Centralized cooking oil fume treating and recycling system

A technology for centralized treatment and oil fume, which is applied in the direction of oil fume removal, application, and household stoves, etc. It can solve the problems of high cost, pollution, and function failure, and achieve the effect of extending the working time limit, broadening the market prospect, and reducing the difficulty of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with specific examples.

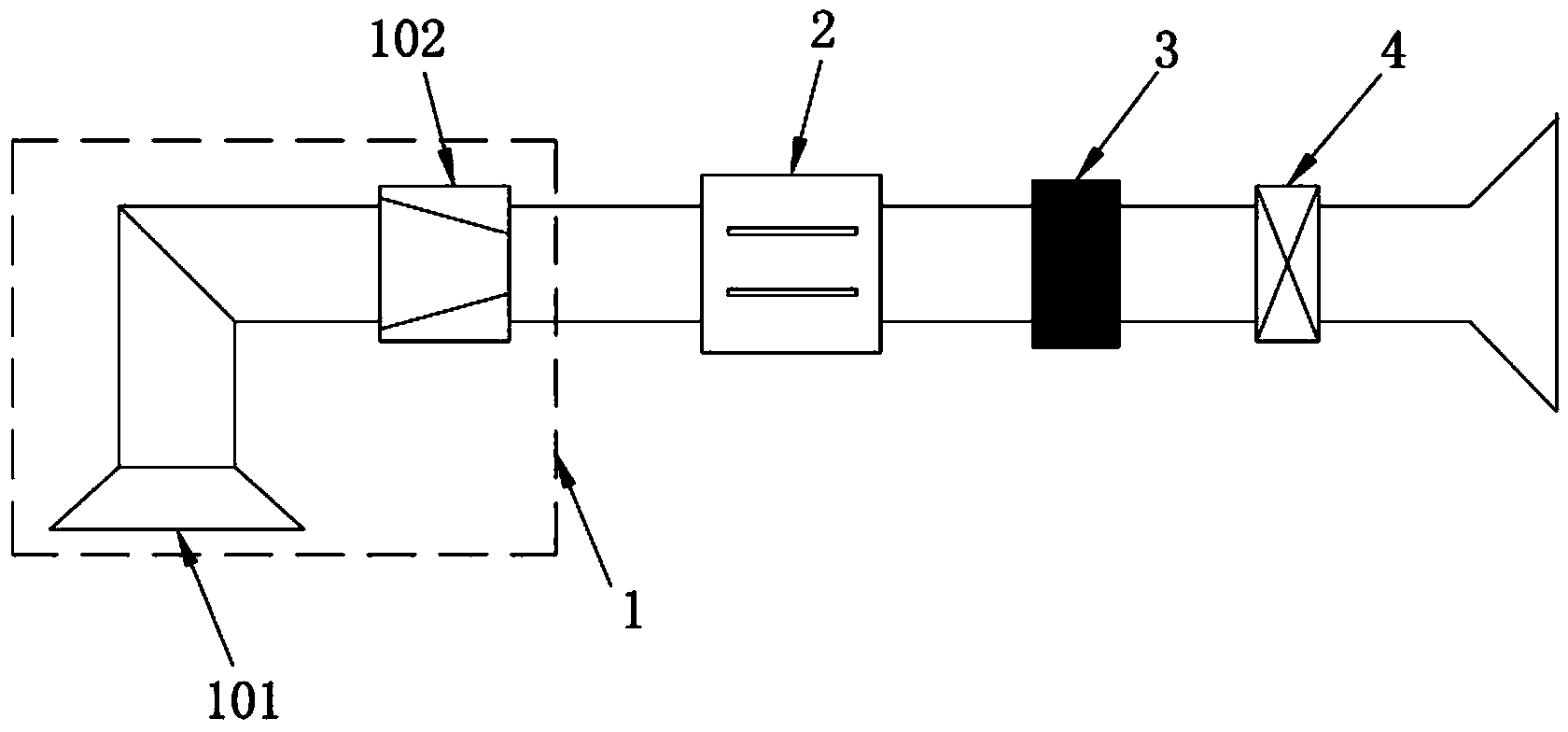

[0030] like figure 1 As shown, the kitchen oil fume centralized treatment and recycling system described in this embodiment includes:

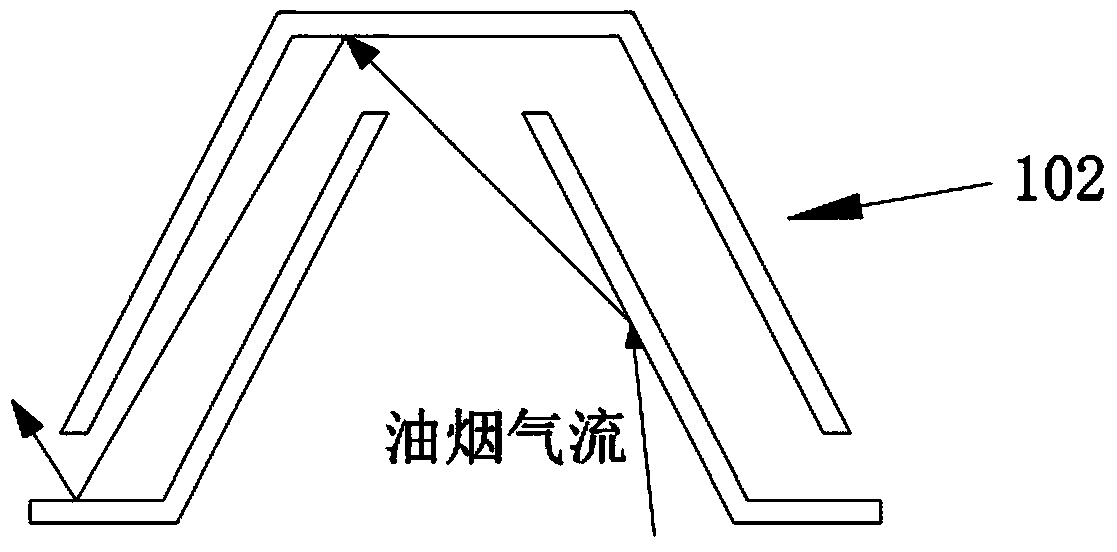

[0031] Pre-processing unit 1 is used for primary filtration of oil fume, capturing large-sized particles and condensed oil mist in oil fume, mainly composed of gas collection hood 101 (specifically side suction type gas collection hood) and baffle filter 102 Composition, the gas collecting hood 101 and the baffle type filter 102 are connected through pipelines;

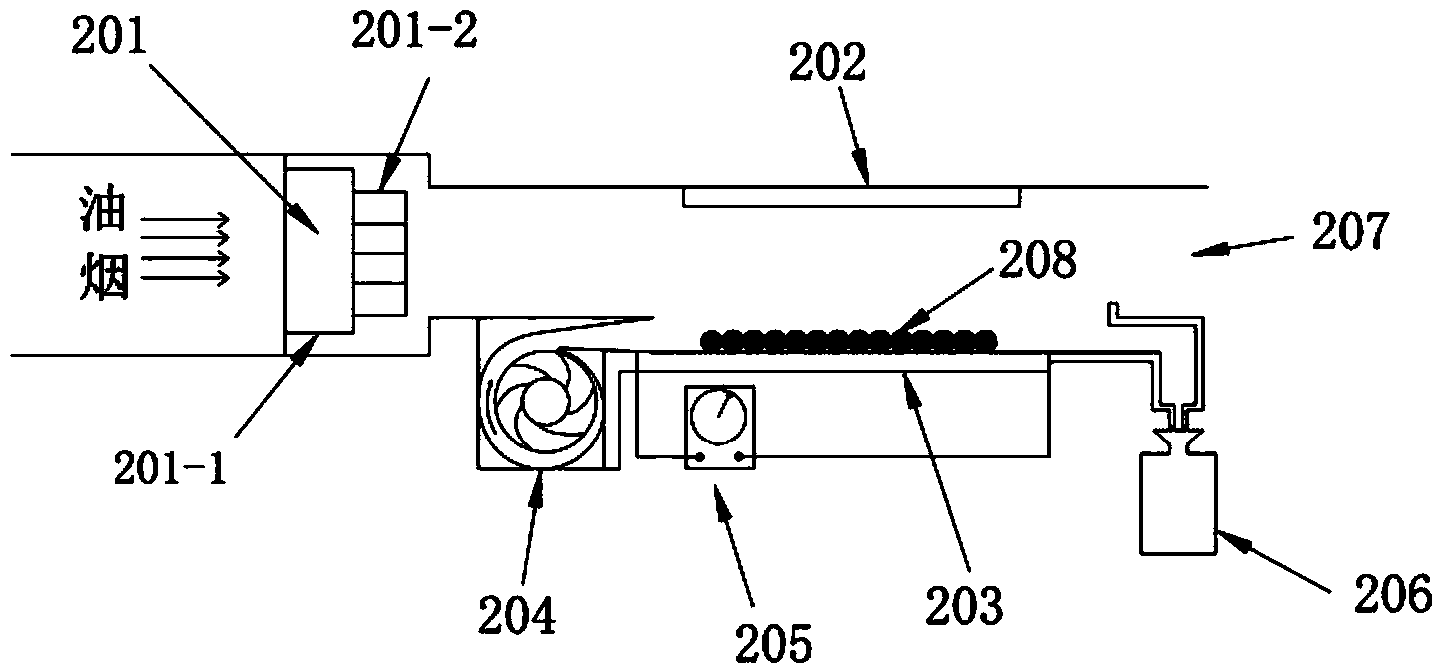

[0032] The electrostatic purification and degreasing unit 2 with pump degreasing is used to electrostatically purify the oil fume after primary filtration to realize the separation of oil fume, generate oil, and automatically remove oil through the oil pump, and discharge the oil into the designated collection container for recycling;

[0033] The post-stage air purification unit 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com