Novel waterproof rubber material

A rubber material and a new type of technology, applied in the field of new waterproof rubber materials, can solve the problems of long processing time, low apparent density, and heavy processing pollution, and achieve the effects of good waterproof performance, reduced mechanical performance, and reduced service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

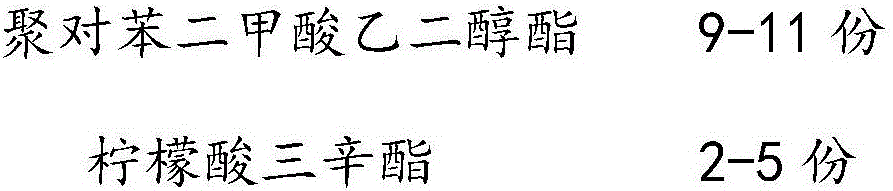

[0026] The present invention proposes a new type of waterproof rubber material, and its raw materials include by weight:

[0027]

[0028]

[0029] The invention also discloses a preparation method of a novel waterproof rubber material, comprising the following steps:

[0030] (1) Mix nano-silica sol, VAE emulsion, hydrated silica, barium sulfate and magnesium hydroxide according to the weight ratio of 1:3, add deionized water and mix thoroughly, then add calcium propionate and heat to boiling under constant stirring. After the viscous material, dry it and grind it for later use;

[0031] (2) Add polyacrylonitrile to the dimethyl sulfoxide solution, stir and beat, the concentration is controlled at 13%, then add methacrylic acid and mix evenly, and dry the graphite and fly ash microbeads in a vacuum drying oven , according to the solid-liquid ratio of 1:4, add deionized water, then add sodium dodecyl sulfate and continue to ultrasonically stir evenly, take the supernata...

Embodiment 2

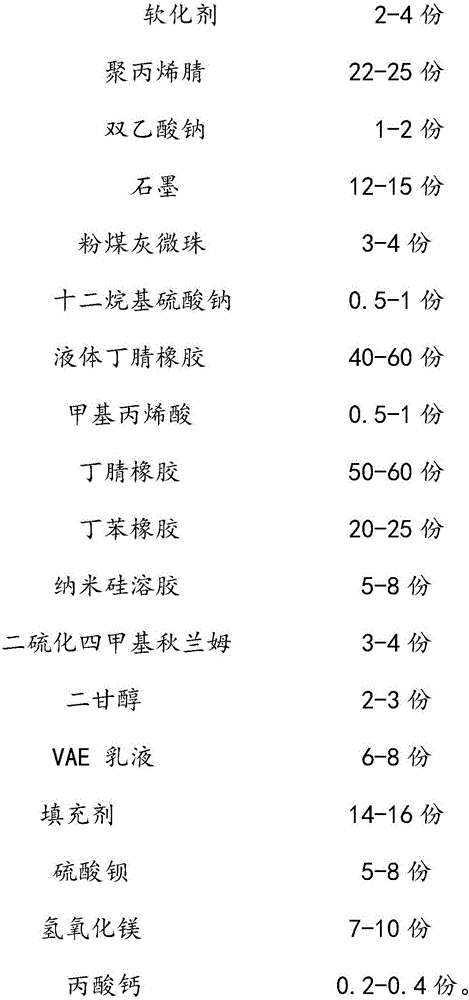

[0035] The present invention proposes a new type of waterproof rubber material, and its raw materials include by weight:

[0036]

[0037]

[0038] The invention also discloses a preparation method of a novel waterproof rubber material, comprising the following steps:

[0039] (1) Mix nano-silica sol, VAE emulsion, hydrated silica, barium sulfate and magnesium hydroxide according to the weight ratio of 1:3, add deionized water and mix thoroughly, then add calcium propionate and heat to boiling under constant stirring. After the viscous material, dry it and grind it for later use;

[0040] (2) Add polyacrylonitrile to the dimethyl sulfoxide solution, stir and beat, the concentration is controlled at 13%, then add methacrylic acid and mix evenly, and dry the graphite and fly ash microbeads in a vacuum drying oven , according to the solid-liquid ratio of 1:4, add deionized water, then add sodium dodecyl sulfate and continue to ultrasonically stir evenly, take the supernata...

Embodiment 3

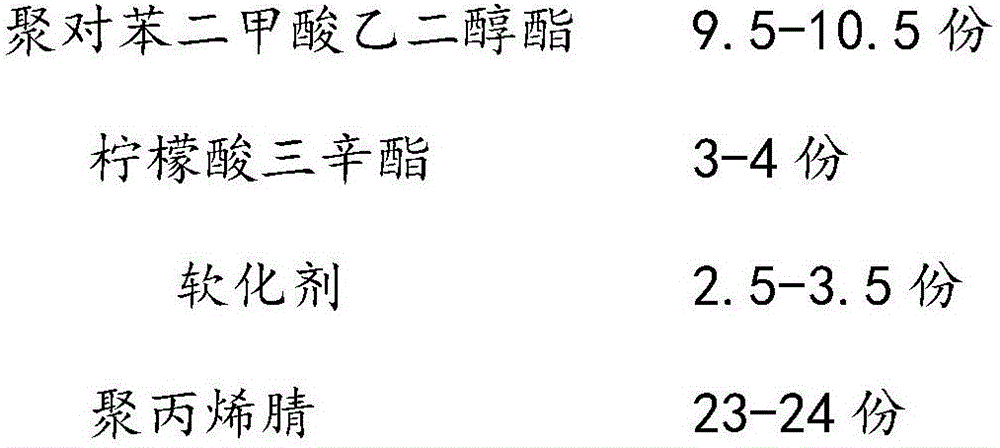

[0044] The present invention proposes a new type of waterproof rubber material, and its raw materials include by weight:

[0045]

[0046] The invention also discloses a preparation method of a novel waterproof rubber material, comprising the following steps:

[0047] (1) Mix nano-silica sol, VAE emulsion, hydrated silica, barium sulfate and magnesium hydroxide according to the weight ratio of 1:3, add deionized water and mix thoroughly, then add calcium propionate and heat to boiling under constant stirring. After the viscous material, dry it and grind it for later use;

[0048] (2) Add polyacrylonitrile to the dimethyl sulfoxide solution, stir and beat, the concentration is controlled at 13%, then add methacrylic acid and mix evenly, and dry the graphite and fly ash microbeads in a vacuum drying oven , according to the solid-liquid ratio of 1:4, add deionized water, then add sodium dodecyl sulfate and continue to ultrasonically stir evenly, take the supernatant and add i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com