A new type of premelted dephosphorization agent for steelmaking and its preparation method

A dephosphorization agent and pre-melting technology, applied in the field of metallurgy, can solve the problems of large temperature drop of molten steel, short action time, unsustainable slag melting, furnace lining erosion, etc., to achieve reduced oxygen consumption, stable and stable dephosphorization efficiency, Effect of reducing lime consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

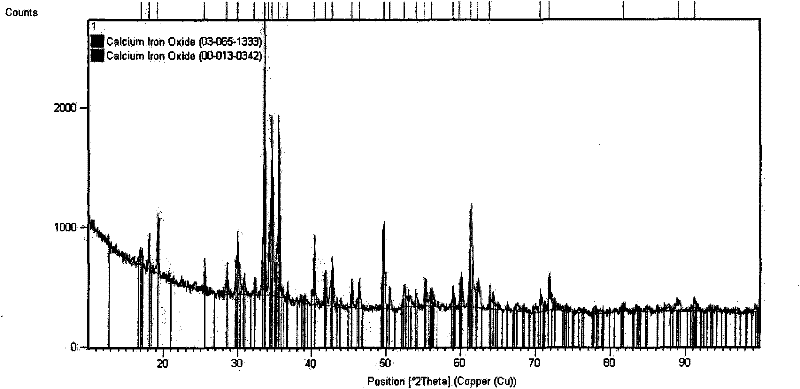

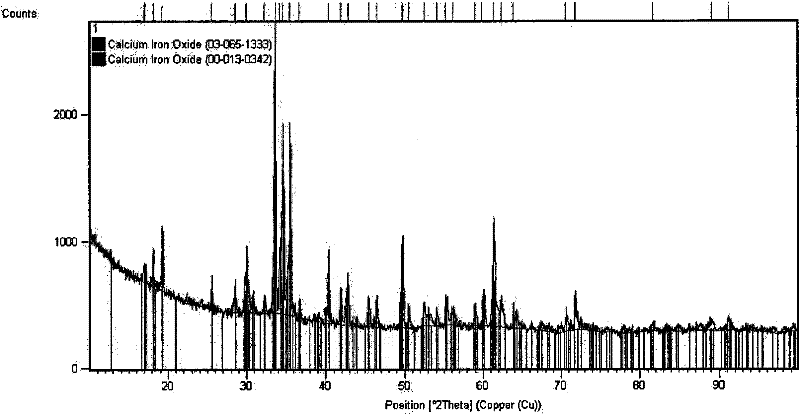

Image

Examples

Embodiment

[0029] The small white ash and iron oxide scales are crushed and mixed with barium carbonate powder in a certain proportion, put into the mixer for mixing for 30 minutes, and then put into the heating furnace to heat the raw materials to 1500 ℃ to melt, keep for 20 minutes to ensure that the slag composition is uniform and melt The slag is air-cooled to room temperature, and finally the frit is broken into pre-melted slag blocks with a particle size of 10-50 mm.

[0030] The mass percentage composition of this pre-melted dephosphorization agent for steelmaking is shown in the following table.

[0031] Table 1 The mass percentage composition of pre-melted dephosphorizer%

[0032] Example

CaO

Fe 2 O 3

BaO

Other impurities

Example 1

35.2

59.6

4.8

0.4

Example 2

31.3

63.1

2.7

2.9

Example 3

39.5

51.4

8.3

0.8

Example 4

30.5

64.5

0.3

4.7

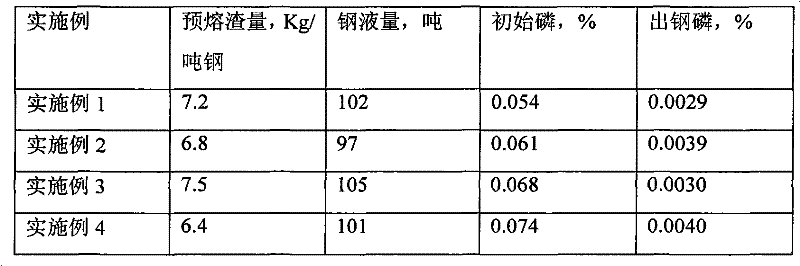

[0033] This pre-melted dephosphorizer was used for deep dephosphorization test. The test was performed on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com