Pallet

a technology of pallets and supports, applied in the field of pallets, can solve the problems of reducing destroying the pallet or damage the support members, and not inserting the tin of the device, so as to reduce the time to load, reduce the damage to the supported products, and increase the strength and durability of the support blocks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

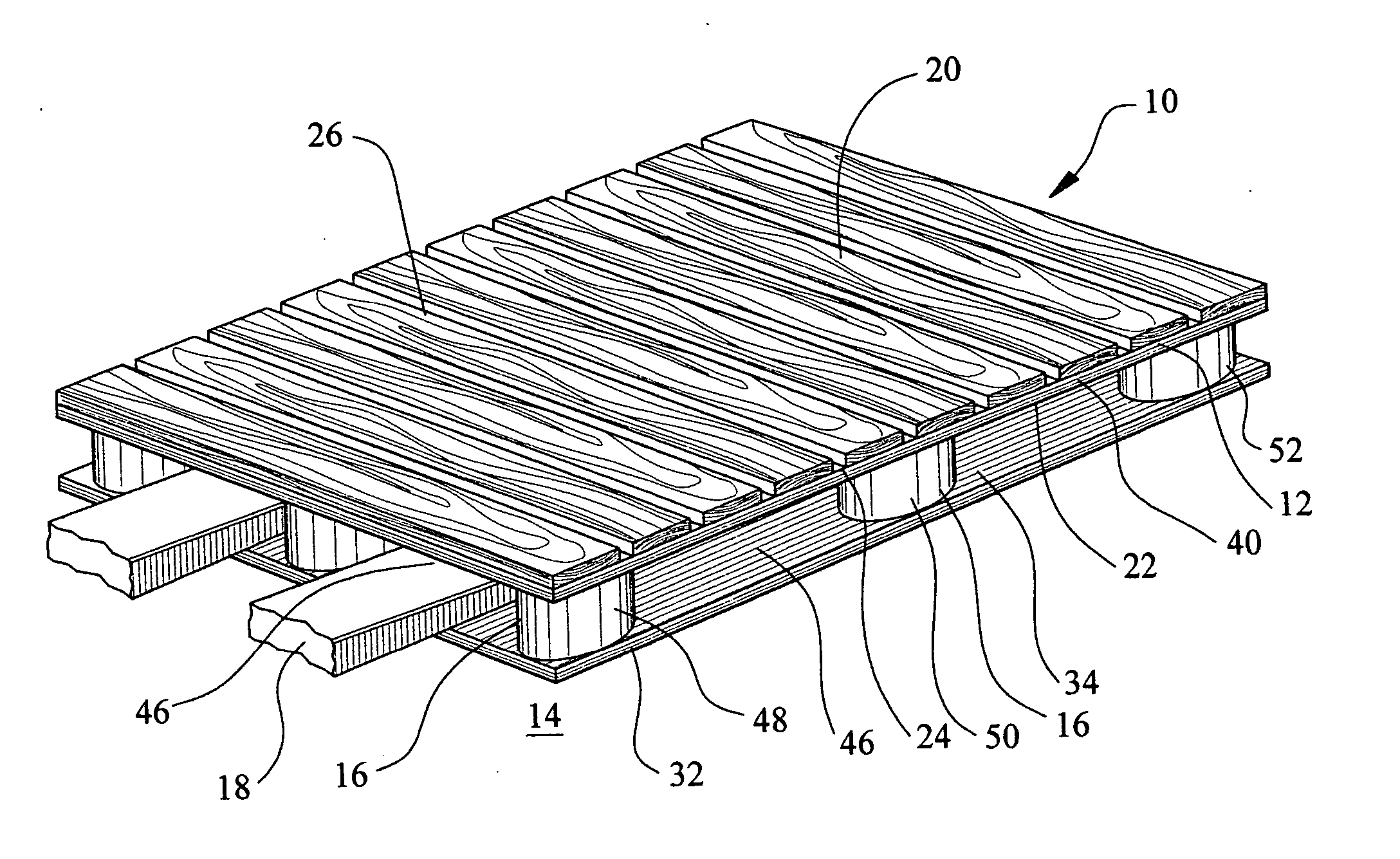

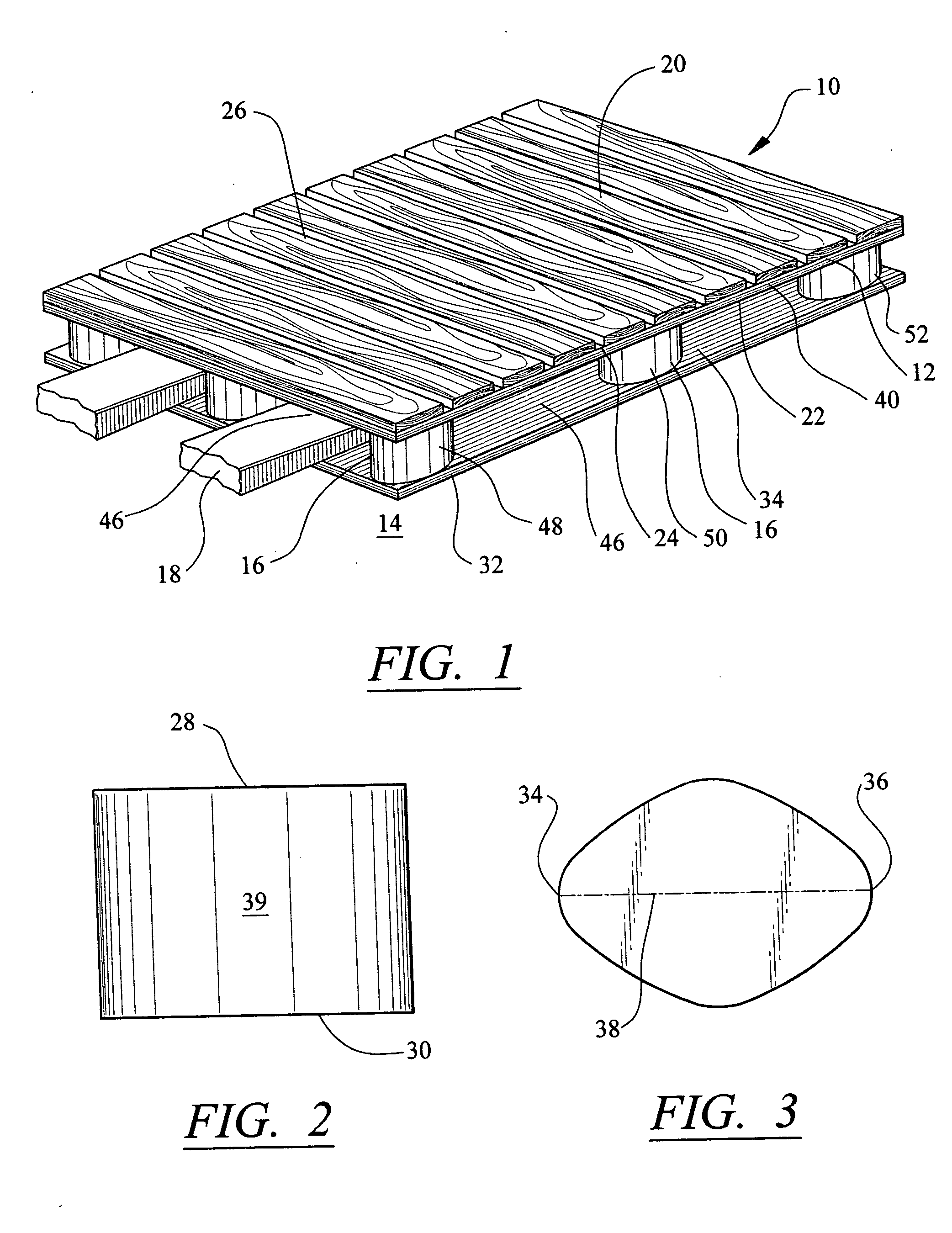

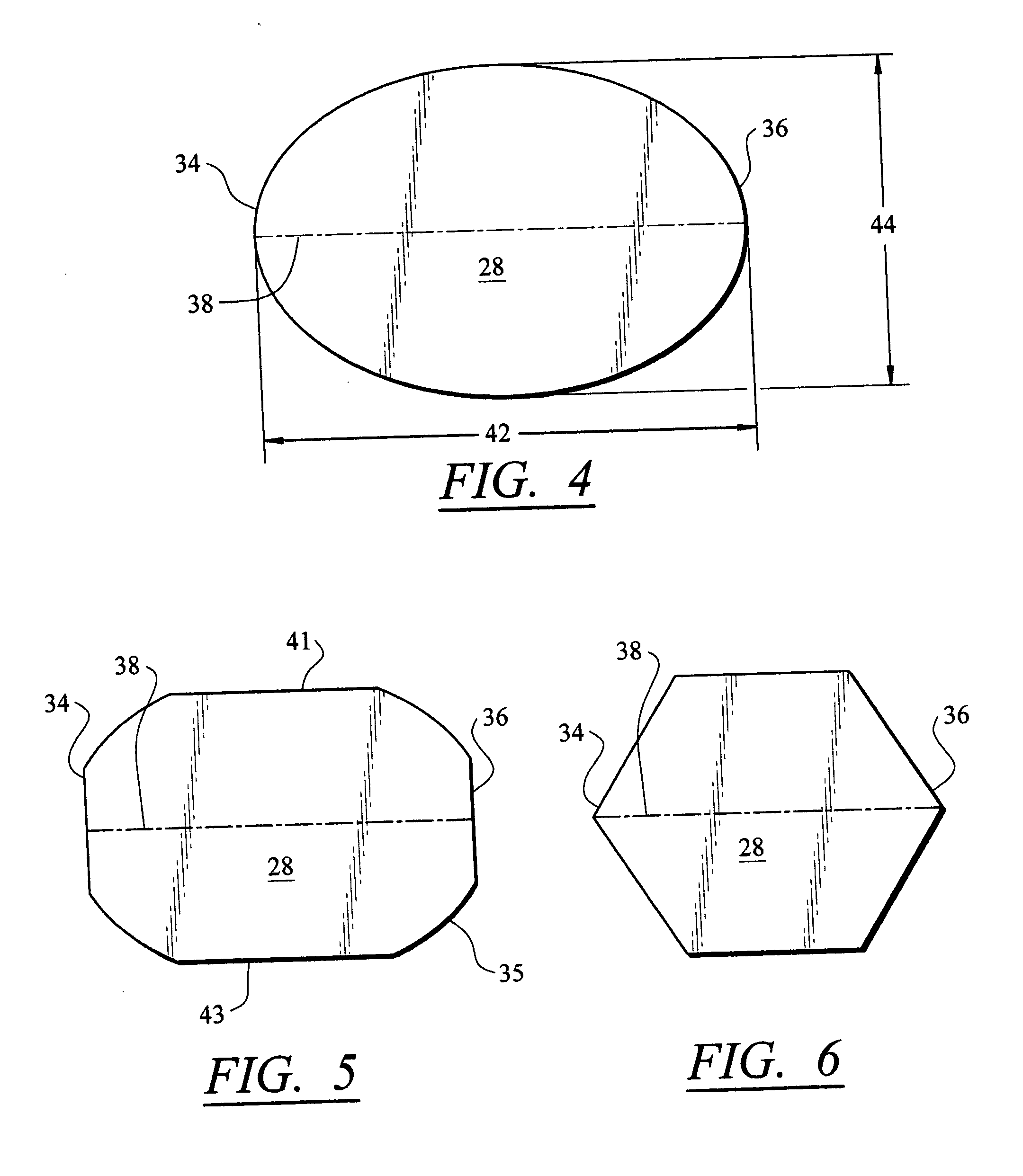

[0022]FIGS. 1-10 illustrate a pallet 10, and related components thereof, configured to support cargo on one or more top support members 12. The top support member 12 is supported above a surface 14 using two or more support blocks 16 positioned to allow lifting members 18 to be placed under the top support member 12 to lift the pallet 10 and the cargo supported by the pallet 10. The top support member 12 may have any suitable shape. In at least one embodiment, as shown in FIG. 1, the top support member 12 may be composed of a generally flat top surface 20 and a bottom surface 22. In other embodiments, top support member 12 may have top surfaces 20 that are not flat. In some embodiments, the top surface 20 may include one or more coatings or other textured materials to prevent cargo from slipping or moving on the top surface 20. In at least one embodiment, as shown in FIG. 1, the top support member 12 may be formed from three cross supports 24 positioned generally parallel to each ot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com