Device and method for cleaning tundish upper water gap nodules

A nodule and nozzle technology, which can be used in casting melt containers, metal processing equipment, casting equipment, etc., and can solve problems such as nozzle nodules

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

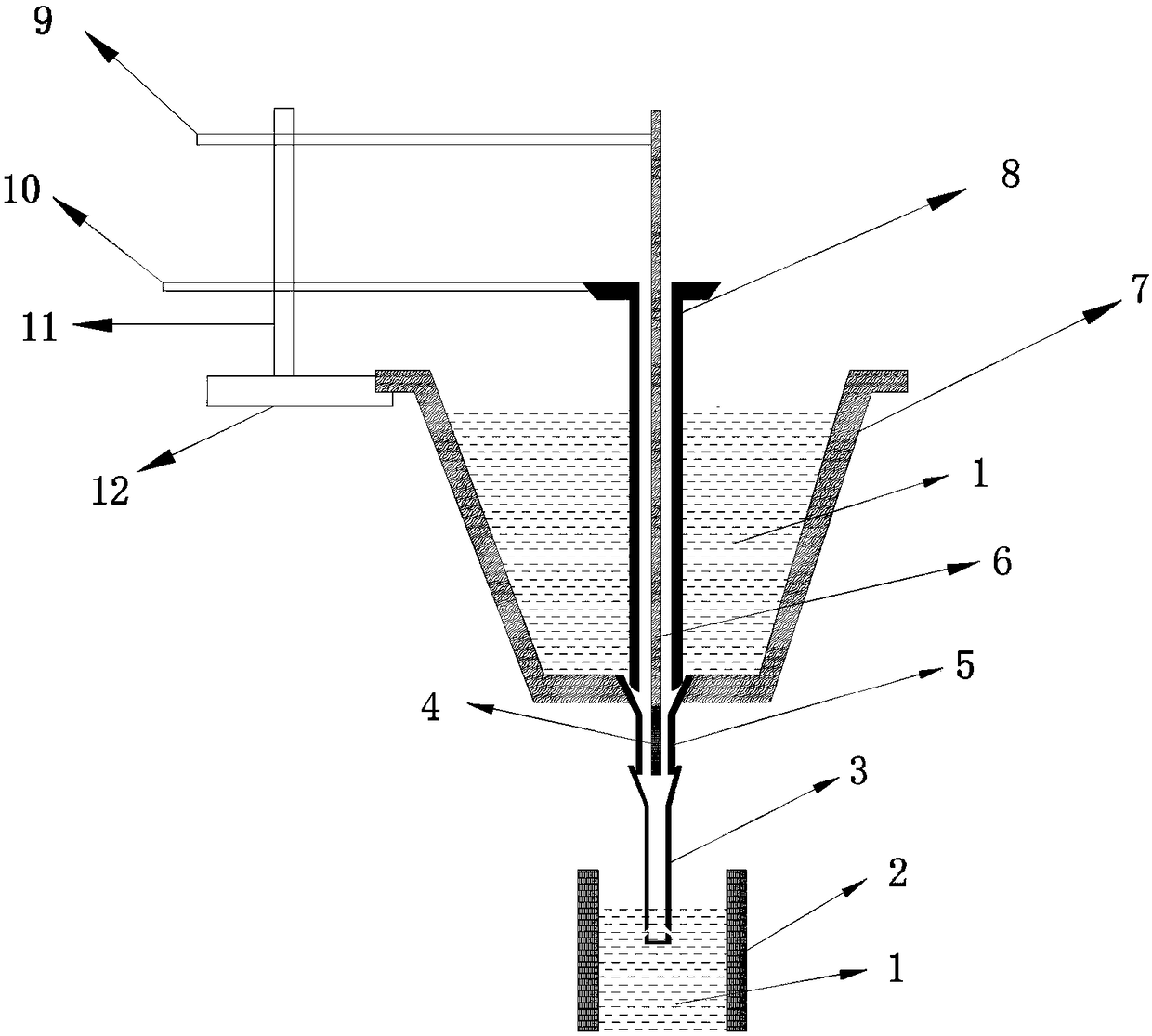

[0053] The following examples are shown together with the device figure 1 , 2 3. Further explain a method for solving the problem of nodulation at the upper nozzle of the tundish.

[0054] The continuous casting ladle capacity is: 50 tons, and the continuous casting equipment is: rectangular billet continuous casting machine, three machines and three streams, and the billet size is 180mm×220mm.

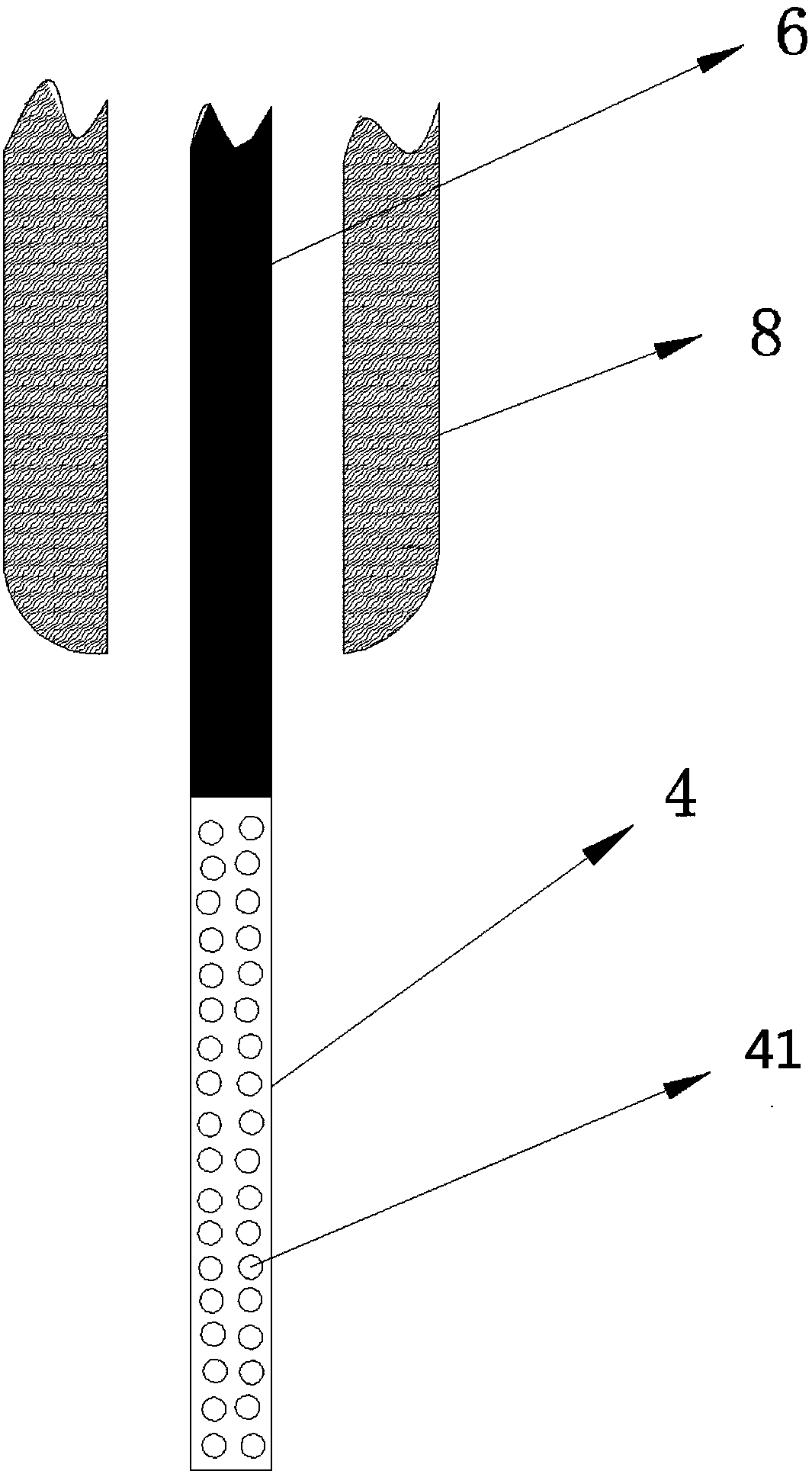

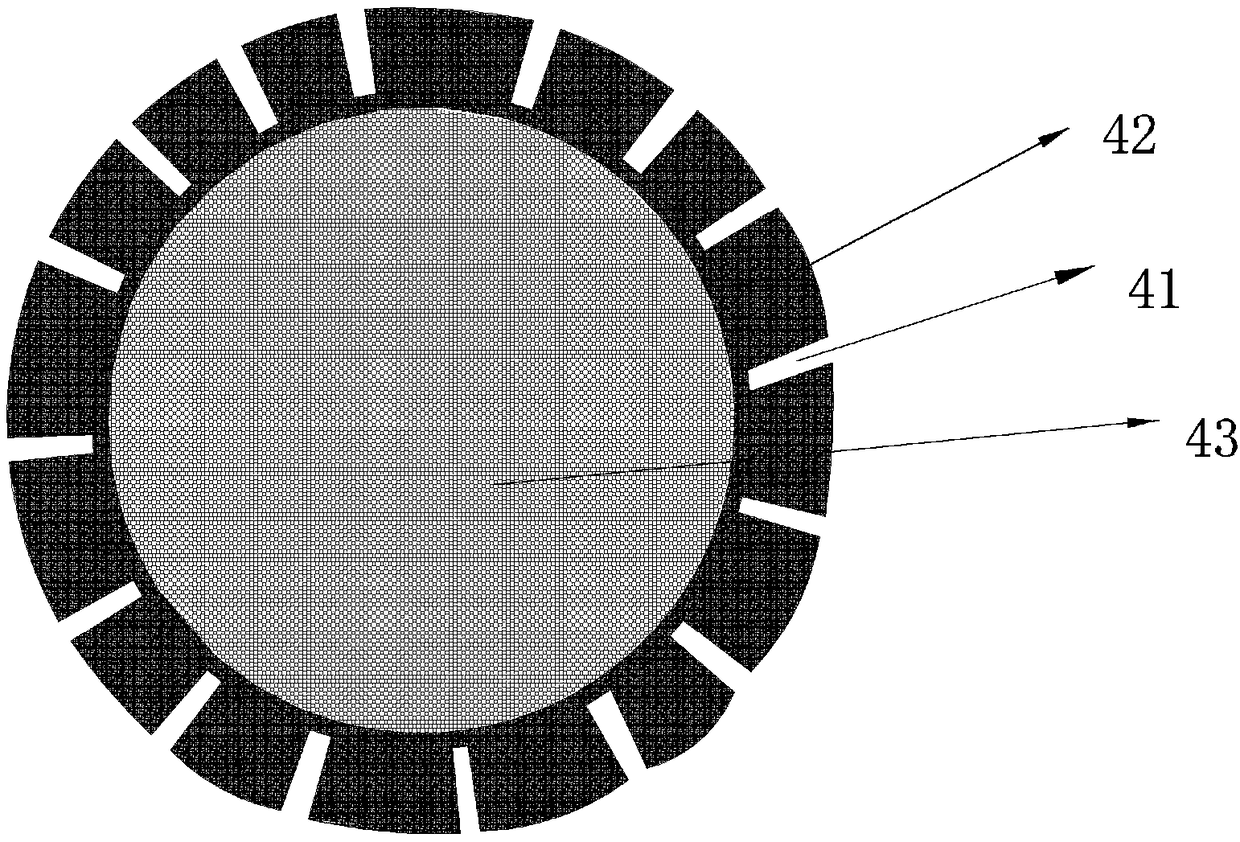

[0055] The device for cleaning Al2O3 nodules at the upper nozzle of the tundish is mainly composed of a round steel rod 4 with a calcium core, a refractory material rod 6, a hollow stopper rod 8, a horizontal holder and a vertical lifting frame. The vertical lifting frame is connected with the horizontal clamper, and the vertical lifting movement of the horizontal clamper can be controlled through the vertical lifting frame. The horizontal clamper is connected with the upper end of the refractory material rod, and the refractory material rod can be fixed and driven The refractory ro...

Embodiment 2

[0069] The following examples are shown together with the device figure 1 , 2 3. Further explain a method for solving the problem of nodulation at the upper nozzle of the tundish.

[0070] The large ladle capacity of continuous casting is: 120 tons, and the continuous casting equipment is: thick slab billet continuous casting machine, a first-class machine, and the billet size is 250mm×2200mm.

[0071] The device for cleaning Al2O3 nodules at the upper nozzle of the tundish is mainly composed of a round steel rod 4 with a calcium core, a refractory material rod 6, a hollow stopper rod 8, a horizontal holder and a vertical lifting frame. The vertical lifting frame is connected with the horizontal clamper, and the vertical lifting movement of the horizontal clamper can be controlled through the vertical lifting frame. The horizontal clamper is connected with the upper end of the refractory material rod, and the refractory material rod can be fixed and driven The refractory rod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com