Polyimide dielectric material and dielectric film

A polyimide electrical and dielectric material technology, applied in the field of polyimide dielectric materials and dielectric films, can solve the problems of complex and expensive synthesis of new monomers, and achieve the effects of reducing dielectric loss and improving dielectric properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

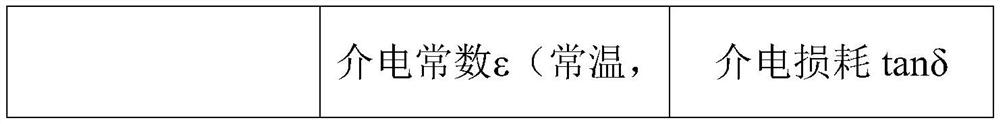

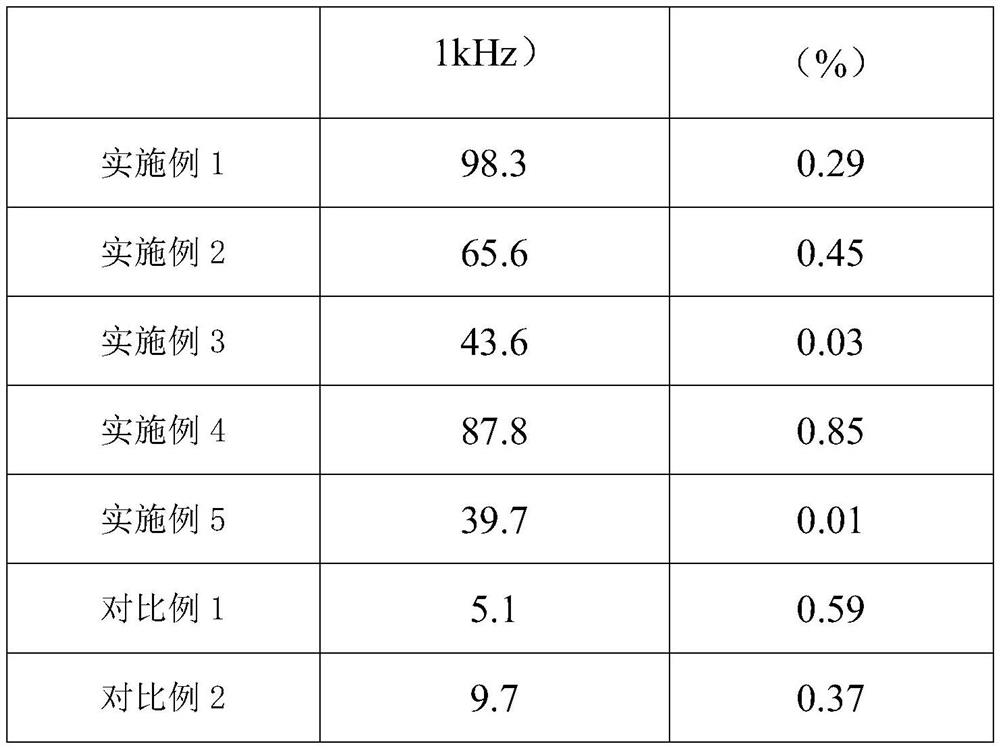

Examples

Embodiment 1

[0020] A kind of dielectric thin film, its preparation method comprises the steps:

[0021] S1. Under nitrogen atmosphere, add 2mmol 3,5-diaminobenzoic acid and 8mmol 4,4'-diaminodiphenyl ether into 50ml of N,N-dimethylacetamide solvent, stir until completely dissolved , then add 10mmol 3,3',4,4'-diphenyl ether tetracarboxylic dianhydride, continue to stir until it is completely dissolved, and after stirring at room temperature for 4 hours, a polyamic acid solution is obtained; add 8ml of pyridine to the polyamic acid solution As an imidization agent, add 1.2ml of acetic anhydride as a dehydrating agent after the dispersion is complete, and after stirring and reacting for 6 hours, a polyimide solution is obtained;

[0022] S2. After mixing 0.5g carbon nanotubes and 5mL concentrated nitric acid, ultrasonically mix, heat and reflux for 6h, after the end, filter, wash with water until neutral, and dry to obtain oxidized carbon nanotubes; the above-mentioned oxidized carbon nanotu...

Embodiment 2

[0025] A kind of dielectric thin film, its preparation method comprises the steps:

[0026] S1. Under nitrogen atmosphere, add 2mmol 3,5-diaminobenzoic acid and 8mmol 4,4'-diaminodiphenyl ether into 50ml of N,N-dimethylacetamide solvent, stir until completely dissolved , then add 10mmol 3,3',4,4'-biphenyltetracarboxylic dianhydride, continue to stir until completely dissolved, and stir at room temperature for 4 hours to obtain a polyamic acid solution; add 8ml of pyridine to the polyamic acid solution as Imidation agent, after the dispersion is complete, add 1.2ml acetic anhydride as a dehydrating agent, and stir and react for 6 hours to obtain a polyimide solution;

[0027] S2. After mixing 0.5g carbon nanotubes and 5mL concentrated nitric acid, ultrasonically mix, heat and reflux for 6h, after the end, filter, wash with water until neutral, and dry to obtain oxidized carbon nanotubes; the above-mentioned oxidized carbon nanotubes and 10g Mix thionyl chloride, ultrasonically...

Embodiment 3

[0030] A kind of dielectric thin film, its preparation method comprises the steps:

[0031] S1. Under nitrogen atmosphere, add 2mmol 3,5-diaminobenzoic acid and 8mmol 4,4'-diaminodiphenyl ether into 50ml of N,N-dimethylacetamide solvent, stir until completely dissolved , then add 10mmol of bisphenol A diether dianhydride, continue to stir until it is completely dissolved, and react with stirring at room temperature for 4 hours to obtain a polyamic acid solution; add 8ml of pyridine to the polyamic acid solution as an imidization agent, and the dispersion is complete Then add 1.2ml of acetic anhydride as a dehydrating agent, and stir for 6 hours to obtain a polyimide solution;

[0032] S2. After mixing 0.5g carbon nanotubes and 5mL concentrated nitric acid, ultrasonically mix, heat and reflux for 6h, after the end, filter, wash with water until neutral, and dry to obtain oxidized carbon nanotubes; the above-mentioned oxidized carbon nanotubes and 10g Mix thionyl chloride, ultr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| relative permittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com