Aluminum electrolysis continuous production method and structure adopting prebaked anode

A prebaked anode and production structure technology, applied in the field of electrolytic aluminum production, can solve the problems of increasing power consumption rate, affecting current efficiency, stable operation of electrolytic cell, and large impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

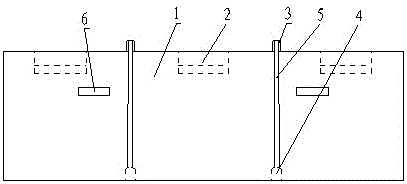

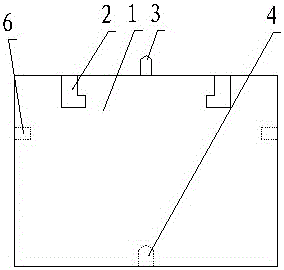

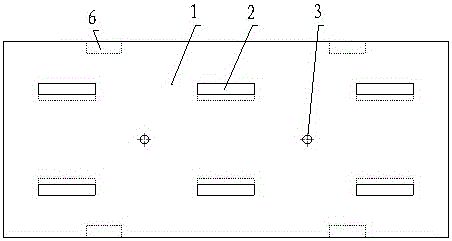

[0027] Example 1 . The continuous production structure of prebaked anode aluminum electrolysis, as shown in the figure 1-9 As shown, the carbon block body including the anode 1 , carbon block body 1 upper set coupling groove 2 , coupling groove 2 Connect steel claw 7 , in the carbon block body 1 Fixed protrusions are set on the top and bottom respectively 3 and fixing groove 4 , new and old carbon block bodies 1 by fixing the nose 3 and fixing groove 4 locating connections, and by fixing the tabs on the 3 and fixing groove 4 Fill the gap between the old and new carbon block body with sintered material or pouring material 1 fixed together.

[0028] The carbon block body 1 Connect auxiliary pendant 12 , used to fix the old anode.

[0029] The auxiliary pendant 12 crossarm can be used 13 , cross arm 13 Connect the boom 14 , can also use a forklift, through the forklift arm 15 To the carbon block body 1 l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com