Nickel-based alloy powder material and 3D printing forming method thereof

A technology for nickel-based alloys and powder materials, applied in the field of high-temperature powder alloys, can solve the problems of ingot-forging method segregation, inability to guarantee material reliability, and complex composition of high-temperature alloys, achieve high structural strength and surface quality, and improve powder The effect of utilization efficiency, high temperature corrosion resistance and excellent microstructure stability of superalloy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035]Example 1 A nickel-based alloy powder material, the composition weight percent of which is: C ≤0.01%, Si 0.2%~0.8%, Mn 0.3%~0.5%, Cr 18.5~25.5%, Mo 8.5~11.5%, Nb 2.5% ~4.5%, the balance is nickel; when preparing, add 250 parts by weight of Cr, 110 parts by weight of Mo, 40 parts by weight of Nb, 4 parts of Mn, 6 parts by weight of Si and 590 parts by weight of Ni into a vacuum induction furnace Heating in the vacuum induction furnace and controlling the melting temperature range of 1500°C to 1600°C in the vacuum induction furnace to obtain the alloy melt; atomizing and granulating the obtained alloy melt, specifically including: pouring the alloy melt into the middle leakage bag, Open the leakage valve, the alloy melt flows into the gas atomization furnace freely through the leakage hole at the bottom of the middle leakage bag, under the impact of the high-speed inert gas flow, the alloy melt is crushed into fine droplets, and the alloy is obtained after cooling and solid...

Embodiment 2

[0037] A 3D printing method for manufacturing turbine disks (other embodiments may also be products such as engine blades) from nickel-based alloy powder materials, comprising the following steps:

[0038] A. Process design: first use the 3D computer software in the computer (including I-DEAS, Pro / E, Solidworks, Solidedge, etc.) to scan and model the turbine disk to obtain a complete mathematical model of the turbine disk; The continuous three-dimensional digital model of the turbine disc is discretely processed in layered slices to obtain slices of each layer with a thickness of 0.5mm, and the above information is transmitted to the control system of the 3D printing machine.

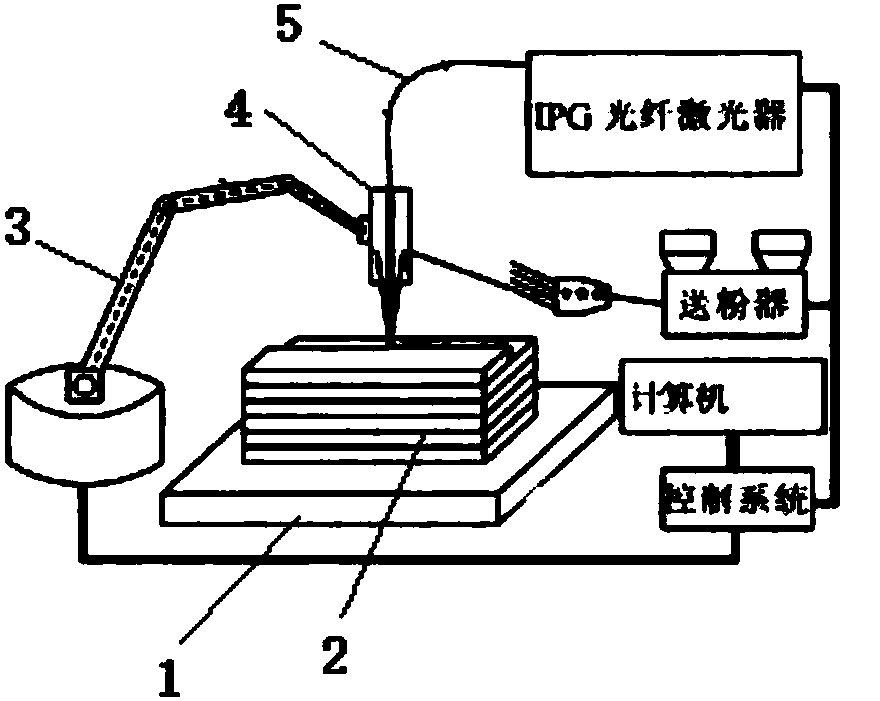

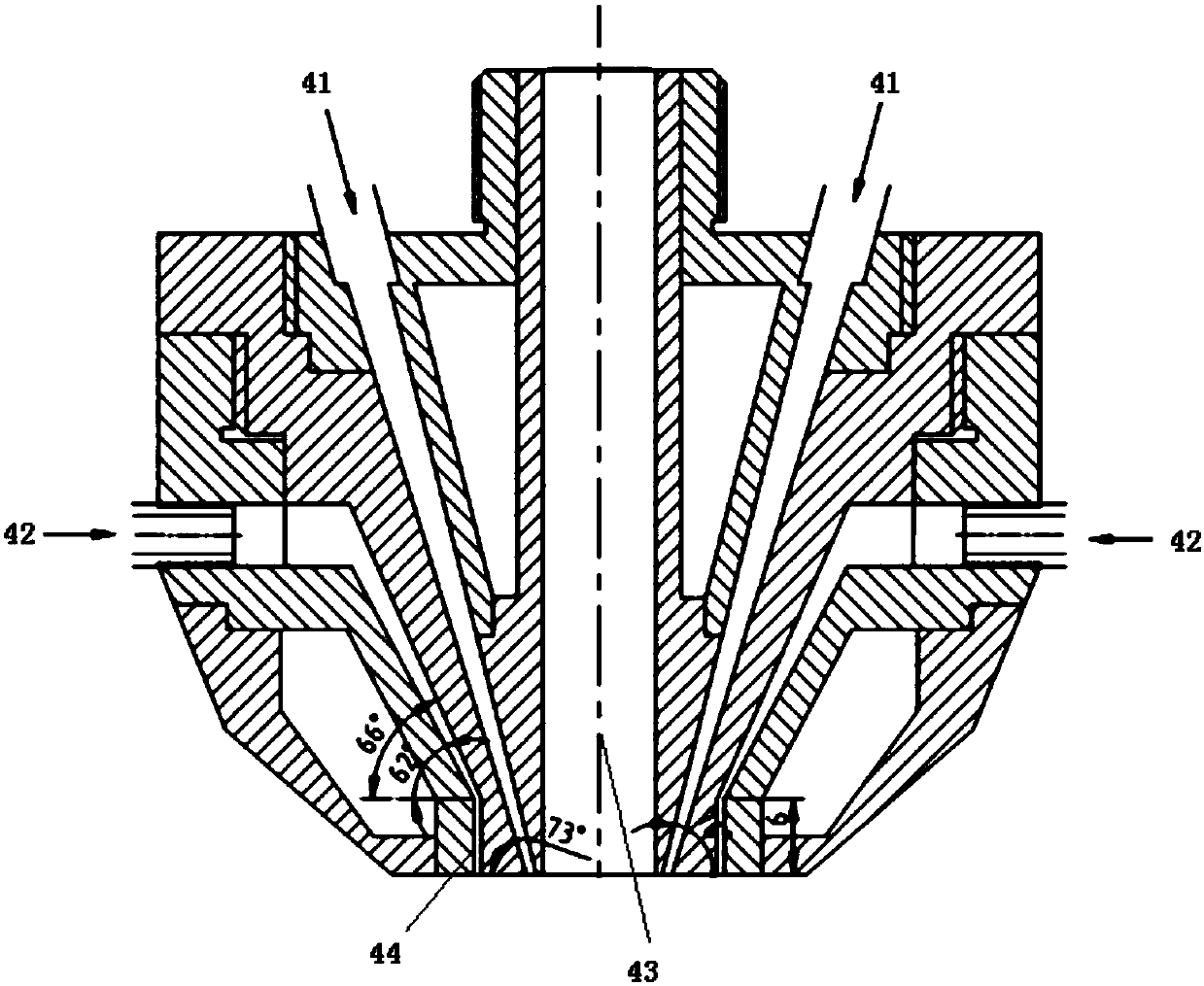

[0039] B. Preparation before processing: Clean up the 3D printer bed to ensure the smooth range of movement of the manipulator 3 and the three-axis chuck in the working space; check the sealing of the working space to ensure the purity of the protective atmosphere in the space; figure 1 As shown, the pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com