Polymer, and preparation method and application thereof

A technology of polymers and gel polymers, applied in electrochemical generators, electrical components, circuits, etc., can solve problems such as electrolyte instability, achieve good rate and cycle performance, good liquid absorption capacity, and good stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

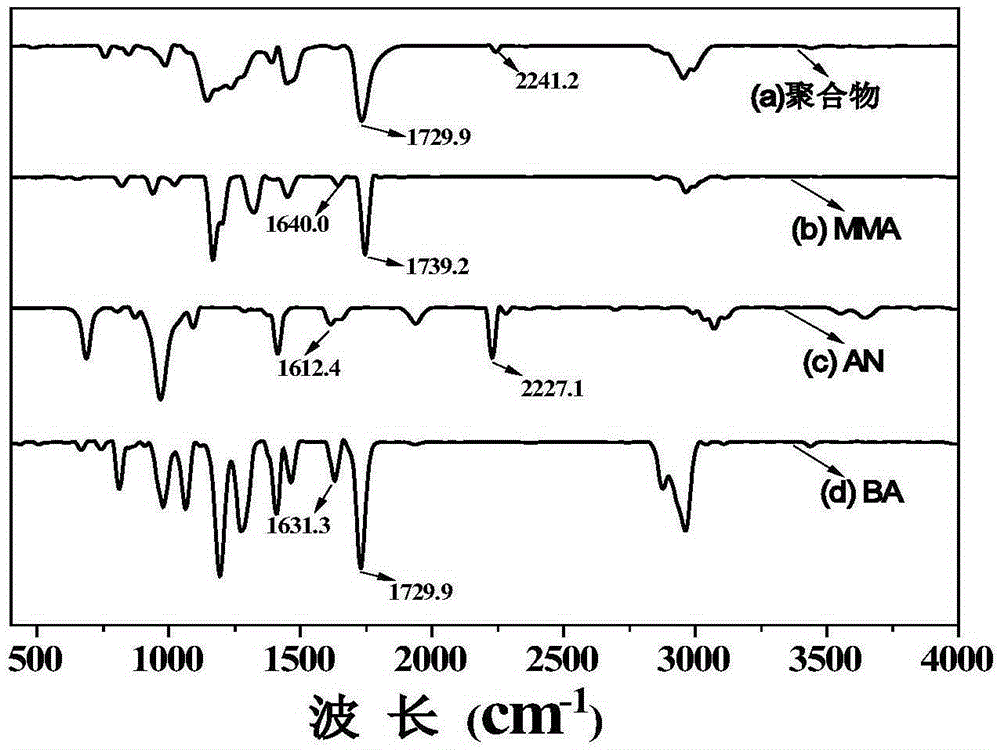

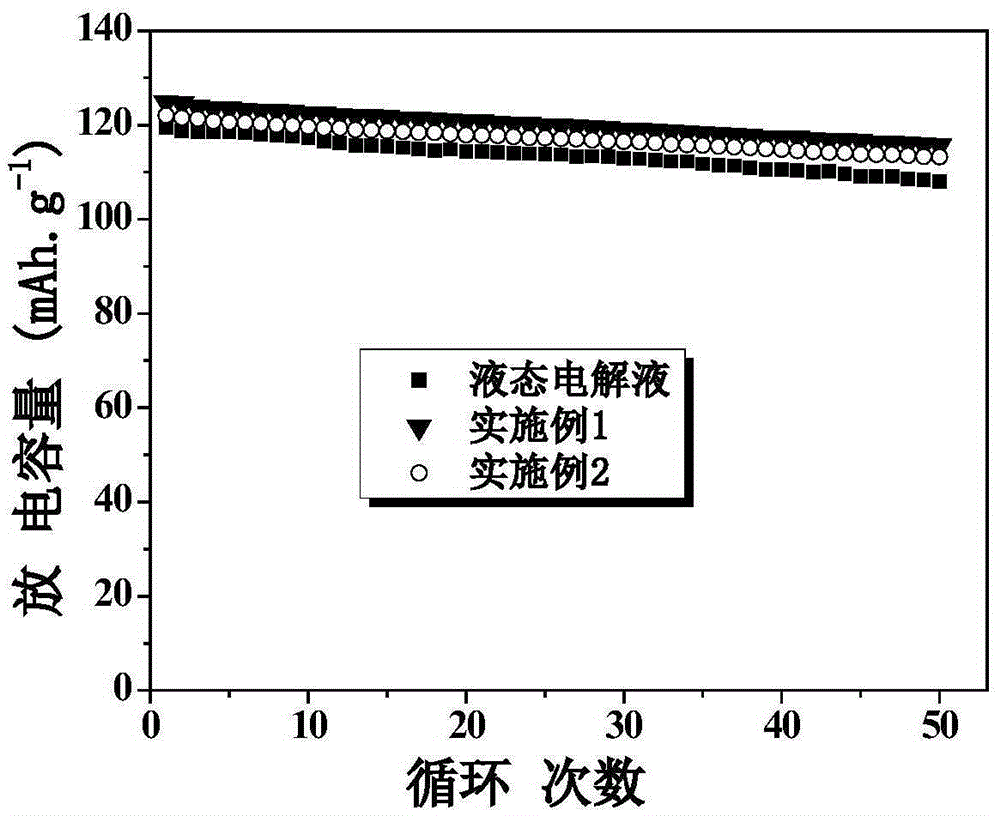

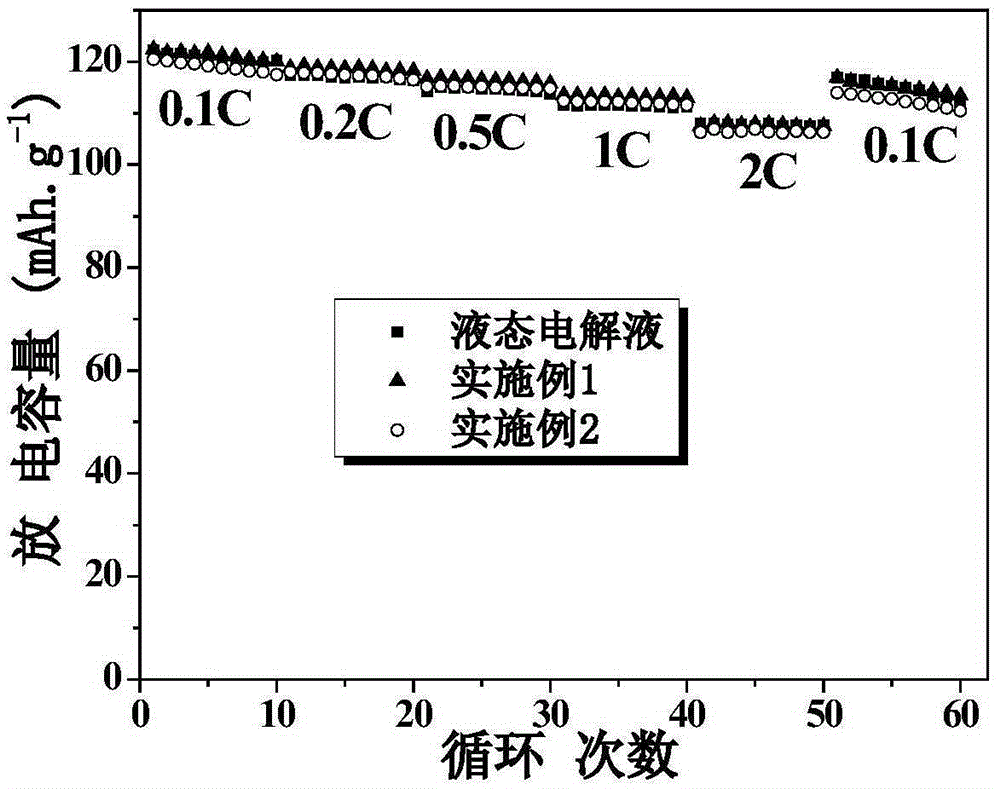

[0042] In the polymer and its preparation method and application provided in this example, the mass percentages of each component in the raw materials used to prepare the polymer are: monomer 33.3%, emulsifier 1.5%, initiator 0.2%, deionized Water 65.0%.

[0043] The preparation method comprises the following steps:

[0044] 1) in N 2 Under the protection of the atmosphere, add the emulsifier sodium lauryl sulfate into deionized water to dissolve, then add the monomer (the mass ratio of methyl methacrylate, acrylonitrile and butyl acrylate is 4:2:1), and stir evenly , add the initiator sodium persulfate with a constant pressure funnel to react at 55°C (adding in two times), the stirring speed is controlled at 1000r / min; after 6 hours of reaction, a white emulsion is obtained, and the white emulsion is poured into 1 times the above reaction Volume, mass percentage is 3.0% Al 2 (SO 4 ) 3 The solution is stirred to break the emulsification, and the polymer is obtained by washi...

Embodiment 2

[0050] In the polymer and its preparation method and application provided in this example, the mass percentages of each component in the raw materials used to prepare the polymer are: 32.3% monomer, 1.5% emulsifier, 0.2% initiator, deionized Water 66%.

[0051] The preparation method comprises the following steps:

[0052] 1) Under the protection of argon atmosphere, add the emulsifier sodium lauryl sulfate into deionized water to dissolve, and then add the monomer (the mass ratio of methyl methacrylate, acrylonitrile and butyl acrylate is 4:2: 1), stir evenly, add the initiator sodium persulfate with a constant pressure funnel to react at 57°C (adding in two times), the stirring speed is controlled at 1020r / min, and the white emulsion is obtained after 6 hours of reaction; then the white emulsion Pour 1.1 times the above reaction volume, the mass percentage is 3% Al 2 (SO 4 ) 3 Stirring in the solution to break the emulsification, washing and drying to obtain the polymer ...

Embodiment 3

[0057] In the polymer and its preparation method and application provided in this example, the mass percentage of each component in the raw materials used to prepare the polymer is: monomer 28.9%, emulsifier 1.0%, initiator 0.1%, deionized Water 70.0%;

[0058] The preparation method comprises the following steps:

[0059] 1) Dissolve the emulsifier potassium lauryl sulfate in deionized water under the protection of an argon atmosphere, and then add monomers (the mass ratio of methyl methacrylate, acrylonitrile and butyl acrylate is 2:2:1 ), after stirring evenly, add the initiator potassium persulfate with a mass percentage of 0.1% at 55°C with a constant pressure funnel, control the stirring speed at 800r / min, and obtain a white emulsion after reacting for 5 hours, then pour the white emulsion into 2% Al by mass concentration 2 (SO 4 ) 3 Stirring in the solution to break the emulsification, washing and drying to obtain the polymer used for the gel polymer electrolyte.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com