Lithium ion battery and cathode material thereof

A technology for lithium-ion batteries and positive electrode materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of not being able to improve the high-temperature storage performance of the battery, and not being able to obtain battery performance, so as to improve the structure and cycle stability and improve the high temperature Storage performance and safety performance, the effect of low and high temperature swelling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

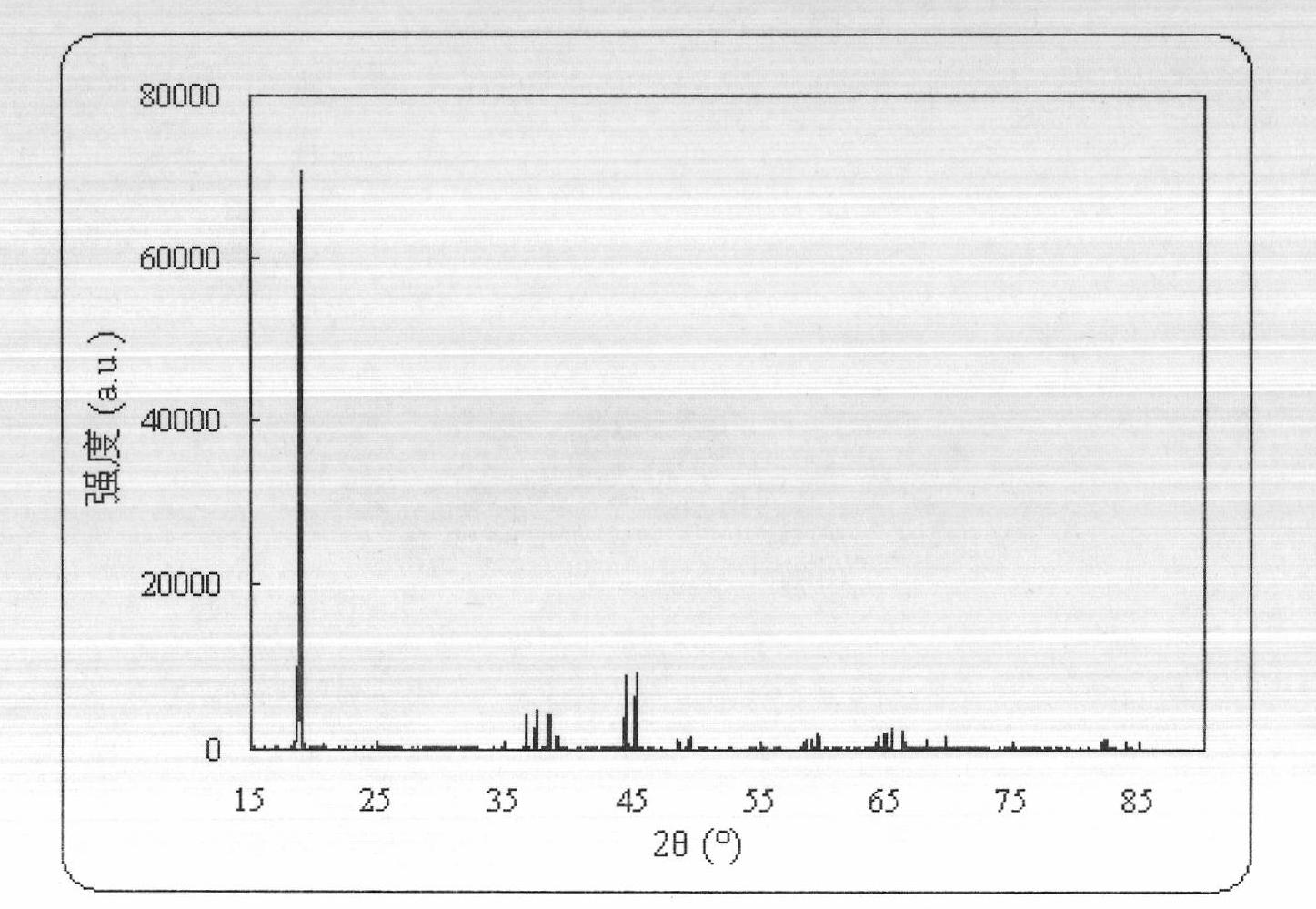

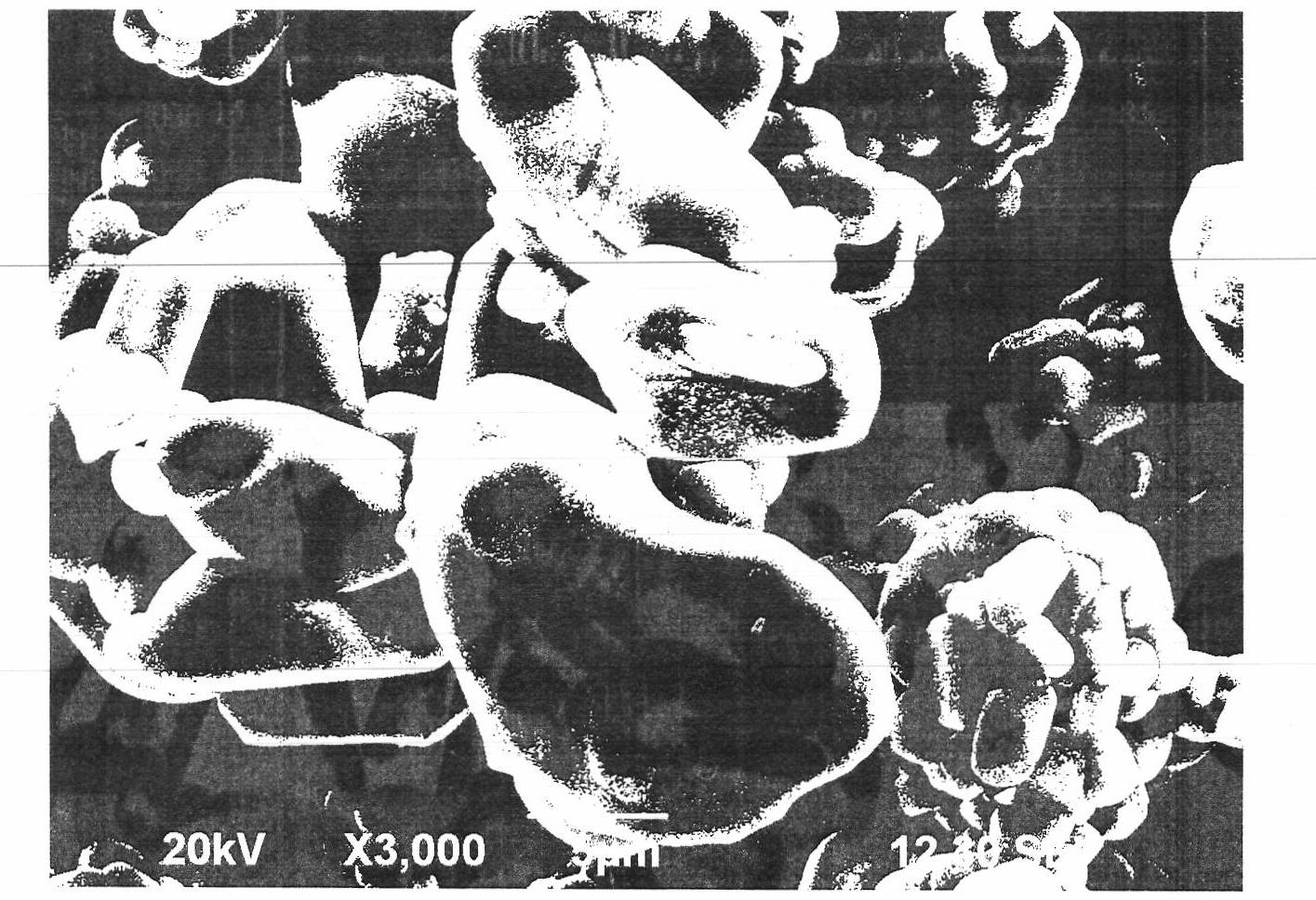

[0046] The positive active material used in this example is LiCoO 2 and Li(Ni 0.5 co 0.2 mn 0.3 )O 2 Mixed composite cathode, where LiCoO 2 The mass fraction is 60%, and its BET is 0.38m 2 / g, doping coating elements and their content are Mg~0.11%, Al~0.08%, Ti~0.15%, La~0.01%. In the XRD pattern, 2θ 1 , 2θ 2 , Δθ 1 , 2θ 3 , 2θ 4 and Δθ 2 18.69°, 18.93°, 0.24°, 44.40°, 45.22° and 0.82° respectively; Li(Ni 0.5 co 0.2 mn 0.3 )O 2 the I 003 / I 104 1.28, LiCoO 2 the I 003 / I 104 is 1.45. The compacted density of the positive electrode prepared with this active material is 4.0g / cm 3 . The XRD spectrum of above-mentioned composite cathode material is as follows figure 1 As shown, its SEM morphology is as figure 2 shown.

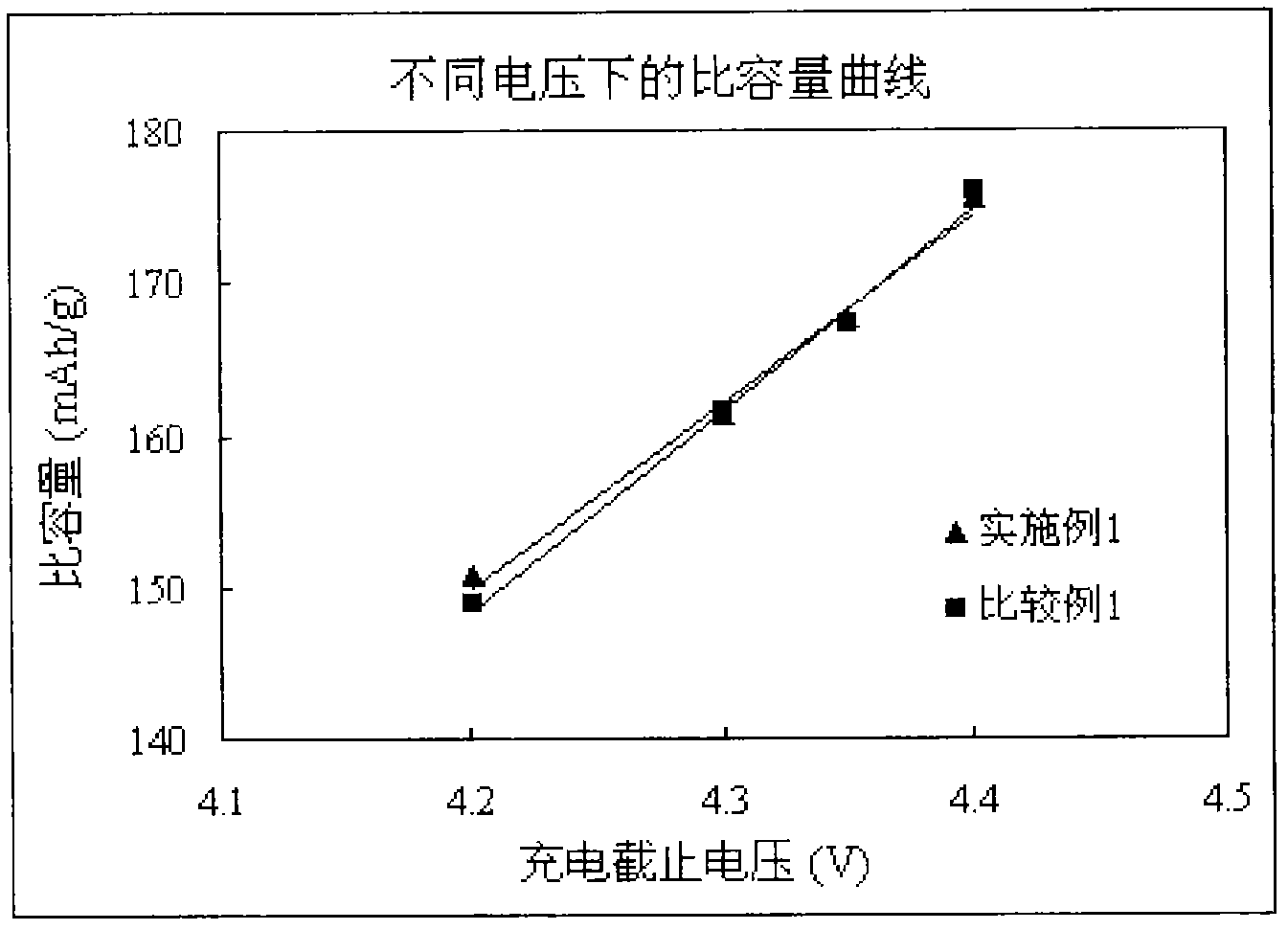

[0047] In the button battery test, the first reversible capacity of the composite positive electrode material at 4.3V cut-off voltage was 161.3mAh / g, and the first reversible capacity at 4.4V cut-off voltage was 175.5mAh / g. Reversible cap...

Embodiment 2

[0050] The positive active material used in this example is LiCoO 2 and Li(Ni 0.5 co 0.2 mn 0.3 )O 2 Mixed composite cathode, where LiCoO 2 The mass fraction is 70%, and its BET is 0.40m 2 / g, doping coating elements and their content are Mg~0.25%, Al~0.05%, Ti~0.08%, Y~0.01%. In the XRD pattern, 2θ 1 , 2θ 2 , Δθ 1 , 2θ 3 , 2θ 4 and Δθ 2 18.65°, 18.90°, 0.25°, 44.40°, 45.20° and 0.80°; Li(Ni 0.5 co 0.2 mn 0.3 )O 2 the I 003 / I 104 1.31, LiCoO 2 the I 003 / I 104 is 1.42. The compacted density of the positive electrode prepared with this active material is 4.0g / cm 3 .

[0051] In the button battery test, the first reversible capacity of the above-mentioned composite positive electrode material at a cut-off voltage of 4.3V was 159.8mAh / g, and the first reversible capacity at a cut-off voltage of 4.4V was 173.0mAh / g.

[0052]In the 454261 pouch battery, the above positive electrode material has a capacity retention rate of 85% after 500 cycles in the voltage...

Embodiment 3

[0054] The positive active material used in this example is LiCoO 2 and Li(Ni 0.5 co 0.2 mn 0.3 )O 2 Mixed composite cathode, where LiCoO 2 The mass fraction is 80%, and its BET is 0.28m 2 / g, doping coating elements and their content are Mg~0.30%, Al~0.08%, Ti~0.06%, Y~0.01%. In the XRD pattern, 2θ 1 , 2θ 2 , Δθ 1 , 2θ 3 , 2θ 4 and Δθ 2 18.71°, 18.94°, 0.23°, 44.42°, 45.23° and 0.81° respectively; Li(Ni 0.5 co 0.2 mn 0.3 )O 2 the I 003 / I 104 1.35, LiCoO 2 the I 003 / I 104 is 1.44. The compacted density of the positive electrode prepared with this active material is 4.0g / cm 3 .

[0055] In the button battery test, the first reversible capacity of the above-mentioned composite positive electrode material was 158.1mAh / g at a cut-off voltage of 4.3V, and the first reversible capacity at a cut-off voltage of 4.4V was 172.4mAh / g.

[0056] In the 454261 pouch battery, the above positive electrode material has a capacity retention rate of 84% after cycling for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com