Tiny hole cleaning method

A technology of micropores and direction angles, applied in the field of laser cleaning, can solve problems such as environmental pollution, cleaning agent residue or pollution, incomplete cleaning, etc., and achieve the effect of avoiding re-pollution, removing impurities or surface oxidation

Active Publication Date: 2013-04-03

JIANGSU UNIV

View PDF11 Cites 10 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] At present, most of the micro through-holes are treated by chemical cleaning methods. The invention patents with patent numbers of 201120211318.6, 200710051536.6, 200910105193.6, and 200510041106.7 all disclose the method of cleaning the inner wall of micropores by chemical methods, but the chemical methods not only pollute the environment , also due to the small diameter of the micropores, it is easy to be limited by the tension and penetration ability of the cleaning agent, the cleaning is not thorough, and it is easy to cause residue or pollution of the cleaning agent, and the chemical cleaning method requires a certain external force to stir the micropores. Therefore, it is not conducive to the operation of individual microwells

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

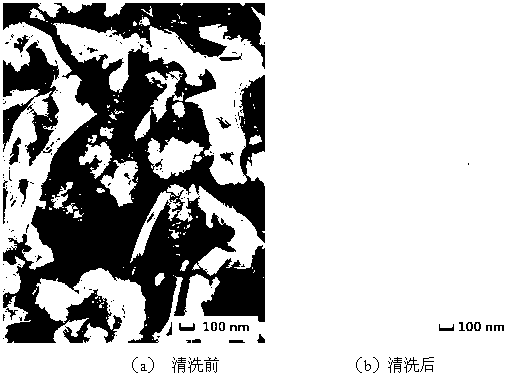

[0022] The target material is Cu metal material. A 1064nm laser is used with an energy of 2J. The angle between the line between the impact point and the axis of the microhole and the vertical incident direction of the laser is 45°. The microhole is a through hole with a diameter of 0.3mm and a depth of 1mm. Laser shock cleaning is performed multiple times at a distance of 1mm from the impact point.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

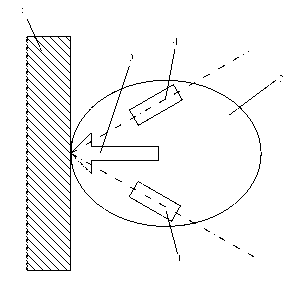

The invention discloses a tiny hole cleaning method. Plasma is generated through a laser shock target material; a tiny hole is arranged in a plasma plume; the included angle between a connecting line of a laser shock point and a tiny hole axis as well as an incident laser direction is 30-60 degrees; the length of the plasma plume is larger than the length of the tiny hole, and the width of the plasma plume is larger than the width of the tiny hole. With the adoption of the tiny hole cleaning method, the tiny hole is cleaned by adopting a manner that the plasma plume is shocked by a laser, so that secondary pollution generated by a cleaning agent can be avoided, and the tiny hole cleaning method can play a role on the surface of an inner wall of the tiny hole and cannot corrode the inner part of the tiny hole, therefore impurities and surface oxidation can be effectively removed.

Description

technical field [0001] The invention belongs to the field of laser cleaning, and in particular relates to cleaning the inner wall of micropores. Background technique [0002] In recent years, micro-vias have been widely used in various industrial products, especially the rapid growth in the use of electronic industrial products. The functional reliability of these industrial products depends largely on the quality of the microhole filling and metallization. Because when the micropores are exposed to the air environment, or during the manufacturing process, pollution is inevitable, and corrosion is also a problem that has not been solved for a long time. Before filling or metallization, pretreatment of the inner wall surface of the micropore must be carried out. [0003] At present, most of the micro through-holes are treated by chemical cleaning methods. The invention patents with patent numbers of 201120211318.6, 200710051536.6, 200910105193.6, and 200510041106.7 a...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B08B7/00

Inventor 佟艳群姚红兵张署光张罗王浩

Owner JIANGSU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com