Thin film multilayer body, electronic device using such thin film multilayer body, actuator, and method for manufacturing actuator

A technology of laminates and regulators, applied in the manufacture/assembly of piezoelectric/electrostrictive devices, semiconductor/solid-state device manufacturing, chemical instruments and methods, etc., can solve the problems of piezoelectricity or electrostriction degradation, Problems such as crystallographic orientation change and polarization direction deviation, etc., to achieve the effect of excellent crystallinity, good crystallinity, and good polarization amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

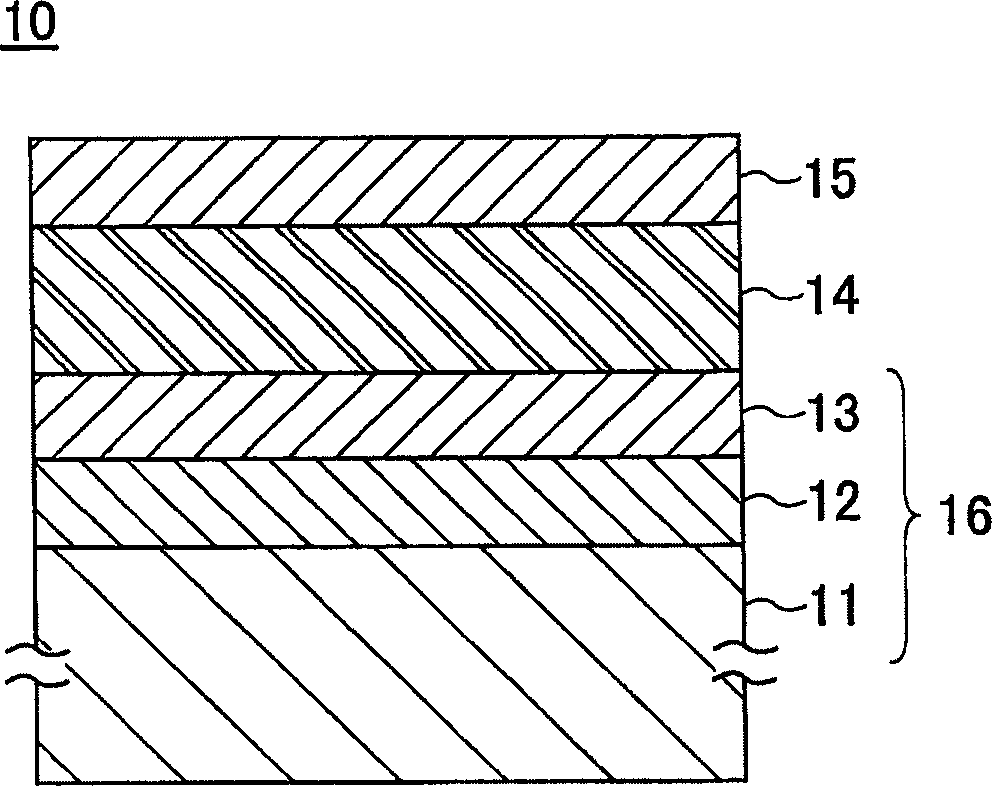

[0054] figure 1 It is a cross-sectional view of the regulator according to the first embodiment of the present invention.

[0055] refer to figure 1 The regulator 10 of this embodiment has a structure in which an intermediate layer 12 , a lower conductive layer 13 , an oxide layer 14 , and an upper conductive layer 15 are sequentially stacked on a single crystal substrate 11 . The regulator 10 is stretched longitudinally by applying a voltage between the lower conductive layer 13 and the upper conductive layer 15 , utilizing the piezoelectricity and electrostriction of the oxide layer 14 , for example, utilizing the longitudinal effect of the oxide layer 14 .

[0056] The single crystal substrate 11 is, for example, a silicon or gallium-arsenic (GaAs) single crystal substrate. The thickness of the single crystal substrate 11 is about 500 μm, and the main surface is a (001) plane. By setting the principal plane as (001), the plane orientations of the layers epitaxially grown...

no. 1 Embodiment

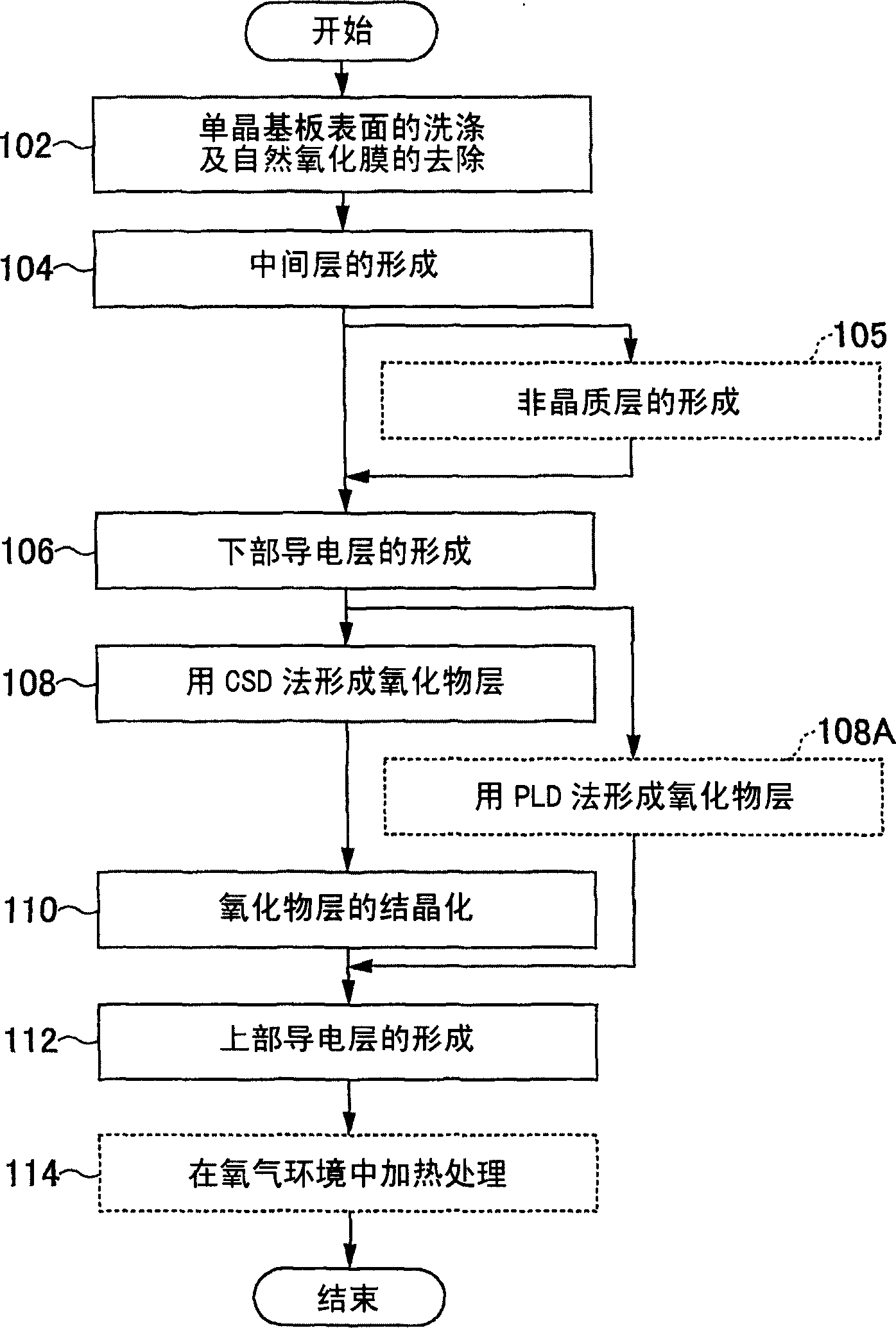

[0087] Hereinafter, a regulator according to an example of the present embodiment will be described. The regulator of this embodiment is formed by sequentially laminating a platinum film as a lower conductive layer (electrode), a PZT film as an oxide layer, and an upper conductive layer on a silicon single crystal substrate.

[0088] First, after washing the 2-inch silicon single crystal substrate with the (001) plane as the main surface, it is immersed in 9% by mass of dilute hydrofluoric acid to remove the natural oxide film (SiO2) of the single silicon crystal substrate. 2 ).

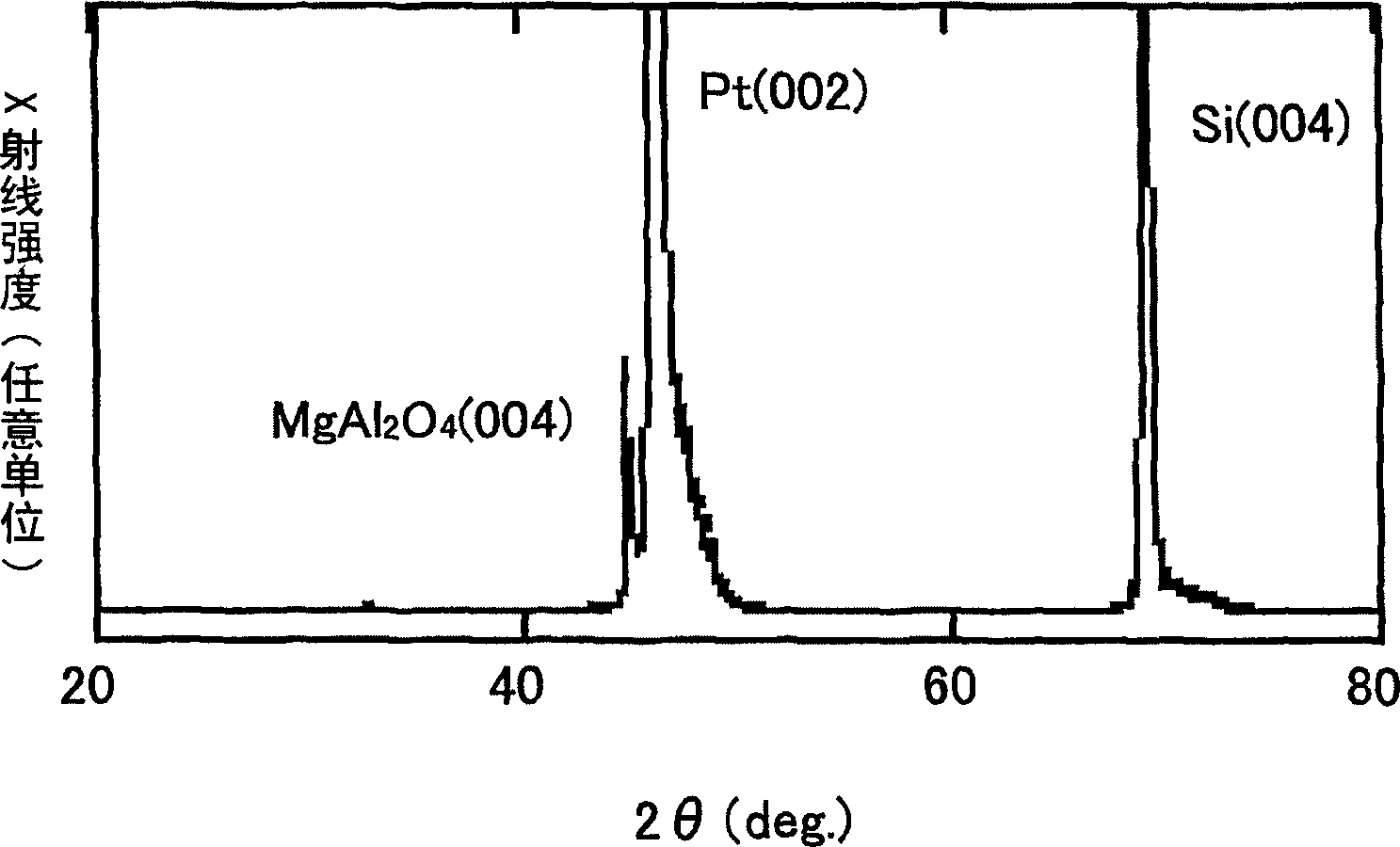

[0089] Then, magnesium aluminate spinel with a thickness of 100 nm was formed on the silicon single crystal substrate by the CVD method. Specifically, the silicon single crystal substrate is placed in a CVD film forming chamber and kept at a substrate temperature of 900°C. Mg raw material adopts MgCl 2 , heated to 500°C in the Mg source chamber to make it evaporate, and the carrier gas is hydrogen...

no. 2 Embodiment

[0096] The regulator of this embodiment is the same as that of the first embodiment except that an iridium film is formed instead of the platinum film of the lower conductive layer of the first embodiment, and PLZT is used for the oxide layer. The description of the same manufacturing process as that of the first embodiment is omitted.

[0097] The regulator of this example is formed by sequentially laminating magnesium aluminate spinel, an iridium film as a lower conductive layer, a PLZT film as an oxide layer, and an upper conductive layer on a silicon single crystal substrate.

[0098] The iridium film was formed to a thickness of 200 nm on the magnesium aluminate spinel film by sputtering. Specifically, make the inside of the sputtering device reach 1Pa (7.5×10 -3 Torr) while flowing 30 sccm of argon gas and 1 sccm of oxygen gas, the substrate was heated to 600° C. for epitaxial growth.

[0099] The PLZT film is formed on the iridium film by the CSD method. Specifically...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com