Thermos kettle

A heat preservation pot and pot body technology, which is applied to household containers, special materials for cooking utensils, cooking utensils, etc., can solve the problems of general heat preservation effect, low decorative effect, low heating efficiency, etc., achieve beautiful decorative effect, shorten heating time, Easy to clean effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

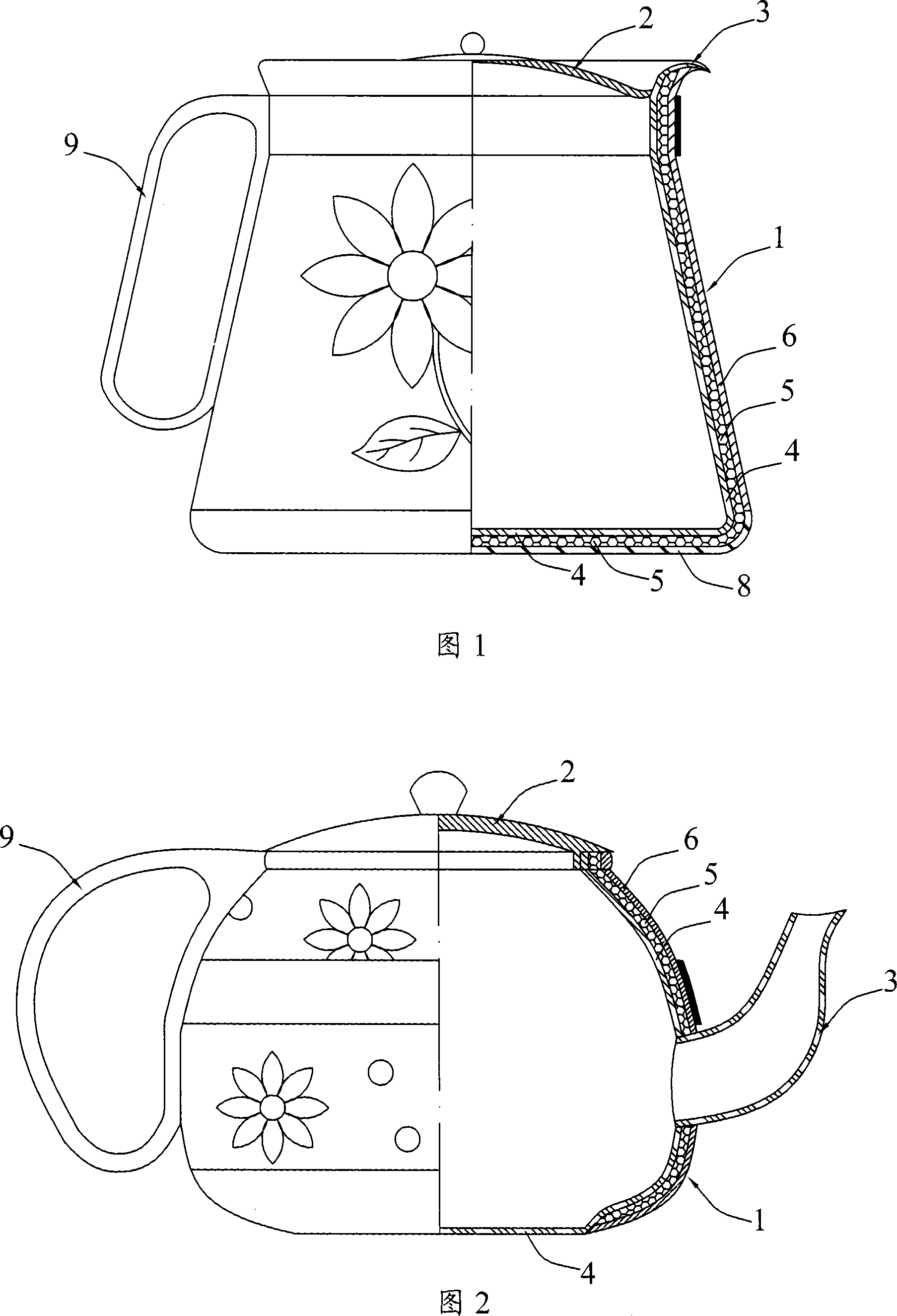

Embodiment 1

[0018] A thermos pot structure as shown in Figure 1, including a pot body 1, a pot cover 2 and a spout 3 extending outward on one side of the pot body 1, the side wall of the pot body 1 includes an inner tank 4, a filling layer 5 It has a three-layer structure with the outer shell 6, the inner tank 4 is made of metal material, the filling layer 5 is made of temperature-insulating foam filling material, and the outer shell 6 is made of ceramic material. The bottom of the pot includes a three-layer structure of an inner container 4, a filling layer 5 and a base 8 matched with the shell 6. The spout 3 is arranged on the top edge of the kettle body 1 and is integrally formed with the inner tank 4 . The pot body 1 is in an inverted cone shape as a whole, and a handle 9 is provided on the side. The insulation pot structure designed in this embodiment is mainly used for holding liquids for heat preservation, such as teapots, coffee pots, etc., and a filter screen can be installed in...

Embodiment 2

[0022] The structure of the thermos pot of this embodiment is shown in Figure 2, comprising a pot body 1, a pot cover 2 and a spout 3 extending outward on one side of the pot body 1, and the side wall of the pot body 1 includes an inner container 4, a filling layer 5 and the outer shell 6 have a three-layer structure, the inner tank 4 is made of metal material, the filling layer 5 is made of heat-insulating foam filling material, and the outer shell 6 is made of ceramic material. The bottom of the pot body 1 is the bottom of the inner container 4, which is integrated with the inner container 4 and is made of metal. The spout 3 is arranged on the side of the kettle body 1 and passes through the filling layer 5 and the shell 6 . The side of the kettle body 1 is provided with a handle 9, and the function and effect of the three-layer heat preservation structure on the side wall are as described in Embodiment 1.

[0023] This design is a direct heating type thermos structure. Dur...

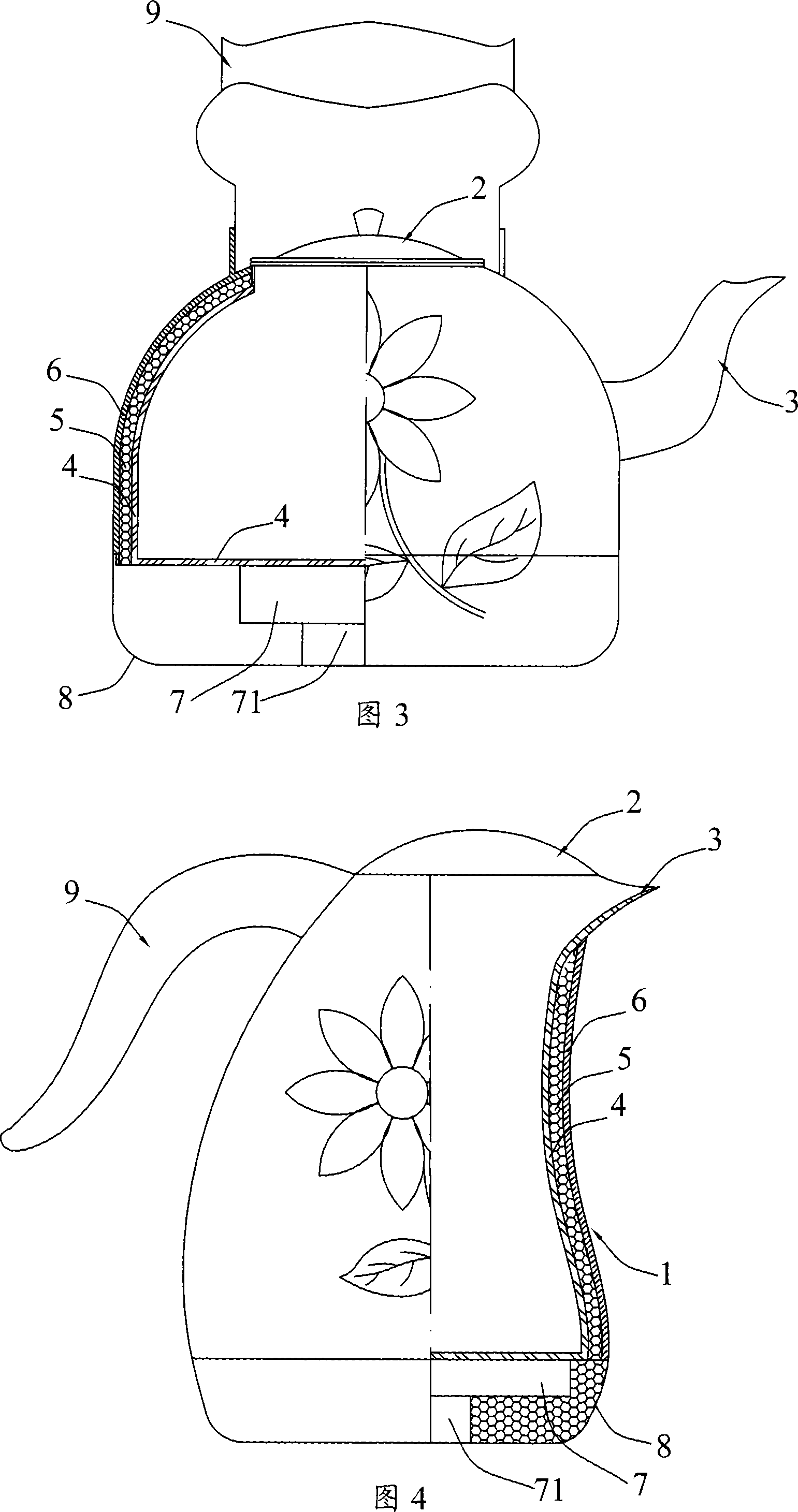

Embodiment 3

[0025] This embodiment provides an electric heating thermos structure, as shown in FIG. 3 . Like the last two embodiments, it includes a kettle body 1, a pot cover 2 and a spout 3 extending outward on one side of the kettle body 1, and the side wall of the kettle body 1 includes an inner container 4, a filling layer 5 and an outer shell 6. Layer structure, the inner tank 4 is made of metal material, the filling layer 5 is made of heat-insulating foam filling material, and the outer shell 6 is made of ceramic material. The improved structure is that an electric heating device 7 is provided on the bottom of the kettle body 1 , and the bottom of the kettle is a metal structure integrally formed with the inner tank 4 . The electric heating device 7 is a general-purpose electric heating plate or a semiconductor electric heating device. A base 8 is provided on the outside of the electric heating device 7 to cooperate with the shell 6. The base 8 is used to protect the electric heati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com