Mining heavy-duty engine coolant

An engine coolant, heavy-duty technology, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of protective film damage, poor chlorine resistance, etc., achieve long-term stable performance, reduce pollution, and improve corrosion inhibition. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

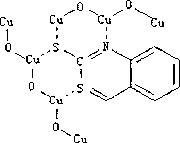

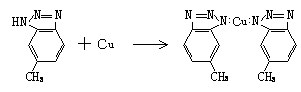

Method used

Image

Examples

Embodiment 1

[0045] It is made by conventional mixing and stirring of the raw materials in the following weight percentages:

[0046] Tolylbenzotriazole 0.1%

[0047] Sodium Sebacate 1.2%

[0048] Triethanolamine Oleic Soap 0.8%

[0049] Sodium Benzoate 0.6%

[0050] Tributylamine octanoate 0.1%

[0051] Maleic acid-methyl acrylate copolymer 1.2%

[0053] Polyethylene glycol 400 0.01%

[0054] Alcoholic Fast Yellow 0.65%

[0055] Ethylene glycol 40%

[0056] The balance is deionized water.

Embodiment 2

[0058]It is made by conventional mixing and stirring of the raw materials in the following weight percentages:

[0059] Tolylbenzotriazole 0.2%

[0060] Sodium Sebacate 2.6%

[0061] Triethanolamine Oleic Soap 1.4%

[0062] Sodium Benzoate 1.2%

[0063] Tributylamine octanoate 0.2%

[0064] Maleic acid-methyl acrylate copolymer 2.0%

[0065] Sodium hydroxide 0.2%

[0066] Polyethylene glycol 400 0.04%

[0067] Alcohol Fast Yellow 1.6%

[0068] Ethylene glycol 70%

[0069] The balance is deionized water.

Embodiment 3

[0071] It is made by conventional mixing and stirring of the raw materials in the following weight percentages:

[0072] Tolylbenzotriazole 0.15 %

[0073] Sodium sebacate 1.8 %

[0074] Triethanolamine Oleic Soap 1.2%

[0075] Sodium Benzoate 1.0 %

[0076] Tributylamine octanoate 0.15 %

[0077] Maleic acid-methyl acrylate copolymer 1.5%

[0078] Sodium hydroxide 0.1%

[0079] Polyethylene glycol 400 0.02%

[0080] Alcohol Fast Yellow 1.2 %

[0081] Ethylene glycol 55%

[0082] The balance is deionized water.

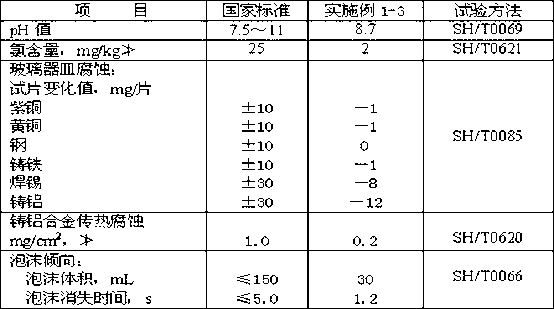

[0083] The mine-used heavy-duty engine coolant of the embodiment 1-3 of the present invention has reached the internal standard Q / AKFZ3-08 [2009] "Heavy-duty mine-use engine coolant product standard (ethylene glycol type)" of Anshan Iron and Steel Enterprise, The performance is higher than the national industry standard SH / T0521-1999.

[0084] In June 2009, it began to be used in mines belonging to Anshan Iron and Steel Group Mining Company. After more than ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com