High temperature-resistant mullite type aerogel composite material and preparation method thereof

A composite material and airgel technology, applied in the field of mullite airgel composite materials and its preparation, can solve the problems of porous structure collapse, poor stability, unstable performance, etc., and achieve uniform properties of sol and gel Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

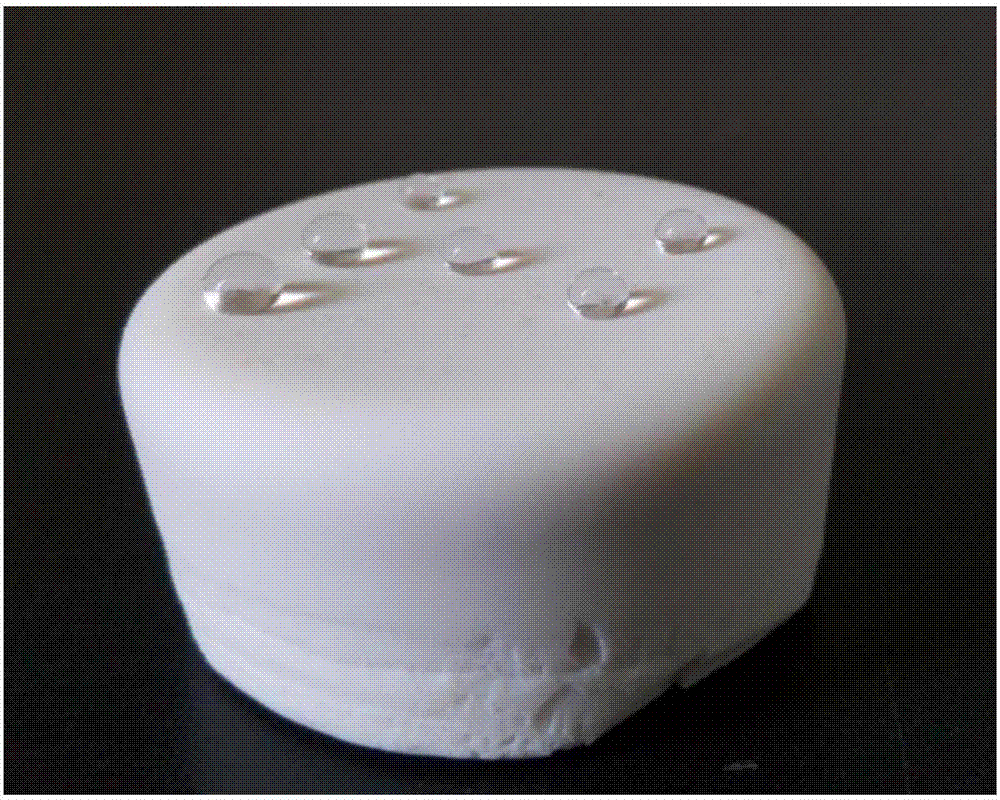

[0034] Such as figure 1 As shown, the preparation method of a high temperature resistant mullite airgel composite material of the present embodiment comprises the following steps:

[0035] S1, hydrolyzing silicon source, aluminum source and titanium source respectively to obtain silica sol, aluminum sol and titanium sol;

[0036] Described silicon source comprises tetraethoxysilane and methyltriethoxysilane, and the mol ratio of described tetraethoxysilane and methyltriethoxysilane is 1:0.1; The molar concentration of silicon element is adjusted to 0.5mol / L.

[0037] The aluminum source is aluminum isopropoxide; the aluminum sol is obtained by wetting, ball milling, chelating, heat preservation, acidolysis and concentration, and the mole of aluminum element in the aluminum sol is obtained by water The concentration was adjusted to 0.5mol / L.

[0038] The titanium source is butyl titanate; the butyl titanate is chelated, diluted and hydrolyzed to obtain the titanium sol, and ...

Embodiment 2

[0044] Such as figure 1 As shown, the preparation method of a high temperature resistant mullite airgel composite material of the present embodiment comprises the following steps:

[0045] S1, hydrolyzing silicon source, aluminum source and titanium source respectively to obtain silica sol, aluminum sol and titanium sol;

[0046] Described silicon source comprises tetraethoxysilane and methyltriethoxysilane, and the mol ratio of described tetraethoxysilane and methyltriethoxysilane is 1:0.3; The molar concentration of silicon element is adjusted to 0.8mol / L.

[0047] The aluminum source is aluminum isopropoxide; the aluminum sol is obtained by wetting, ball milling, chelating, heat preservation, acidolysis and concentration, and the mole of aluminum element in the aluminum sol is obtained by water The concentration was adjusted to 0.8mol / L.

[0048] The titanium source is butyl titanate; the butyl titanate is chelated, diluted and hydrolyzed to obtain the titanium sol, and ...

Embodiment 3

[0054] Such as figure 1 As shown, the preparation method of a high temperature resistant mullite airgel composite material of the present embodiment comprises the following steps:

[0055] S1, hydrolyzing silicon source, aluminum source and titanium source respectively to obtain silica sol, aluminum sol and titanium sol;

[0056] Described silicon source comprises tetraethoxysilane and methyltriethoxysilane, and the mol ratio of described tetraethoxysilane and methyltriethoxysilane is 1:0.5; The molar concentration of silicon element was adjusted to 1.0mol / L.

[0057] The aluminum source is aluminum isopropoxide; the aluminum sol is obtained by wetting, ball milling, chelating, heat preservation, acidolysis and concentration, and the mole of aluminum element in the aluminum sol is obtained by water The concentration was adjusted to 1.0 mol / L.

[0058] The titanium source is butyl titanate; the butyl titanate is chelated, diluted and hydrolyzed to obtain the titanium sol, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Maximum operating temperature | aaaaa | aaaaa |

| Hydrophobic angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com