Cleaning liquid composition for plasma etching residues in semi-conductor industry

A technology for etching residues and cleaning solutions, applied in detergent compositions, organic detergent compositions, non-surface-active detergent compositions, etc., can solve the problem of inability to simultaneously control metal and non-metal etching rates, channel feature size changes, Change the semiconductor structure and other issues to achieve good applicable environment and effect, good corrosion inhibition effect, and environmental safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

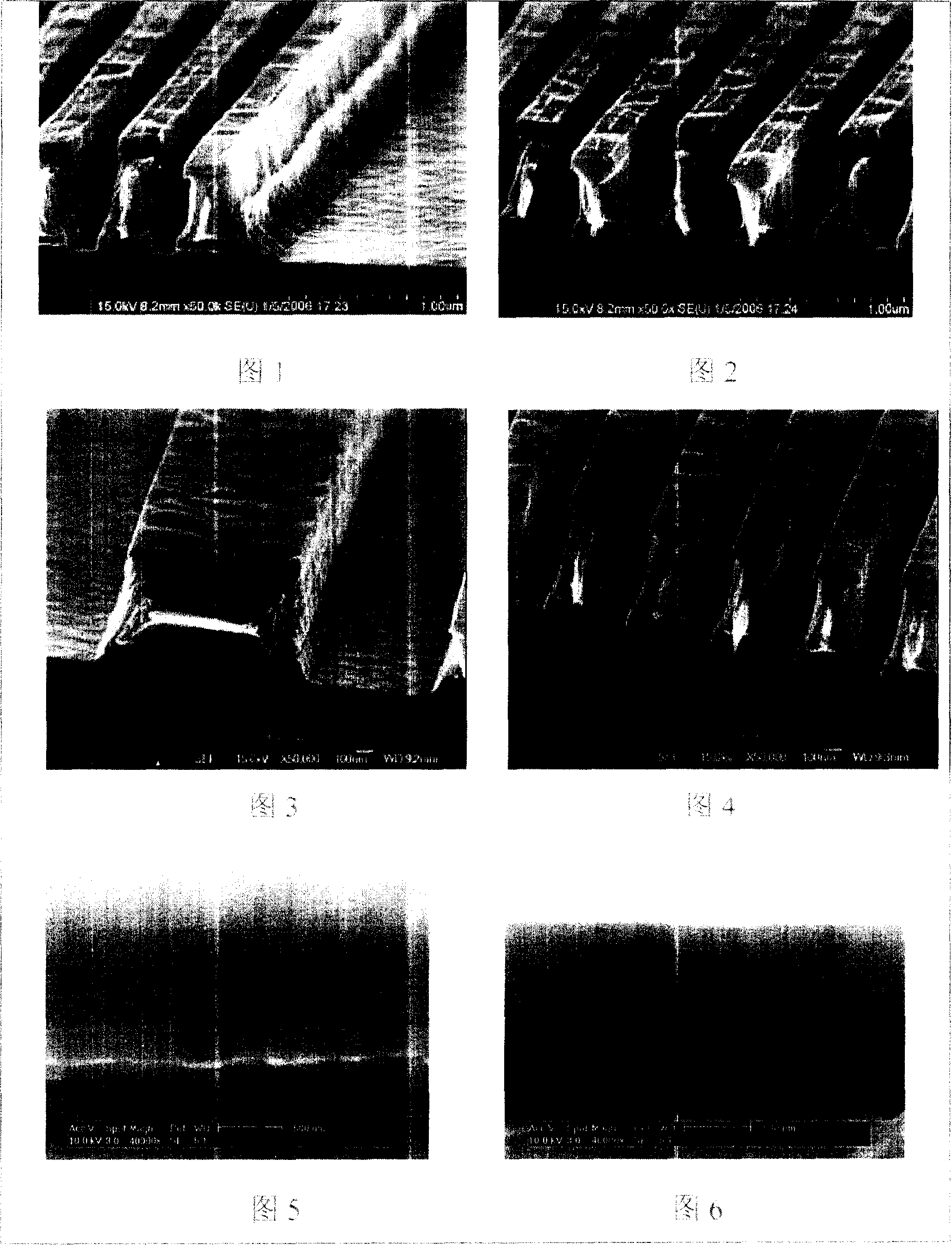

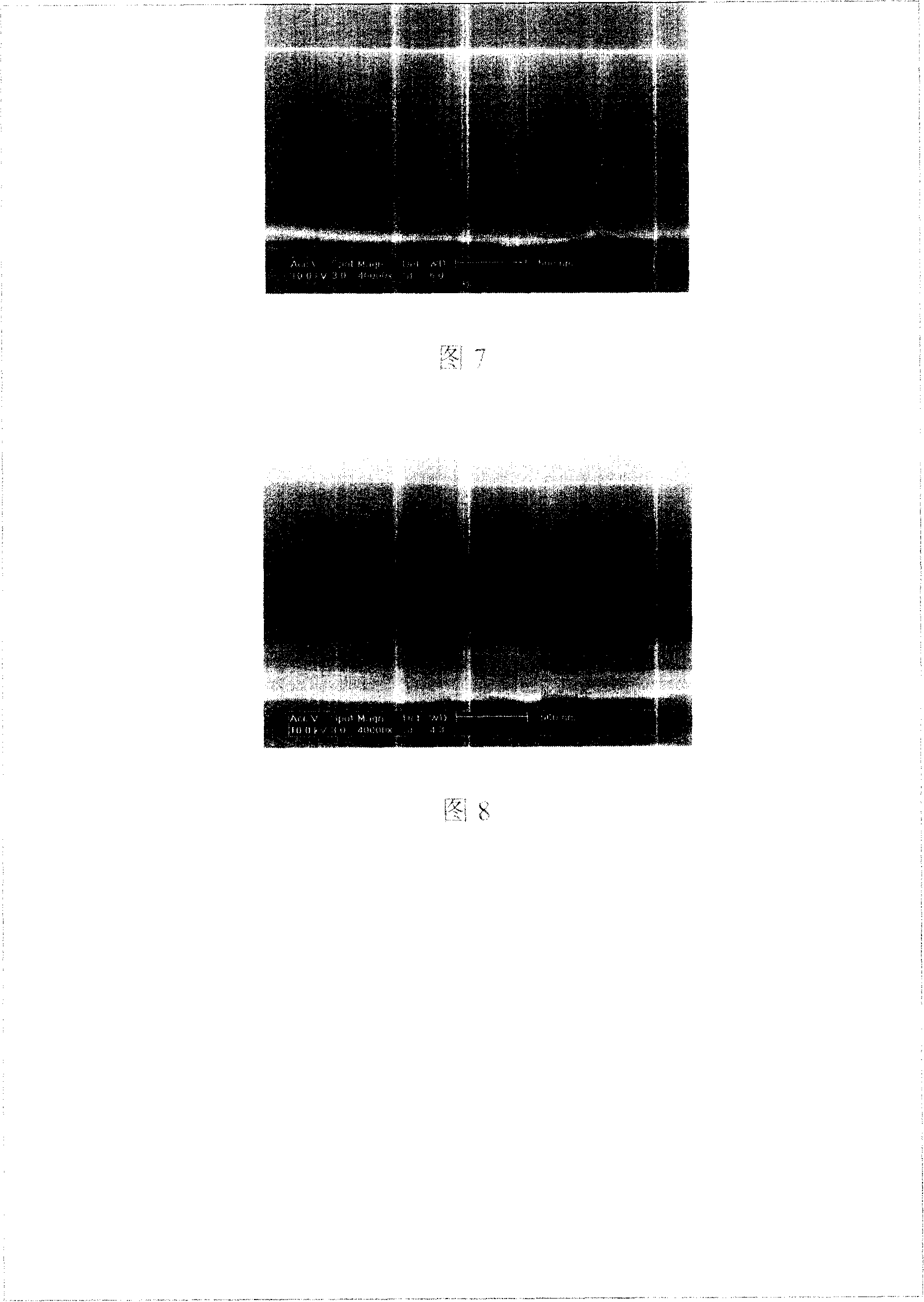

Image

Examples

Embodiment 1

[0039] Components of cleaning solution composition 1: N-methylpyrrolidone 60wt%, DI 28.44wt%, NH 4 F 1.25wt%, Ac 1.56wt%, AcNH 4 7.8wt%, 0.3wt% benzotriazole (BTA), ammonium polyacrylate (molecular weight: 600), 0.15wt%, G 0.5wt%.

Embodiment 2

[0041] Components of cleaning solution composition 2: N-methylpyrrolidone 50wt%, DI 26.3wt%, NH 4 F 3wt%, Ac 5.1wt%, AcNH 4 12.4wt%, benzotriazole (BTA) 0wt%, ammonium polyacrylate (molecular weight: 600), 0.3wt%, G 0.2wt%.

Embodiment 3

[0043] Components of cleaning liquid composition 3: N-methylpyrrolidone 85wt%, DI 8wt%, NH 4 F0.05wt%, Ac 1wt%, AcNH 4 1wt%, benzotriazole (BTA) 0.94wt%, ammonium polyacrylate (molecular weight: 600), 00.01wt%, G 4wt%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com