A kind of water-based nail polish base adhesive and preparation method thereof

A nail polish and adhesive technology, applied in manicure, pedicure, adhesive and other directions, can solve the problems of high price, difficult to meet the special physical state and chemical resistance state of nail polish, difficult to retain, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

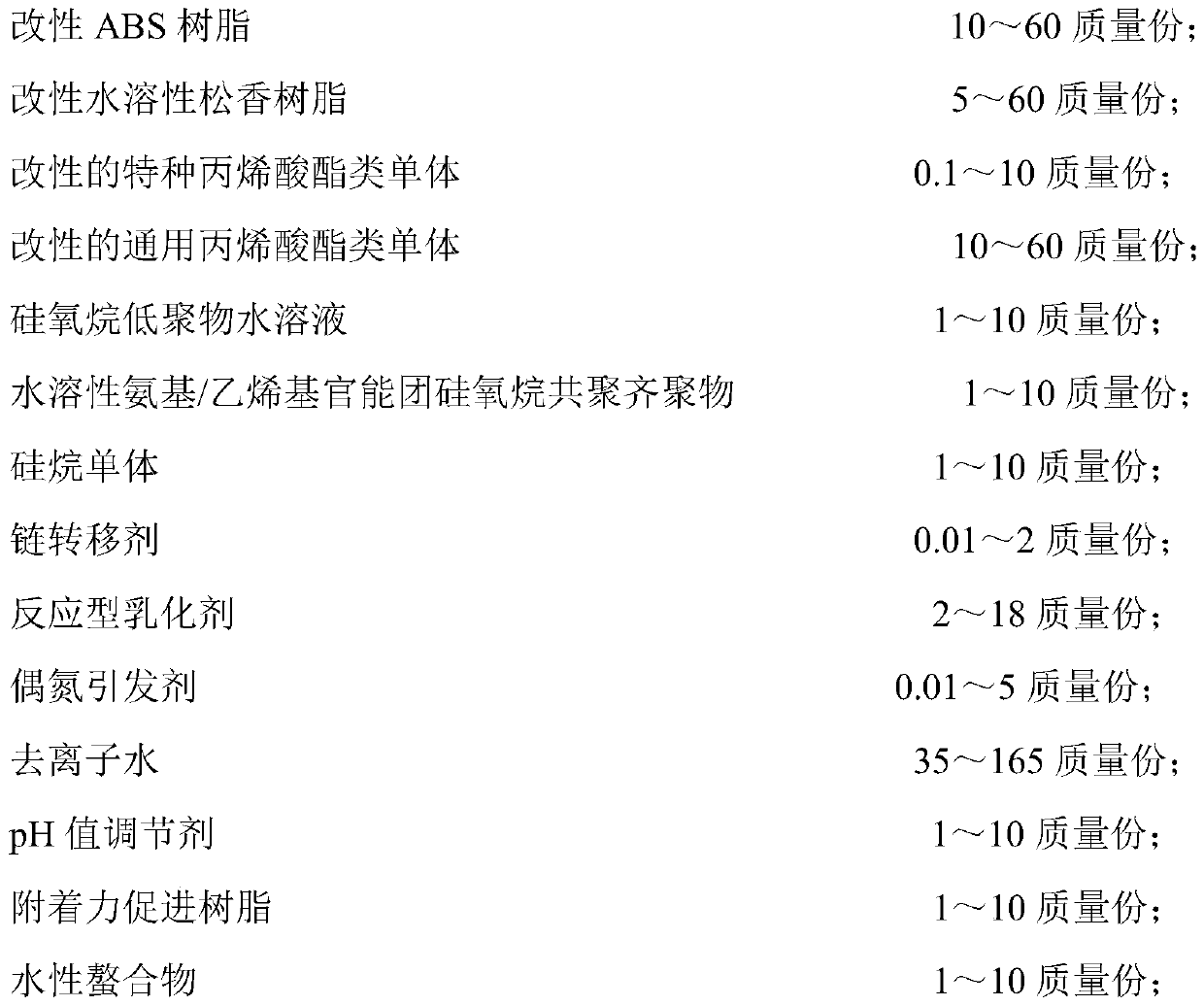

Method used

Image

Examples

Embodiment 1

[0072] The preparation method of the water-based nail polish base bonding material provided in the present embodiment is as follows:

[0073] (1), take each component according to the mass fraction of each component, and carry out modification treatment; Wherein ABS resin obtains soluble ABS resin after modification; Water-soluble rosin resin molecular weight diversity changes after modification; Acetoacetic acid Hydrolysis resistance was enhanced after modification with ethyl methacrylate.

[0074] (2), the modified ABS resin of 20 mass parts is dissolved in the mixture of the butyl methacrylate of 20 mass parts, methyl methacrylate, butyl acrylate, stir until completely dissolving;

[0075] (3) Add an appropriate amount of 5% NaOH aqueous solution to the mixed solution, continue to stir, and separate the water layer after the color changes;

[0076] (4) Add 0.5 parts by mass of modified acetoacetoxyethyl methacrylate;

[0077] (5) 2 parts by mass of HYDROSIL 2627 Reactiv...

Embodiment 2

[0107] The preparation method of the water-based nail polish base bonding material provided in the present embodiment is as follows:

[0108] (1), take each component according to the mass fraction of each component, and carry out modification treatment; Wherein ABS resin obtains soluble ABS resin after modification; Water-soluble rosin resin molecular weight diversity changes after modification; Hydrolysis resistance was enhanced after modification with ethyl methacrylate.

[0109] (2), the modified ABS resin of 35 parts by mass is dissolved in the mixture of butyl methacrylate and methyl methacrylate of 35 parts by mass, stir until fully dissolved;

[0110] (3) Add an appropriate amount of 5% NaOH aqueous solution to the mixed solution, continue to stir, and separate the water layer after the color changes;

[0111] (4) Add 3 parts by mass of modified acetoacetoxy ethyl methacrylate;

[0112] (5) 5 mass parts of HYDROSIL 2627 Reactive organofunctional siloxane oligomer aqu...

Embodiment 3

[0142] The preparation method of the water-based nail polish base bonding material provided in the present embodiment is as follows:

[0143] (1), take each component according to the mass fraction of each component, and carry out modification treatment; Wherein ABS resin obtains soluble ABS resin after modification; Water-soluble rosin resin molecular weight diversity changes after modification; Hydrolysis resistance was enhanced after modification with ethyl methacrylate.

[0144] (2), the modified ABS resin of 50 mass parts is dissolved in the butyl methacrylate of 40 mass parts, stir until completely dissolving;

[0145] (3) Add an appropriate amount of 5% NaOH aqueous solution to the mixed solution, continue to stir, and separate the water layer after the color changes;

[0146] (4) Add 6 parts by mass of modified acetoacetoxy ethyl methacrylate;

[0147] (5) 8 parts by mass of HYDROSIL 2627 Reactive organofunctional siloxane oligomer aqueous solution, 8 parts by mass...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com