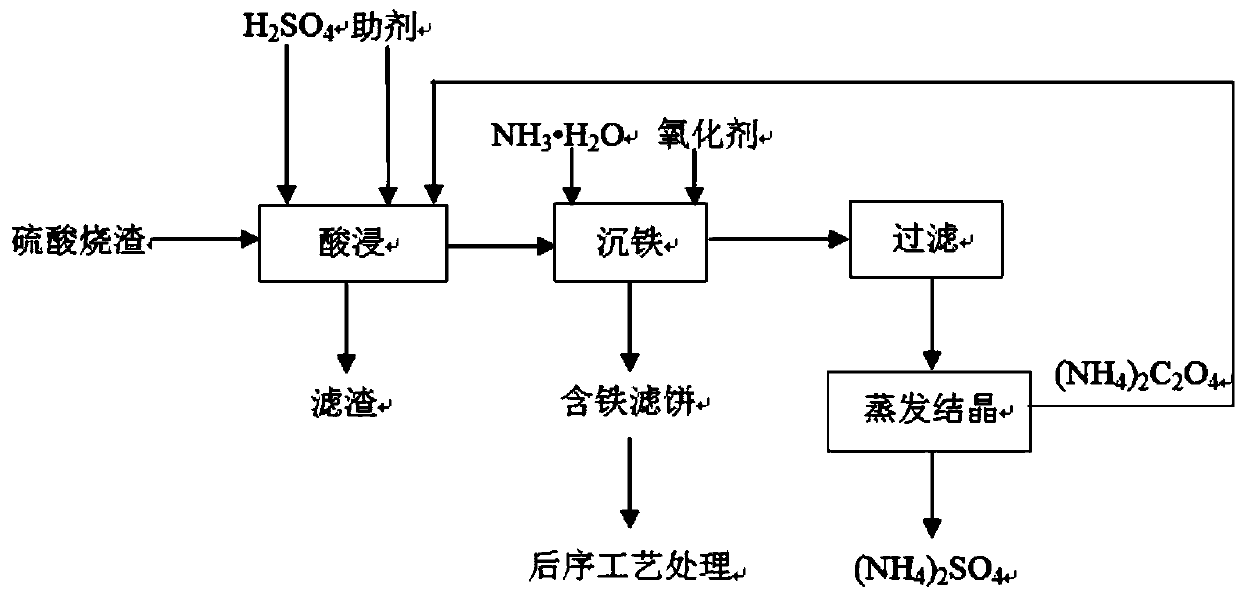

Process for extracting iron in sulfuric-acid slag through auxiliary-strengthening acid leaching method

A technology of sulfuric acid slag and acid leaching, applied in the direction of improving process efficiency, etc., can solve the problems of high equipment material requirements, large amount of additives, and secondary pollution of the environment, so as to improve the leaching rate and reduce the cost of additives , the effect of low acid leaching temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

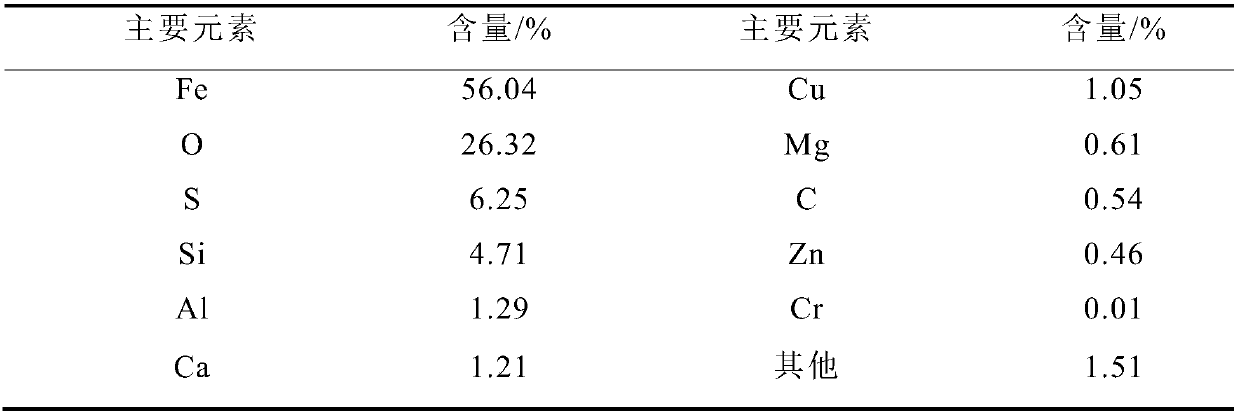

[0031] Get sulfuric acid slag 100g (iron content is 56.04%, the same below), add 10gH 2 C 2 o 4 Auxiliary, mixed evenly, put it into a 1000mL normal-pressure reactor, add a sulfuric acid solution with a mass concentration of 30% according to a solid-to-liquid ratio of 1:8, stir and react in a constant temperature water bath at 60°C for 6 hours, and filter to obtain an acid dipping solution. The acid leaching solution was tested, and the iron leaching rate was 90%.

Embodiment 2

[0033] Take sulfuric acid slag 100g, add 15gH 2 C 2 o 4 Auxiliaries, mixed evenly, put into a 1000mL normal-pressure reaction kettle, add a sulfuric acid solution with a mass concentration of 40% according to a solid-to-liquid ratio of 1:6, stir and react in a constant temperature water bath at 80°C for 8 hours, filter to obtain an acid dipping solution, and The acid leaching solution was tested, and the iron leaching rate was 93%.

Embodiment 3

[0035] Get sulfuric acid slag 100g, add 20g (NH 4 ) 2 C 2 o 4 Auxiliary, mixed evenly, put it into a 1000mL normal-pressure reaction kettle, add a sulfuric acid solution with a mass concentration of 50% according to a solid-to-liquid ratio of 1:6, stir and react in a constant temperature water bath at 95°C for 8 hours, filter to obtain an acid dipping solution, and The acid leaching solution was tested, and the iron leaching rate was 97%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com