SiO2 aerogel thermal insulation latex paint and preparation method thereof

A thermal insulation and latex coating technology, applied in latex paint, coatings, fibrous fillers, etc., can solve the problems affecting the service life of building thermal insulation systems, the reduction of thermal insulation performance of coatings, and the thickness of thermal insulation coatings. Achieve good heat insulation effect, improve performance, and simple construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

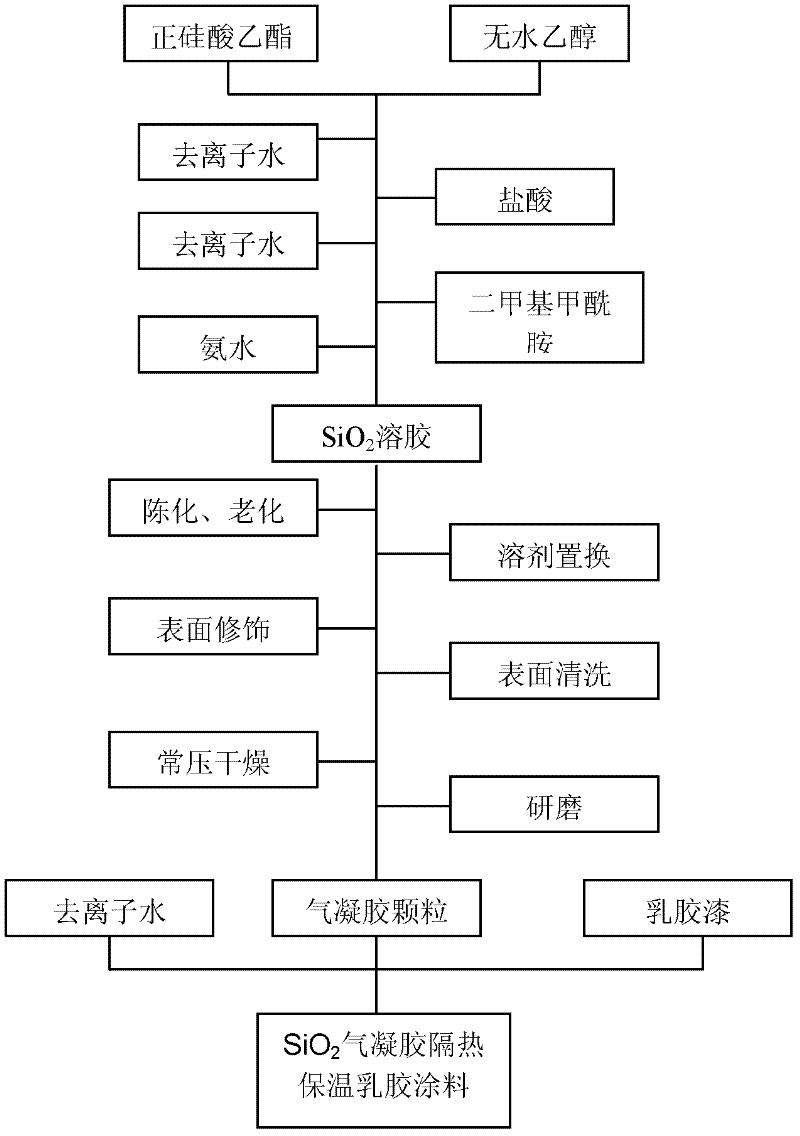

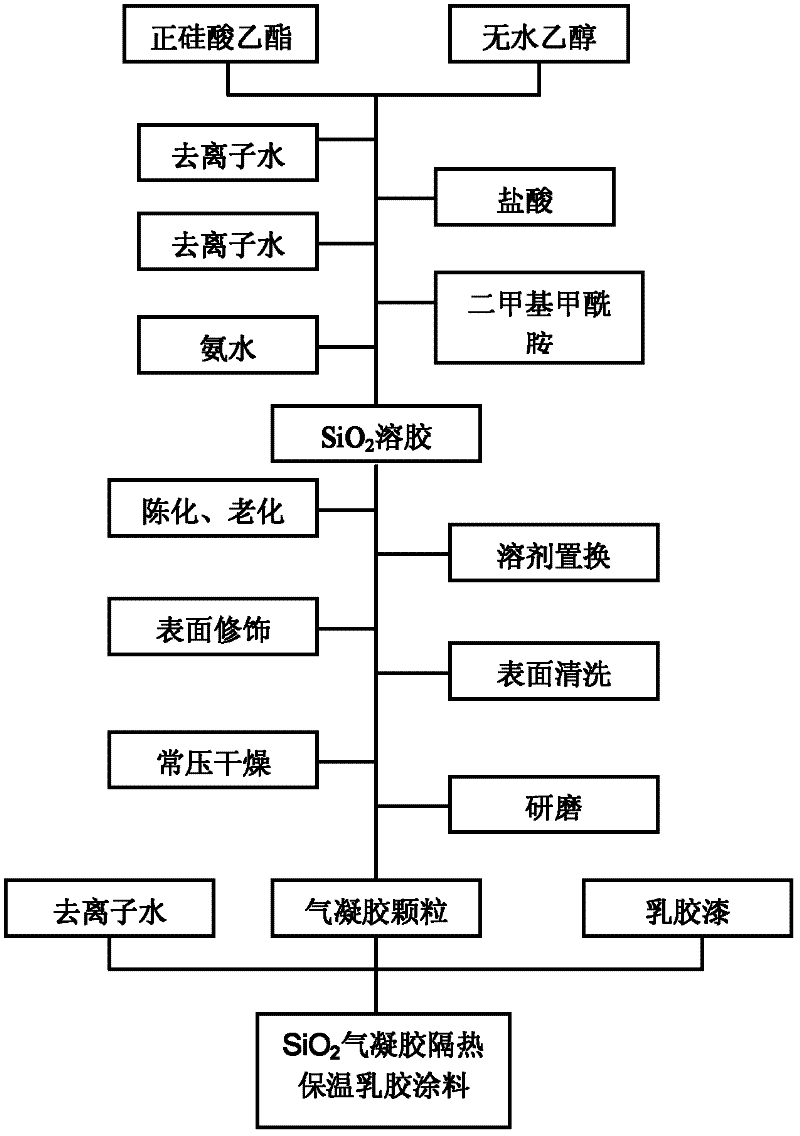

Method used

Image

Examples

Embodiment 1

[0045] This embodiment is SiO by mass percentage 2 1% of airgel particles, 89% of silicone acrylic exterior wall latex paint and 10% of deionized water are mixed and configured.

[0046] Dilute the silicone-acrylic exterior wall latex paint with deionized water first, and place it on a magnetic stirrer to stir for 20 minutes, then divide it into two parts of equal mass and mark them as A and B respectively, and use A as a control sample; Weigh SiO with a mass percentage of 1% 2 Mix one part of airgel particles with B part of diluted latex paint and stir for 20 minutes to obtain a uniformly mixed SiO 2 Airgel thermal insulation latex paint and marked as C, the following is A part of silicone acrylic exterior wall latex paint and C part of SiO 2 Comparison of the performance of airgel thermal insulation latex coatings:

[0047] First, clean the surface of an ordinary white glass sheet with a size of 25mm×30mm and a thickness of 5mm, that is, first wash off various stains on t...

Embodiment 2

[0049] In this embodiment, the content by mass percentage is SiO 2 5% airgel particles, 80% silicone acrylic exterior wall latex paint and 15% deionized water are mixed for configuration. The steps are the same as in Example 1, and the thermal conductivity of the sample is measured with a flat-panel transient thermal conductivity meter, and the silicon acrylic exterior wall latex paint coating and SiO can be obtained correspondingly. 2 The thermal conductivity coefficients of airgel thermal insulation latex coatings are 0.976, 0.887, 0.844W / mK and 0.611, 0.520, 0.397W / mK respectively. It can be seen that adding 5% SiO 2 After airgel, SiO 2 Compared with the silicone acrylic exterior wall latex paint, the thermal conductivity of the silicone airgel thermal insulation latex paint is reduced by more than 40%.

Embodiment 3

[0051] In this embodiment, the content by mass percentage is SiO 2 10% airgel particles, 75% silicone acrylic exterior wall latex paint and 15% deionized water are mixed for configuration. Step is the same as embodiment 1, except that the volumes of the selected silicon acrylic exterior wall latex paint and thermal insulation latex paint are 100mm respectively 3 、450mm 3 , and then the silicone acrylic exterior wall latex paint and SiO 2 Airgel thermal insulation latex coating. Measure the thermal conductivity of the sample with a flat-panel transient thermal conductivity meter, and the corresponding silicon acrylic exterior wall latex paint and SiO 2 The thermal conductivity coefficients of airgel thermal insulation latex coatings are 1.075, 0.976W / mK and 0.214 and 0.187W / mK, respectively. Visible, after adding 10% airgel, SiO 2 The thermal conductivity of airgel thermal insulation latex paint is more than 80% lower than that of silicone acrylic exterior wall latex paint...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com