Anti-oxidizing rubber material

A rubber material, anti-oxidation technology, applied in the field of rubber materials, can solve difficult problems such as hardness, air permeability, flying, singleness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

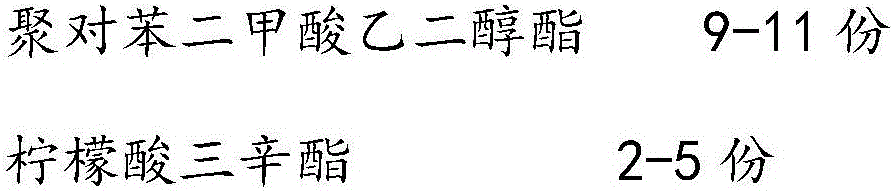

[0027] The present invention proposes a kind of anti-oxidation rubber material, and raw material comprises by weight:

[0028]

[0029]

[0030] The invention also discloses a preparation method of an anti-oxidation rubber material, comprising the following steps:

[0031] (1) Mix nano-silica sol, VAE emulsion, hydrated silica, tea polyphenols and magnesium hydroxide, add deionized water and mix thoroughly according to the weight ratio of 1:3, then add calcium propionate and heat to boiling under constant stirring. After forming a viscous substance, dry it and grind it for later use;

[0032] (2) Add polyacrylonitrile to the dimethyl sulfoxide solution, stir and beat, and control the concentration at 13%, then add methacrylic acid to mix and stir evenly, dry the graphite and fly ash microbeads in a vacuum oven , add deionized water according to the solid-to-liquid ratio of 1:4, then add sodium lauryl sulfate and continue to ultrasonically stir evenly, take the supernata...

Embodiment 2

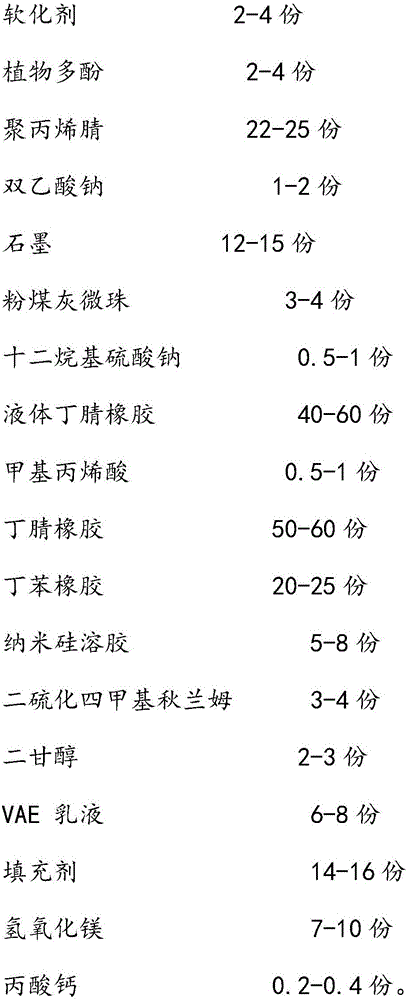

[0036] The present invention proposes a kind of anti-oxidation rubber material, and raw material comprises by weight:

[0037]

[0038]

[0039] The invention also discloses a preparation method of an anti-oxidation rubber material, comprising the following steps:

[0040] (1) Mix nano-silica sol, VAE emulsion, hydrated silica, tea polyphenols and magnesium hydroxide, add deionized water and mix thoroughly according to the weight ratio of 1:3, then add calcium propionate and heat to boiling under constant stirring. After forming a viscous substance, dry it and grind it for later use;

[0041] (2) Add polyacrylonitrile to the dimethyl sulfoxide solution, stir and beat, and control the concentration at 13%, then add methacrylic acid to mix and stir evenly, dry the graphite and fly ash microbeads in a vacuum oven , add deionized water according to the solid-to-liquid ratio of 1:4, then add sodium lauryl sulfate and continue to ultrasonically stir evenly, take the supernata...

Embodiment 3

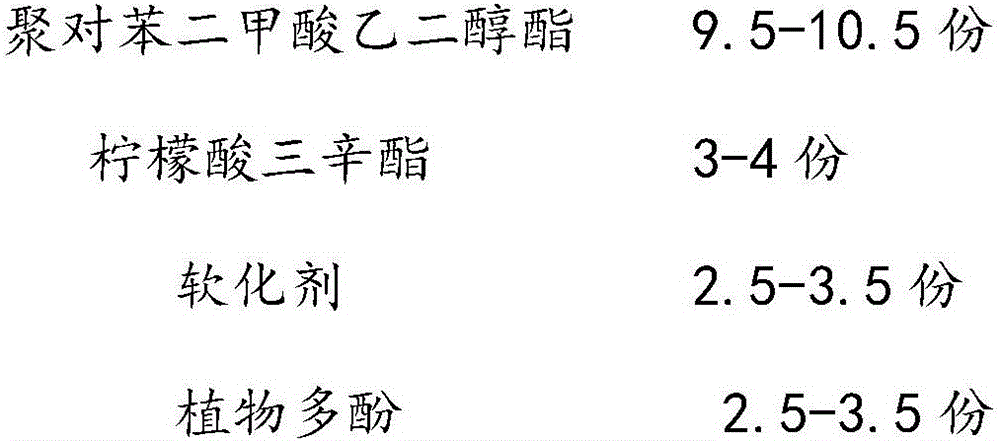

[0045] The present invention proposes a kind of anti-oxidation rubber material, and raw material comprises by weight:

[0046]

[0047] The invention also discloses a preparation method of an anti-oxidation rubber material, comprising the following steps:

[0048] (1) Mix nano-silica sol, VAE emulsion, hydrated silica, tea polyphenols and magnesium hydroxide, add deionized water and mix thoroughly according to the weight ratio of 1:3, then add calcium propionate and heat to boiling under constant stirring. After forming a viscous substance, dry it and grind it for later use;

[0049] (2) Add polyacrylonitrile to the dimethyl sulfoxide solution, stir and beat, and control the concentration at 13%, then add methacrylic acid to mix and stir evenly, dry the graphite and fly ash microbeads in a vacuum oven , add deionized water according to the solid-to-liquid ratio of 1:4, then add sodium lauryl sulfate and continue to ultrasonically stir evenly, take the supernatant and add i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com