Non-aqueous coolant composition for engine

A composition and water cooling technology, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of start-up and heat transfer effects, etc., achieve excellent corrosion inhibition effects, prolong service life, and excellent high-temperature corrosion resistance Effect

Active Publication Date: 2013-04-24

CHINA PETROLEUM & CHEM CORP +1

View PDF8 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The boiling point of this coolant is higher than 150°C, but the problem is that glycerol is more viscous than propylene glycol. Although a viscosity specific heat regulator is added, its starting and heat transfer effects are still affected.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1-5 and comparative example 1-7

[0053] See Table 1 for the composition of the composition examples 1-5 and comparative examples 1-6 of the present invention.

[0054] Table 1

[0055]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Login to View More

Abstract

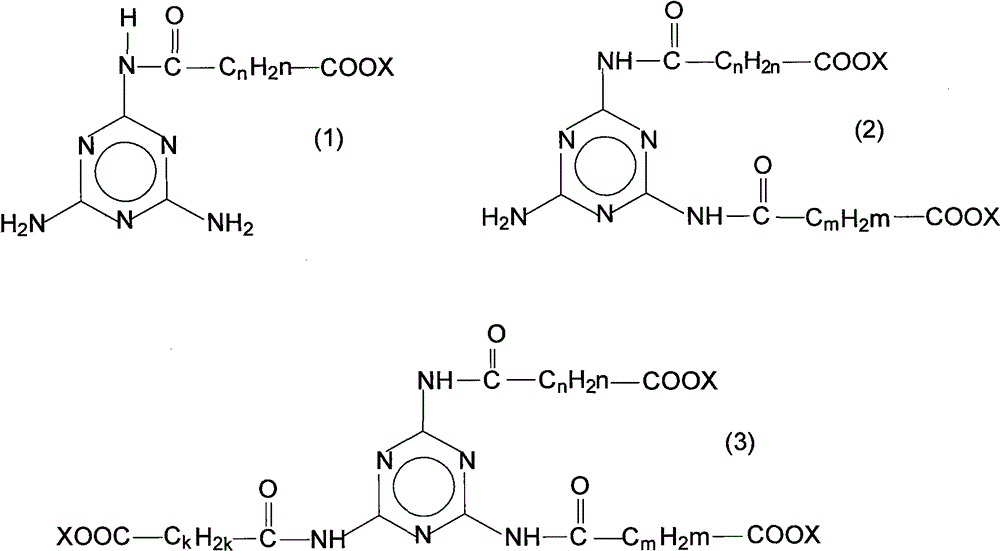

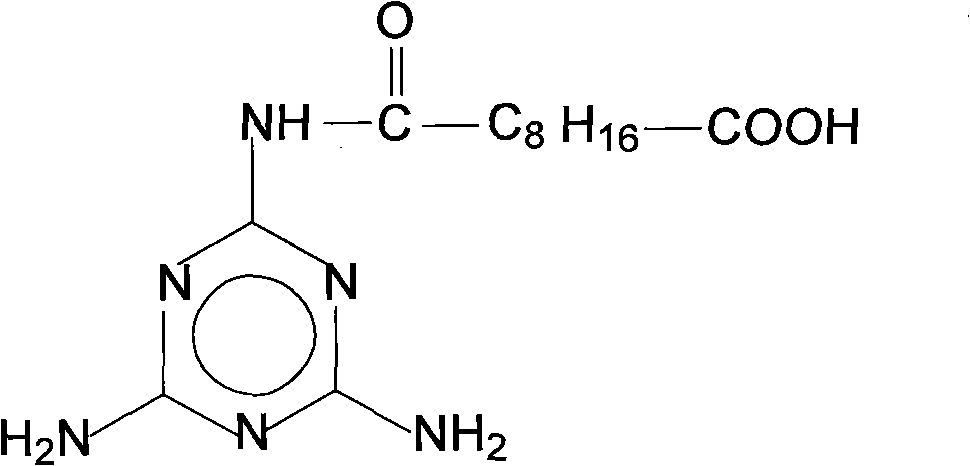

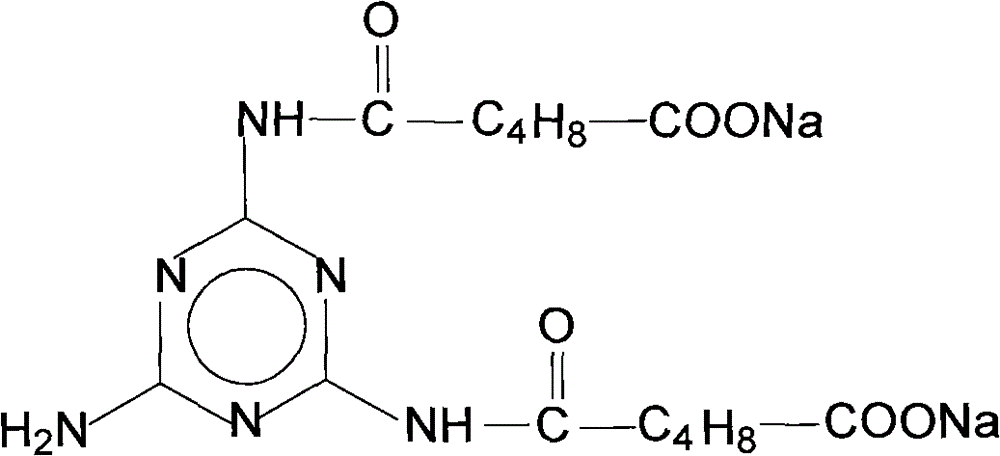

The invention relates to a non-aqueous coolant composition for an engine, which comprises a propylene glycol basic solution and a composite corrosion inhibitor, the composite corrosion inhibitor comprises acylates of tripolycyanamide and poly fatty acid and water soluble salt, hydroxy aromatic acid and its water soluble salt, and also comprises other types of corrosion inhibitors, such as fatty acid and its water soluble salt, molybdate, silicate and a silicate stabilizer. The composition takes propylene glycol as the basic solution, the toxicity is low, the toxic and harmful addictives on human body and environment such as nitrite, nitrate, alcohol amine, phosphate and borate are not contained, the non-aqueous coolant composition is an environment-friendly product, the high temperature corrosion resistance performance is excellent, the low temperature cooling performance and high temperature boiling resistance performance are excellent, and the non-aqueous coolant composition is suitable for the engines with large power, heavy loading and high temperature working environment.

Description

technical field [0001] The invention relates to an engine coolant composition, in particular to an engine anhydrous coolant composition. Background technique [0002] Engine coolant has multiple functions such as cooling, anti-boiling, anti-corrosion, and anti-scaling, and is widely used as a coolant for engines such as automobiles, trains, airplanes, and ships. With the rapid development of the engine manufacturing industry, the engine is developing towards high power, heavy load, and high speed, but the volume is gradually reduced, and the operating temperature of the engine is continuously increasing. ℃ above, good corrosion inhibition, good heat transfer effect coolant. [0003] The most common coolant on the market is ethylene glycol-water coolant. The boiling point of this water-containing coolant is generally around 107°C, which cannot meet the performance requirements of modern high-power engines. At the same time, because of the presence of water, polyols are more...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C09K5/20C23F11/04

Inventor 韩恒文段庆华孙洪伟李勇

Owner CHINA PETROLEUM & CHEM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com