Recycling method of waste printed circuit board

A technology for printed circuit boards and wastewater, applied in chemical instruments and methods, improvement of process efficiency, instruments, etc., can solve the problems of secondary pollution, high cost, no industrial feasibility, etc. The effect of reducing iron content and realizing waste recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

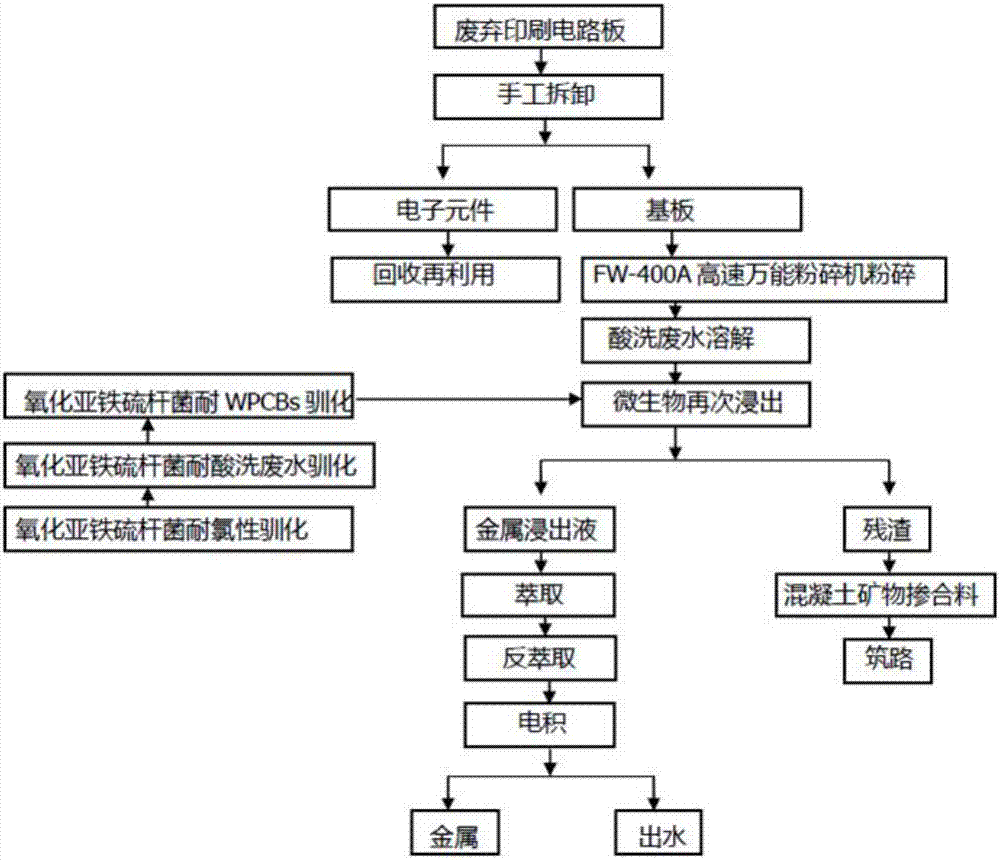

[0024] ① Pretreatment of waste printed circuit boards: disassemble the electronic components in the waste printed circuit boards by hand and crush them with a FW-400A high-speed universal grinder, pass through a 10-mesh standard sieve, and continue to crush the fragments that cannot pass the sieve until all After sieving, the collected powder was dried in an oven at 105°C for 24 hours, and the dried sample was used for leaching experiments.

[0025] The main metal content of the dried waste printed board powder was digested on the electric heating plate, and the results are shown in Table 1 below:

[0026] Table 1 Metal content in waste printed circuit board powder

[0027]

[0028]

[0029] ② Domestication of acidophilic Thiobacillus ferrooxidans: The acidophilic Thiobacillus ferrooxidans was domesticated successively to resistance to chloride ion, acid washing wastewater and WPCBs. First, carry out chloride ion tolerance acclimatization, set Cl - Concentration is 0g / ...

Embodiment 2

[0037] Steps ①②⑤ are the same as in Example 1 for the pretreatment of waste printed circuit boards, the domestication of Thiobacillus acidophilus ferrooxidans, and the recovery of metals.

[0038] ③Chemical leaching of waste printed circuit boards: Chemical leaching of waste printed circuit boards: Add 12g of WPCBs to 200mL of pickling wastewater, heat and stir, adjust the speed to 500rpm, the temperature to 25°C, and the leaching time to 3d. After chemical leaching, samples were taken to measure the metal content in the leaching solution. The concentrations of metal copper, zinc and lead were 6.89g / L, 3.95g / L and 1.57g / L, respectively, to determine the leaching rate. The experimental results show that the leaching rates of the three metals with the highest content: copper, zinc and lead are 46%, 100% and 100%, respectively.

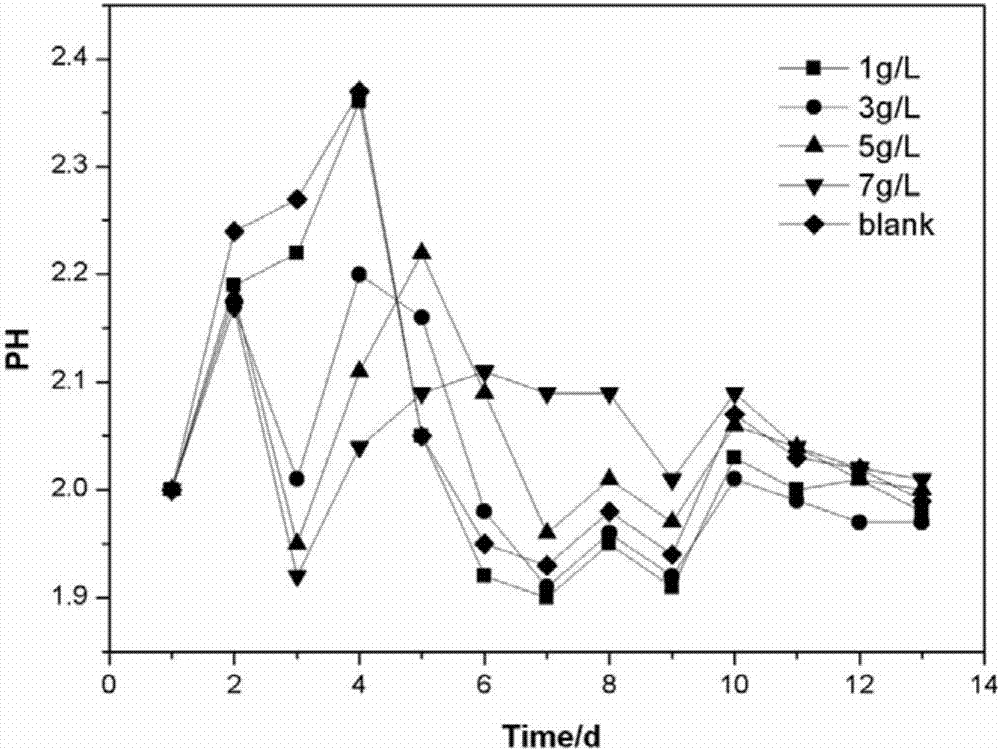

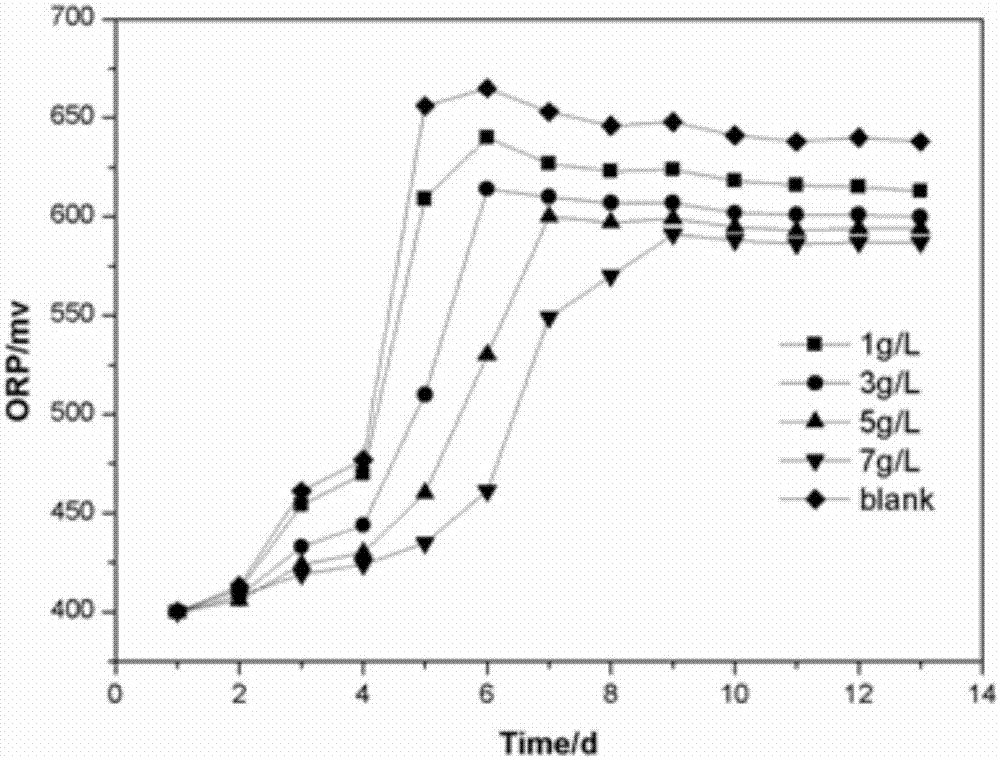

[0039] ④ Microbial leaching of waste printed circuit boards: Add 20 mL of acclimated and cultured strains to the leaching solution of chemical leaching,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com