Formable sheet and interior finishing material

A formability, sheet technology, applied in the direction of thin material processing, transportation and packaging, synthetic resin layered products, etc., can solve the problems of poor formability, insufficient stretchability, surface wrinkles, etc., and achieve the effect of full stretchability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

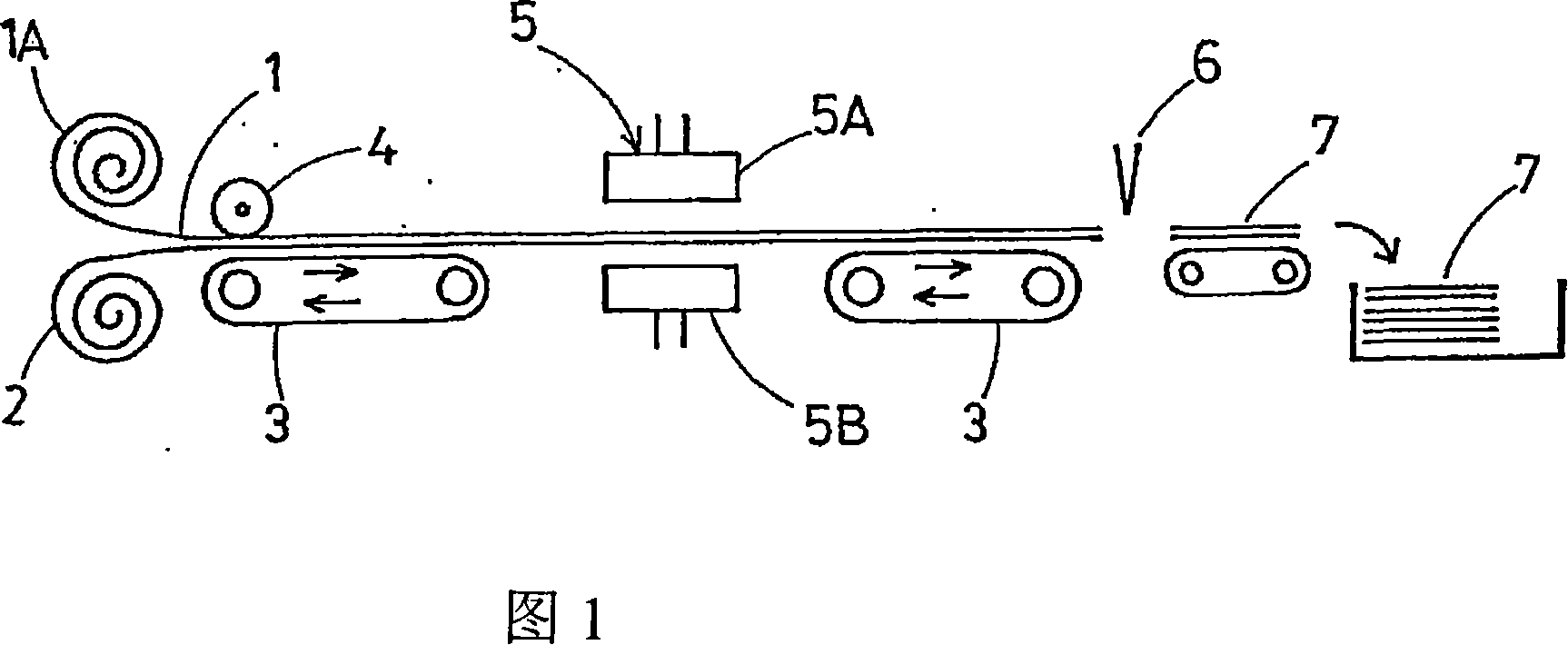

Image

Examples

Embodiment 1

[0095] Used in the initial phenol-formaldehyde condensate (aqueous solution of 50% by mass solid content), and added in proportions of 0.1, 5.0, 10.0, 20.0, 40.0, and 50.0% by mass to the solid content of the phenol-formaldehyde initial condensate Various mixtures obtained by mixing diethylene glycol (DEG) by stirring and mixing, with a weight per unit area of 150 g / m compared to polyester fibers produced by needle punching 2 Fiber sheets of non-woven fabrics, to achieve a coating weight of 30% by mass (solid content) (45g / m 2 ) dipping and coating various mixed liquids with a coating roller, drying at a temperature of 120-130° C. for 2 minutes, and then pre-curing the impregnated initial condensate to stage B to obtain a formable sheet A.

Embodiment 2

[0097]Use in acrylic polymer latex (aqueous solution of 50% by mass solid content), and add and stir in proportions of 0.1, 5.0, 10.0, 20.0, 40.0, 50.0 mass% to the solid content of the acrylic polymer latex Various mixtures of polyethylene glycol (PEG) are used in non-woven fiber sheets made of polyester fibers and made by spunbonding (weight per unit area: 30g / m 2 ) on overlapping glass fibers (weight per unit area: 100g / m 2 ), from the glass fiber surface, the mixed liquid is applied in an amount of 60% by mass (solid content) relative to the glass fiber (60g / m 2 ) was applied with a sprayer, and then dried at a temperature of 120 to 130° C. for 2 minutes to obtain a moldable sheet B with a polyester nonwoven fabric.

Embodiment 3

[0137] By 30 mass parts of sulfomethylated phenol-alkyl resorcinol-formaldehyde initial condensation product (50 mass % solid content aqueous solution), 5 mass parts of ethylene glycol, 1 mass part of carbon black dispersion ( 35 mass % solid content aqueous solution), 2 mass parts of fluorine-based water and oil repellent (20 mass % solid content aqueous solution), 2 mass parts of flame retardant (50 mass % of nitrogen-containing, phosphorus flame retardant Aqueous solution of solid content) and 60 parts by mass of water have a weight per unit area of 30 g / m with respect to polyester fibers produced by the spunbond method 2 The fibrous sheet of the non-woven fabric is dip-coated on the fibrous sheet with a coating roller in a coating amount of 45% by mass, and then dried at a temperature of 120 to 130°C for 1 minute, and the impregnated initial The condensate is pre-cured to B-stage to produce a formable sheet. The obtained formable sheet was used as a skin material, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com