High-energy X-ray industrial CT ionization detector

An X-ray and ionization-type technology, applied in the field of nuclear technology applications, can solve the problems of low detection efficiency of high-energy accelerator X-rays, and achieve the effects of volume reduction, lower processing precision requirements, and reduced crosstalk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Preferred embodiments of the present invention will be described in detail below.

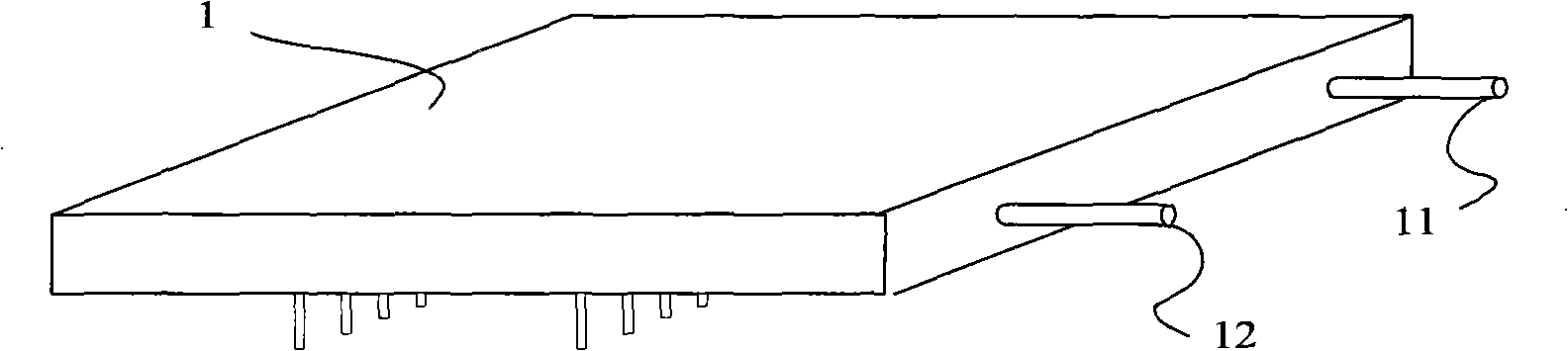

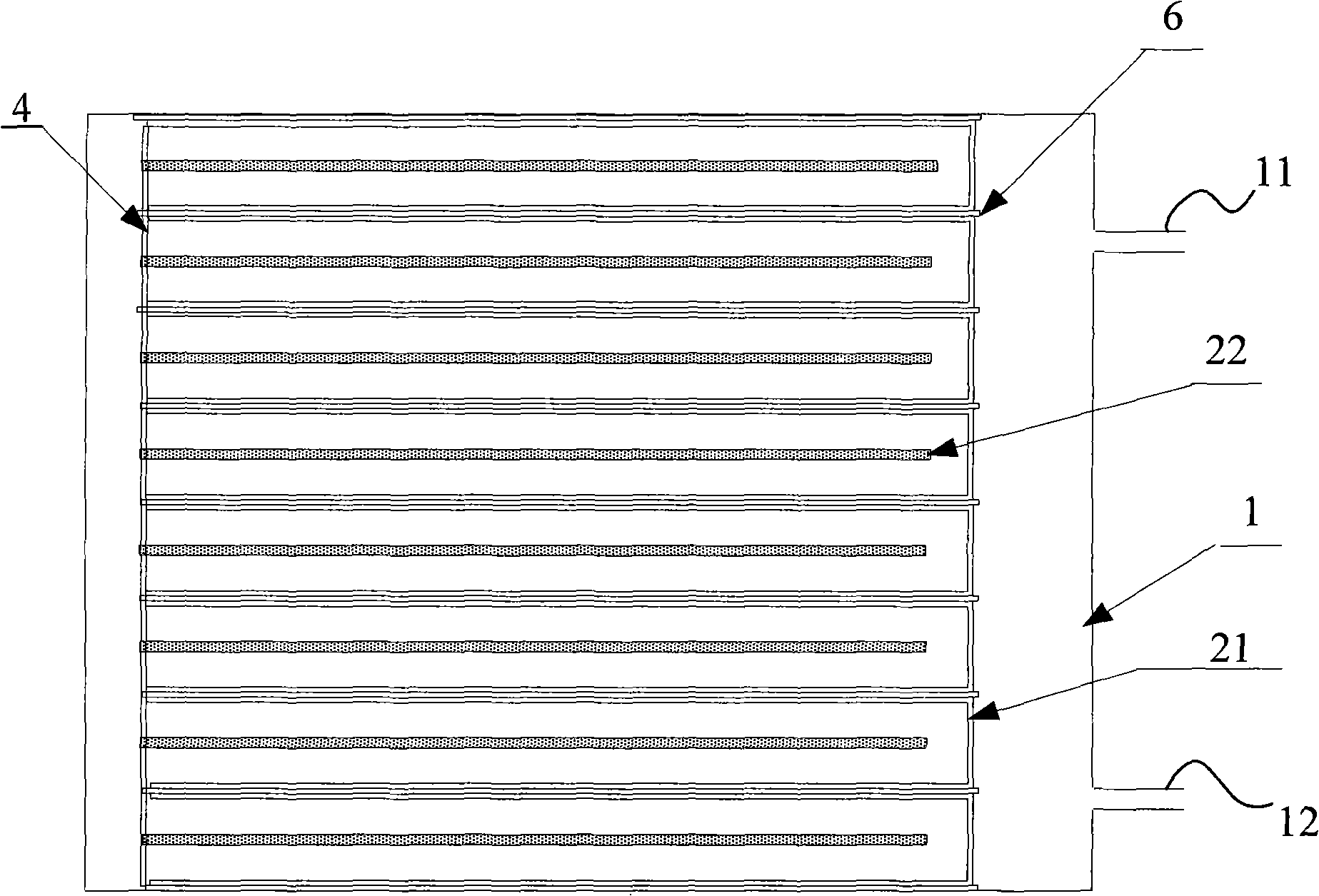

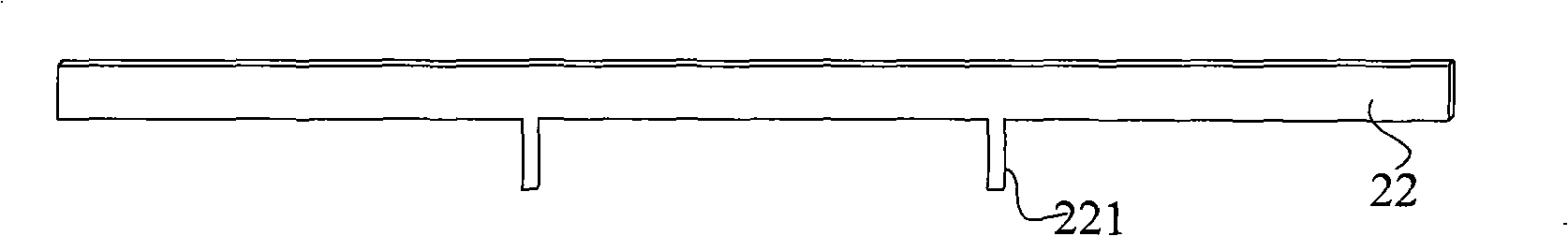

[0025] see figure 1 , figure 2 , the high-energy X-ray industrial CT ionization detector of this embodiment includes a sealed casing 1, and the inner cavity of the sealed casing 1 is filled with a pressure of 1 to 5×10 5 Pascal’s working gas with inert gas as the main component, such as argon, krypton, xenon, etc. or a mixed gas based on them, the sealed casing 1 is provided with an inlet pipe 11 and an outlet pipe 12 communicating with the inner cavity, Eight ionization chamber units 2 arranged side by side in the sealed housing 1 and separated by insulating sheets 6, the ionization chamber units 2 include a U-shaped ionization chamber wall 21 as a collector and a thin wall as a high-voltage cathode and a radiation converter. Metal sheet 22, the U-shaped ionization chamber wall 21 is made of aluminum, iron, nickel, copper or an alloy of at least two of them, and the thin metal sheet ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com