High-temperature-oxidation-resistant cold-rolled steel sheet for hot forming and production and manufacturing method thereof

A high-temperature oxidation-resistant, manufacturing method technology, applied in temperature control, metal rolling, etc., can solve the problem of high cost of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1- Embodiment 3

[0042] A high-temperature oxidation-resistant steel sheet suitable for hot forming, including the following components in mass percentage: as shown in Table 1, the balance not shown in Table 1 is Fe and unavoidable impurities.

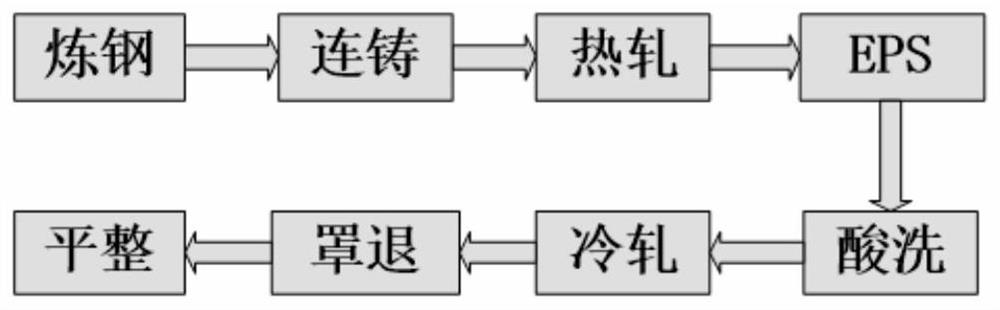

[0043] Example 1-Example 3 The manufacturing method of high temperature oxidation resistant steel plate suitable for hot forming, including the following process flow: smelting → continuous casting → hot rolling → EPS surface treatment → pickling → cold rolling → bell annealing → leveling → finished product. The specific process control is as follows:

[0044] 1) Steelmaking and continuous casting: suitable for smelting in converters, electric furnaces and induction furnaces. Continuous casting is used to produce slabs. Electromagnetic stirring and dynamic light reduction devices are used in the pouring process to reduce the risk of center loosening and tissue segregation;

[0045] 2) The billet is heated at a temperature of 1150-1200°C, held for 2-3 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com