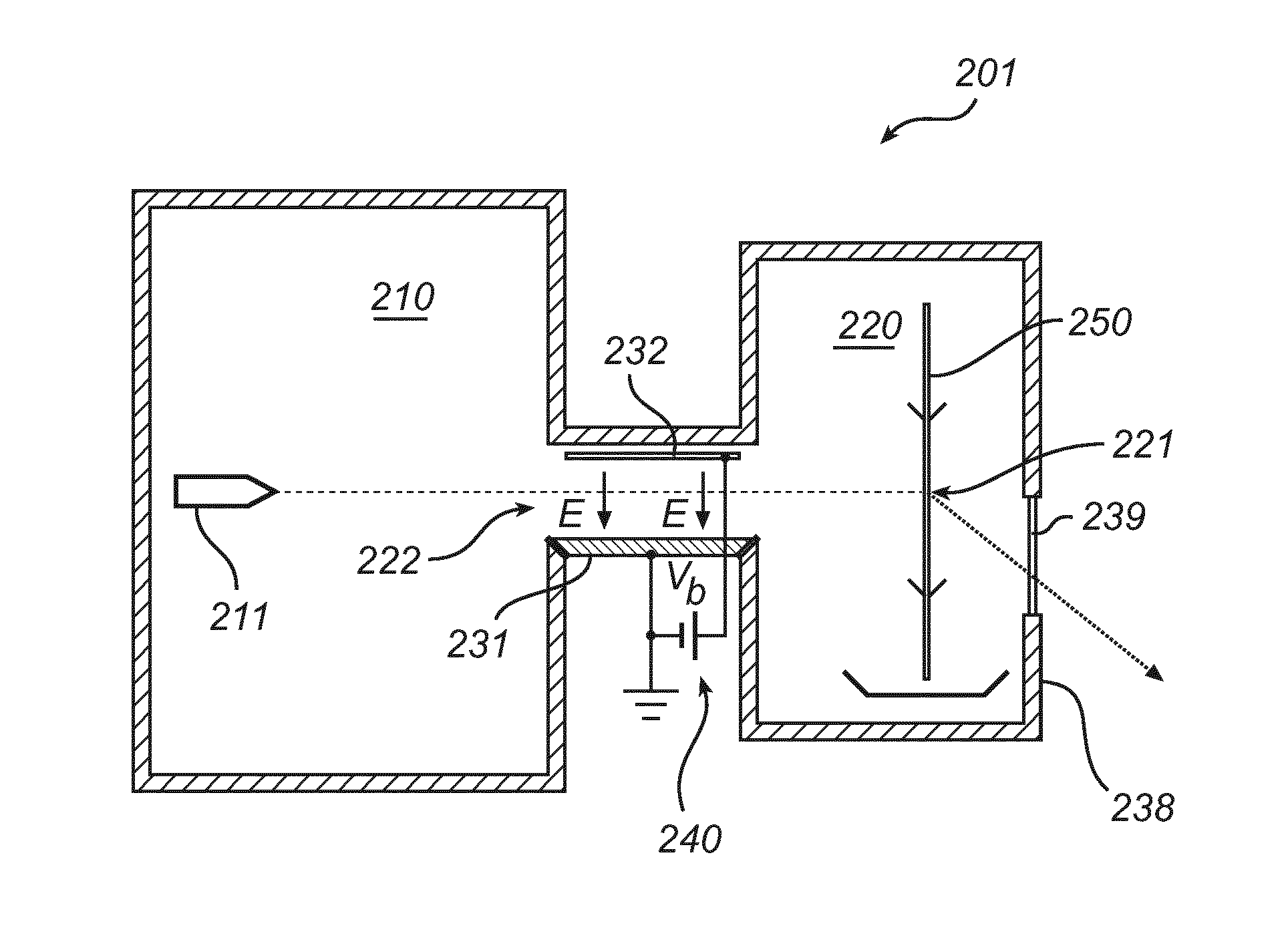

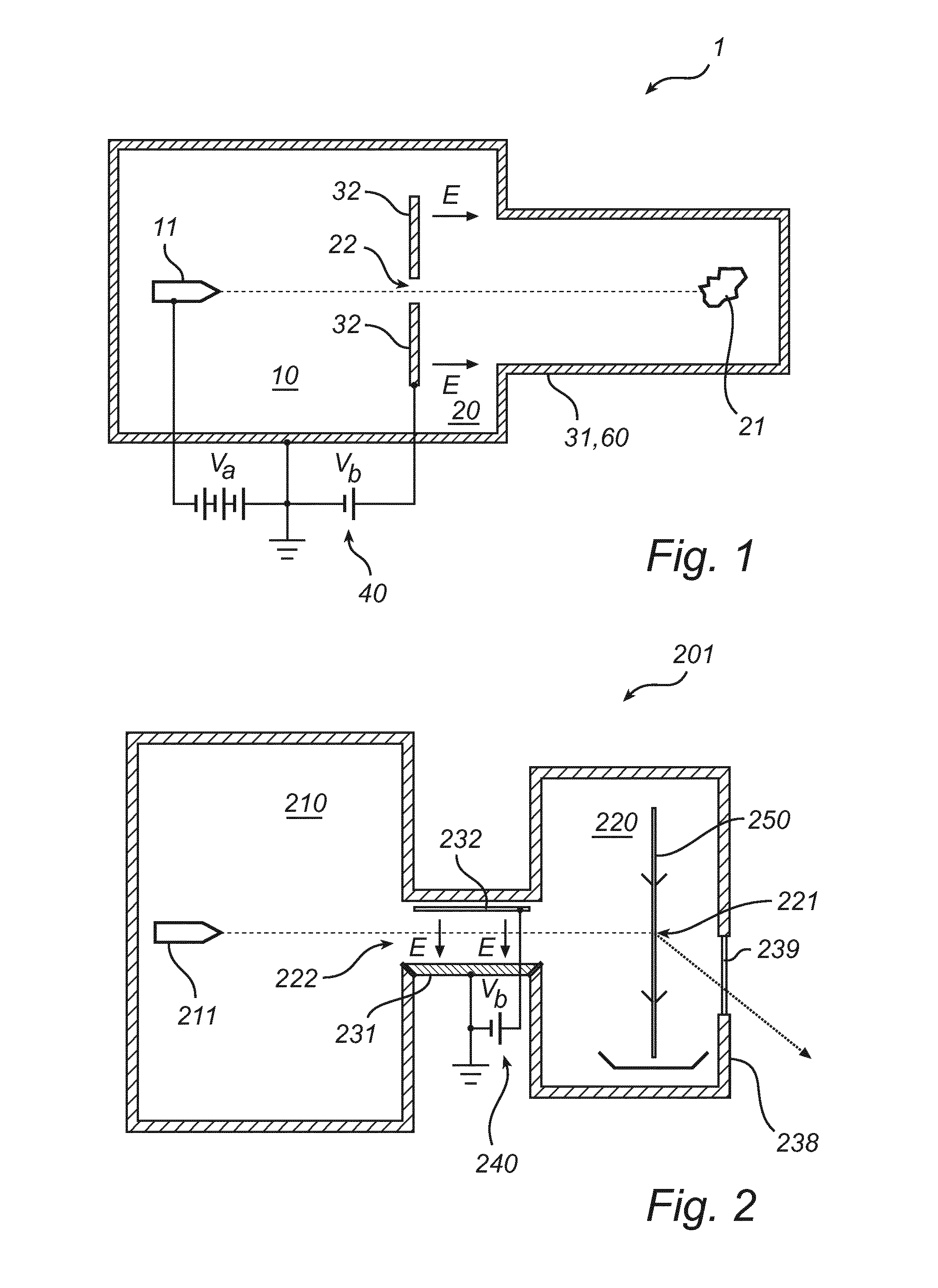

ActiveUS20150179388A1Extend cathode lifeLow mobilityX-ray tube electrodesCathode ray concentrating/focusing/directingHigh pressureHigh voltage cathode

In an electron irradiation system, a gas-tight housing encloses a cathode region and an irradiation region, which communicate through at least an aperture. In the cathode region, there is arranged a high-voltage cathode for emitting an electron beam. In the irradiation region, there is an irradiation site arranged to accommodate a stationary or moving object to be irradiated. The migration of cathode-degrading debris is limited by means of an electric field designed to prevent positively charged particles from entering the cathode region via the aperture. The invention can be embodied with an axial electric field, which realizes an energy threshold, or a transversal field which deflects charged particles away from trajectories leading into the cathode region.

Owner:EXCILLUM

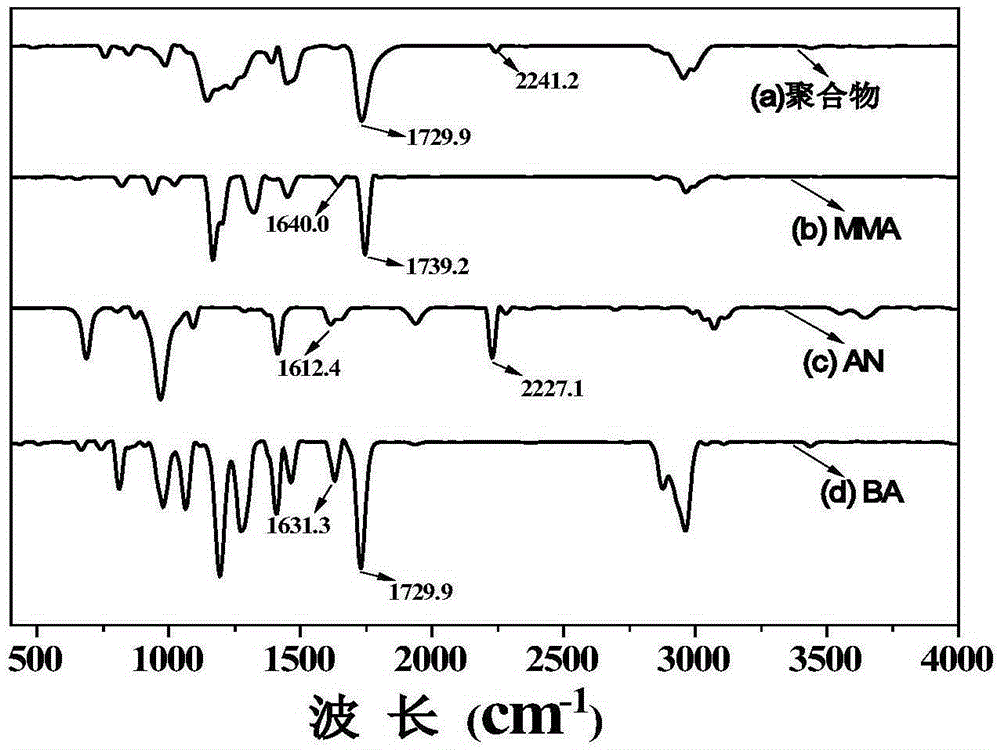

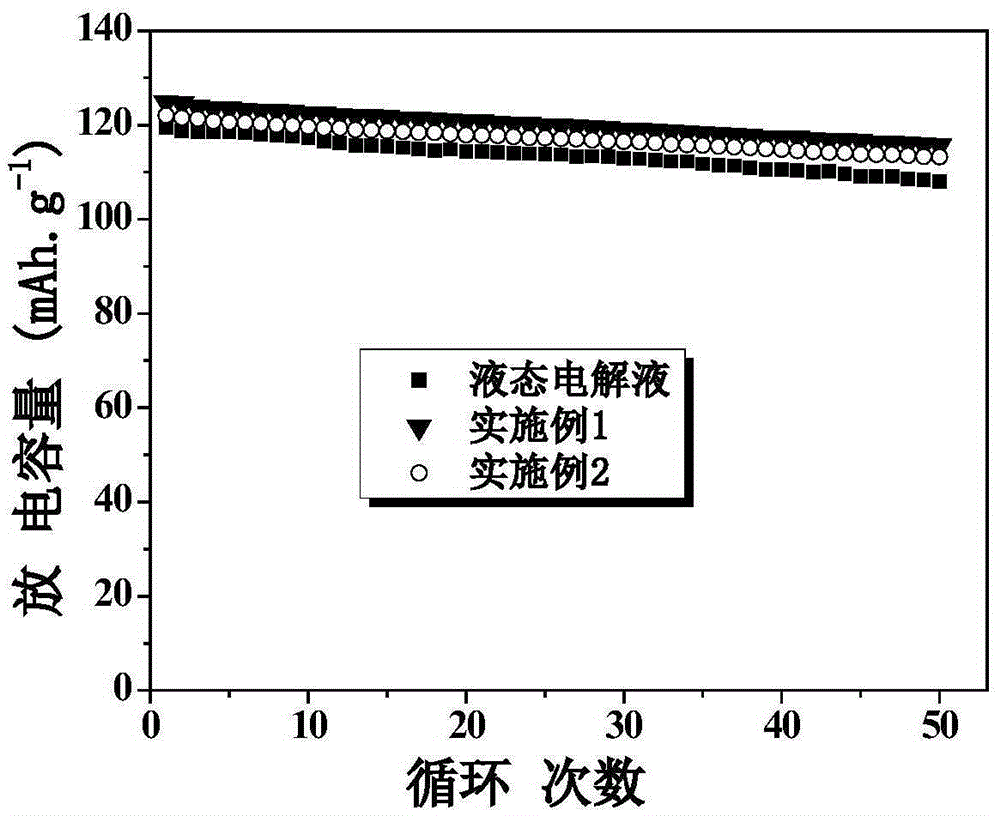

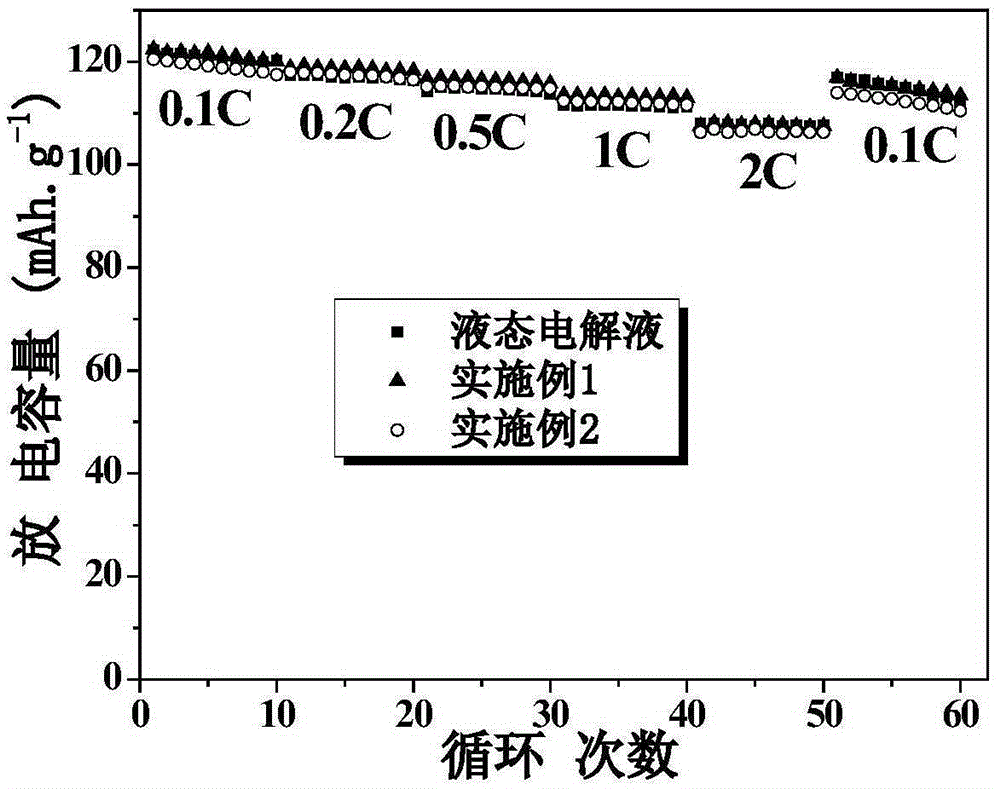

Polymer, and preparation method and application thereof

InactiveCN106519104ARaw materials are cheap and easy to getEasy to processSecondary cellsPolymer electrolytesPolymer science

The invention relates to a polymer, and a preparation method and application thereof. The polymer has a structural formula as shown in the specification. In the structural formula, the polymer is prepared by using a mixture of methyl methacrylate, acrylonitrile and butyl acrylate as a monomer through polymerization; meanwhile, the mass ratio of methyl methacrylate to acrylonitrile to butyl acrylate in the monomer is (4-1): (4-1): (2-1). The polymer provided by the invention is used for preparing a gel polymer electrolyte, enables the gel polymer electrolyte to have high electrochemical stability window, shows a longer cycle life compared with a traditional carbonate liquid electrolyte battery after applied to a lithium ion battery with a voltage level of 5 V, and is an ideal electrolyte matching with a high-voltage cathode material.

Owner:SOUTH CHINA NORMAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com