Patents

Literature

44results about How to "High dielectric" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dielectric ceramic and multilayer ceramic capacitor

ActiveUS20080112109A1High dielectricSuperior reliabilityFixed capacitor dielectricStacked capacitorsRare-earth elementCeramic

A dielectric ceramic includes a compound represented by the general formula: (Ba1-tCat)m(Ti1-u-xZruCux)O3 (where 0.96≦m≦1.02, 0.001≦x≦0.03, 0≦t≦0.1, and 0≦u≦0.06) as a primary component, a rare earth element Re such as Dy, a metal element M such as Mn, Mg, and Si. In the dielectric ceramic, the Cu is uniformly and dispersedly present in the primary phase grain forming the primary component, and the contents of the accessory components with respect to 100 molar parts of the primary component are 0.1 to 1.5 molar parts of Re, 0.1 to 0.6 molar parts of M, 0.1 to 1.5 molar parts of Mg and 0.1 to 2.0 molar parts of Si. Accordingly, a multilayer ceramic capacitor can be realized which has a high dielectric constant, superior temperature properties, and a high reliability, and also has a small change in electrostatic capacitance with time.

Owner:MURATA MFG CO LTD

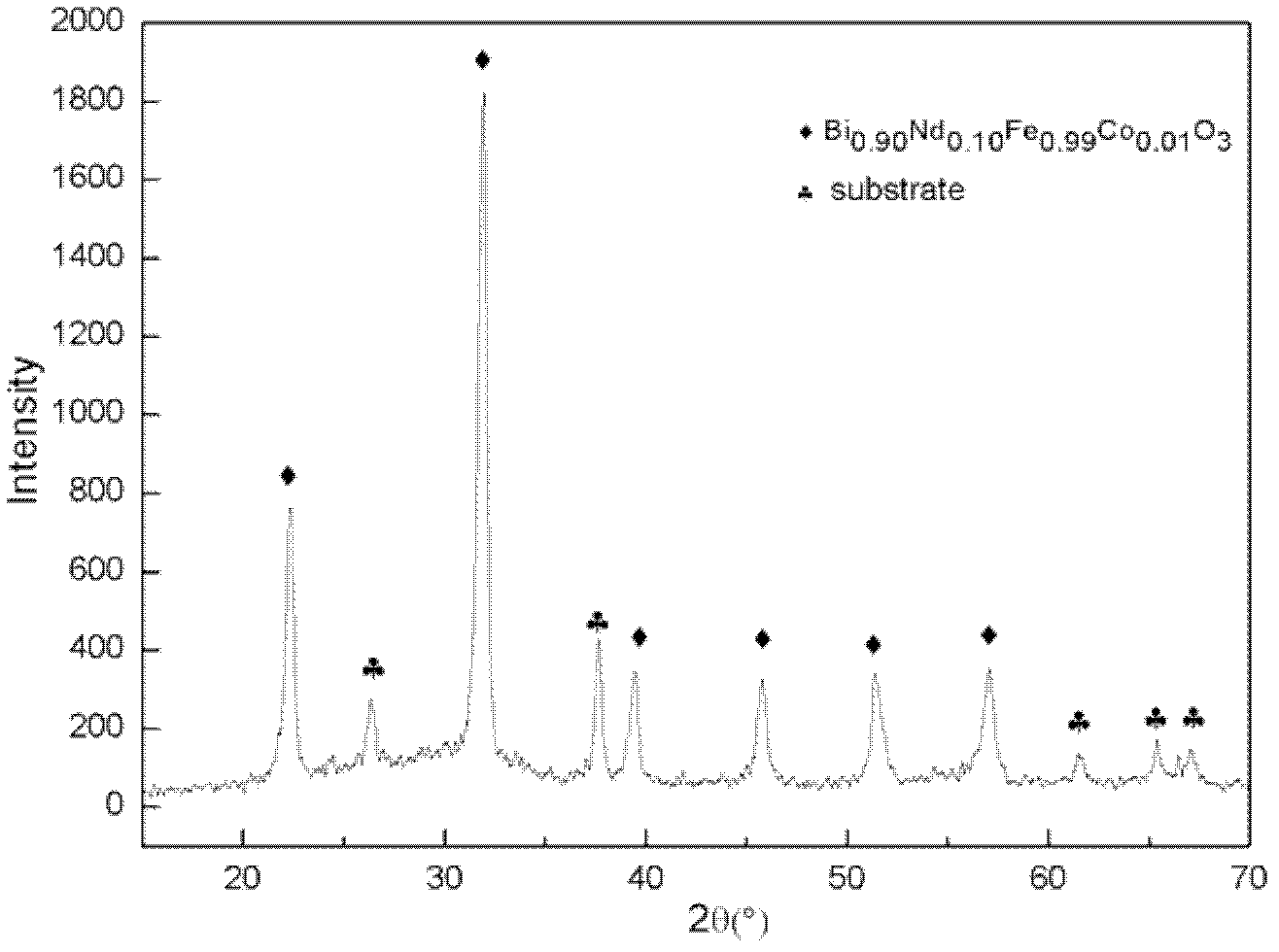

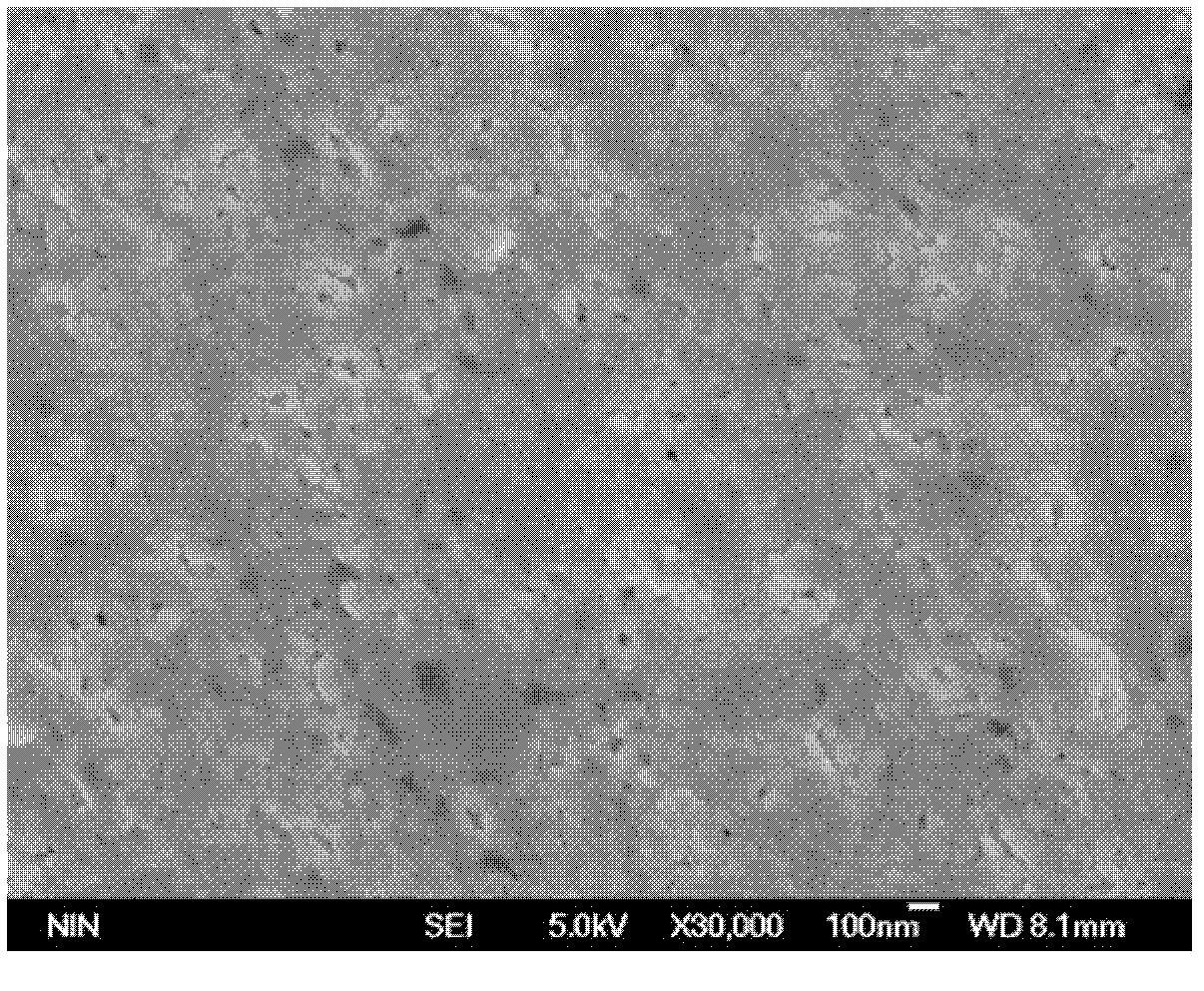

Method for preparing Nd/Co-codoped BiFeO3 film on FTO (fluorine-doped tin oxide)/glass substrate surface

InactiveCN102534588AImprove uniformityExcellent dielectric propertiesSolid/suspension decomposition chemical coatingPolymer scienceAcetic anhydride

The invention provides a method for preparing an Nd / Co-codoped BiFeO3 film on an FTO (fluorine-doped tin oxide) / glass substrate surface, which comprises the following steps: after cleaning an FTO substrate, carrying out ultraviolet irradiation, and dissolving bismuth nitrate (8% excessive), ferric nitrate, neodymium nitrate and cobalt nitrate which serve as raw materials in mixed ethylene glycol monomethyl ether and acetic anhydride in a mol ratio of 0.98:(1-x):0.1:x (x=0.01-0.05), thereby obtaining a stable BiFeO3 precursor solution of which the metallic ion concentration is 0.1-0.5mol / L; and after spin coating, drying to obtain a dry film, preannealing, naturally cooling, repeating the process above to obtain the film with expected thickness, and finally, annealing to obtain the crystalline BiFeO3 film. In the invention, the facility requests are simple, the experiment conditions can be easily achieved, the prepared film has good uniformity, the doping amount is easy to control, andthe dielectric properties of the film can be greatly enhanced by doping.

Owner:SHAANXI UNIV OF SCI & TECH

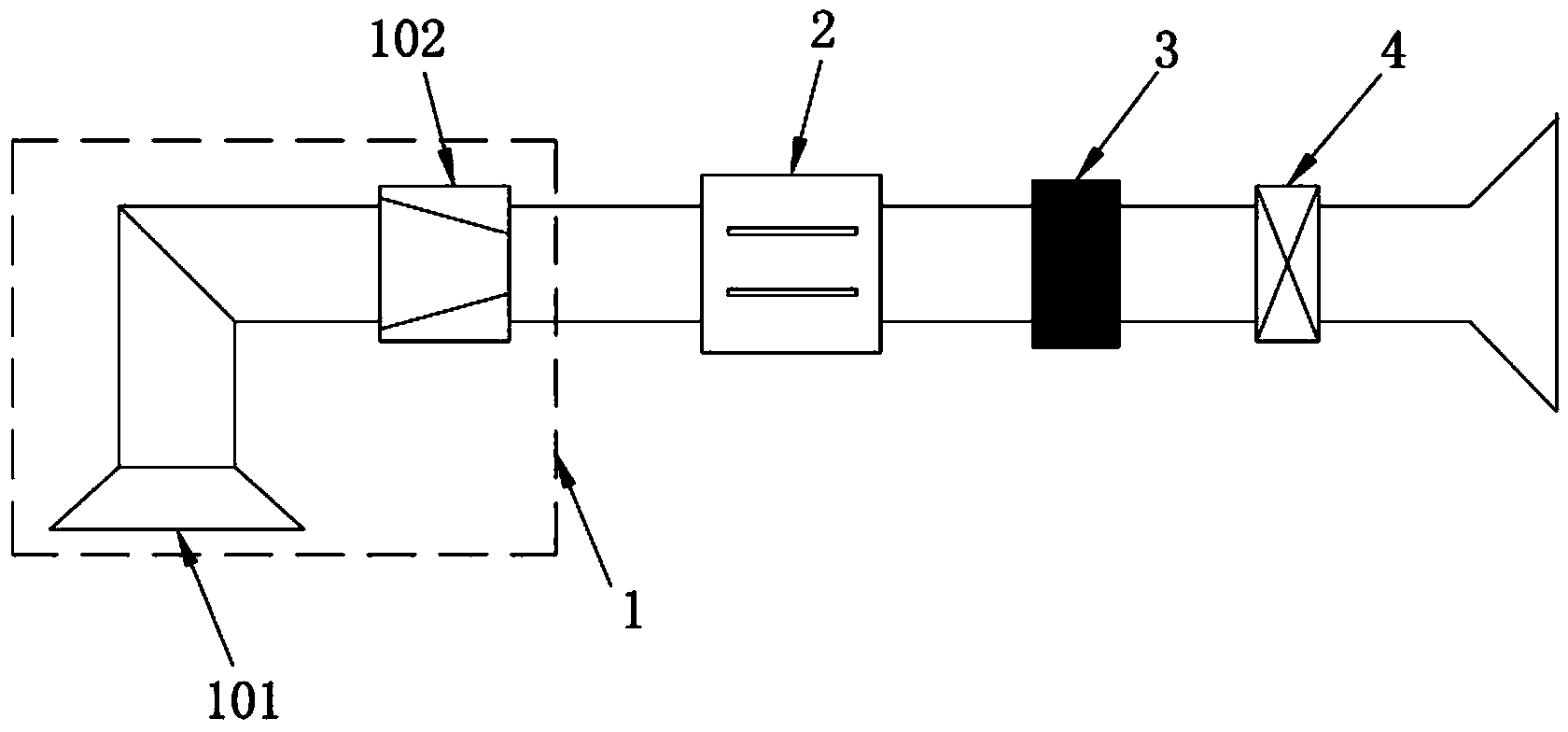

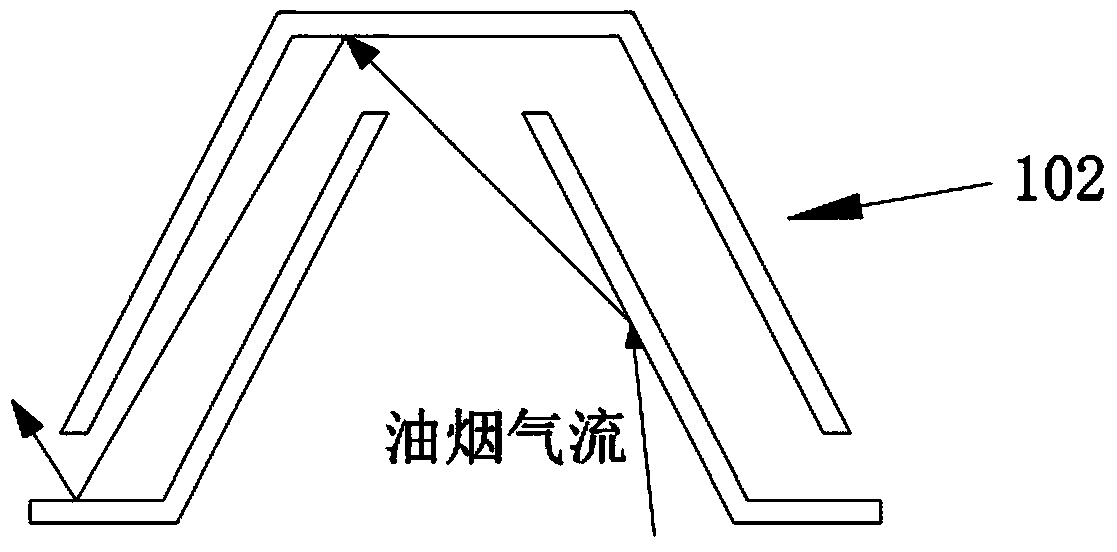

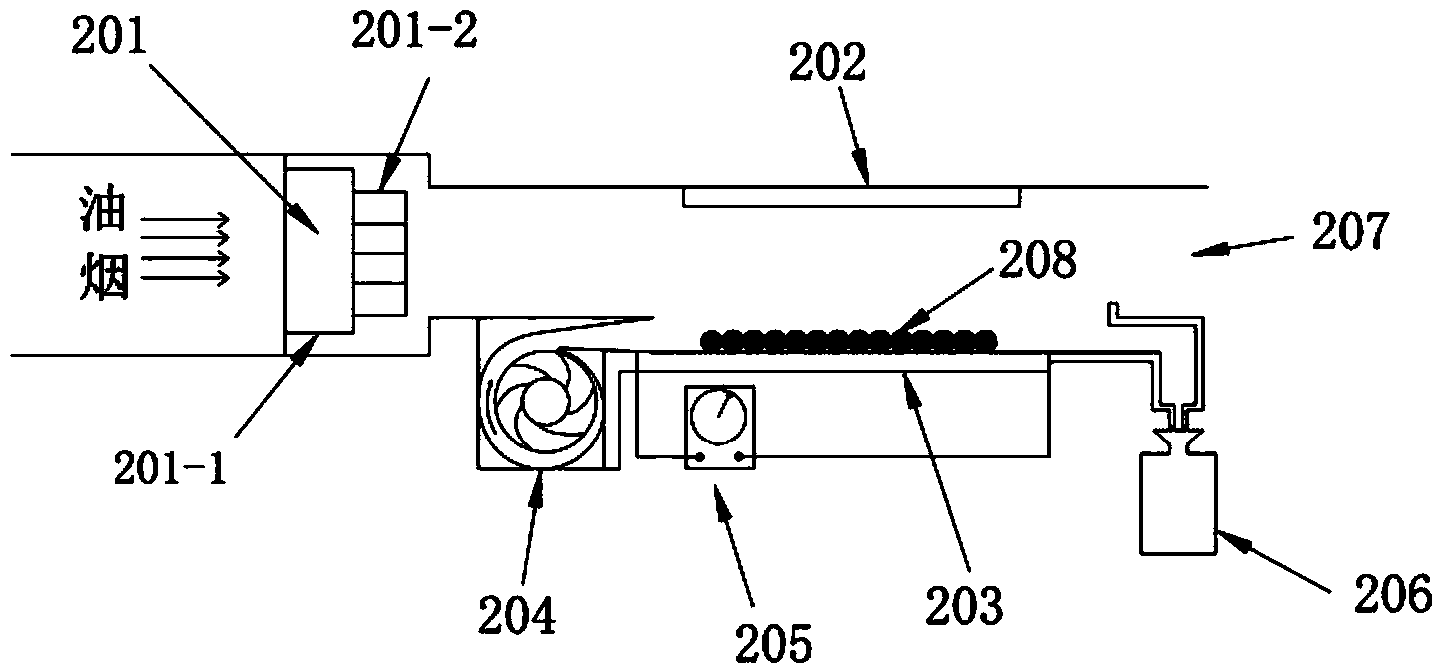

Centralized cooking oil fume treating and recycling system

InactiveCN104006432AAvoid cloggingRealize secondary useDomestic stoves or rangesLighting and heating apparatusHigh voltage cathodeHigh pressure

The invention discloses a centralized cooking oil fume treating and recycling system which comprises an early-stage pretreatment unit, an electrostatic purification oil removal unit with a pump oil removal function, a later-stage air purification unit and an exhaust fan, wherein the early-stage pretreatment unit, the electrostatic purification oil removal unit, the later-stage air purification unit and the exhaust fan are sequentially connected through pipelines along the oil fume running direction; the electrostatic purification oil removal unit comprises a high voltage electric field generating area, a high voltage cathode electrode, a high voltage anode electrode, an oil pump, a hydraulic pressure gauge and a detachable collection container; the high voltage electric field generating area is formed in an oil fume inlet of the electrostatic purification oil removal unit; the high voltage cathode electrode and the high voltage anode electrode are vertically opposite to each other; the high voltage anode electrode is connected with the hydraulic pressure gauge, and oil on the high voltage anode electrode can be discharged into the collection container through the oil pump along the pipeline. Energy in the waste oil fume is utilized to the greatest degree when an electrostatic treatment device is not required to be detached, so that the device is simplified, and the aims of energy conservation and environment friendliness are achieved.

Owner:SOUTH CHINA UNIV OF TECH

Oil-resistant anti-aging rubber cable material

InactiveCN105949547AImprove reinforcement effectImprove the reinforcing effect and improve the chemical stability of rubberRubber insulatorsFiberButadiene-styrene rubber

The invention discloses an oil-resistant anti-aging rubber cable material which is prepared from the raw materials including, by weight, 3-4 parts of vinyl phenyl silicone oil, 5-7 parts of chlorosulfonated polyethylene powder, 4-5 parts of sulfur, 2-3 parts of palm wax, 7-9 parts of steel wool fiber, 16-20 parts of fluoro-rubber, 12-14 parts of barite powder, 7-9 parts of carbon black, 2-3 parts of ascorbyl palmitate, 2-3 parts of emulsified methyl silicone oil, 0.5-1 part of triphenyl phosphate, 45-56 parts of styrene-butadiene rubber, 55-60 parts of chloroprene rubber, 55-70 parts of natural rubber, 30-40 parts of hollow glass micro beads, 3-5 parts of polytetrafluoroethylene, 1-1.3 parts of a silane coupling agent kh550, 12-16 parts of epoxy resin E44, 0.06-0.1 parts of diethylene triamine, 0.1-0.2 parts of an accelerator M, 2.6-3 parts of a silane coupling agent kh570, and a proper amount of distilled water. The cable material is excellent in mechanical performance, is not liable to cause circuit fault and is valuable to promote.

Owner:ANHUI CABLE

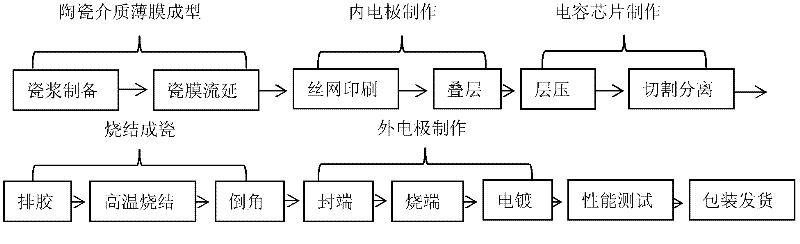

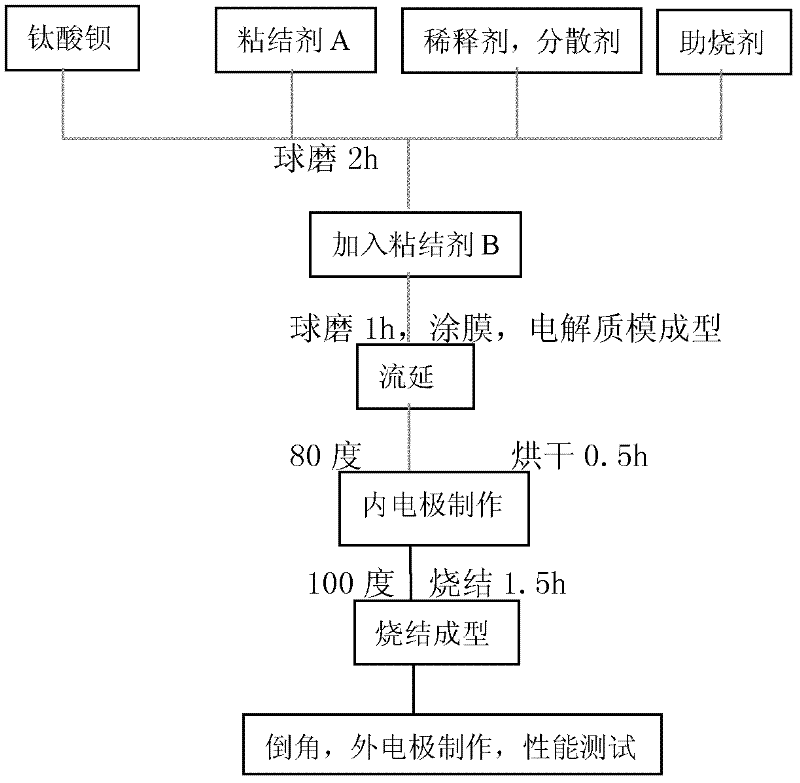

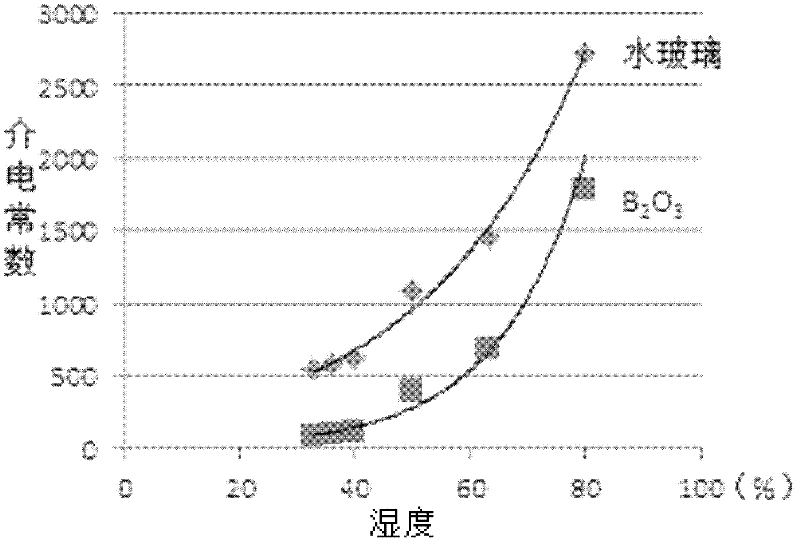

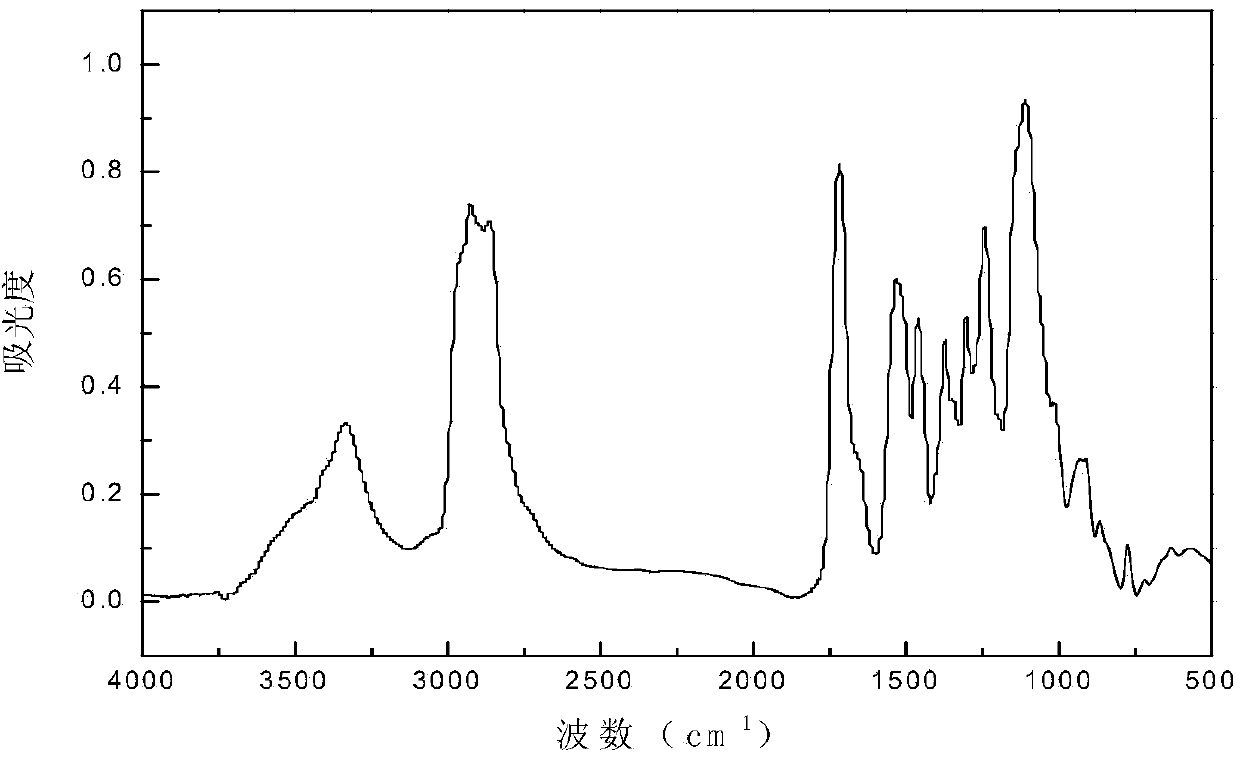

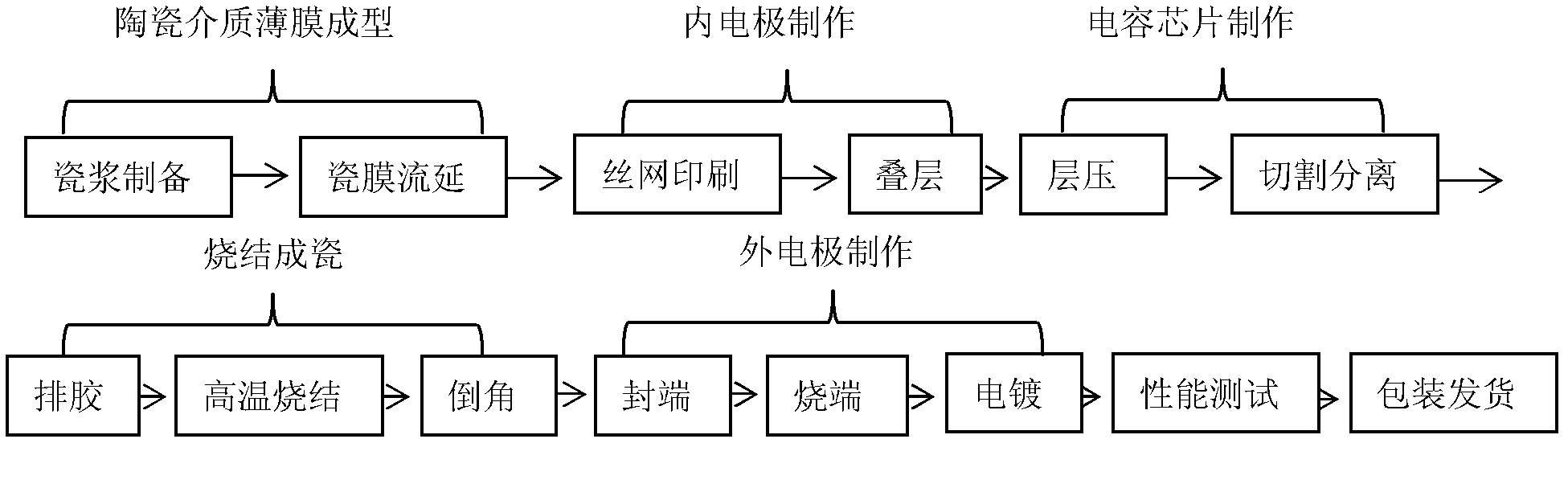

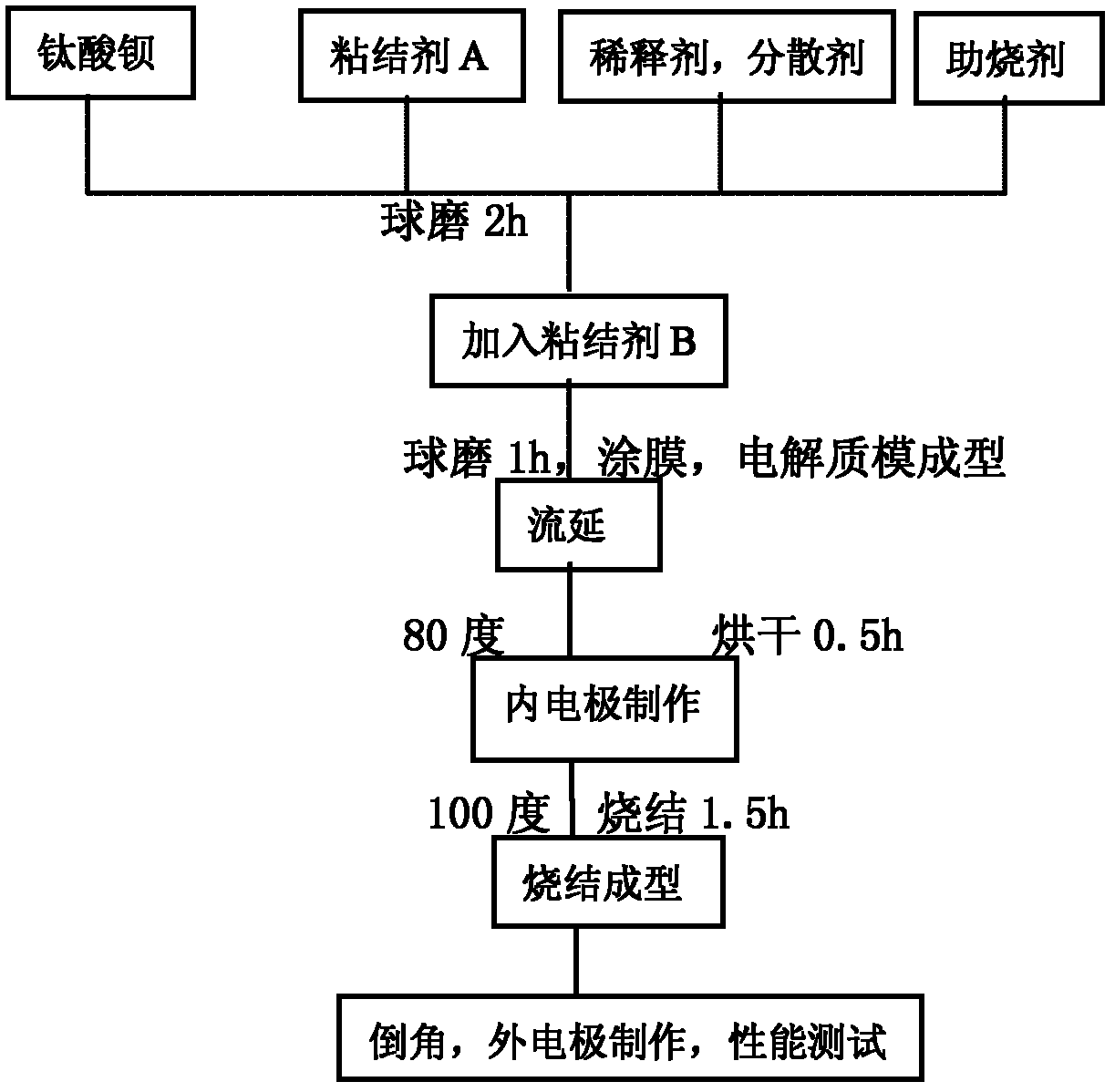

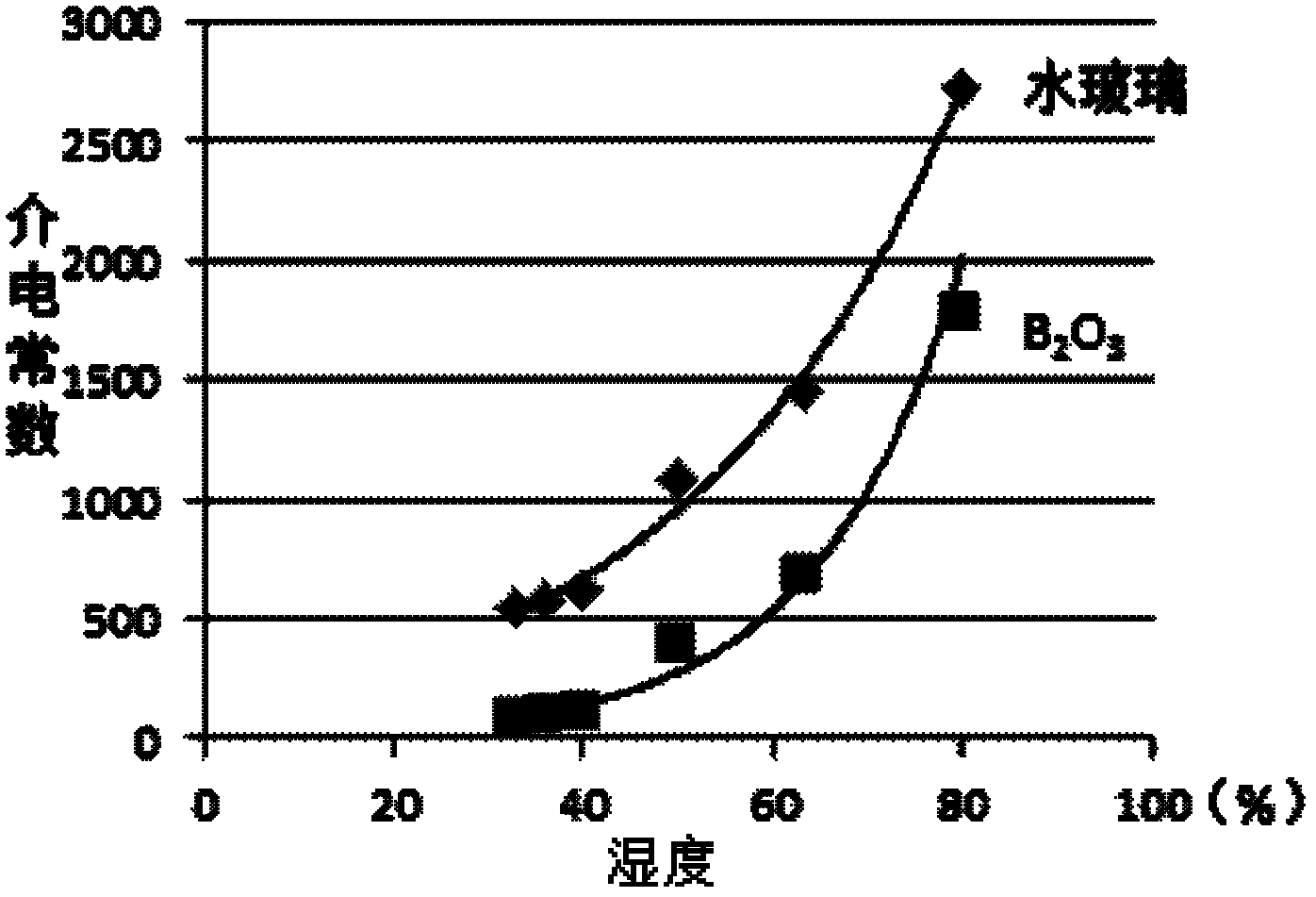

Chip multilayer ceramic capacitor dielectric ceramic slurry and preparation method of dielectric

The invention discloses a chip multilayer ceramic capacitor dielectric ceramic slurry and preparation method of a dielectric, and belongs to the field of ceramic dielectric materials. The main component of the ceramic slurry provided by the invention is barium titanate, and also comprises a burning supporting agent, wherein the burning supporting agent comprises water glass and silicon dioxide, wherein the mass ratio of water glass to barium titanate is 1%-10%, and the mass ratio of silicon dioxide to barium titanate is 0.8%-1.2%. The preparation method of the dielectric comprises the following steps: 1) selecting a set quantity of the main component barium titanate, as well as the burning supporting agent, a diluent, a dispersion agent and a bonding agent A, and putting them into a ball milling machine for ball milling; 2) carrying out ball milling for a set period of time, then adding a set quantity of a bonding agent B in slurry after ball milling, and carrying out ball milling continuously; and 3) carrying out plate coating and sintering on the obtained slurry after ball milling for a set time, thereby obtaining the dielectric material. According to the invention, the energy consumption is reduced from all aspects greatly, and an MLCC (multiplayer ceramic chip capacitor) produced by the method is low in production cost and has good energy storage effect.

Owner:GUODIAN LONGYUAN ELECTRICAL

A soft rubber cable material

InactiveCN105968809AImprove reinforcement effectGood chemical stabilityTetrabromobisphenol APliability

A soft rubber cable material is disclosed. The cable material is prepared from 3-4 parts by weight of tetrabromobisphenol A, 8-11 parts by weight of aluminum hypophosphite, 13-16 parts by weight of ceramic powder, 16-20 parts by weight of carbon black, 55-60 parts by weight of chloroprene rubber, 58-64 parts by weight of silicone rubber, 3-4 parts by weight of bismaleimide, 55-70 parts by weight of natural rubber, 30-40 parts by weight of hollow glass micro beads, 3-4 parts by weight of poly(ethylene oxide), 1-1.3 parts by weight of a silane coupling agent kh550, 2-3 parts by weight of paraffin oil, 3-4 parts by weight of stearic acid, 3-4 parts by weight of hydroxyl silicone oil, 2-3 parts by weight of DCP, 2-3 parts by weight of dioctyl phthalate, 12-16 parts by weight of epoxy resin E44, 0.06-0.1 part by weight of diethylenetriamine, 0.1-0.2 part by weight of an accelerant DA, 2.6-3 parts by weight of a silane coupling agent kh570 and a proper amount of distilled water. The cable material prepared is good in flame retardance and wear resistance, improved in processing performance, increased in toughness and not liable to be fractured and deserves popularization.

Owner:ANHUI CABLE

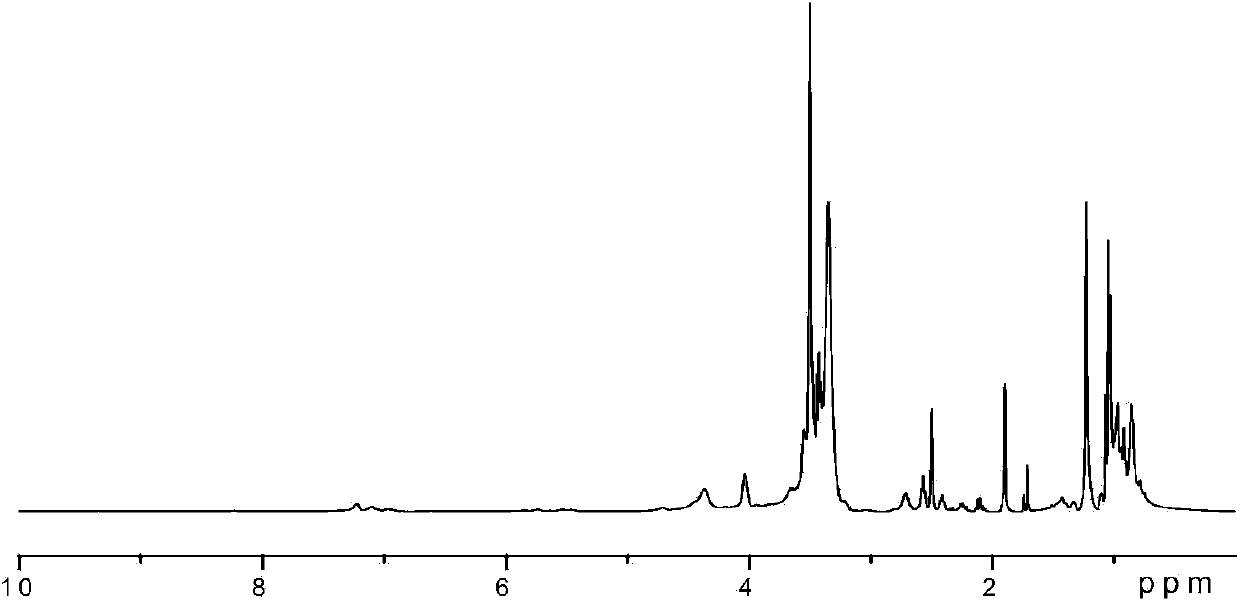

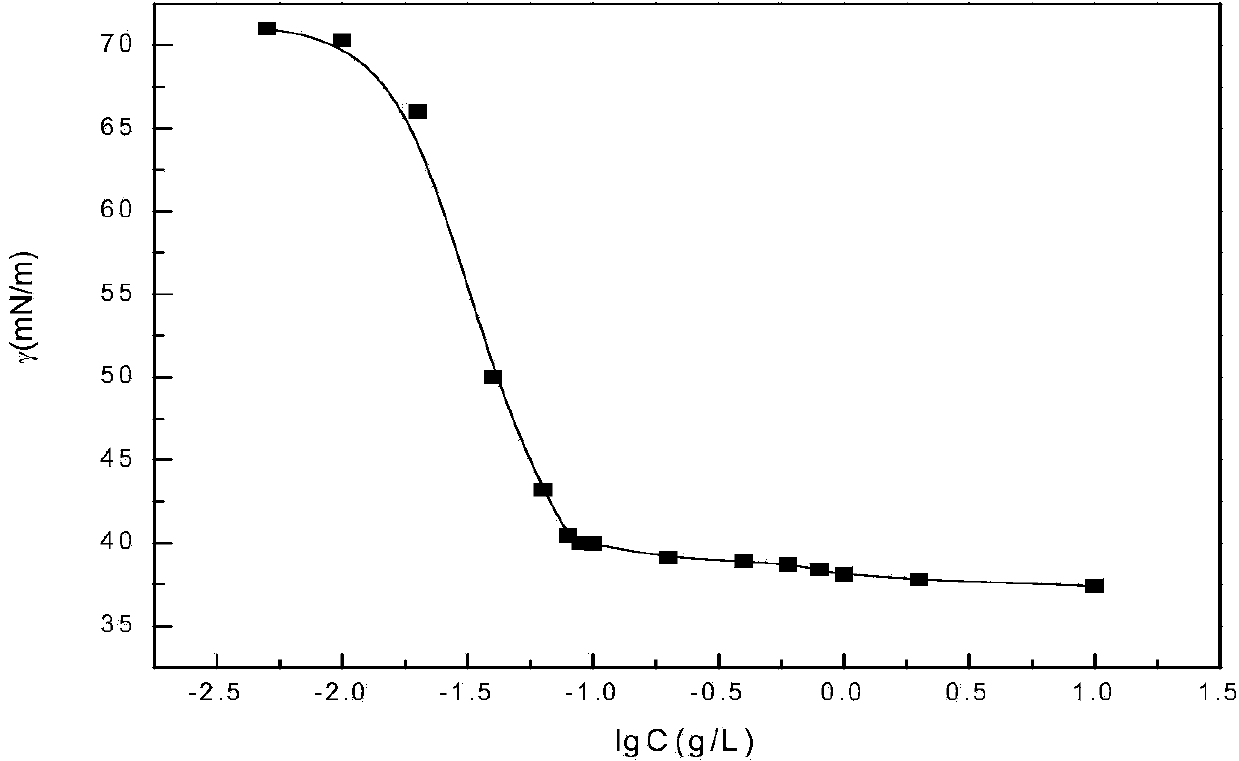

Cationic reactive Gemini polyurethane surfactant and preparation method thereof

InactiveCN104211896AImprove surface activityReduce surface tensionOptical transparencyPolymer science

The invention discloses a cationic reactive Gemini polyurethane surfactant and a preparation method thereof and belongs to the technical field of fine chemicals. The cationic reactive Gemini polyurethane surfactant is obtained by enabling excess diisocyanate to sequentially react with fatty amine polyoxyethylene ether and a chain extender, further adding a blocking agent to block remaining isocyanate groups, then neutralizing and dispersing in water. A series of surfactants with different performances, uses and unblocking temperatures can be obtained by selecting the types of fatty amine polyoxyethylene ether, the chain extender and the blocking agent. The cationic reactive Gemini polyurethane surfactant disclosed by the invention can solve the problem that the traditional surfactant is easy to migrate and precipitate on the one hand, and improve the compatibility of the cationic reactive Gemini polyurethane surfactant and the traditional surfactant, as well as water resistance, dielectricity, optical transparency and other performances on the other hand; furthermore, the cationic reactive Gemini polyurethane surfactant can realize the effects of strengthening, toughening, reducing surface tension and the like for a matrix, and shows broad application prospects in the fields of preparation of polymer emulsions, finishing of leather and synthetic leather, textile coating and the like.

Owner:SICHUAN UNIV

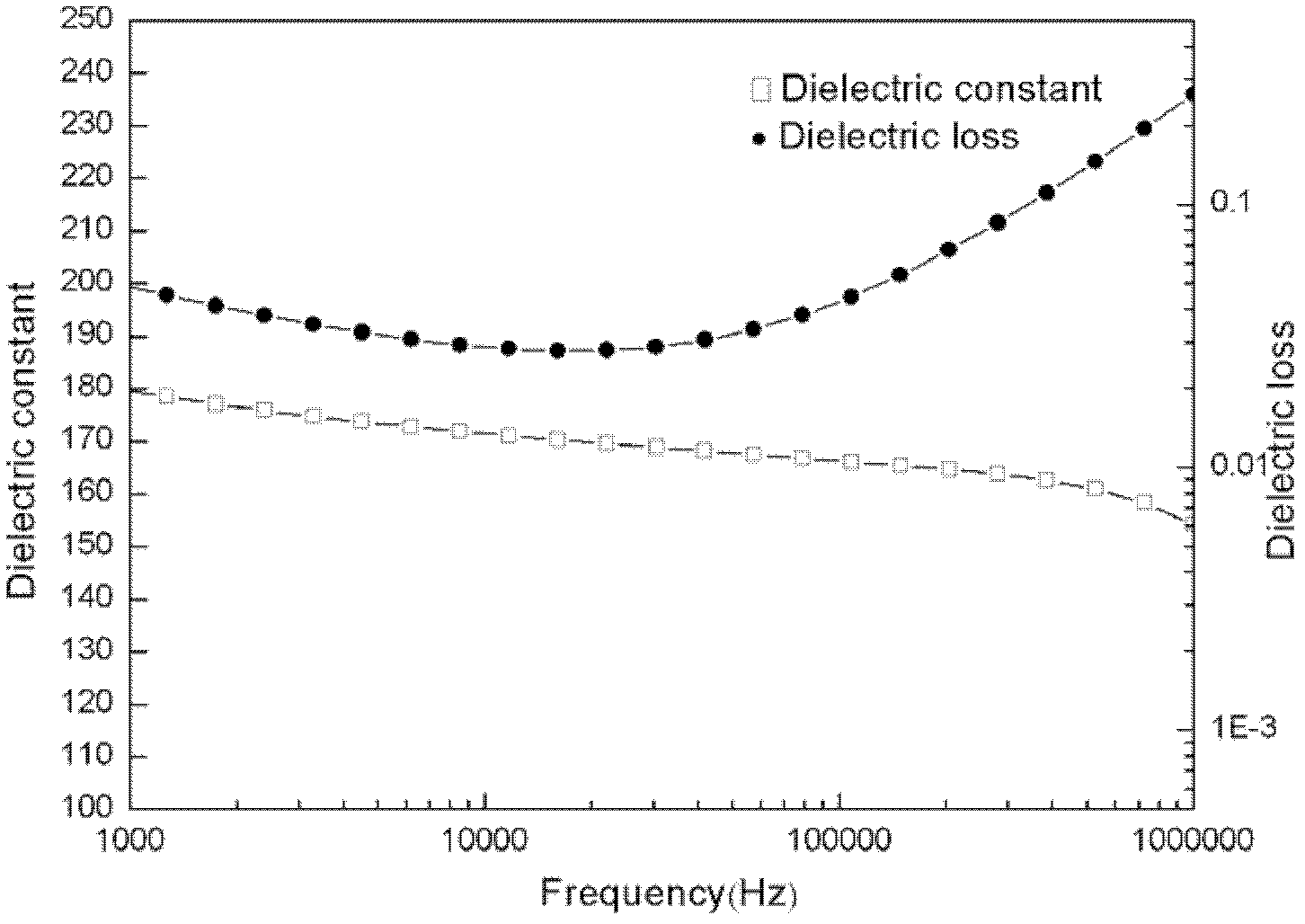

High dielectric polyimide/carbon nanotube composite material and preparation method thereof

The invention discloses a high dielectric polyimide / carbon nanotube composite material and a preparation method thereof. The preparation method comprises the steps that 1, the surface of a hydroxylation carbon nanotube is coated with a layer of copper phthalocyanine; 2, the high dielectric polyimide / carbon nanotube composite material is prepared. The surface of the hydroxylation carbon nanotube is coated with one layer of copper phthalocyanine through an esterification reaction, so that the disperse state of the carbon nanotube in the polyimide can be improved, and the dielectric performance of the composite material can be improved; meanwhile, due to the fact that the surface of the carbon nanotube is coated with one layer of non-conductive copper phthalocyanine, the problem that the dielectric loss is obviously increased due to the seepage effect can be solved.

Owner:SHANGHAI SECOND POLYTECHNIC UNIVERSITY

Lanthanum-oxide-modified rubber cable material

InactiveCN105985552AImprove reinforcement effectGood chemical stabilityRubber insulatorsVulcanizationCarbon nanotube

The invention discloses a lanthanum-oxide-modified rubber cable material which is prepared from the following raw materials in parts by weight: 5-6 parts of tantalum carbide, 0.6-0.8 part of lanthanum oxide, 62-68 parts of hydrogenated nitrile-butadiene rubber, 10-13 parts of carbon nanotube, 7-9 parts of nano kaolin, 55-60 parts of chloroprene rubber, 1-1.5 parts of montanin wax, 2-2.4 parts of calcium stearate, 2-3 parts of epoxy soybean oil, 2-3 parts of vulcanization accelerator TMTD, 55-70 parts of natural rubber, 2-3 parts of decabromodiphenyl oxide, 30-40 parts of hollow glass microsphere, 1-1.3 parts of silane coupling agent kh550, 12-16 parts of epoxy resin E44, 0.06-0.1 part of diethylenetriamine, 0.1-0.2 part of accelerator DA, 2.6-3 parts of silane coupling agent kh570 and a right amount of distilled water. The cable material has favorable flame retardancy, satisfies the requirements for application at high temperature, and has the advantages of favorable aging resistance, favorable oxidation resistance and longer service life.

Owner:JING FENG GRP

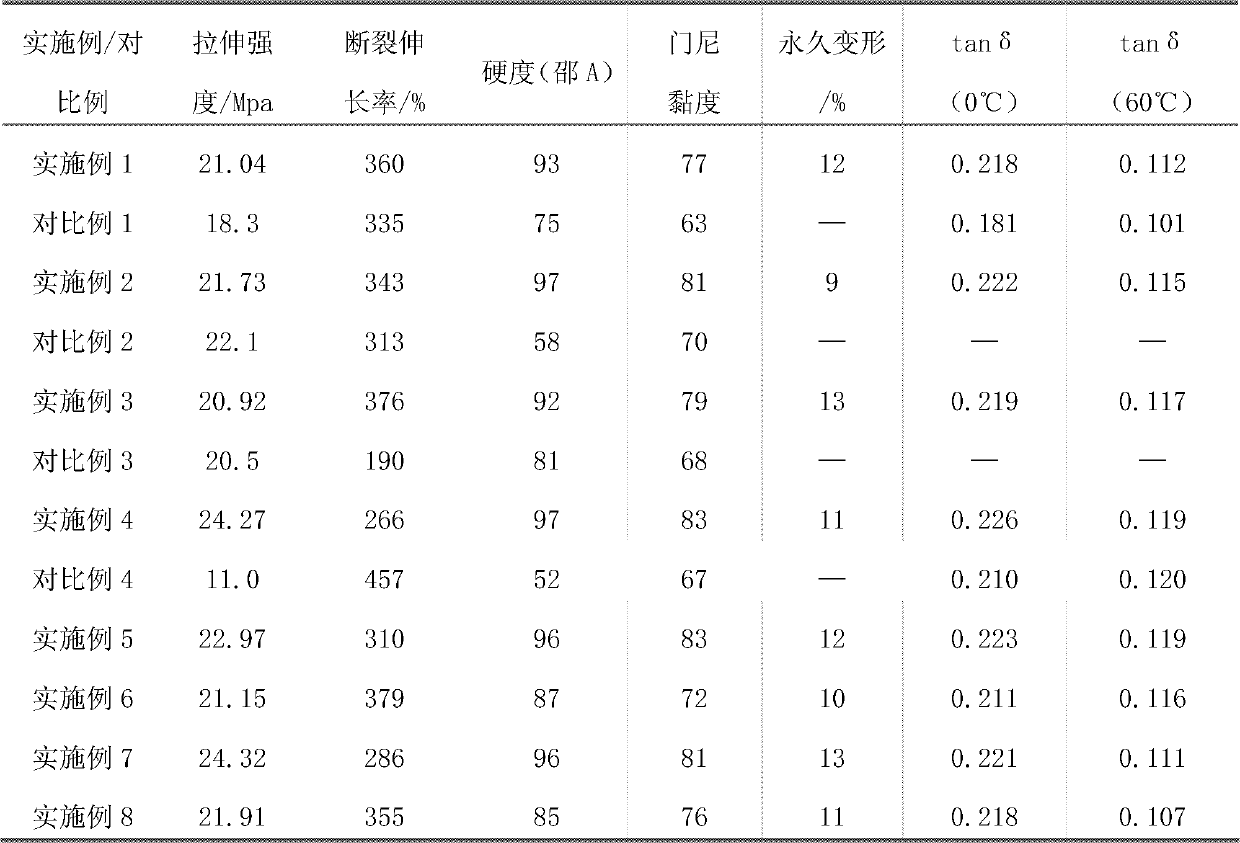

Star-shaped isoprene-styrene copolymer and preparation method thereof

InactiveCN103374109AFacilitate Co-OptimizationImprove hardness and dynamic mechanical propertiesIsoprenePolystyrene

The invention provides a star-shaped isoprene-styrene copolymer containing a random transition section and a preparation method thereof. The star-shaped isoprene-styrene copolymer is characterized in that the structural formula is [I1-S1-I2 / S2]n-Y,], wherein Y is Si or Sn, n is a branching degree, n is more than or equal to 2.5 and less than or equal to 4, and I1-S1 is a transition section copolymer of polystyrene and polyisoprene; I2 / S2 is a random section copolymer of the polystyrene and the polyisoprene, the mass fractions of transition sections of the polystyrene and the polyisoprene are 40-75wt%, and the mass fractions of random sections of the polystyrene and the polyisoprene are 25-60wt%. High styrene rubber disclosed by the invention has the characteristics of high hardness and good intensity and elasticity; when the high styrene rubber is used simultaneously with multiple synthetic rubber or natural rubber, the properties of rigidity, hardness, wearing resistance, tear resistance, dielectricity and the like of rubber products can be improved, and the high styrene rubber can be widely applied to the rubber processing fields of tires, tapes, rubber tubes, rubber overshoes and the like and other industries and can be further used for modifying synthetic plastics.

Owner:PETROCHINA CO LTD

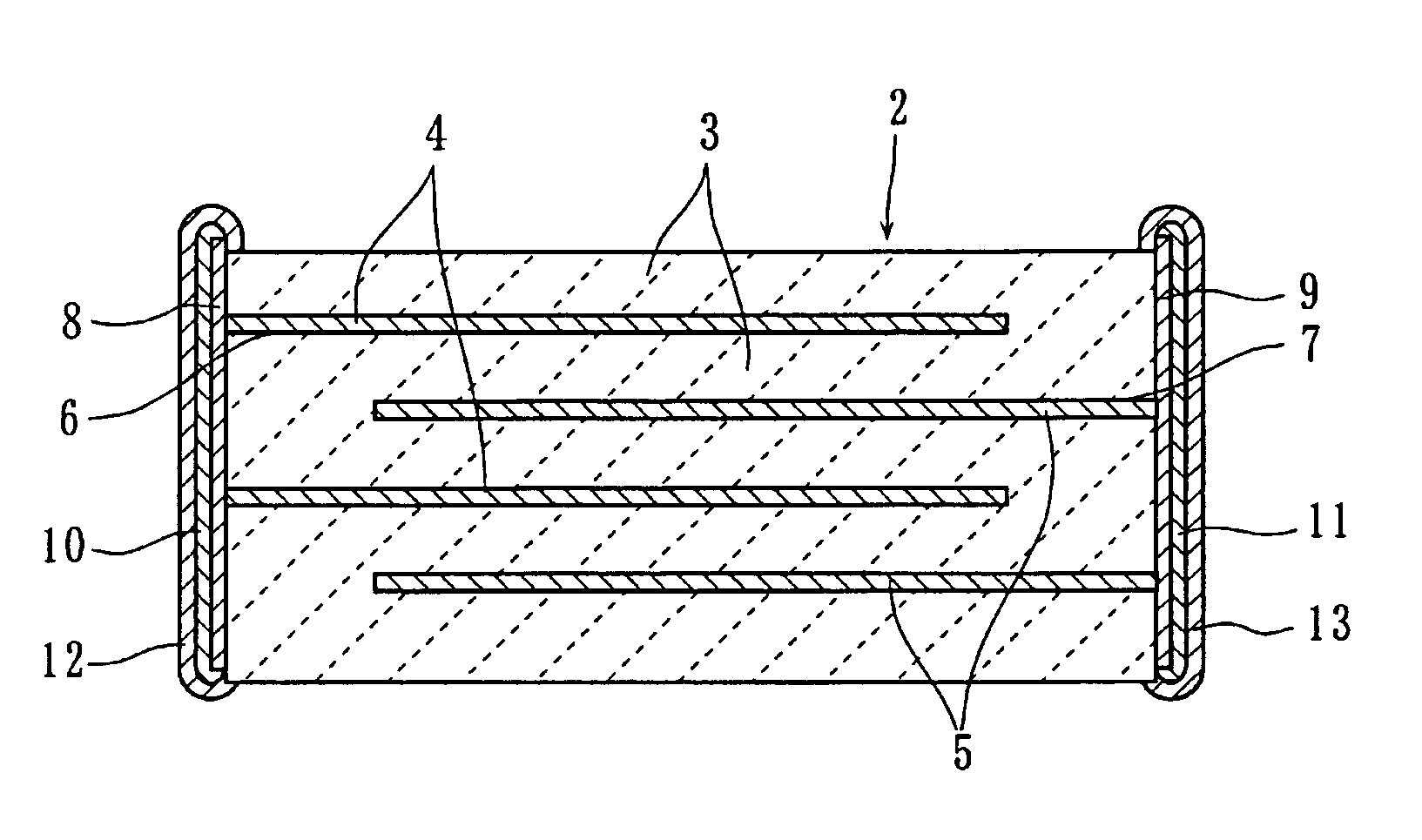

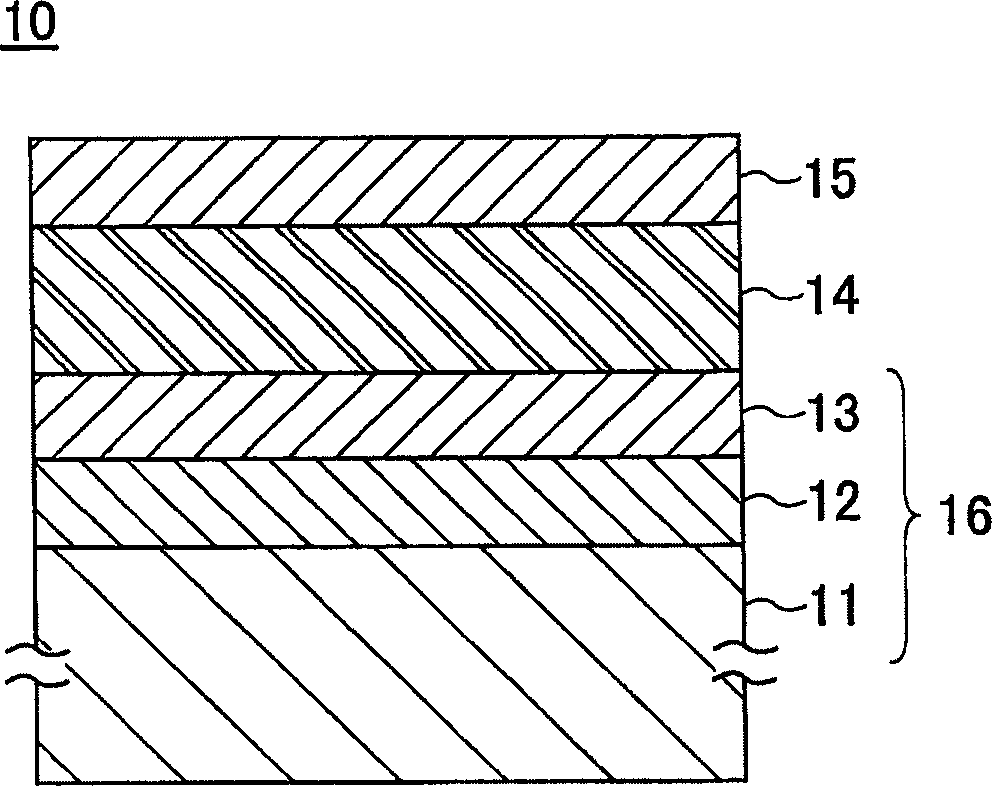

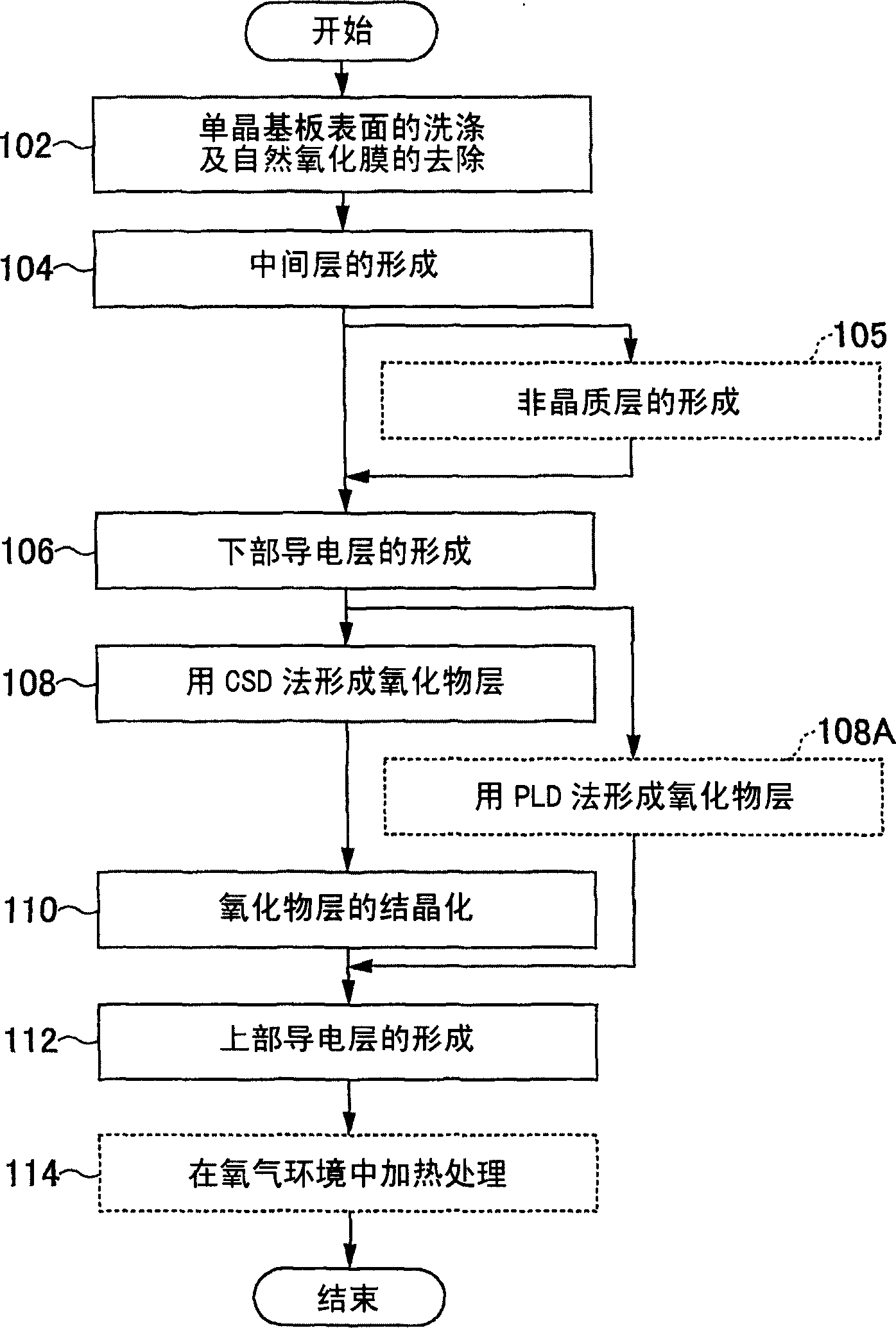

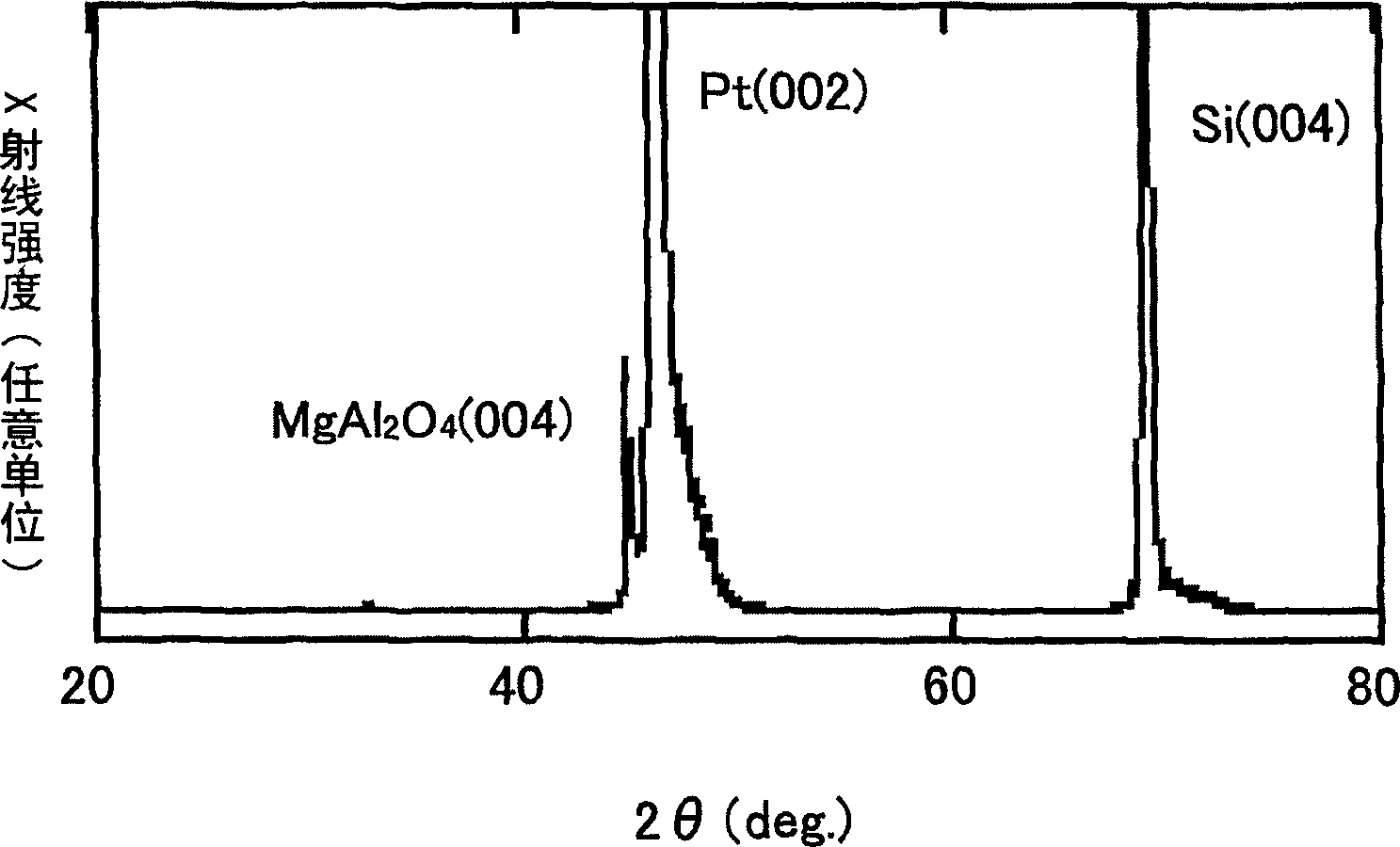

Thin film multilayer body, electronic device using such thin film multilayer body, actuator, and method for manufacturing actuator

InactiveCN1692506AHigh crystallinityLow costPolycrystalline material growthPiezoelectric/electrostrictive device manufacture/assemblyDielectricAlloy

An actuator (10) is formed by sequentially stacking an intermediate layer (12), a lower conductive layer (13), an oxide layer (14), and an upper conductive layer (15) on a silicon or GaAs single crystal substrate (11). The intermediate layer (12) of magnesia spinel (MgAl2O4), the lower conductive layer (13) of a platinum-group element or its alloy, and the oxide layer (14) of a crystalline structure having a simple perovskite lattice are epitaxially grown and formed. The oxide layer (14) is composed of a crystal having a simple perovskite lattice, and its (001) surface grows epitaxially. Accordingly, the oxide layer (14) has good crystallinity, and is excellent in dielectric constant, piezoelectric property, and electrostrictive property since a voltage application direction matches the polarization axis.

Owner:FUJITSU LTD

Improved composite rubber cable material

InactiveCN105985644AImprove reinforcementHigh chemical stabilityRubber insulatorsInsulated cablesDiethylenetriamineNatural rubber

The invention discloses an improved composite rubber cable material which is prepared from the following raw materials in parts by weight: 8-9 parts of bone black, 5-6 parts of fumed silica, 10-13 parts of quartz powder, 4-6 parts of sepiolite fiber, 55-60 parts of chloroprene rubber, 56-60 parts of silicone rubber, 55-70 parts of natural rubber, 30-40 parts of hollow glass beads, 1-1.3 parts of silane coupling agent kh550, 2-3 parts of antioxidant 1035, 1-2 parts of dibutyl phthalate, 1-2 parts of dibutyltin dilaurate, 3-4 parts of oleic acid, 3-5 parts of molybdenum disulfide, 12-16 parts of epoxy resin E44, 0.06-0.1 part of diethylenetriamine, 0.1-0.2 part of accelerant DA, 2.6-3 parts of silane coupling agent kh570 and appropriate distilled water. In the invention, the elasticity of the cable material is improved, the properties of insulation, thermal insulation and wear resistance of the cable material are enhanced, and the application range is expanded.

Owner:JING FENG GRP

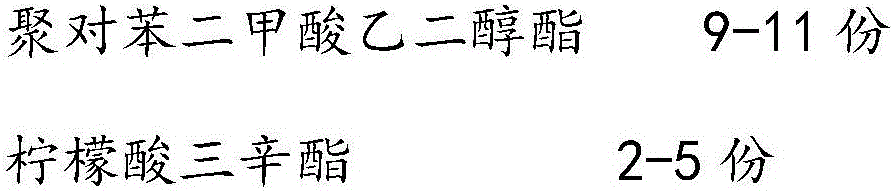

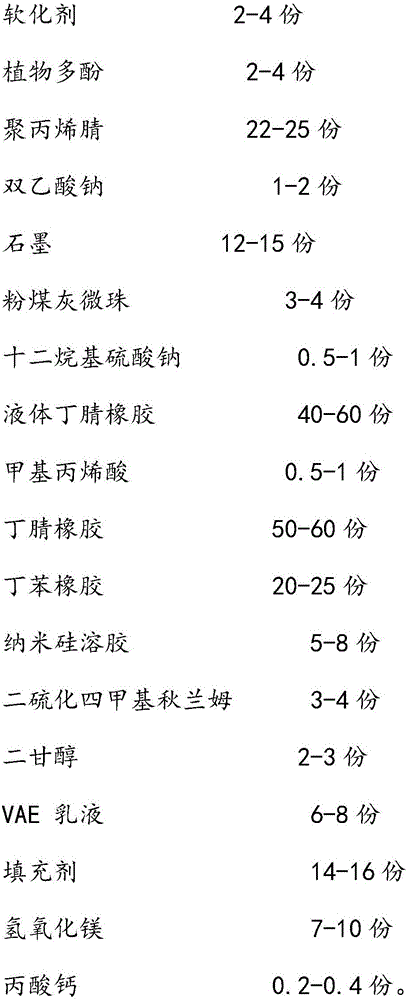

Anti-oxidizing rubber material

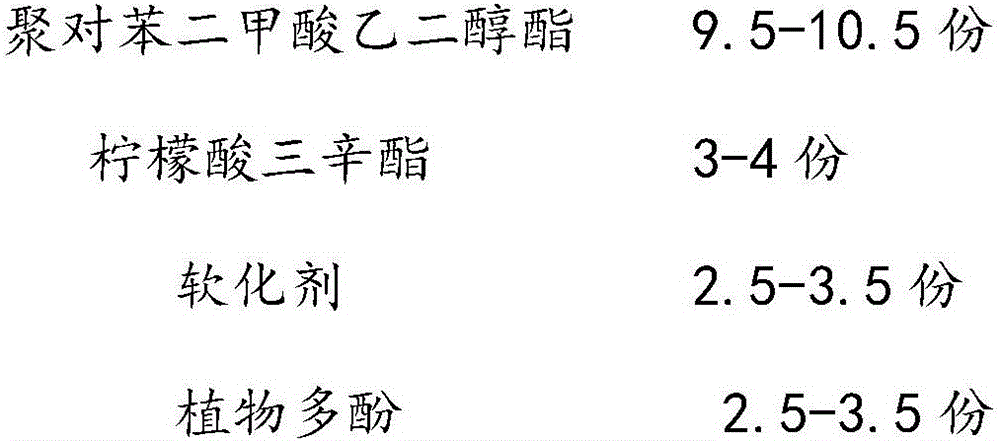

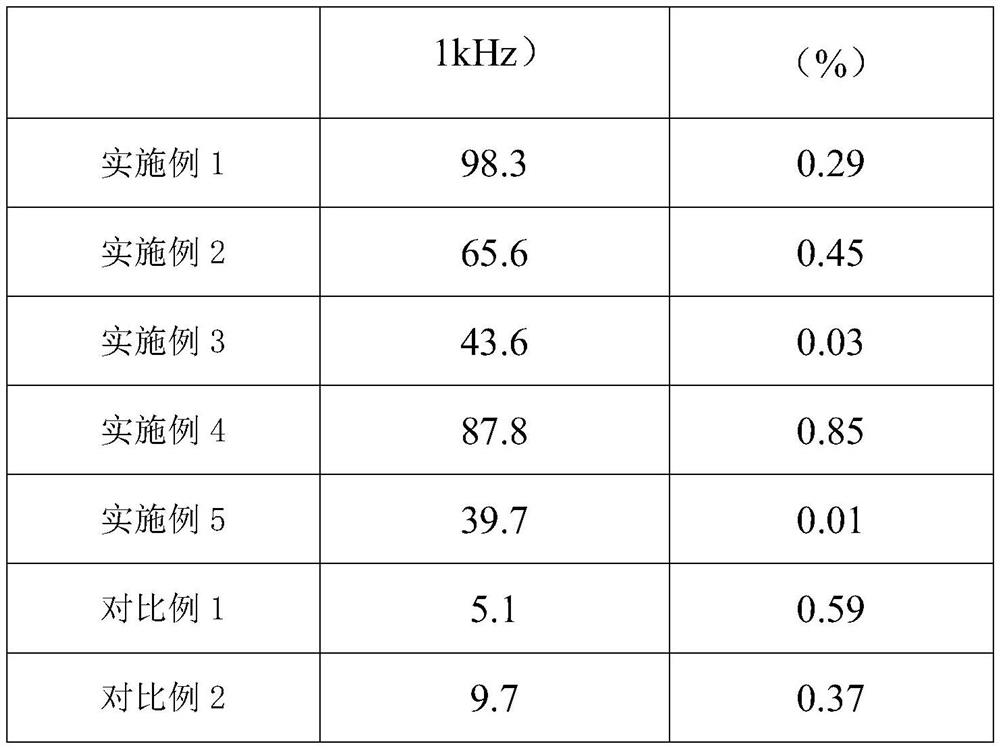

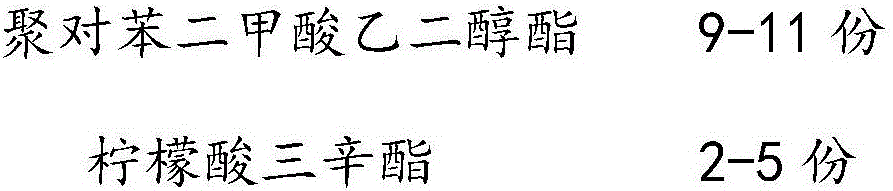

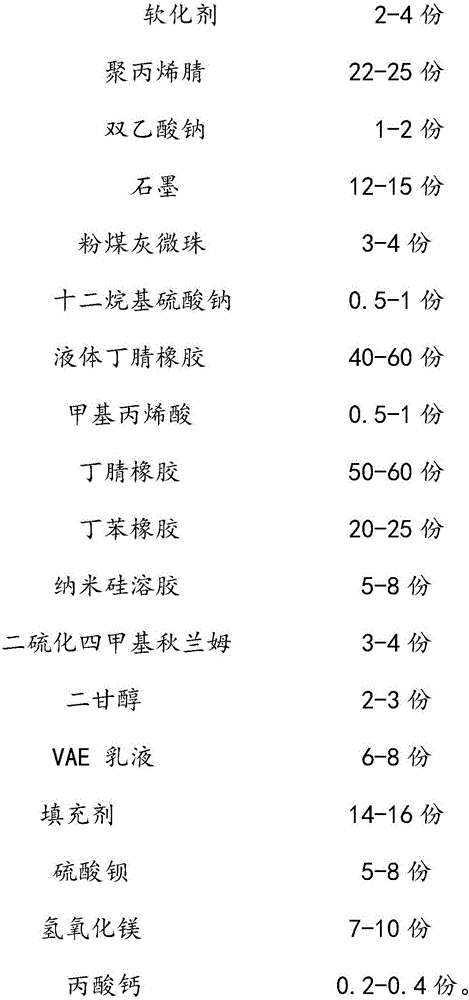

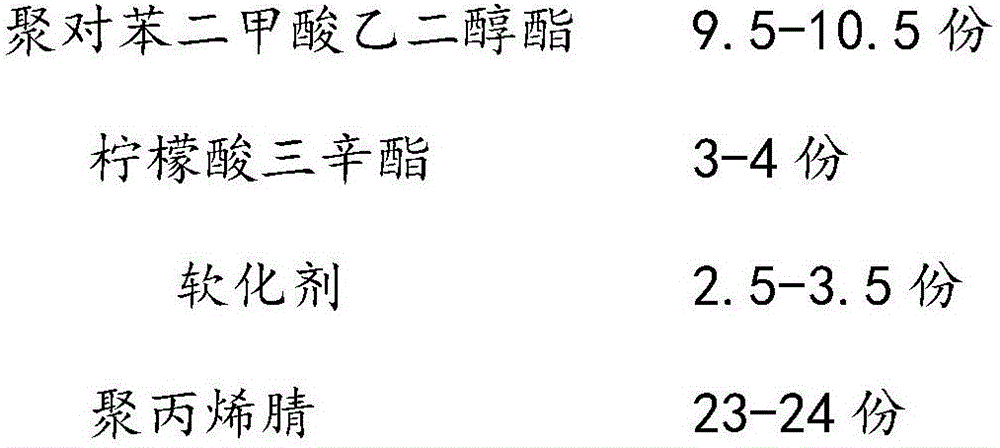

The invention discloses an anti-oxidizing rubber material including, by weight, 9-11 parts of polyethylene glycol terephthalate, 2-5 parts of trioctyl citrate, 2-4 parts of a softener, 2-4 parts of plant polyphenol, 22-25 parts of polyacrylonitrile, 1-2 parts of sodium diacetate, 12-15 parts of graphite, 3-4 parts of micro beads of fly ash, 0.5-1 part of lauryl sodium sulfate, 40-60 parts of liquid nitrile butadiene rubber, 0.5-1 part of methylacrylic acid, 50-60 parts of nitrile butadiene rubber, 20-25 parts of styrene butadiene rubber, 5-8 parts of nano silicon sol, 3-4 parts of tetramethyl thiuram disulfide, 2-3 parts of diethylene glycol, 6-8 parts of VAE emulsion, 14-16 parts of a filling agent, 7-10 parts of magnesium hydroxide, and 0.2-0.4 parts of calcium propanoate. The anti-oxidizing rubber material has excellent water proof performance, is acid-resistant, oil-resistant and flame-retarding and satisfies demands in production well.

Owner:ANHUI WEIWEI RUBBER PARTS GRP

Heat-resistant rubber cable sheath material

The invention discloses a heat-resistant rubber cable sheath material which is prepared from the following raw materials in parts by weight: 3-4 parts of magnesium stearate, 12-14 parts of mica powder, 8-11 parts of aluminum nitride, 4-6 parts of nano silver fiber, 5-6 parts of urea, 55-60 parts of chloroprene rubber, 2-3 parts of liquid paraffin, 10-13 parts of isoprene rubber, 46-55 parts of cis-1,4-polybutadiene rubber, 55-70 parts of natural rubber, 30-40 parts of hollow glass microsphere, 0.3-0.4 part of antioxidant BHT, 2-3 parts of sulfur, 2-3 parts of organobentonite, 1-1.3 parts of silane coupling agent kh550, 12-16 parts of epoxy resin E44, 0.06-0.1 part of diethylenetriamine, 0.1-0.2 part of accelerator DA, 2.6-3 parts of silane coupling agent kh570 and a right amount of distilled water. The rubber cable sheath has the characteristics of excellent heat resistance, excellent oil resistance, no combustion spreading, chemical corrosion resistance and the like, prolongs the service life of the cable, saves the resources and lowers the cost.

Owner:JING FENG GRP

Chip multilayer ceramic capacitor dielectric ceramic slurry and preparation method of dielectric

The invention discloses a chip multilayer ceramic capacitor dielectric ceramic slurry and preparation method of a dielectric, and belongs to the field of ceramic dielectric materials. The main component of the ceramic slurry provided by the invention is barium titanate, and also comprises a burning supporting agent, wherein the burning supporting agent comprises water glass and silicon dioxide, wherein the mass ratio of water glass to barium titanate is 1%-10%, and the mass ratio of silicon dioxide to barium titanate is 0.8%-1.2%. The preparation method of the dielectric comprises the following steps: 1) selecting a set quantity of the main component barium titanate, as well as the burning supporting agent, a diluent, a dispersion agent and a bonding agent A, and putting them into a ball milling machine for ball milling; 2) carrying out ball milling for a set period of time, then adding a set quantity of a bonding agent B in slurry after ball milling, and carrying out ball milling continuously; and 3) carrying out plate coating and sintering on the obtained slurry after ball milling for a set time, thereby obtaining the dielectric material. According to the invention, the energy consumption is reduced from all aspects greatly, and an MLCC (multiplayer ceramic chip capacitor) produced by the method is low in production cost and has good energy storage effect.

Owner:GUODIAN LONGYUAN ELECTRICAL

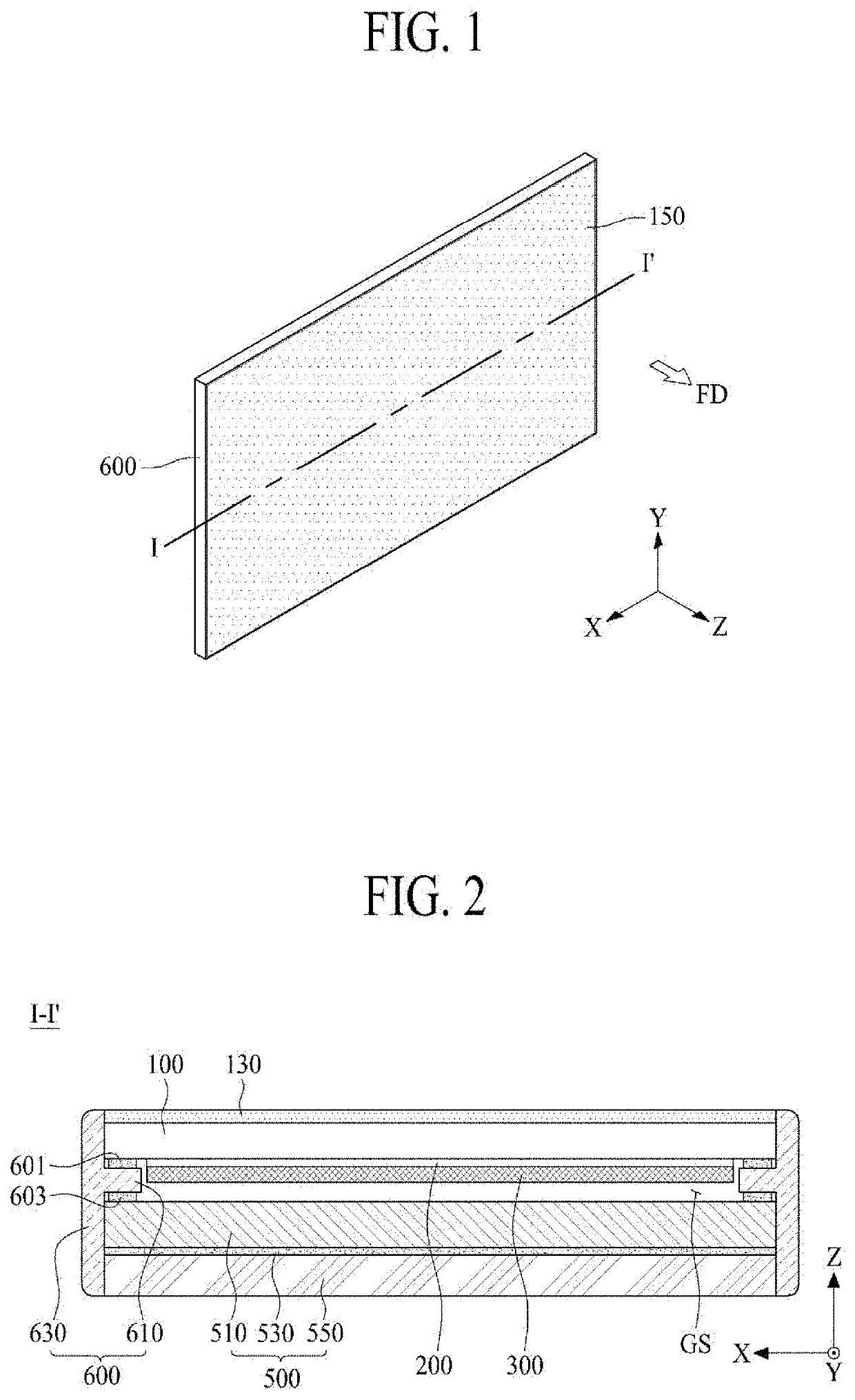

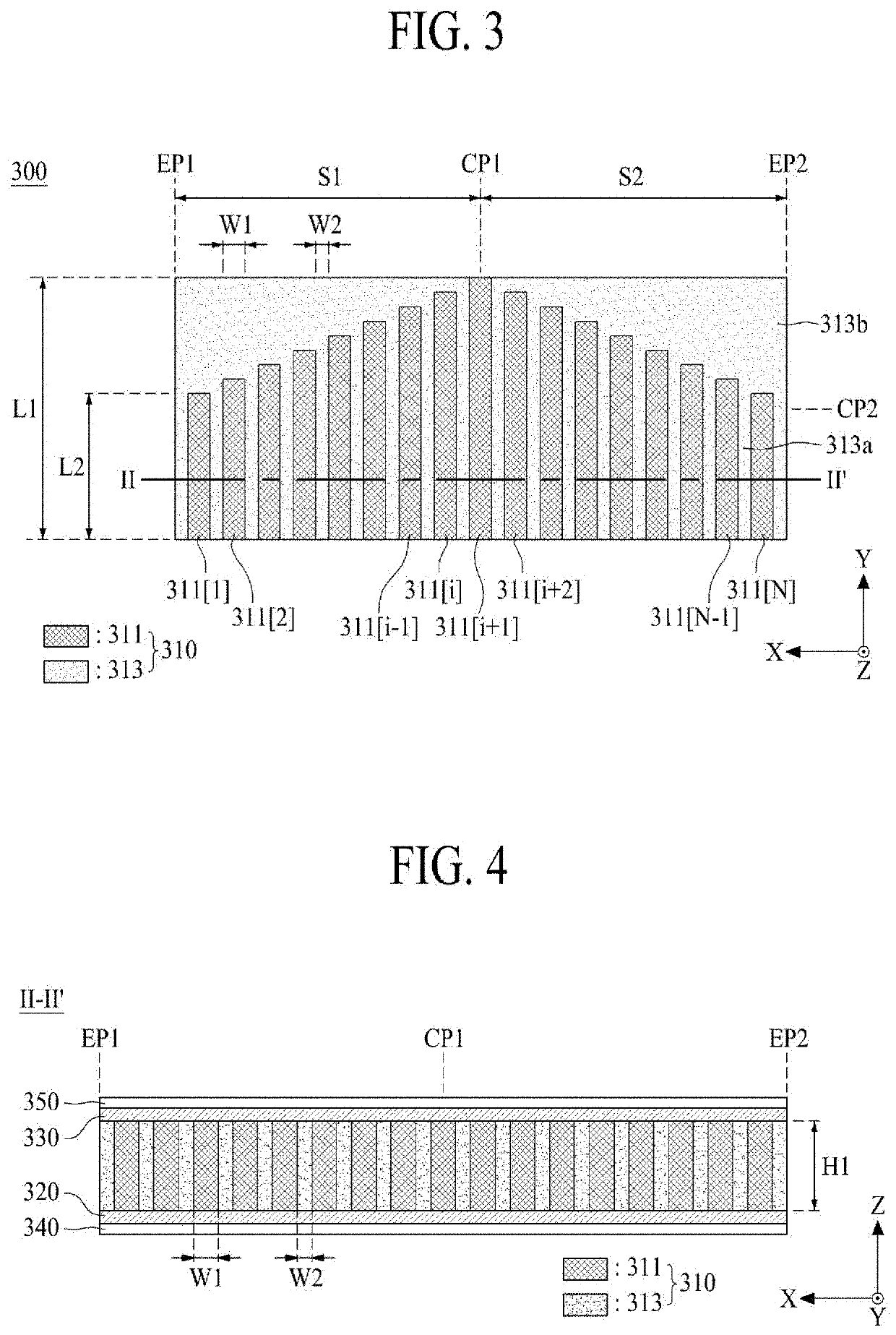

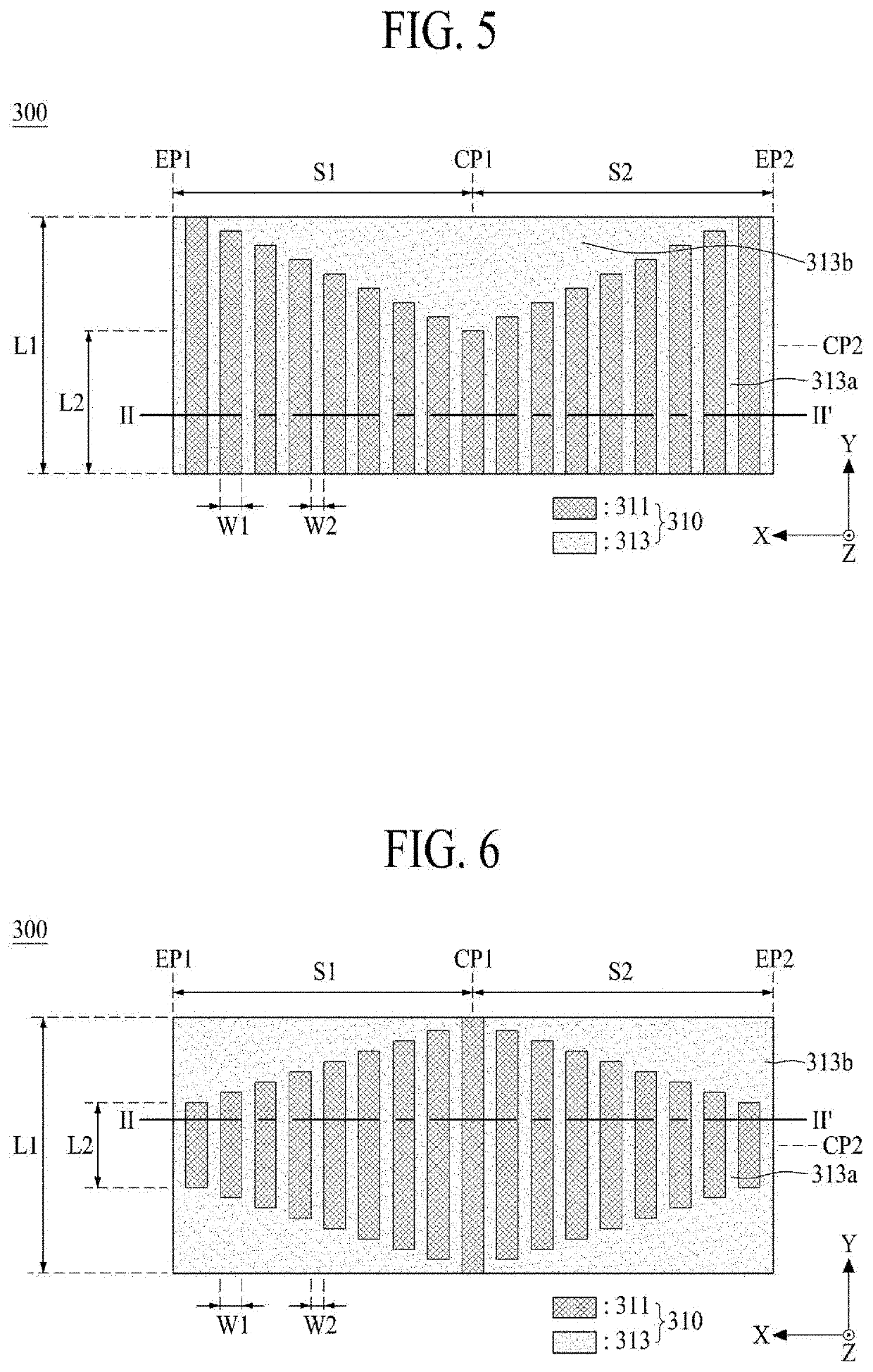

Flexible vibration module and display apparatus including the same

ActiveUS20200314556A1Enhance stiffness and flexibilityHigh dielectricMicrophonesPiezoelectric/electrostrictive device manufacture/assemblyPhysicsEngineering

A flexible vibration module is disclosed. The flexible vibration module includes a piezoelectric composite layer, including: a plurality of piezoelectric portions each having a piezoelectric characteristic, where at least two of the plurality of piezoelectric portions have different sizes; and a flexible portion between the plurality of piezoelectric portions.

Owner:LG DISPLAY CO LTD

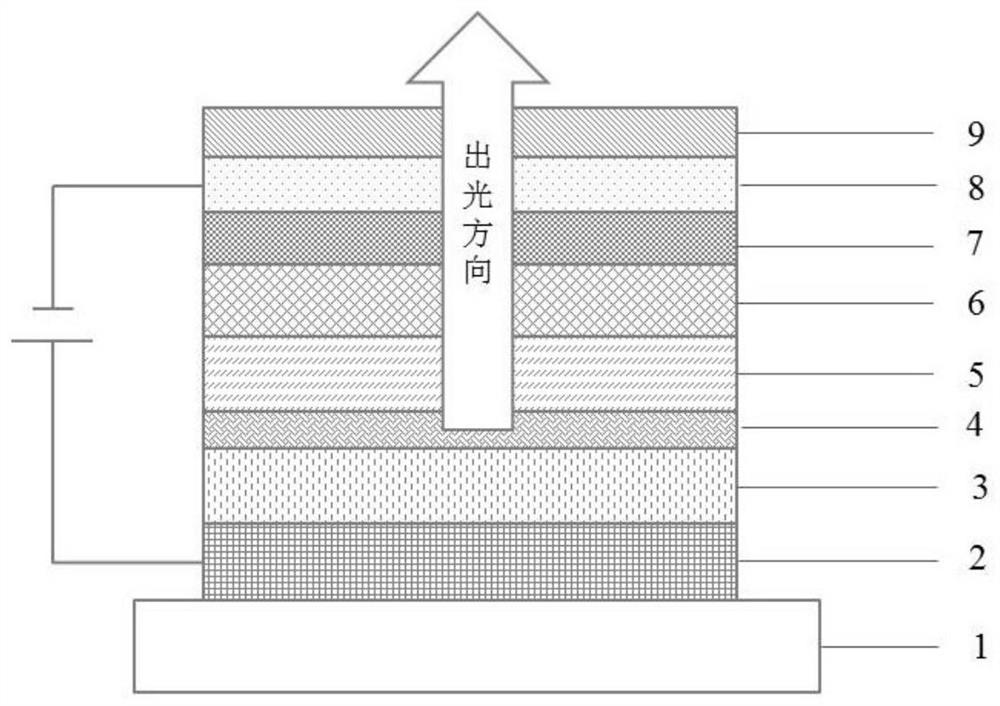

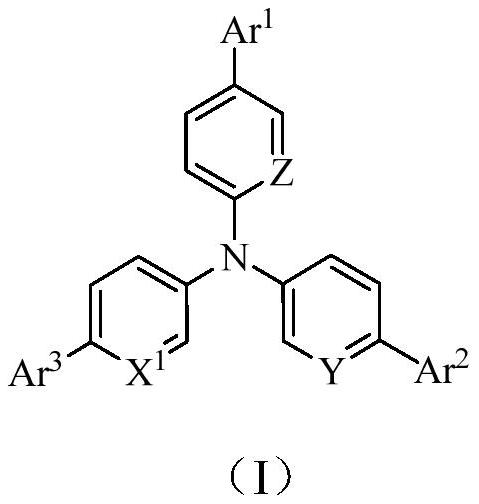

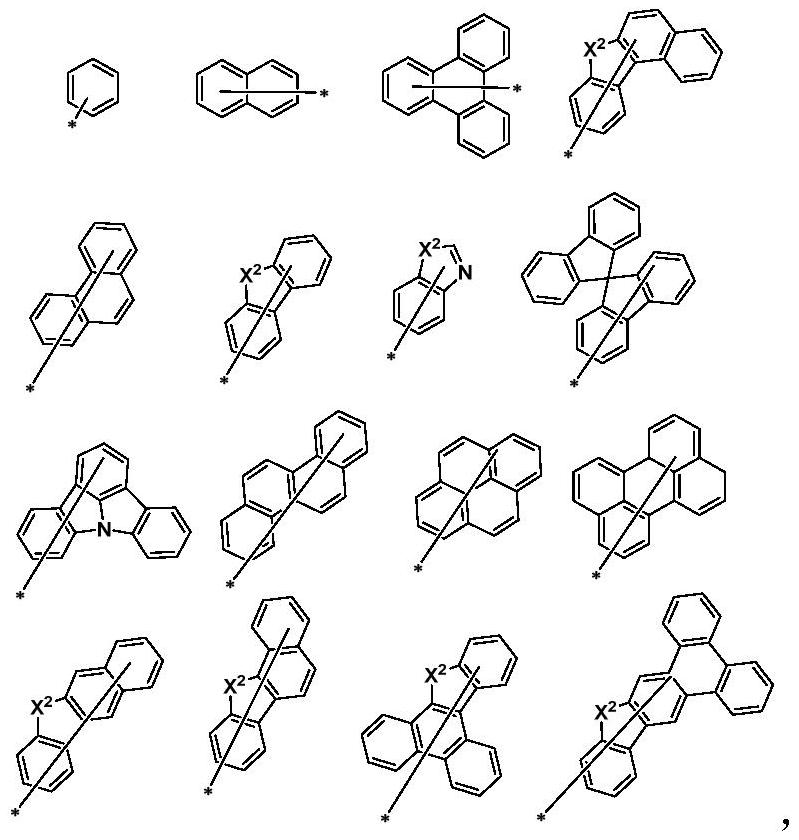

Compound, light extraction material and organic electroluminescent device

ActiveCN112939959AGood planaritySpeed up removalIsotope introduction to heterocyclic compoundsSolid-state devicesDisplay deviceOrganic electroluminescence

The present application provides a compound of general formula (I), and the compound can be used in light extraction materials. Pyridine and connected aromatic groups in the parent nucleus structure of the compound have good planarity, and the compound can be used as a light extraction material to improve the luminous efficiency of an organic electroluminescent device. The invention further provides an organic electroluminescent device and a display device.

Owner:YANTAI XIANHUA CHEM TECH CO LTD +1

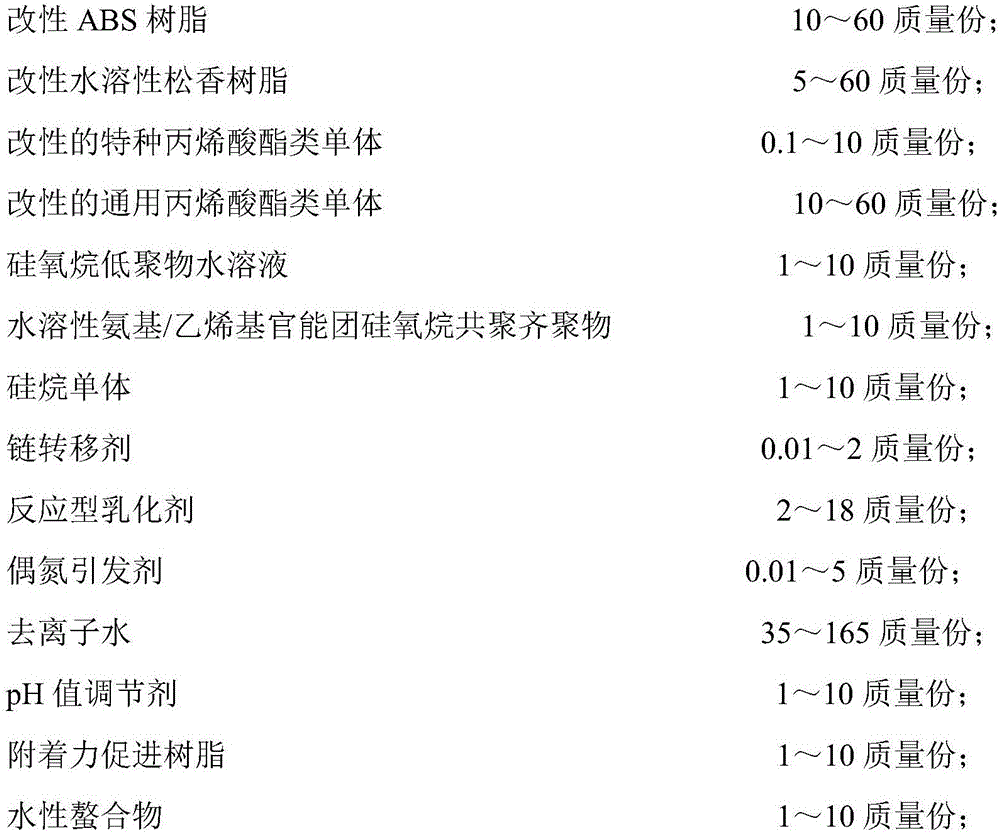

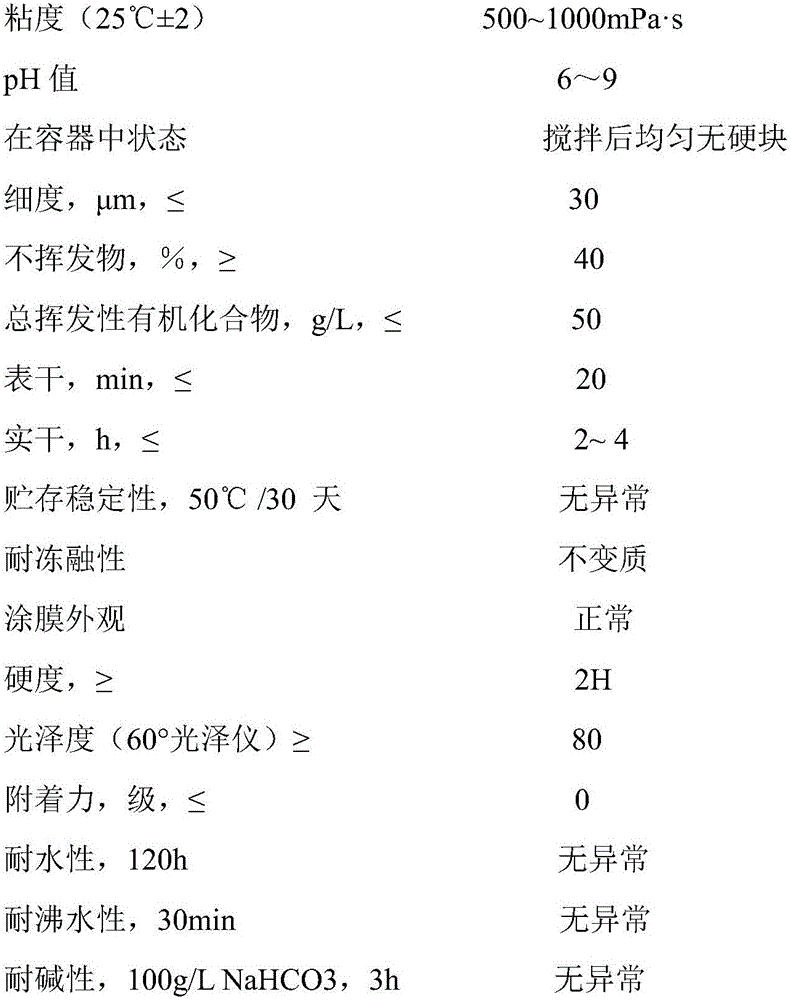

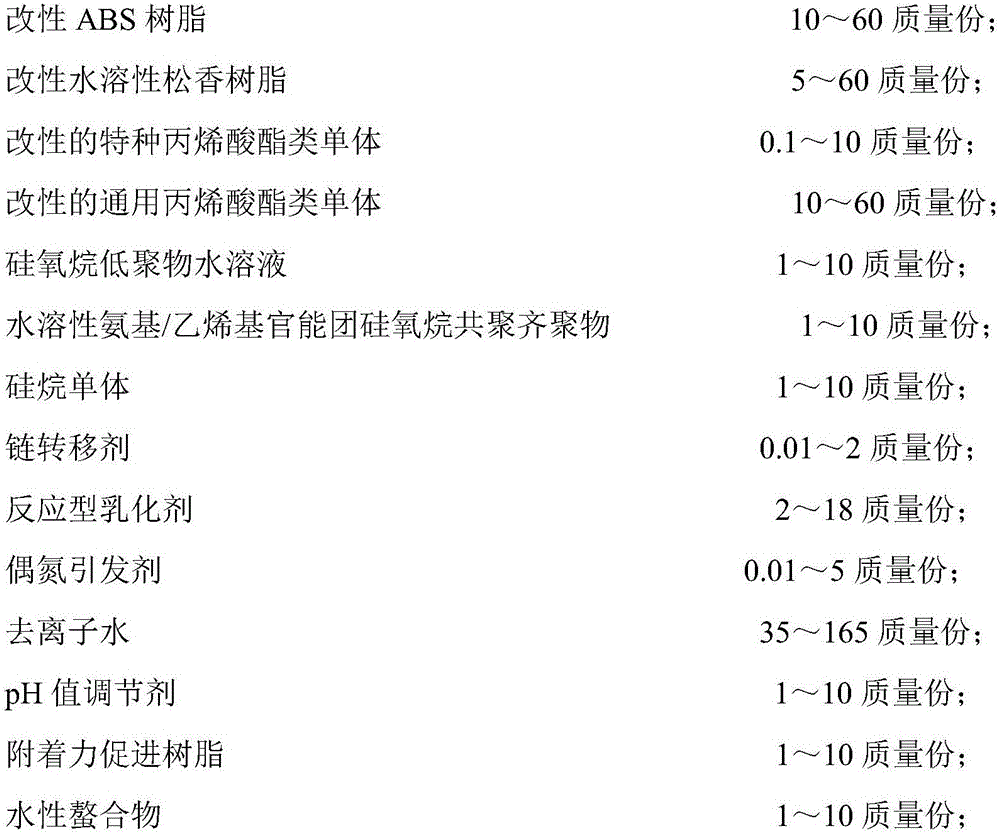

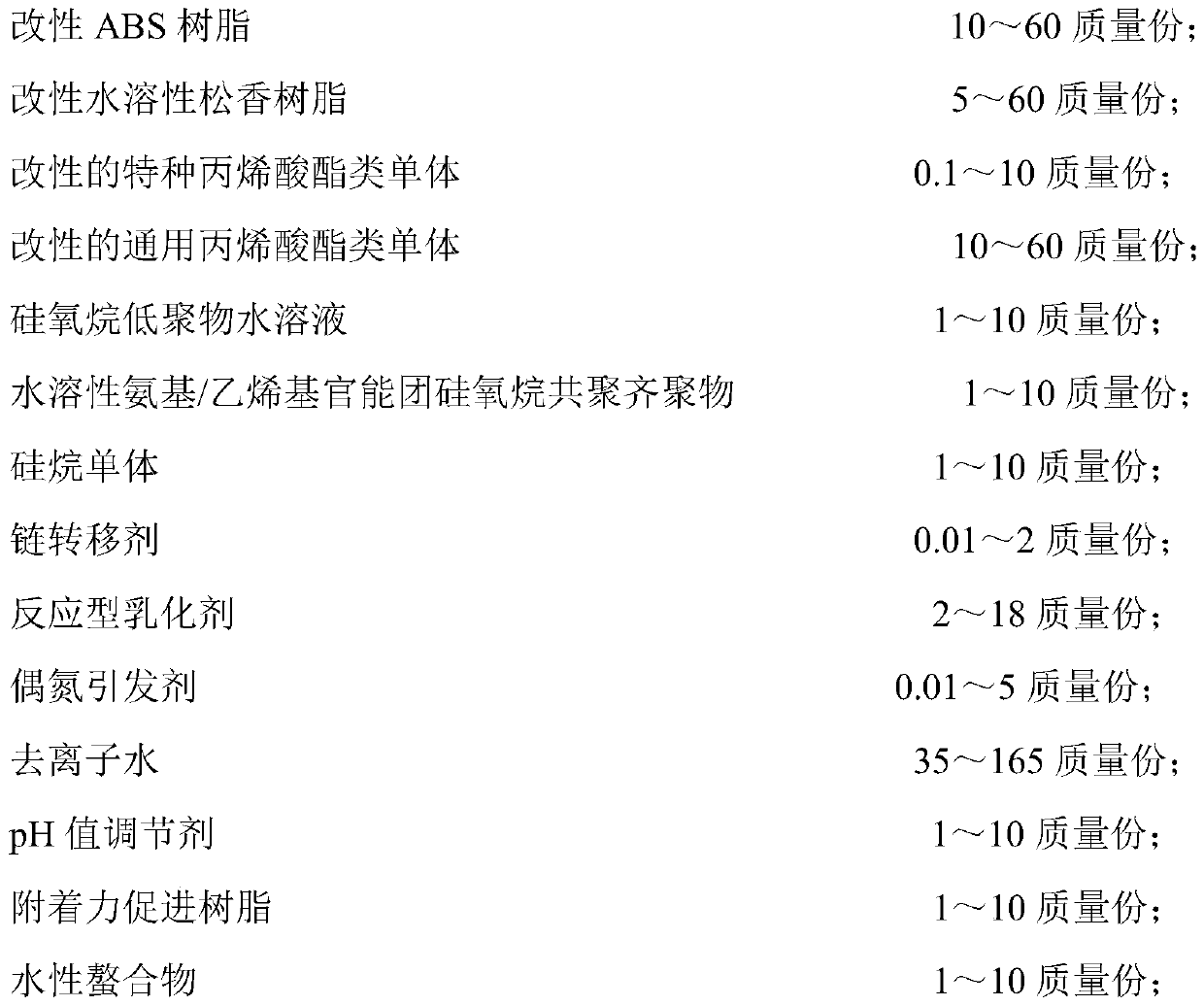

Water-based wood lacquer basic sticking material and preparation method of water-based wood lacquer basic sticking material

ActiveCN106752191AExtensive physicsWide range of chemical propertiesFireproof paintsWater basedLacquer

The invention provides a water-based wood lacquer basic sticking material. The water-based wood lacquer basic sticking material is prepared from the following components: modified ABS (Acrylonitrile Butadiene Styrene) resin, modified water-soluble rosin resin, a modified specific acrylate monomer, a modified general acrylate monomer, a siloxane low-polymer water solution, a water-soluble amino / vinyl functional group siloxane copolymerized oligomer, a siloxane monomer, a chain transfer agent, a reaction type emulsifier, an azo initiator, de-ionized water, a pH (Potential of Hydrogen) regulator, adhesion promoting resin, a water-based chelate and a water repellent agent. The invention further provides a preparation method of the water-based wood lacquer basic sticking material. By adopting the water-based wood lacquer basic sticking material provided by the invention, the quality effect can be get close to oily wood lacquer.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

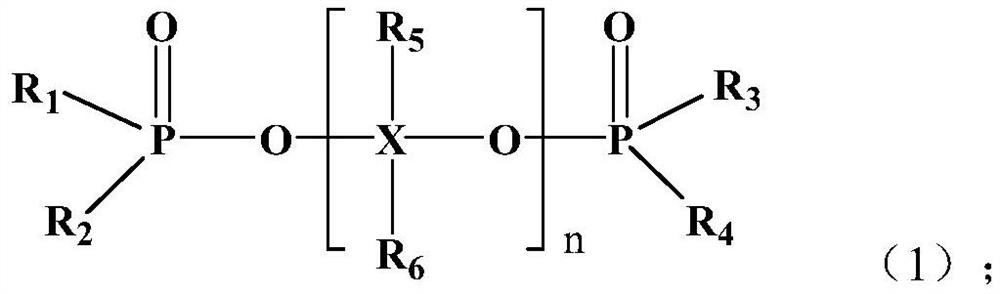

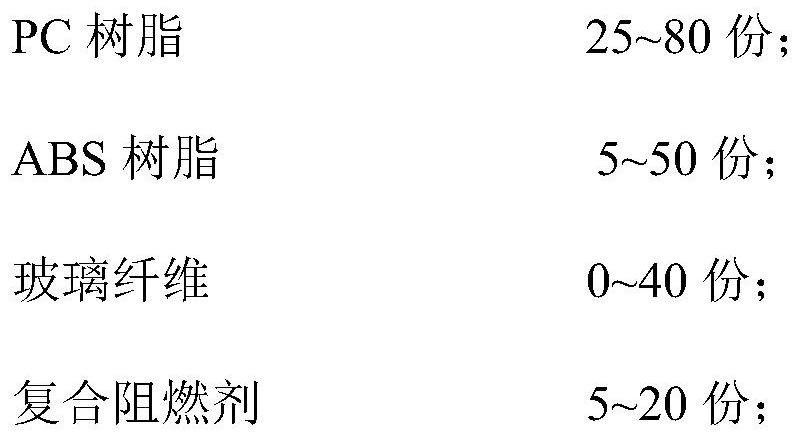

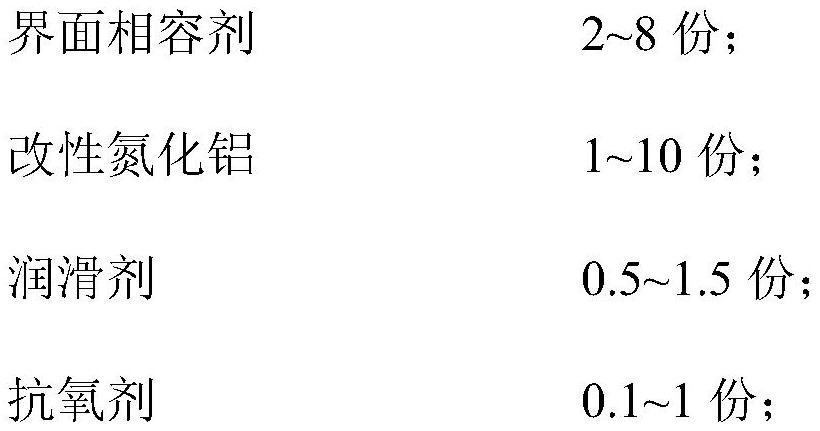

PC/ABS alloy material as well as preparation method and application thereof

PendingCN114479400AImprove thermal conductivityImprove flame retardant performanceDielectricTetrafluoroethylene

The invention relates to a PC (polycarbonate) / ABS (acrylonitrile butadiene styrene) alloy material which comprises PC resin, ABS resin, an interface compatilizer, a composite flame retardant, modified aluminum nitride and the like, and the composite flame retardant comprises a phosphate flame retardant, graphene and polytetrafluoroethylene. The invention also provides a preparation method and application of the PC / ABS alloy material. The efficient composite flame retardant disclosed by the invention not only has excellent flame retardant property, but also can form a high-thermal-conductivity network structure by simultaneously introducing the graphene and the modified aluminum nitride, so that the heat dissipation performance is improved. The dielectricity, flame retardance and conductivity of the low-dielectric flame-retardant PC / ABS alloy material disclosed by the invention are remarkably improved, and a better technical effect is achieved. Meanwhile, the preparation method is simple, easy to implement and suitable for large-scale production and application.

Owner:CHINA PETROLEUM & CHEM CORP +1

Water-based nail polish basic sticking material and preparation method of water-based nail polish basic sticking material

ActiveCN106726777AImprove adhesionEnhanced resistance to peelingCosmetic preparationsNon-macromolecular adhesive additivesWater basedCause injury

The invention provides a water-based nail polish basic sticking material. The water-based nail polish basic sticking material is prepared from the following components: modified ABS (Acrylonitrile Butadiene Styrene) resin, modified water-soluble rosin resin, a modified specific acrylate monomer, a modified general acrylate monomer, a siloxane low-polymer water solution, a water-soluble amino / vinyl functional group siloxane copolymerized oligomer, a siloxane monomer, a chain transfer agent, a reaction type emulsifier, an azo initiator, de-ionized water, a pH (Potential of Hydrogen) regulator, adhesion promoting resin and a water-based chelate. The invention further provides a preparation method of the water-based nail polish basic sticking material. By adopting the water-based nail polish basic sticking material provided by the invention, a scheme for solving the problem is pertinently provided, and the quality and performances of a nail polish basic material are greatly improved by utilizing relatively low cost, so that the quality and performances can get close to or basically meet the expectation of the society and users; a real and feasible scheme is provided for elimination of a coating technology and a nail polish removing process, which cause injuries to bodies, of toxic and harmful nail polish.

Owner:瑞雅科医药(北京)有限公司

A modified nitrile butadiene rubber cable material

InactiveCN105968448AImprove reinforcement effectGood chemical stabilityRubber insulatorsInsulated cablesDiethylene triamineMagnesium borate

A modified nitrile butadiene rubber cable material is disclosed. The cable material is prepared from 11-14 parts by weight of magnesium borate crystal whiskers, 10-13 parts by weight of emery powder, 6-8 parts by weight of clay, 2-3 parts by weight of sodium carboxymethylcellulose, 2-2.5 parts by weight of lauric acid, 0.7-1 part by weight of polyoxyethylene ester, 58-65 parts by weight of nitrile butadiene rubber, 3-4 parts by weight of polyethylene wax, 55-60 parts by weight of chloroprene rubber, 0.8-1 part by weight of an antioxidant 1010, 1-2 parts by weight of lauric acid, 55-70 parts by weight of natural rubber, 30-40 parts by weight of hollow glass micro beads, 1-1.3 parts by weight of a silane coupling agent kh550, 12-16 parts by weight of epoxy resin E44, 0.06-0.1 part by weight of diethylenetriamine, 0.1-0.2 part by weight of an accelerant DA, 2.6-3 parts by weight of a silane coupling agent kh570 and a proper amount of distilled water. The cable material is good in thermal stability, excellent in performance and low in raw materials cost, saves resources, can be produced in a large scale and deserves popularization.

Owner:ANHUI CABLE

High-tear-resistance rubber cable material

InactiveCN105985545AImprove reinforcementHigh chemical stabilityRubber insulatorsChemistryGlass microsphere

The invention discloses a high-tear-resistance rubber cable material which is prepared from the following raw materials in parts by weight: 11-13 parts of barium fluoride, 5-7 parts of magnesium carbonate, 7-9 parts of peat soil, 60-66 parts of nitrile-butadiene rubber, 55-60 parts of chloroprene rubber, 3-4 parts of eucalyptus essential oil, 1-1.4 parts of copper naphthenate, 55-70 parts of natural rubber, 2-3 parts of zinc oxide, 30-40 parts of hollow glass microsphere, 2-2.4 parts of argil, 2-3 parts of calcium hydroxide, 1-1.3 parts of silane coupling agent kh550, 12-16 parts of epoxy resin E44, 0.06-0.1 part of diethylenetriamine, 0.1-0.2 part of accelerator DA, 2.6-3 parts of silane coupling agent kh570 and a right amount of distilled water. The high-tear-resistance rubber cable material can effectively prevent the cable from cracking, has the advantages of fewer cable short circuits and moisture resistance and prolongs the service life of the cable.

Owner:JING FENG GRP

High-cold-resistance rubber cable material

InactiveCN105985542AImprove reinforcement effectGood chemical stabilityRubber insulatorsDiethylenetriamineGlass microsphere

The invention discloses a high cold-resistant rubber cable material, which is made of the following raw materials in parts by weight: pine oil 2-3, aluminum tripolyphosphate 1-1.4, heavy calcium powder 10-13, tungsten boride 4-5, crushed Glass powder 10‑13, diisodecyl adipate 0.8‑1, ethanolamine 2‑2.5, silicone masterbatch 3‑4, petrolatum 3‑4, ACR anti-impact agent 2‑3, isoprene rubber 60‑67, chlorine Butadiene rubber 55‑60, natural rubber 55‑70, hollow glass microspheres 30‑40, silane coupling agent kh5501‑1.3, epoxy resin E4412‑16, diethylenetriamine 0.06‑0.1, accelerator DA0.1‑0.2 , silane coupling agent kh5702.6‑3, appropriate amount of distilled water; the rubber cable material prepared by the present invention has excellent mechanical properties, good aging resistance, high hardness, and is not easily damaged. It is used as a cable material with good overall performance, long service life, and application prospects widely.

Owner:JING FENG GRP

A high-temperature resistant low-smoke flame retardant rubber cable material

InactiveCN105968451AImprove reinforcement effectGood chemical stabilityRubber insulatorsInsulated cablesFiberFireproofing

A high-temperature resistant low-smoke flame retardant rubber cable material is disclosed. The cable material is prepared from 12-15 parts by weight of friction powder made of cashew nut shell oil, 13-15 parts by weight of barium metaphosphate, 7-8 parts by weight of alumina, 10-13 parts by weight of basalt fibres, 4-5 parts by weight of castor oil, 2-3 parts by weight of dioctyl terephthalate, 3-4 parts by weight of an antioxidant 1035, 3-4 parts by weight of triallyl isocyanurate, 55-65 parts by weight of butadiene-acrylonitrile rubber, 55-60 parts by weight of chloroprene rubber, 2-3 parts by weight of paraffin oil, 3-4 parts by weight of zinc stearate, 55-70 parts by weight of natural rubber, 30-40 parts by weight of hollow glass micro beads, 1-1.3 parts by weight of a silane coupling agent kh550, 12-16 parts by weight of epoxy resin E44, 0.06-0.1 part by weight of diethylenetriamine, 0.1-0.2 part by weight of an accelerant NS, 2.6-3 parts by weight of a silane coupling agent kh570 and a proper amount of distilled water. The cable material is good in fireproofing performance, flame retardant, not liable to combust, low in smoke, long in service lifetime, capable of saving resources and good in practicability.

Owner:ANHUI CABLE

Cold-resistant and impact-resistant rubber cable material

InactiveCN105985544AImprove reinforcement effectGood chemical stabilityRubber insulatorsEpoxyPolymer science

The invention discloses a cold-resistant and impact-resistant rubber cable material, prepared from the following raw materials in parts by weight: 5-6 of gas-phase alumina, 58-65 of nitrile rubber, 6-8 of humite, 10-13 of wear-resistant carbon black, 3-4 of magnesia, 4-6 of zinc borate, 2-3 of polytetrafluoroethylene, 55-60 of neoprene, 55-70 of natural rubber, 1-2 of 1,2-hydroxy stearic acid, 30-40 of hollow glass microspheres, 1-1.3 of silane coupling agent kh550, 12-16 of epoxy resin E44, 0.06-0.1 of diethylenetriamine, 0.1-0.2 of accelerant DA, 2.6-3 of silane coupling agent kh570 and a proper amount of distilled water. The cold-resistant and impact-resistant rubber cable material has excellent cold resistance and impact resistance, good oxygen and ozone resistance, aging resistance, long service life, simple preparation process and convenience in actual operation.

Owner:JING FENG GRP

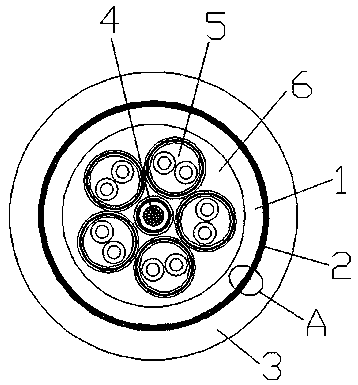

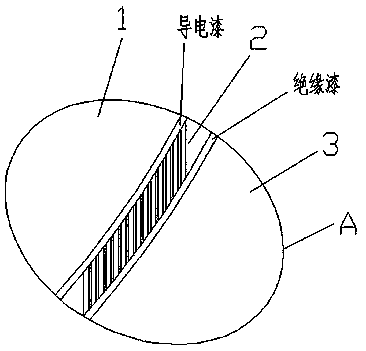

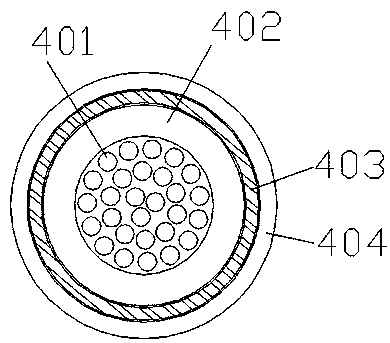

Computer cable with light shielding structure

PendingCN110098014AImprove anti-interference abilityAvoid accumulationCables with twisted pairs/quadsClimate change adaptationDielectricCoated membrane

The invention discloses a computer cable with a light shielding structure. The computer cable comprises a cable core, a master insulating layer, a master shielding layer and a sheath layer; the cablecore is composed of a control core, twisted cores and a wrapping layer; the control core is composed of control conductors, a control insulating layer, a control shielding layer and a control rubber sleeve; each twisted core is composed of transmission conductors, transmission insulated sheaths, a twisting wrapping belt, a transmission insulation layer, a transmission shielding layer and a transmission rubber sheath; and each of the master, control and transmission shielding layers is of a double-side coated membrane structure in which the basement membrane is coated with a conducting paint and the other side is coated with an insulating paint. A light PET dielectric film serves as the master, control and transmission shielding layers to form the light shielding structure of the computer cable, the dielectricity is improved greatly, charge accumulation is effectively avoided, and the anti-interference performance of the computer cable is improved; and the bending performance of the cable is ensured, the cable weight is reduced, and the computer cable is worth of popularization.

Owner:ANHUI DUJIANG CABLE GROUP

Polyimide dielectric material and dielectric film

The invention provides a polyimide dielectric material and a dielectric film. The dielectric material is obtained by an esterification reaction of carboxyl-containing polyimide and hydroxylated carbonnanotubes. According to the invention, the polyimide and the carbon nanotubes are compounded, so that the dielectric property of the polyimide is effectively improved.

Owner:阜阳申邦新材料技术有限公司

A kind of high dielectric polyimide/carbon nanotube composite material and preparation method thereof

Owner:SHANGHAI SECOND POLYTECHNIC UNIVERSITY

Novel waterproof rubber material

The invention discloses a novel waterproof rubber material prepared from the following raw materials in parts by weight: 9-11 parts of polyethylene glycol terephthalate, 2-5 parts of trioctyl citrate, 2-4 parts of softener, 22-25 parts of polyacrylonitrile, 1-2 parts of sodium diacetate, 12-15 parts of graphite, 3-4 parts of coal ash microspheres, 0.5-1 part of sodium dodecyl sulfate, 40-60 parts of liquid nitrile rubber, 0.5-1 part of methylacrylic acid, 50-60 parts of nitrile rubber, 20-25 parts of butadiene styrene rubber, 5-8 parts of nano-silicon sol, 3-4 parts of tetramethyl thiuram disulfide, 2-3 parts of diglycol, 6-8 parts of VAE emulsion, 14-16 parts of filler, 5-8 parts of barium sulfate, 7-10 parts of magnesium hydroxide, and 0.2-0.4 part of calcium propionate. The novel waterproof rubber material has favorable waterproofness, is acid-resistant, oil-resistant and flame-resistant, and can well meet requirements in production.

Owner:ANHUI WEIWEI RUBBER PARTS GRP

A kind of water-based nail polish base adhesive and preparation method thereof

ActiveCN106726777BImprove adhesionEnhanced resistance to peelingCosmetic preparationsNon-macromolecular adhesive additivesPolymer scienceOligomer

The invention provides a water-based nail polish basic sticking material. The water-based nail polish basic sticking material is prepared from the following components: modified ABS (Acrylonitrile Butadiene Styrene) resin, modified water-soluble rosin resin, a modified specific acrylate monomer, a modified general acrylate monomer, a siloxane low-polymer water solution, a water-soluble amino / vinyl functional group siloxane copolymerized oligomer, a siloxane monomer, a chain transfer agent, a reaction type emulsifier, an azo initiator, de-ionized water, a pH (Potential of Hydrogen) regulator, adhesion promoting resin and a water-based chelate. The invention further provides a preparation method of the water-based nail polish basic sticking material. By adopting the water-based nail polish basic sticking material provided by the invention, a scheme for solving the problem is pertinently provided, and the quality and performances of a nail polish basic material are greatly improved by utilizing relatively low cost, so that the quality and performances can get close to or basically meet the expectation of the society and users; a real and feasible scheme is provided for elimination of a coating technology and a nail polish removing process, which cause injuries to bodies, of toxic and harmful nail polish.

Owner:瑞雅科医药(北京)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com