Chip multilayer ceramic capacitor dielectric ceramic slurry and preparation method of dielectric

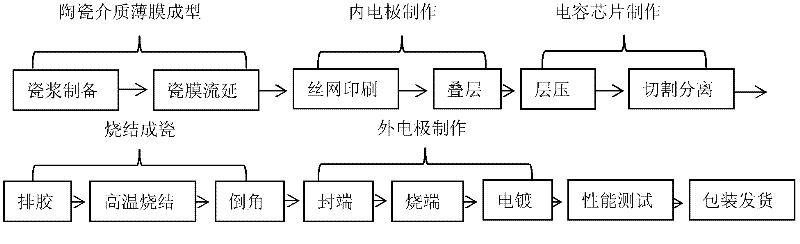

A multi-layer ceramic capacitor and dielectric technology, applied in ceramics, inorganic insulators, etc., can solve the problems of non-compliance with low carbon, high production cost, and high energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

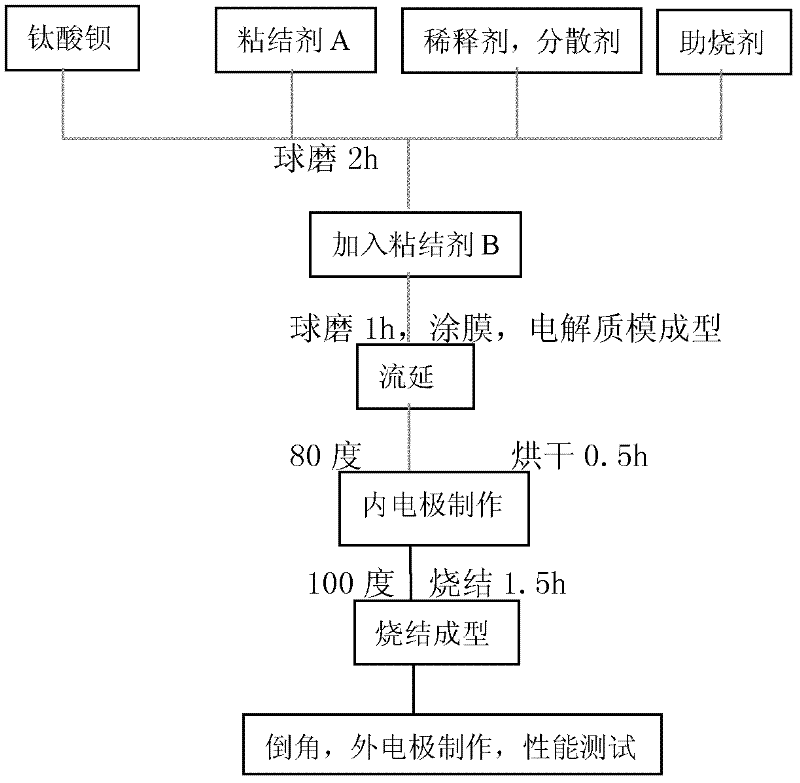

[0028] The present invention takes barium titanate (500nm in particle size) as the main component (92-97% of the mass of the slurry), adding a proper amount of diluent, dispersant, defoamer, binder A, and a certain amount of Sintering aid, put it in a ball mill for 2 hours, take it out, add binder B, continue ball milling for 1 hour, then spread the obtained slurry evenly on the aluminum plate, dry it at room temperature, put it in a resistance furnace for sintering, and sinter After the completion, take out the aluminum plate for detection; among them, the main function of the adhesive is to make the slurry stick to the aluminum plate when coating the plate. The adhesive A is mainly composed of polyurethane acrylate, and B is mainly composed of diamine and imidazole compounds. , Silane coupling agent, the ratio of A and B is about 5:1, adding A and B at the same time will make the slurry solidify quickly in a short time, so that the slurry cannot be fully ground.

[0029] (1)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com