PC/ABS alloy material as well as preparation method and application thereof

A technology of alloy materials and ABS resin, which is applied in the field of PC/ABS alloy materials and its preparation, can solve the problems of performance degradation, inability to realize low dielectric, flame retardancy, and heat conduction of PC/ABS alloy materials, and achieve flame retardancy and Improved electrical conductivity, suitable for mass production applications, and excellent flame retardant properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

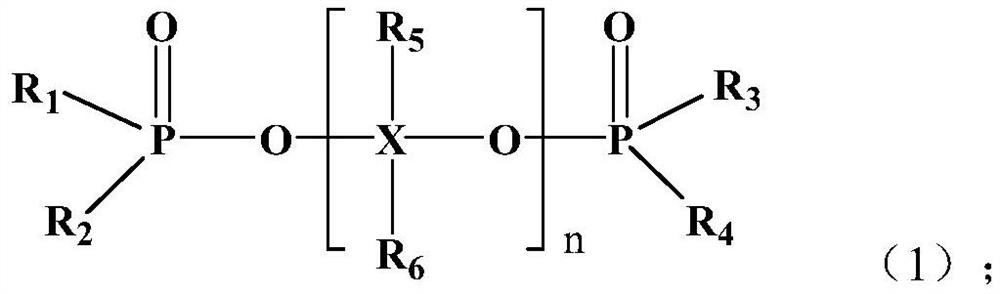

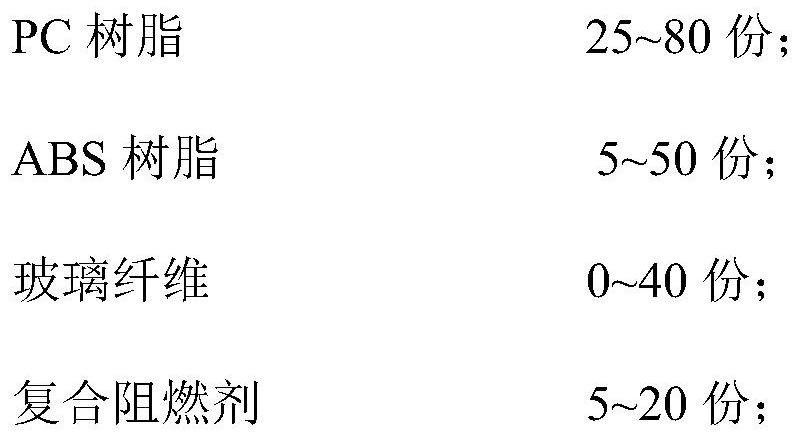

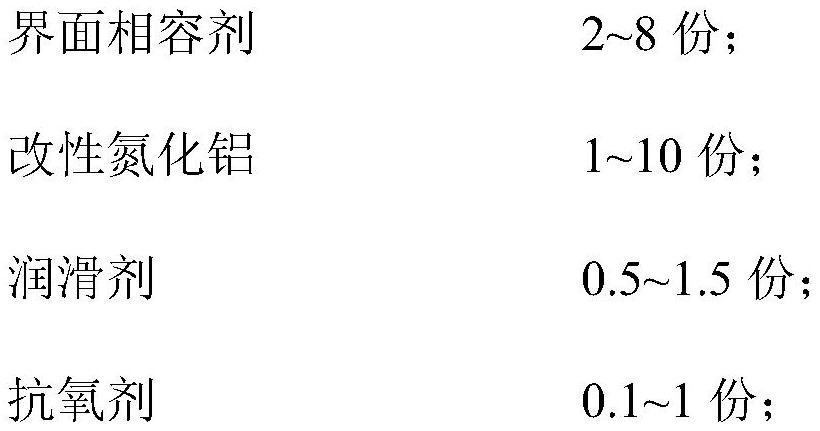

Method used

Image

Examples

Embodiment 1

[0049] Preparation of low dielectric flame retardant PC / ABS alloy material:

[0050] 66 parts (6.6kg) of dry-treated PC resin (300°C, 1.2kg melt flow rate 11.9g / 10min), 16.5 parts ( 1.65kg), maleic anhydride grafted ethylene-octene copolymer (grafting rate 1.3%) 5 parts (0.5kg), white oil 1 part (0.1kg), fully mixed at room temperature; 2 parts (0.2kg) of aluminum nitride (average particle size 10 μm) treated with 2% γ-aminopropyltriethoxysilane, 1,3-phenylene diphosphate tetrakis (2,6-di 10 parts (1kg) of methyl phenyl) ester, 0.5 part of polytetrafluoroethylene (0.05kg), 0.8 part of tetrakis [β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid] pentaerythritol ester (0.08kg), continue to mix evenly. Then, it was introduced into the main feeding port of LABTECH co-rotating twin-screw extruder (screw diameter 16mm, aspect ratio 40), and was melted and kneaded and extruded under the process conditions of 280°C, 250rpm, and feeding rate 4kg / h, cooled, Pelletizing to prepare l...

Embodiment 2

[0052] Preparation of low dielectric flame retardant PC / ABS alloy material:

[0053] 65.6 parts of dry treated PC resin (300°C, 1.2kg melt flow rate 11.9g / 10min), 16.4 parts of dry treated ABS resin (220°C, 10kg melt flow rate 15.8g / 10min), maleic anhydride 5 parts of branched ethylene-octene copolymer (grafting rate 1.3%), 1 part of white oil, fully mixed at room temperature; 2 parts of treated aluminum nitride (average particle size 10 μm), 10 parts of 1,3-phenylene diphosphate tetrakis (2,6-dimethylphenyl) ester, flake graphene (thickness 100 nm, plane dimension width 20 μm) 0.5 part, polytetrafluoroethylene 0.5 part, tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol 0.8 part, and continue to mix evenly. Then, it was introduced into the main feeding port of LABTECH co-rotating twin-screw extruder (screw diameter 16mm, aspect ratio 40), and was melted and kneaded and extruded under the process conditions of 280°C, 250rpm, and feeding rate 4kg / h, coo...

Embodiment 3

[0055] Preparation of low dielectric flame retardant PC / ABS alloy material:

[0056] 65.2 parts of dry treated PC resin (300°C, 1.2kg melt flow rate 11.9g / 10min), 16.3 parts of dry treated ABS resin (220°C, 10kg melt flow rate 15.8g / 10min), maleic anhydride 5 parts of branched ethylene-octene copolymer (grafting rate 1.3%), 1 part of white oil, fully mixed at room temperature; 2 parts of treated aluminum nitride (average particle size 10 μm), 10 parts of 1,3-phenylene diphosphate tetrakis (2,6-dimethylphenyl) ester, flake graphene (thickness 100 nm, plane dimension width 20 μm) 1 part, 0.5 part of polytetrafluoroethylene, 0.8 part of tetrakis [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester, and continue to mix evenly. Then, it was introduced into the main feeding port of LABTECH co-rotating twin-screw extruder (screw diameter 16mm, aspect ratio 40), and was melted and kneaded and extruded under the process conditions of 280°C, 250rpm, and feeding rate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com