Preparation method for water-preserving and salt-tolerant alkaline concrete internal curing agent

A technology of concrete internal and curing agent, which is applied in the field of concrete admixture to achieve good construction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

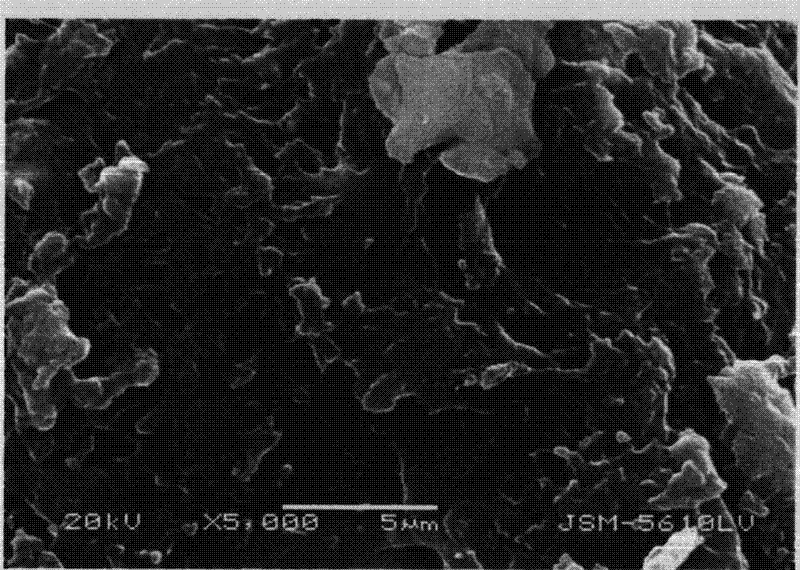

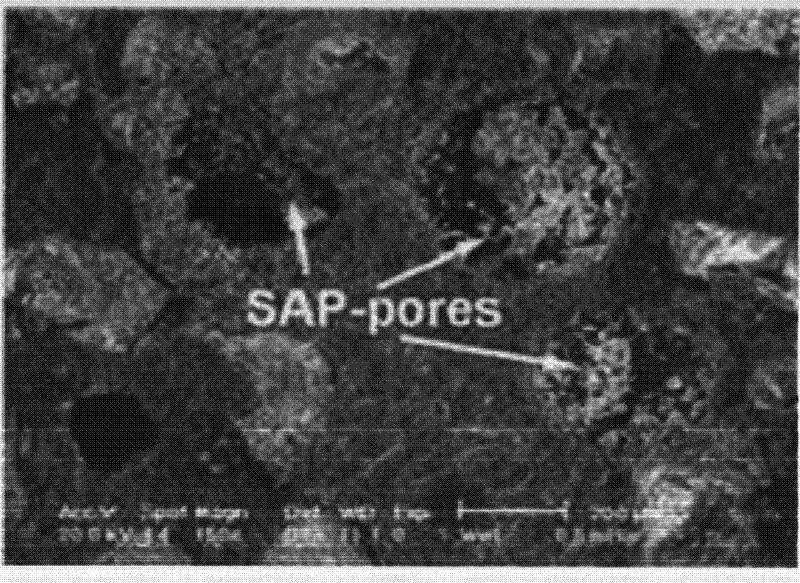

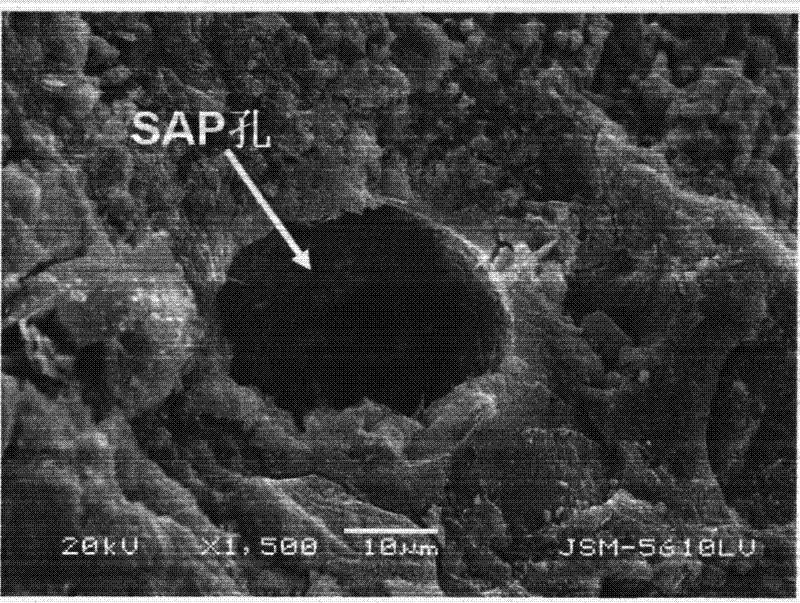

Image

Examples

Embodiment 1

[0022] (1) Weigh 2.5g of tapioca starch, 1g of kaolin, 0.02g of ammonium cerium nitrate, 0.18g of ammonium persulfate and 0.012g of N,N'-methylenebisacrylamide into a beaker, dissolve in 100ml of distilled water, and use glass Stir the rod until fully dissolved to obtain a mixed solution; put the mixed solution into a four-neck flask and place it in a water bath at 80°C and stir thoroughly;

[0023] (2) Weigh 7.5g of acrylamide and 2.5g of 2-acrylamido-2-methylpropanesulfonic acid into a beaker, add 100ml of deionized water, and stir evenly to obtain a monomer solution;

[0024] (3) At 80°C, add the monomer solution prepared in step (2) dropwise into a four-necked flask, and control the monomer solution addition time at 0.5 hours; carry out the mixed solution prepared in step (1) Graft copolymerization reaction with the monomer solution, the reaction time is 4 hours, and the gel-like graft copolymer is obtained after the reaction;

[0025] (4) The graft copolymer prepared in ...

Embodiment 2

[0028] (1) Weigh 2.5g of tapioca starch, 1g of bentonite, 0.015g of cerium ammonium nitrate, 0.135g of potassium persulfate and 0.012g of N, N'-methylenebisacrylamide into a beaker, dissolve in 100ml of distilled water, and use a glass rod Stir until fully dissolved to obtain a mixed solution; put the mixed solution into a four-necked flask, place it in a 70°C water bath and stir thoroughly;

[0029] (2) Weigh 6g of acrylamide and 4g of sodium methacrylate into a beaker, add 100ml of deionized water, and stir until fully dissolved to obtain a monomer solution;

[0030] (3) At 70°C, add the monomer solution prepared in step (2) dropwise into a four-necked flask, and control the time for adding the monomer solution to 0.5 hours; carry out the mixed solution prepared in step (1) Graft copolymerization reaction with the monomer solution, the reaction time is 4 hours, and the gel-like graft copolymer is obtained after the reaction;

[0031] (4) The graft copolymer prepared in step...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com