Complex enzyme preparation for sewage treatment and application method thereof

A compound enzyme preparation and sewage treatment technology, applied in the field of environmental treatment, can solve the problems of high cost, poor impact resistance, and difficulty in the harmless treatment of sludge.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0109] A compound enzyme preparation for sewage treatment, said compound enzyme preparation is formed by mixing compound enzyme and mineral water, and the weight ratio of compound enzyme to mineral water is 1:9;

[0110] Described mineral water contains the trace element of following volume content:

[0111] Silicon 0.2ug / L;

[0112] Sodium 74mg / L;

[0113] Calcium 71mg / L;

[0114] Magnesium 200mg / L;

[0115] Potassium 69mg / L;

[0116] Iodine 9ug / L;

[0117] Selenium 0.5ug / L;

[0118] Iron 0.4ug / L.

[0119] Described complex enzyme is made up of the component of following volume content:

[0120] Pineapple enzyme 65mg / L;

[0121] Papain 70mg / L;

[0122] L-aspartase 25mg / L;

[0123] Glutathione 23mg / L;

[0124] Yeast extract 120mg / L;

[0125] Cellulase 70mg / L;

[0126] Glutamic acid 35mg / L;

[0127] Aspartic acid 15mg / L;

[0128] Inulin 20mg / L;

[0129] Pyruvate 21mg / L;

[0130] Lysozyme 16mg / L;

[0131] Glucose 6-phosphate 14mg / L;

[0132] 5-phosphate decarb...

Embodiment 2

[0144]Change the compound enzyme ratio to: pineapple enzyme 60mg / L; papain 75mg / L; L-aspartase 18mg / L; glutathione 26mg / L; yeast extract 110mg / L; cellulase 70mg / L; The weight ratio of compound enzyme and mineral water is 1: 19; Others are with embodiment 1.

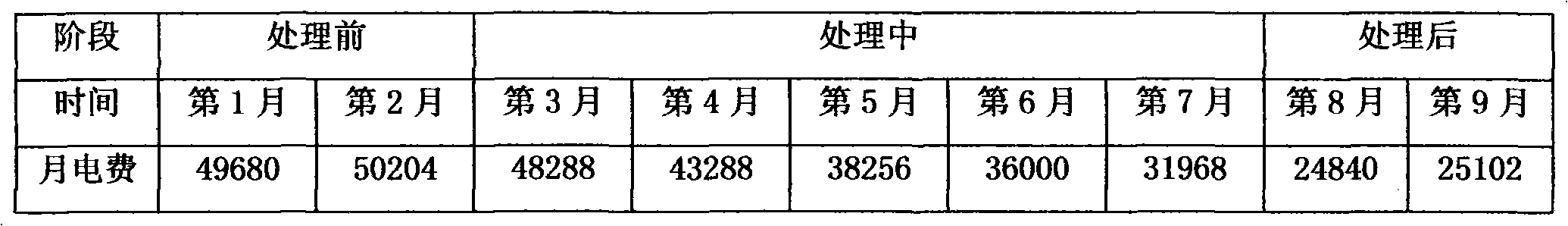

[0145] The composite enzyme preparation of the present invention is used to treat the excess sludge of a sewage treatment plant in a certain garden (residential area), the water volume in winter: 1000t / day, and the summer water volume: 1600t / day, with an average of about 19t of sludge per day. After 12 weeks, the residual sludge The amount is 0.

Embodiment 3

[0147] Change the compound enzyme ratio as follows: pineapple enzyme 65mg / L; papain enzyme 75mg / L; L-aspartase 25mg / L; glutathione 25mg / L; yeast extract 120mg / L; cellulase 70mg / L; Glutamic acid 45mg / L; Aspartic acid 15mg / L; Inulin 25mg / L; Pyruvate 25mg / L. The weight ratio of compound enzyme and mineral water is 1: 29; Others are with embodiment 1.

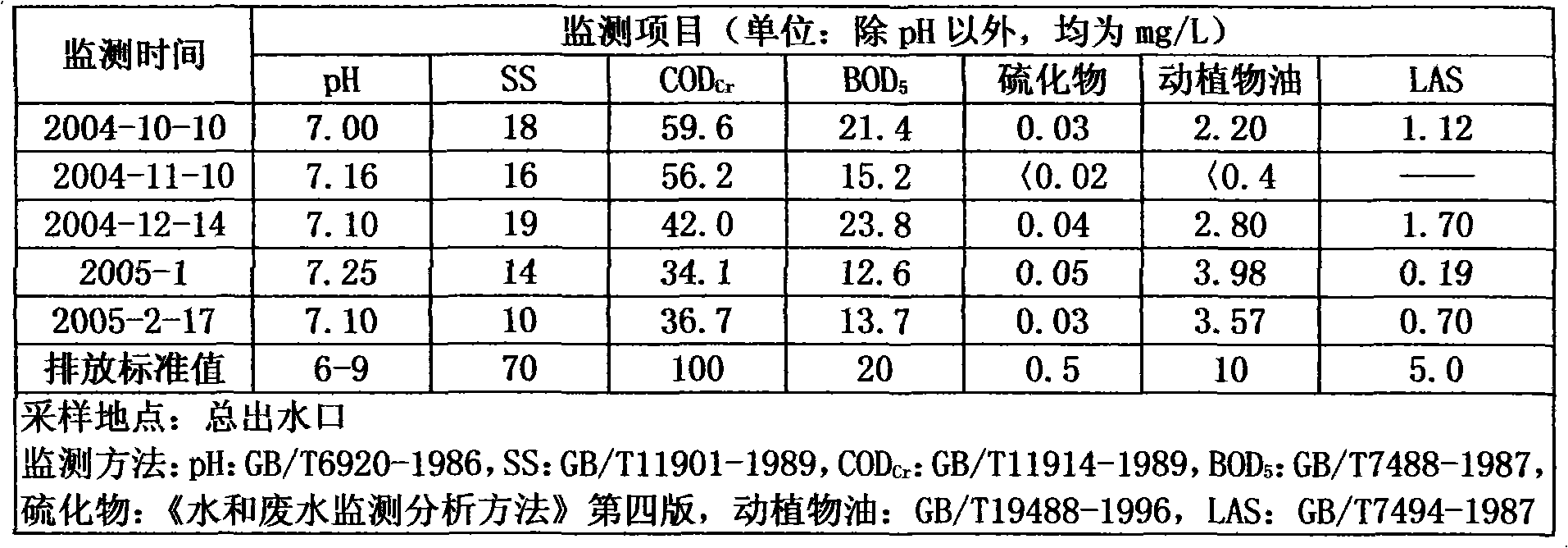

[0148] The composite enzyme preparation of the present invention is used to treat the printing and dyeing sewage of an enterprise, which is mainly engaged in the dyeing and finishing of cotton chemical fiber and its deep processing. , SS is 100-200mg / L, and the chromaticity is 100-400 times. With the change of processed products, the quality of wastewater varies greatly.

[0149] The sewage treatment system of the enterprise consists of a three-stage treatment system:

[0150] Primary treatment: regulating pool + air flotation;

[0151] Secondary treatment: anaerobic hydrolysis (HRT4h) + tertiary contact oxidation (HRT7.6h); ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com