Patents

Literature

77results about How to "Won't swell" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

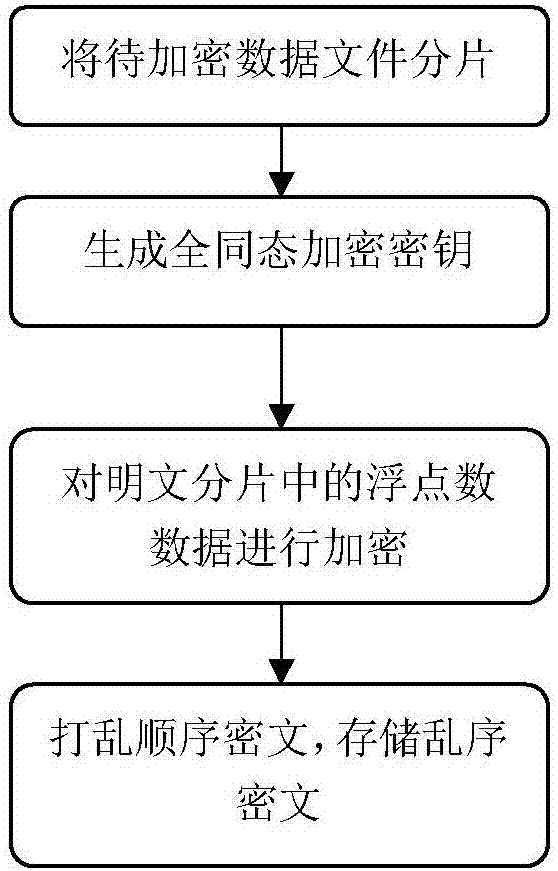

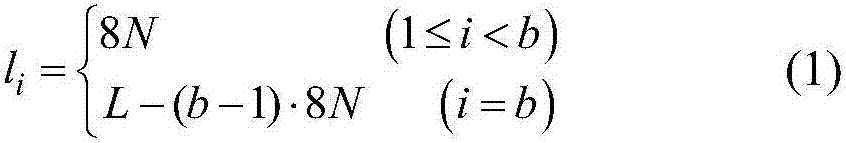

Parallel fully-homomorphic encryption and decryption methods supporting floating point arithmetic

ActiveCN107317666AEnsure safetyWon't swellKey distribution for secure communicationCommunication with homomorphic encryptionPlaintextComputer hardware

The invention provides a parallel fully-homomorphic encryption method supporting floating point arithmetic, and belongs to the technical field of information security. The encryption method comprises the three steps of encryption key initialization, plaintext data encryption and out-of-order storage of child ciphertext, and by means of a parallel computing mechanism of a cloud computing environment and grouped encryption on plaintext data, a whole to-be-encrypted file is encrypted and then stored in a storage system of the cloud computing environment. The invention further provides a decryption method based on the parallel fully-homomorphic encryption method, an addition homomorphic encryption method and a multiplication homomorphic encryption method. According to the methods, the algorithm is simple, easy to achieve, high in security and capable of supporting homomorphic addition and multiplication at any depth and has the compact characteristic; and the efficiency of the algorithm can be further improved through parallel frameworks such as Spark, and the methods are suitable for the cloud computing environment.

Owner:深圳大道云科技有限公司

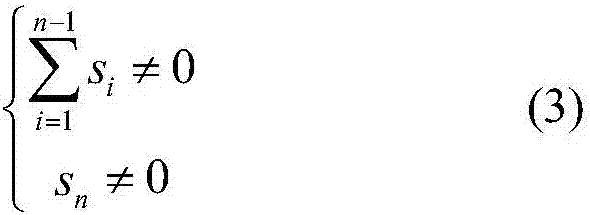

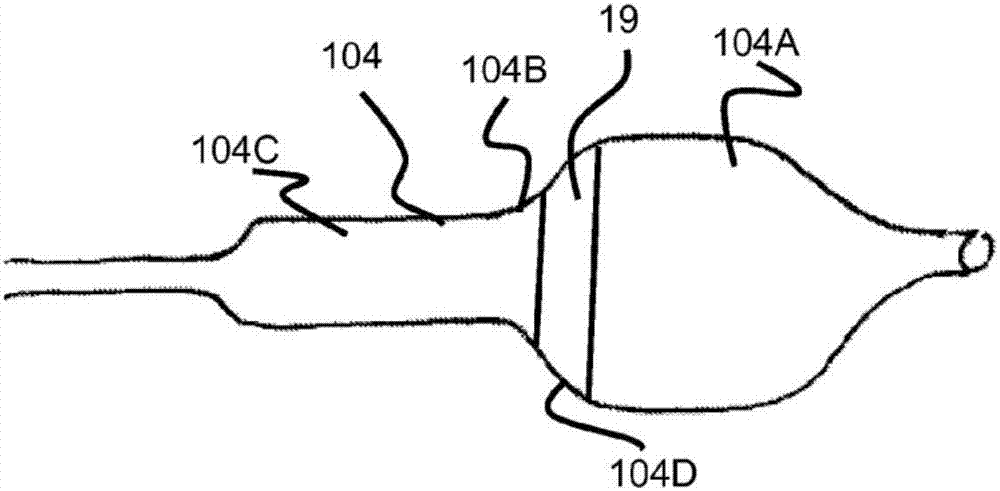

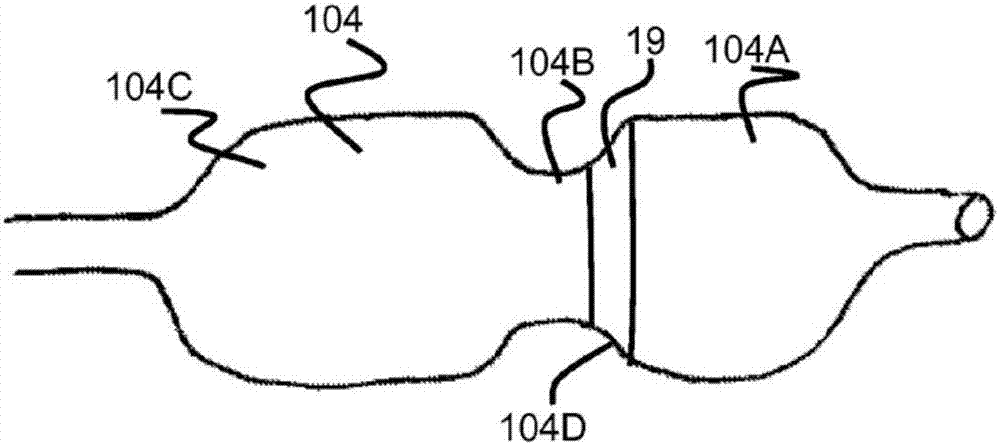

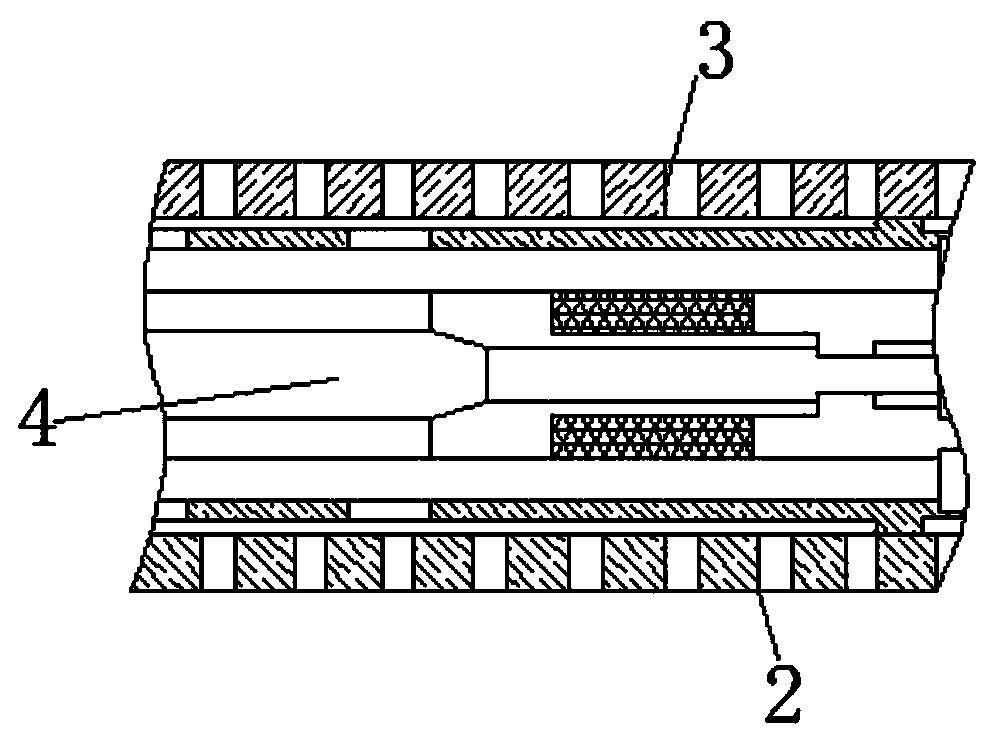

Balloon catheter with marker and processing and positioning methods

InactiveCN107115161ALarge tissue deformationWon't swellBalloon catheterHeart valvesMaximum diameterUltrasonic imaging

The invention discloses a balloon catheter with a marker and processing and positioning methods. The balloon catheter comprises a catheter. The near end of the catheter is connected to a fluid conveying device while the far end is provided with a balloon communicating with the fluid conveying device. The balloon comprises the far end, the near end and a waist between the far end and the near end. The maximum diameter of the waist is smaller than the maximum diameter of the far end and the near end. Marker rings are distributed around the balloon. By means of an X-ray or ultrasonic imaging technology, the marker on the balloon catheter can be displayed in real time in an operating process, and the release degree of the balloon catheter and the position relationship with an aortic valve ring are determined by means of position and shape of the marker.

Owner:茵特瓦医疗有限公司

Method for manufacturing redwood furniture

ActiveCN103817764ASolve the problem of not leaving expansion jointsMild colorWood working apparatusWaxSurface layer

The invention discloses a method for manufacturing redwood furniture. Expansion and cracking caused by wood characteristic changes are reduced to the largest extent, losses of original waxiness of wood are reduced, the mechanical property of the wood is increased, and reduction of the original toughness of the wood is lowered. A mortise and tenon joint structure is high in precision, high in efficiency and proper in looseness. The natural texture, color and flavor of furniture materials can be kept, and the color is gentle and natural. The real materials of the furniture are easy to recognize. Fineness of engraving, polishing and other manufacturing processes is easy to recognize. Wax on the surface of the furniture is natural and environmentally friendly, and the furniture conforms to healthy life positions. In the use process, the gloss of the surface layer of the waxed furniture is lighter and lighter.

Owner:江苏虞林世家红木家具有限公司

Energy-saving cooling fluid

The invention relates to an energy-saving cooling fluid which takes glycol as a base material, and has the following components according to mass percentage: 92 to 95 of the glycol, 1 to 3 of deionized water, 0.5 to 1.5 of decanedioic acid, 0.6 to 2 of n-octanoic acid, 0.4 to 1.5 of potassium hydroxide, and 0.3 to 0.8 of methenamine. The cooling fluid has low freezing point, wide boiling spread, excellent heat conductivility at high temperature, and energy-saving efficiency, prevents frozen injury and occurrence of steam blocking layer when the engine works, improves the thermal equilibrium temperature when the engine works, with the fuel completely combusted, reduces tail gas discharge, and obviously promotes the power.

Owner:周振华

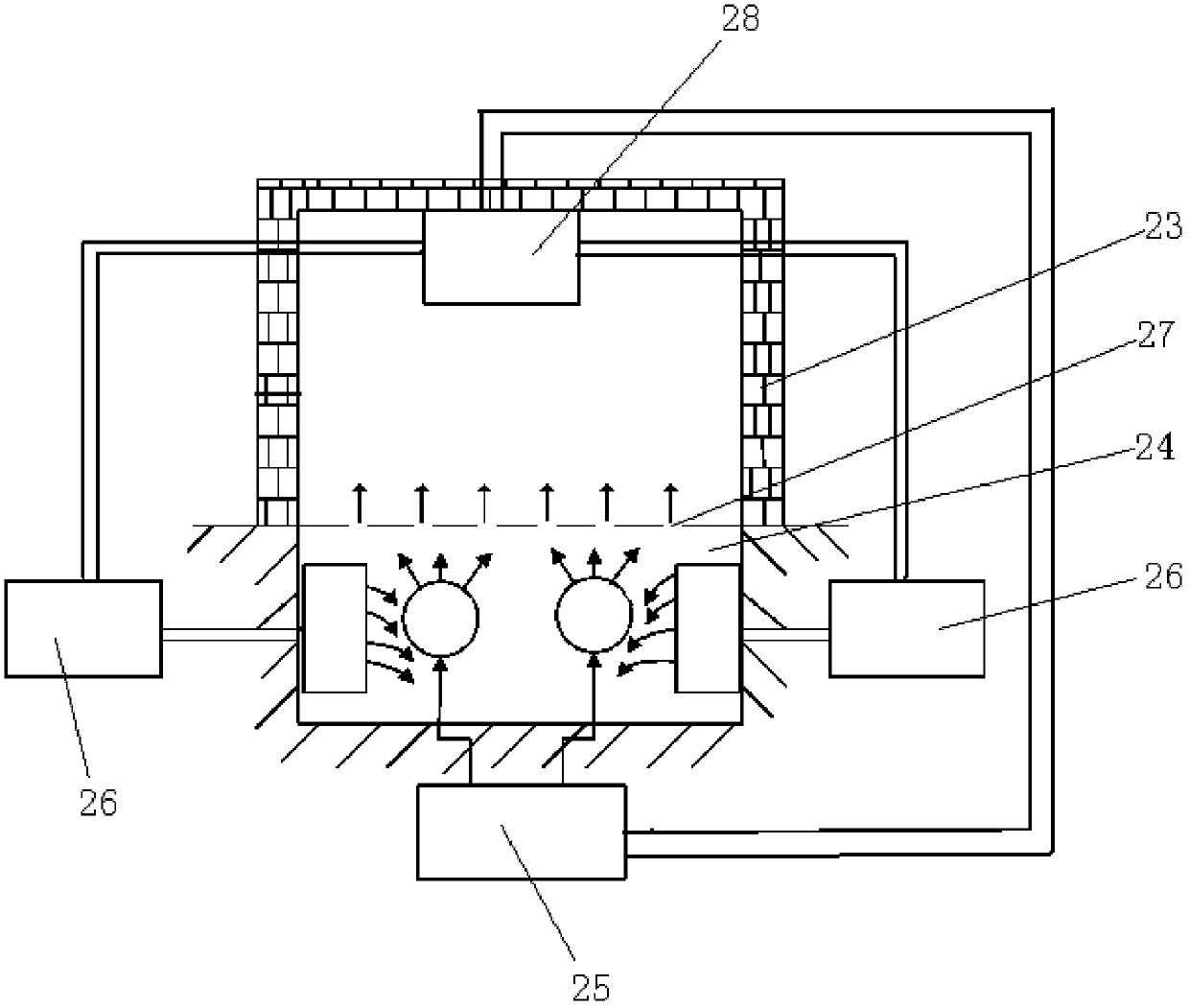

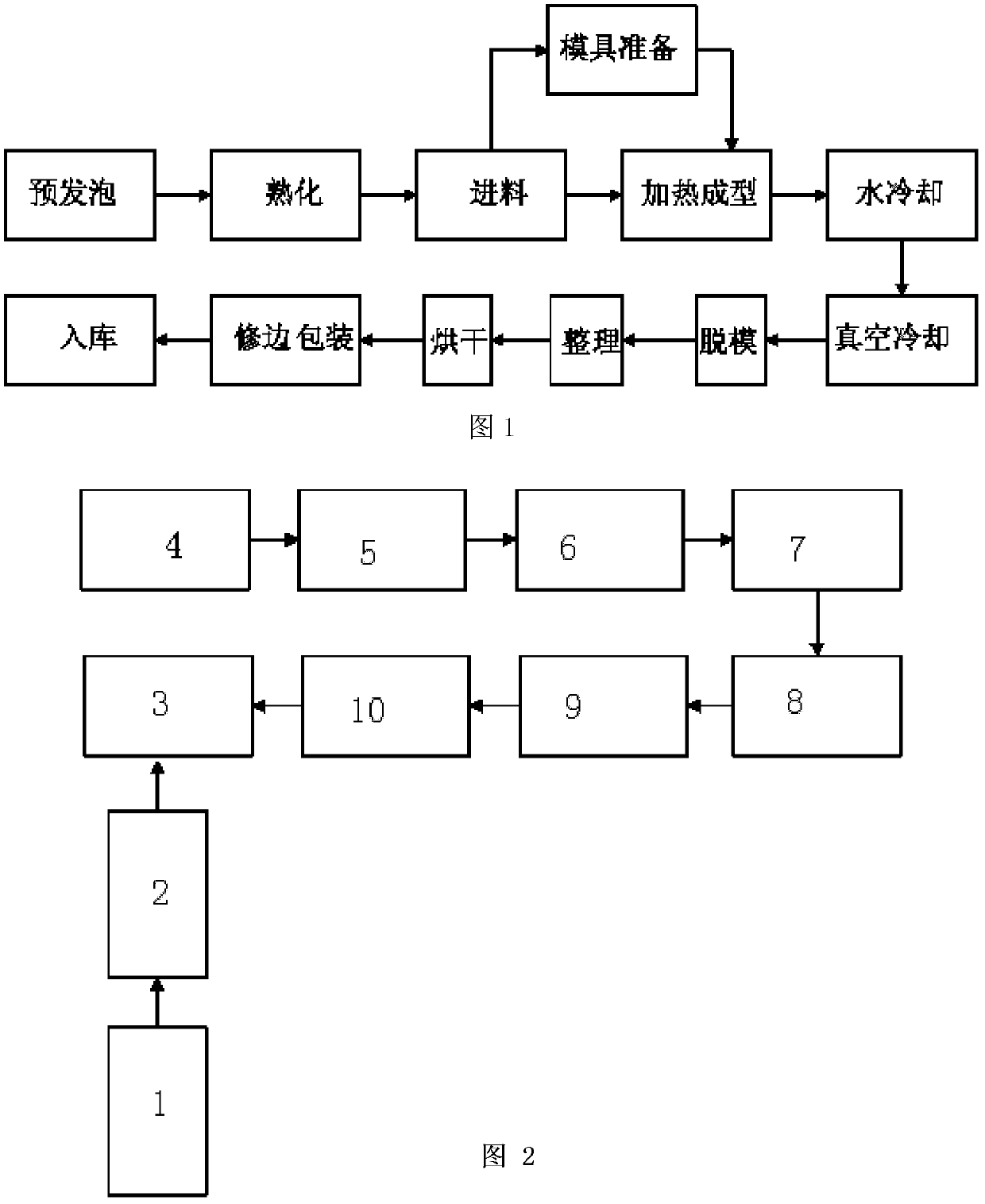

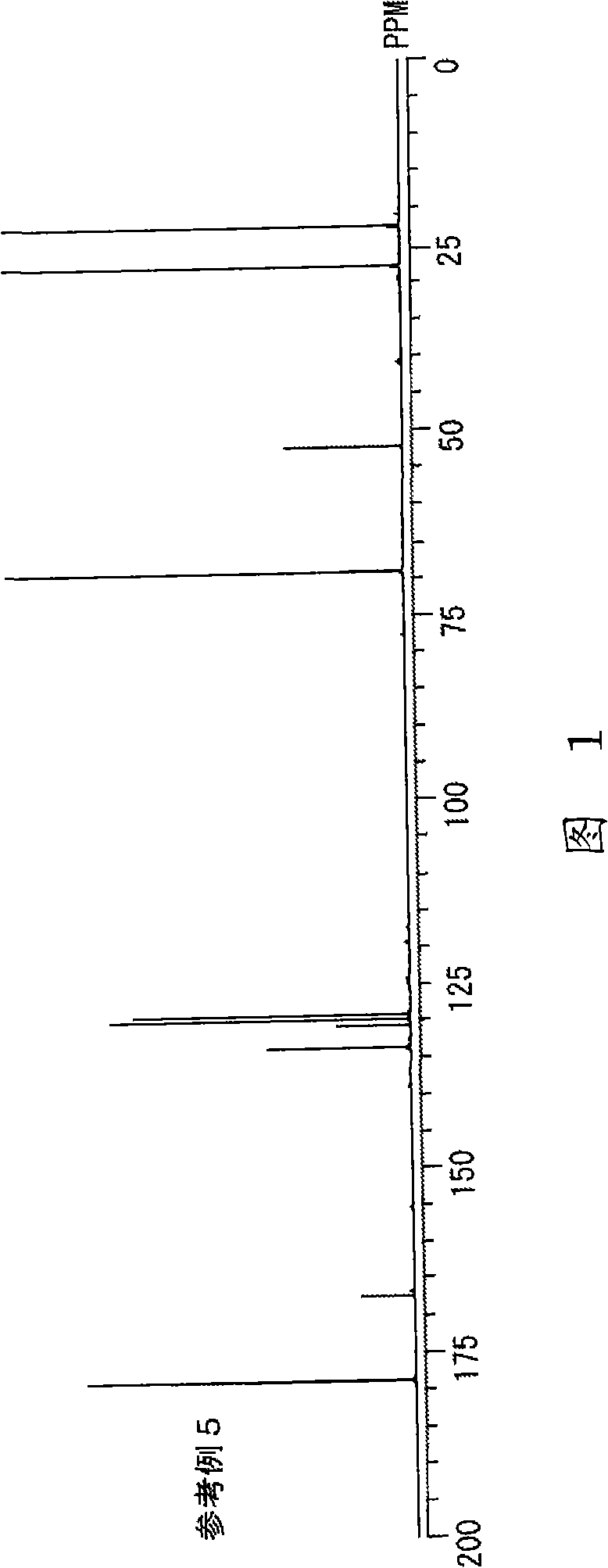

Production technique of EPS (expandable polystyrene) foam articles

The invention discloses a production technique of EPS (expandable polystyrene) foam articles. The production technique is characterized by comprising the following steps: pre-foaming, curing, feeding, preparing mould, heating and forming, water cooling, vacuum cooling, demoulding, trimming, drying, trimming, packaging and storing in warehouse, and the production technique improves the compressed air, water circular cooling and drying process. The technique disclosed by the invention has simple and reasonable technique procedures and utilizes two paths of compressed air supply systems, so that the pipeline pressure is very stable, an electromagnetic valve acts flexibly, a cylinder switching valve quickly and reliably acts, and a cooling water circulating system can quickly cool to improve the cooling efficiency, save the electric energy and vapor and reasonably utilize the energy sources; besides, a mixed mode of high and low temperature air is used, so that the articles are not deformed or expanded irrespective to the foaming density, the drying time is shortened and the resources are reasonably utilized.

Owner:安徽艾柯泡塑股份有限公司

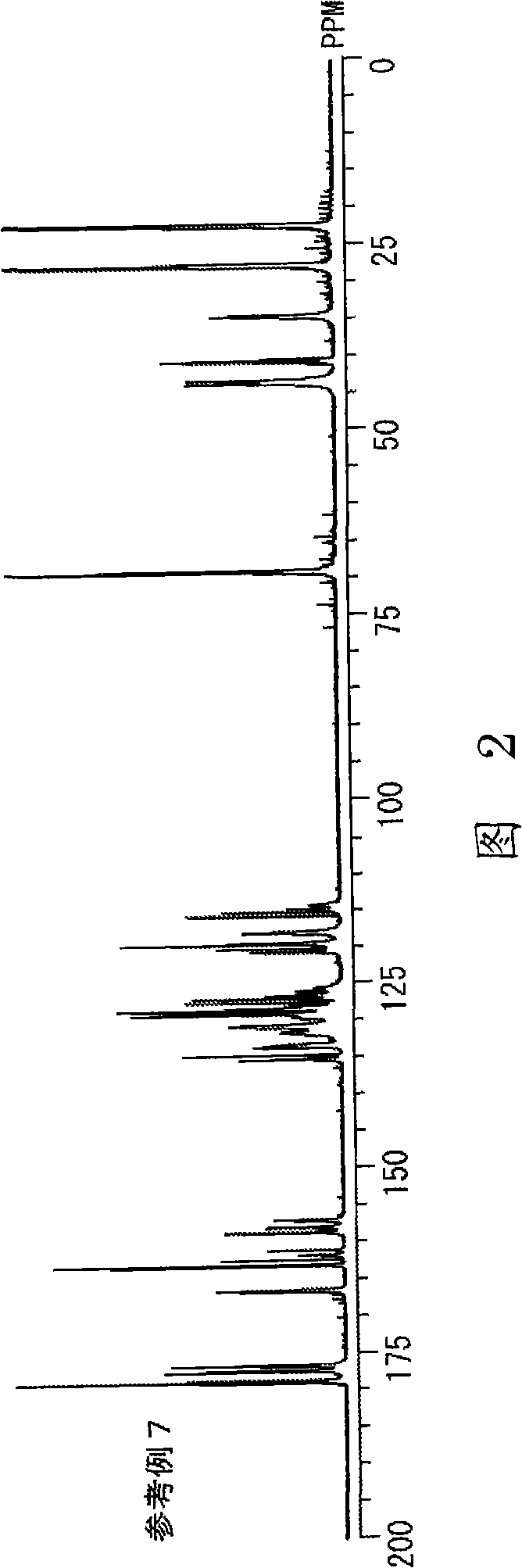

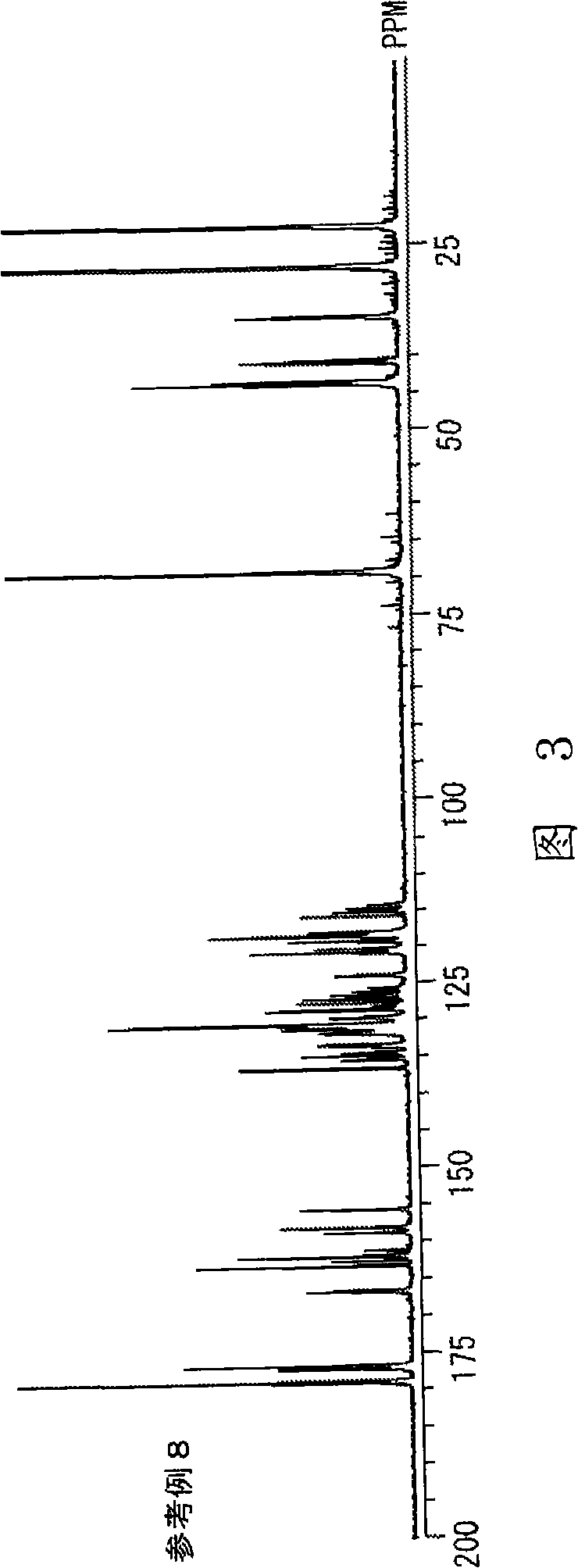

Positive photosensitive resin composition

ActiveCN101278234AWon't swellIncreased sensitivitySemiconductor/solid-state device manufacturingPhotosensitive material processingOrtho positionDiazonaphthoquinone

A photosensitive resin composition comprising 100 parts by mass of polycondensate (A) having a structure resulting from dehydration condensation between one or two or more tetracarboxylic acid dianhydride and one or two or more aromatic diamines having mutually ortho-positioned amino and phenolic hydroxyl groups and 1 to 100 parts by mass of photosensitive diazonaphthoquinone compound (B), wherein the polycondensate (A) has a weight average molecular weight of 3000 to 70,000.

Owner:HEFEI HANZHIHE MATERIAL SCI & TECH CO LTD

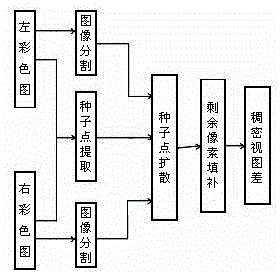

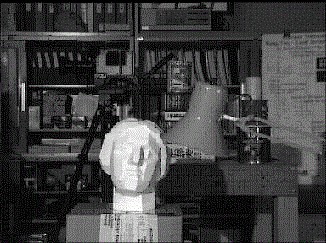

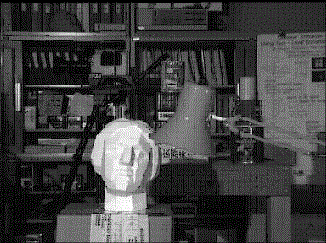

Stereo matching algorithm based on image segmentation

InactiveCN103606162ANarrow down the parallax rangeEasy to detectImage analysisColor imageStereo matching

The invention relates to a stereo matching algorithm based on image segmentation. The method comprises the steps of S01, conducting image segmentation on a left color image and a right color image by means of the mean-shift algorithm; S02, matching the left color image with the right color image by means of the large window matching method based on matching cost with statistics combined with absolute error summation (SAD), and extracting seed points high in matching accuracy; S03, diffusing the seed points obtained from the S02 to the whole area with the small window matching method by means of the image segmentation result obtained from the S01 in each area according to the smoothness restriction condition of the area; S04, filling up a disparity map obtained from the S03; S05, obtaining a dense disparity map finally. According to the stereo matching algorithm based on image segmentation, a low-grain area can be well detected, and foreground expansion can not be caused in uncontinuous-parallax areas.

Owner:FUZHOU UNIV

Road isolation fence for buffering and warning

InactiveCN110924333AShort timeReduce impact speedMachines/enginesTraffic signalsEmbedded systemAutomotive engineering

The invention discloses a road isolation fence for buffering and warning. Isolation pile, a warning lamp is mounted at the top of the isolation pile; two square grooves are symmetrically formed in theside wall of the isolation pile, an air bag is glued to the side wall of the isolation pile, an induction cavity is formed in the isolation pile, the induction cavity is communicated with the two square grooves, a storage box is fixedly arranged on the side, close to the induction cavity, of each square groove, and a circuit box is fixedly installed in the middle of the induction cavity. Rigid collision between a vehicle and the isolation pile is converted into elastic collision between the vehicle and the air bag when an accident occurs, so that the impact force between the vehicle and the air bag is reduced, the buffer to the vehicle is increased, the protection effect of the isolation pile is improved, and the isolation pile can be prevented from being seriously damaged; after collision, the warning lamps on the isolation piles automatically emit light and can be kept for a certain period of time, so that other drivers are reminded to avoid accident vehicles in time, and chain traffic accidents and rear-end collisions are reduced.

Owner:商河园通市政工程有限公司

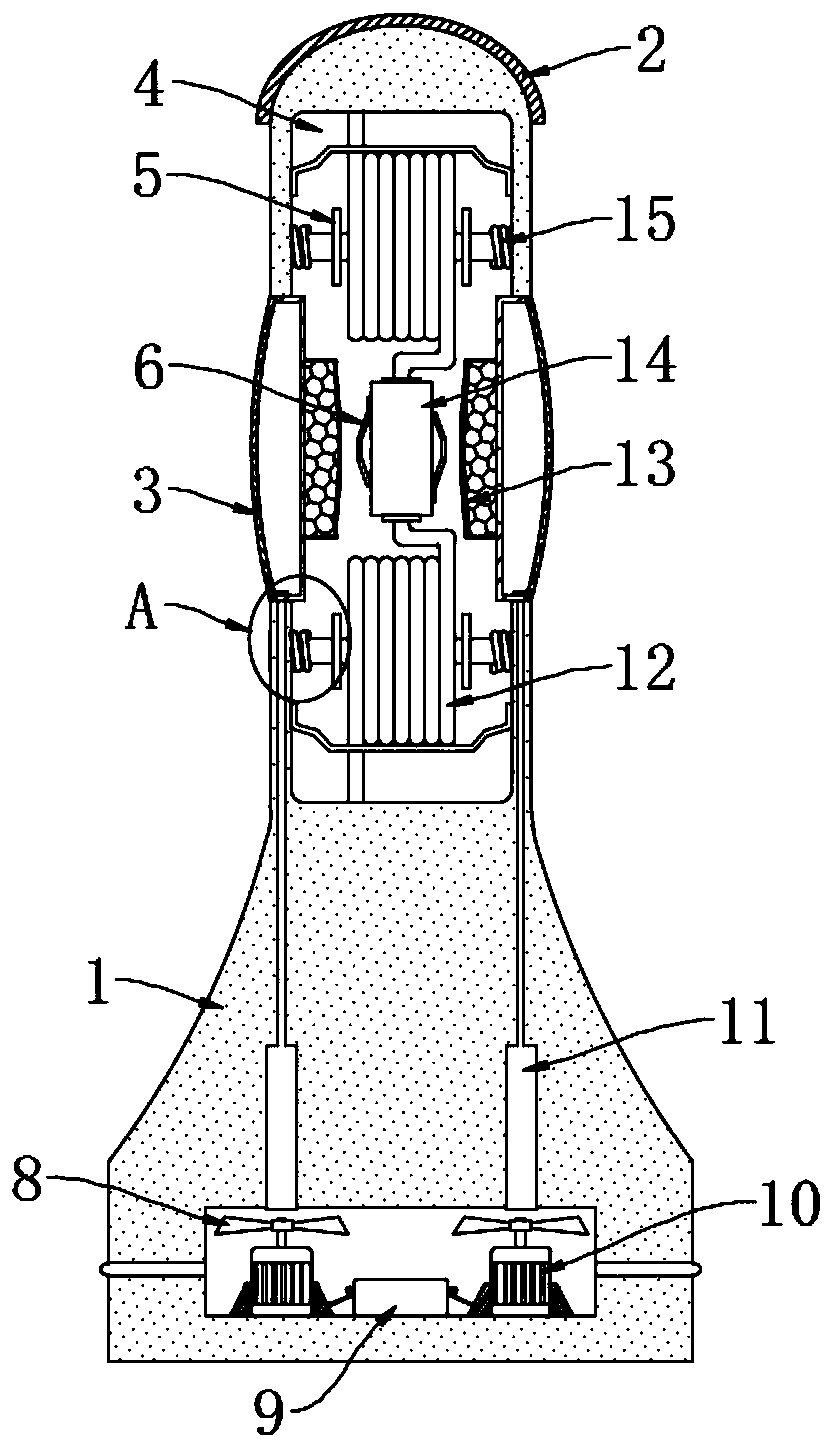

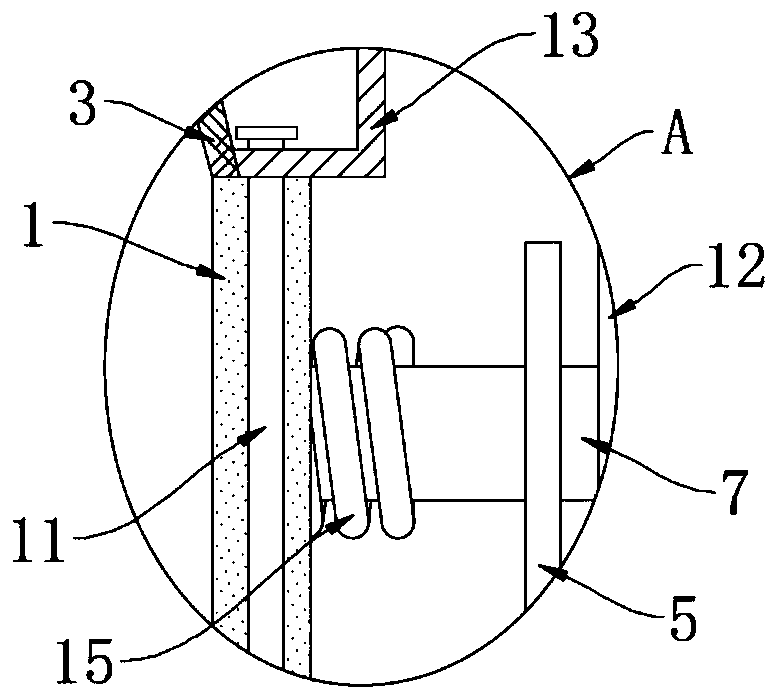

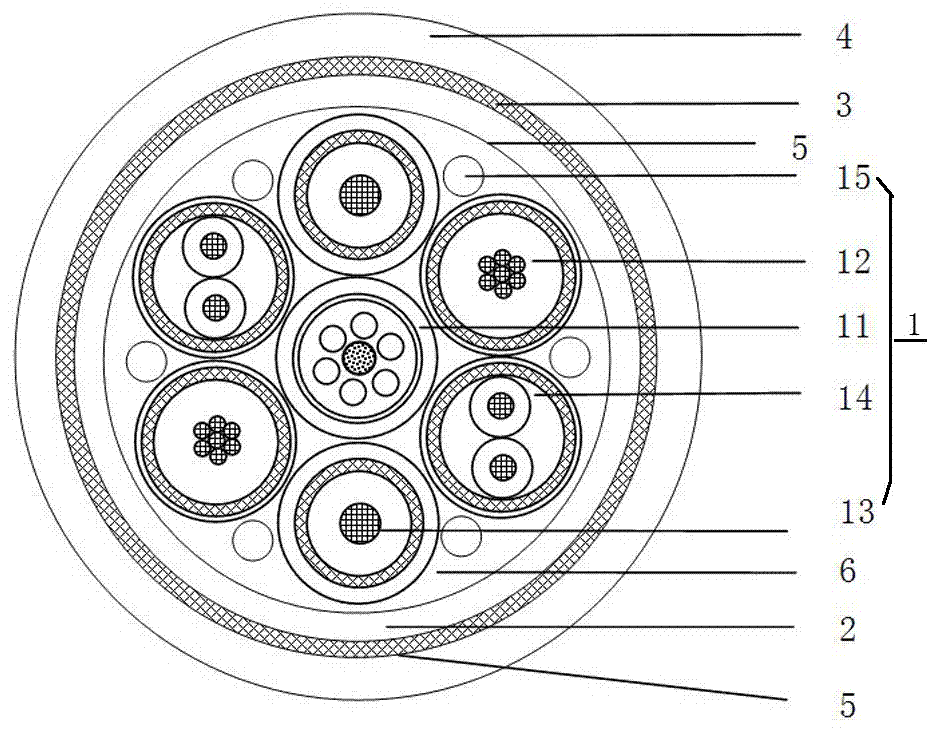

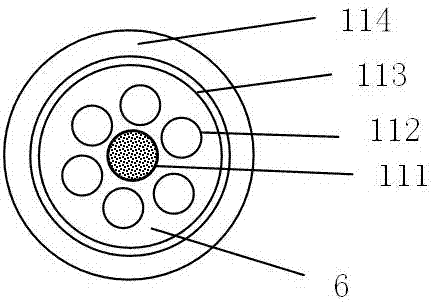

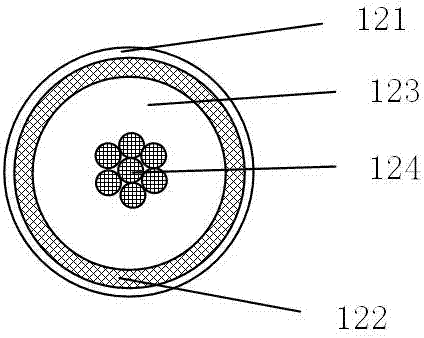

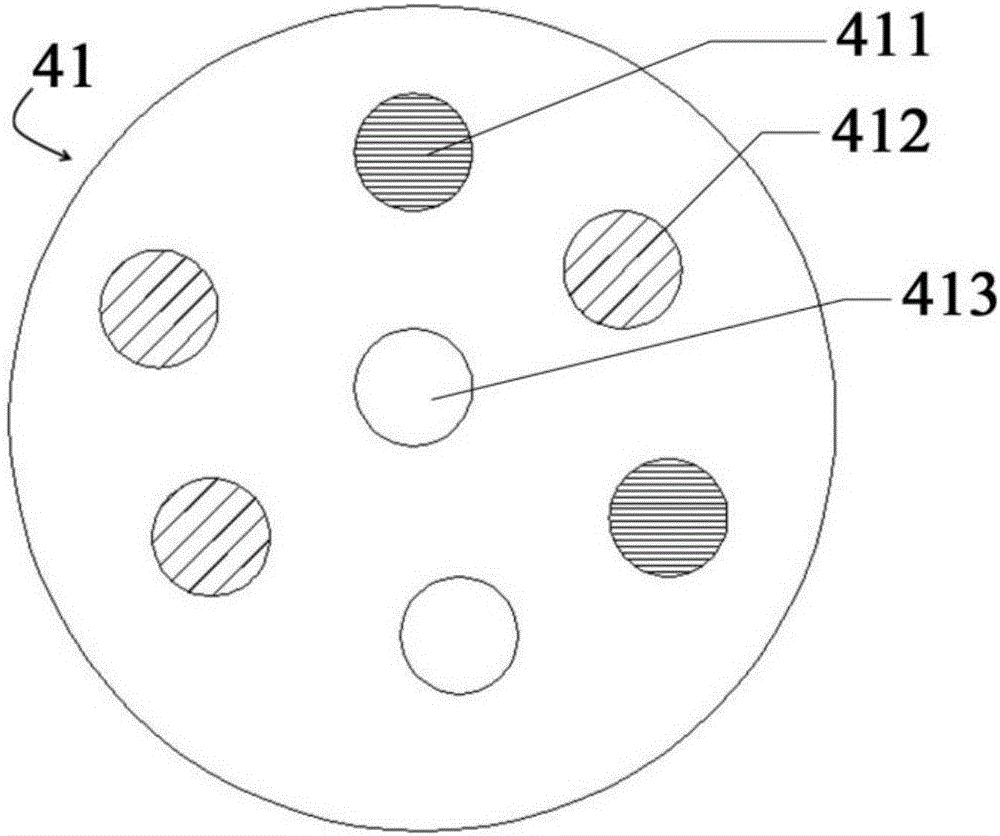

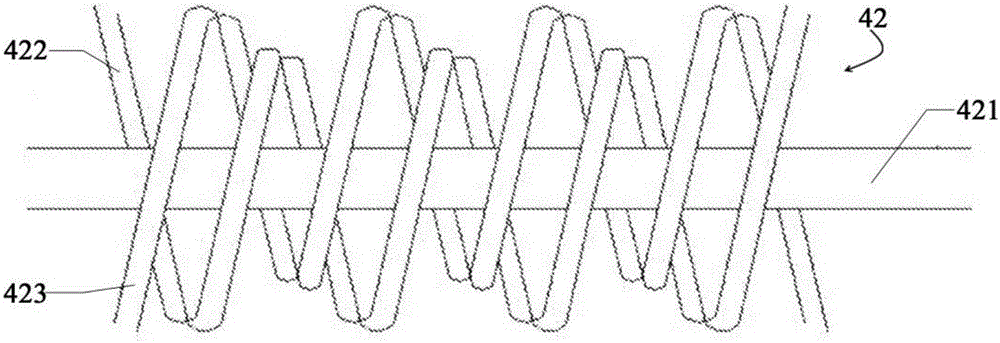

Total cross-section water-stop sealing multi-signal composite cable and preparation technique thereof

PendingCN107958724ARich varietyLarge transmission capacityNon-insulated conductorsInsulated cablesRadio frequencyCoaxial line

The invention discloses a total cross-section water-stop sealing multi-signal composite cable including a cable core, an inner protection layer, a shielding layer and an outer protection layer. The cable core is externally provided with a wrapping tape. The inner protection layer and the outer protection layer are formed outside the wrapping tape through extrusion. The shielding layer is formed ina braiding manner between the outer protection layer and the inner protection layer. A wrapping tape is also arranged between the shielding layer and the outer protection layer. The cable core is formed by twisting an optical unit, a power line, a coaxial line, a twisting pair and a filler rope in a spiral manner. The twisting gap of the cable core and the gap in the shielding layer are both filled with filler glue. Each of the power line, the coaxial line, the twist pair and the outer protection layer in the composite cable is therein provided with a braided shielding layer, water-resistingand wear-resisting chemical material is adopted for a sheath, and the gaps among the different units are filled with water-stop filler glue. Therefore, the composite cable provided by the invention has a capability of total cross-section high pressure resistance and water leakage prevention. In underwater application, the composite cable can provide optical fibers for transmitting optical signalsand can also provide a power line for transmitting control signals, a coaxial line for transmitting radio frequency signals and a twisting pair for transmitting communication signals. Besides, the composite cable provided by the invention is small in product size, diversified in functions and stable in transmission.

Owner:JIANGSU ZHONGTIAN TECH CO LTD

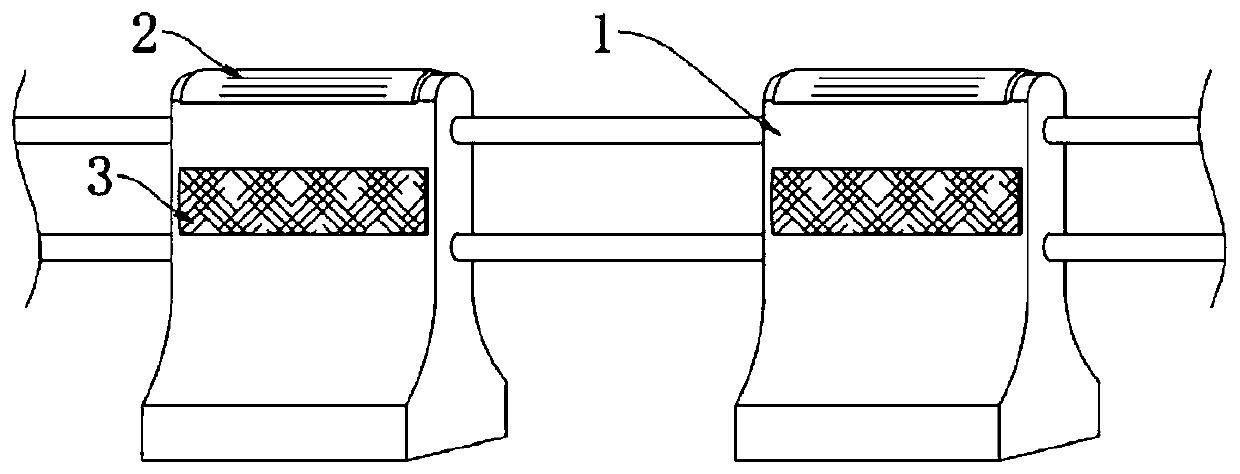

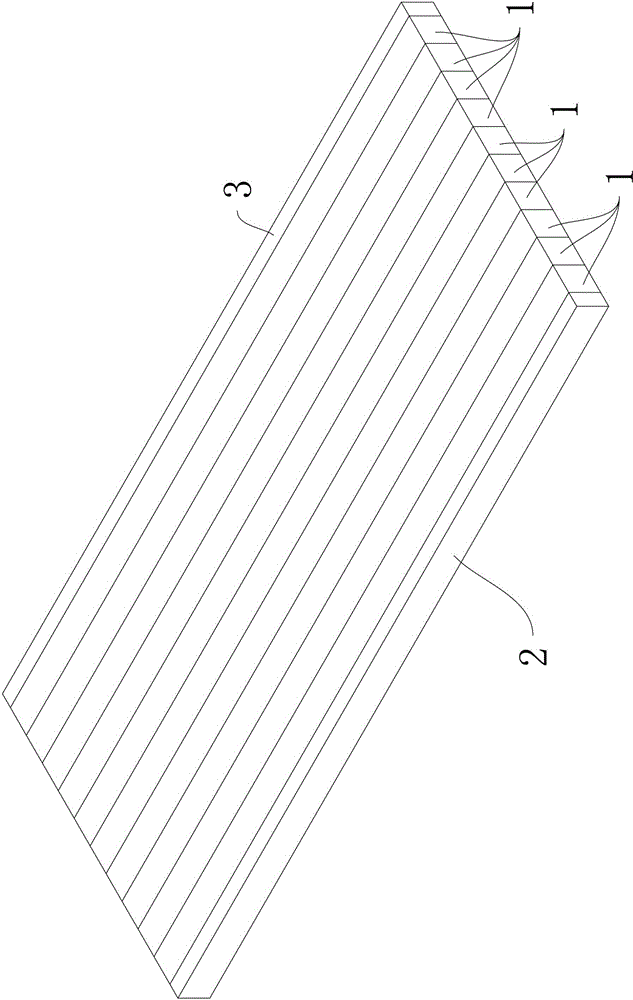

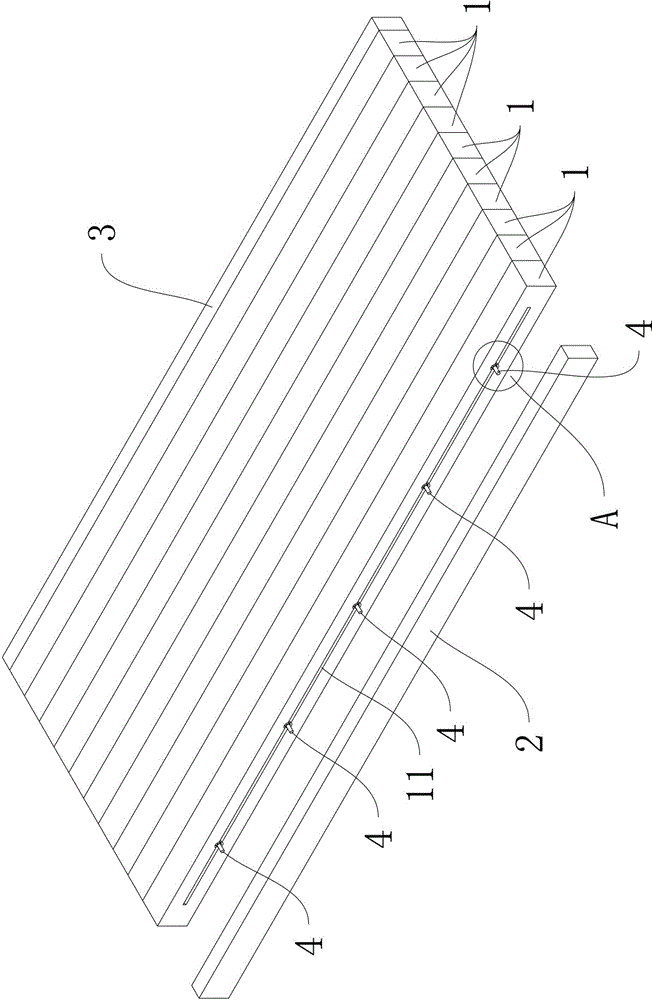

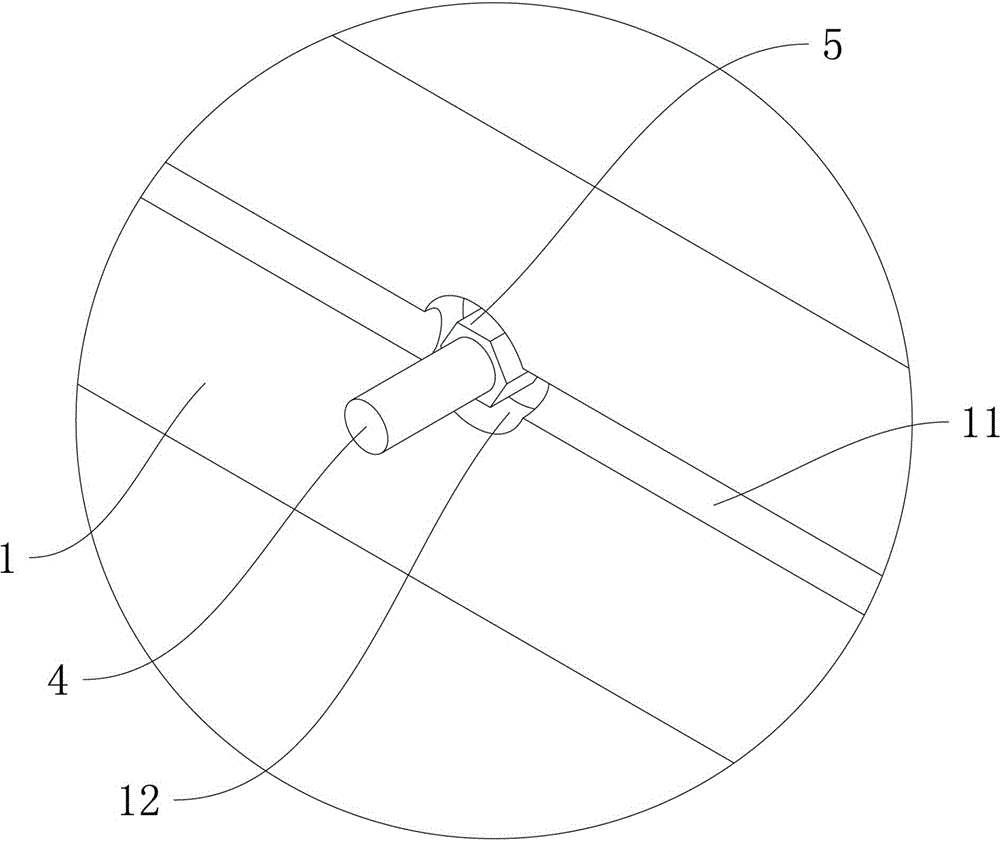

Pure log spliced board and aluminum-wood composited spliced board device using same

InactiveCN105113702AWon't swellWon't archConstruction materialCovering/liningsAdhesiveMechanical engineering

The invention relates to a pure log spliced board and an aluminum-wood composited spliced board device using the same. The pure log spliced board comprises a plurality of pure log boards, a first pure log side board, a second pure log side board, a plurality of screws and a plurality of nuts, each pure log board is made to have a splicing lateral side, an extensible groove slit and multiple screw holes are formed in each splicing lateral side, an adhesive is coated on each splicing lateral side, the pure log boards are arranged, spliced and pressed to form an integrated pure log spliced board body, each screw is penetratingly nested in the corresponding screw hole of the corresponding pure log board, two ends of each screw are tightened and locked by using the nuts, and the pure log side boards are arranged on the splicing lateral sides on two sides of the pure log spliced board body respectively to hide the ends of the screws and the nuts in the spliced board. The pure log spliced board is simple in structure, convenient to assemble and easy to realize, unfavorable factors like material cracking and deforming caused by thermal expansion and cold contraction of pure log are prevented effectively, and a log product is more attractive, more environment friendly and longer in service life.

Owner:彭志军

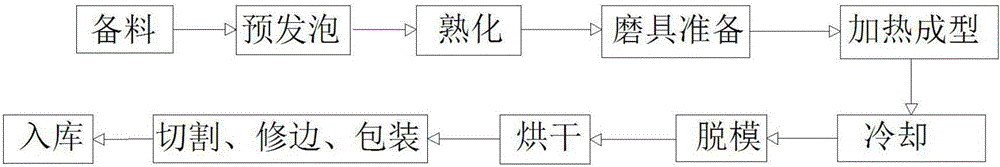

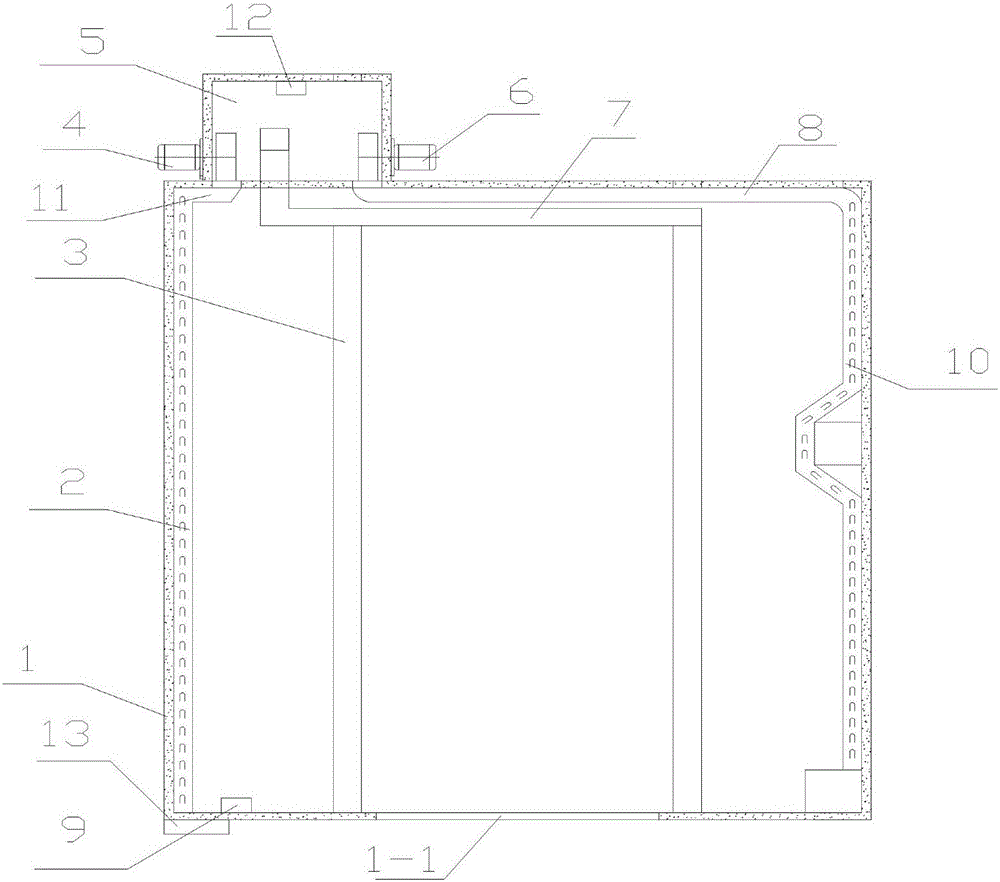

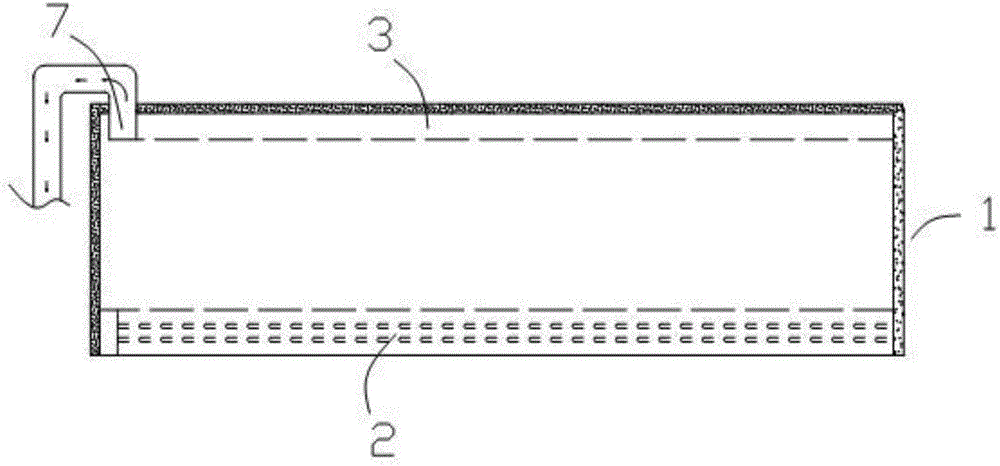

High-efficiency production process of EPS (Expandable polystyrene) foam product

The invention discloses a high-efficiency production process of an EPS foam product and relates to the technical field of foam processing. The production process comprises the following steps: preparing materials; pre-foaming; ageing; preparing a mold; performing heating formation; cooling; demolding; drying; cutting; trimming; packaging; and putting in storage, wherein compressed air and a drying procedure are improved. The production process disclosed by the invention is simple and reasonable in technological procedure; compressed air supply systems are adopted; a drying room body, a combustion chamber, a hot air system and an air returning system of a drying room form a circulation system; most of hot air is circulated inside the drying room, so high thermal efficiency is realized, energy is saved, and reasonable utilization of resources is realized.

Owner:泸州市青林包装有限公司

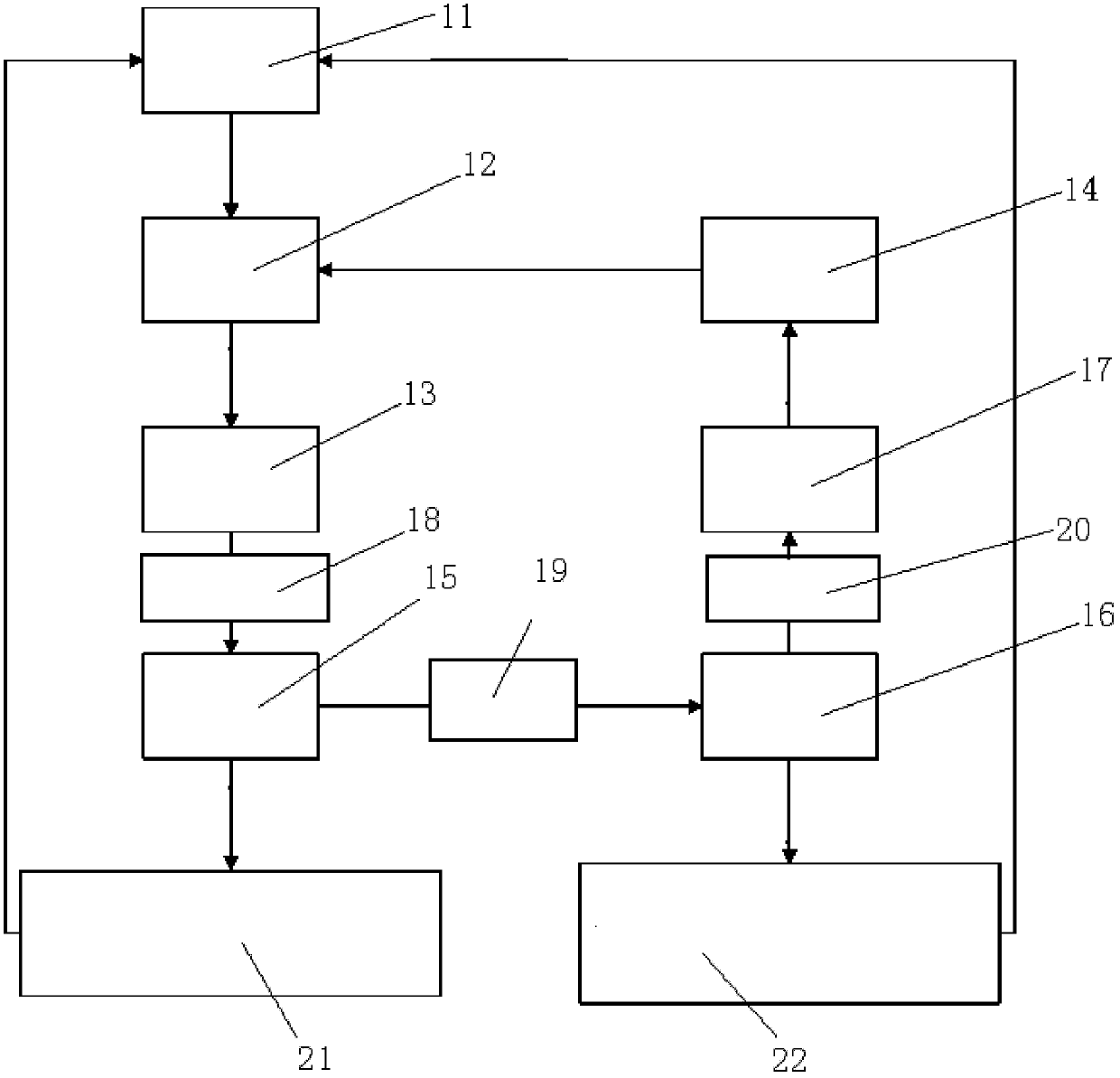

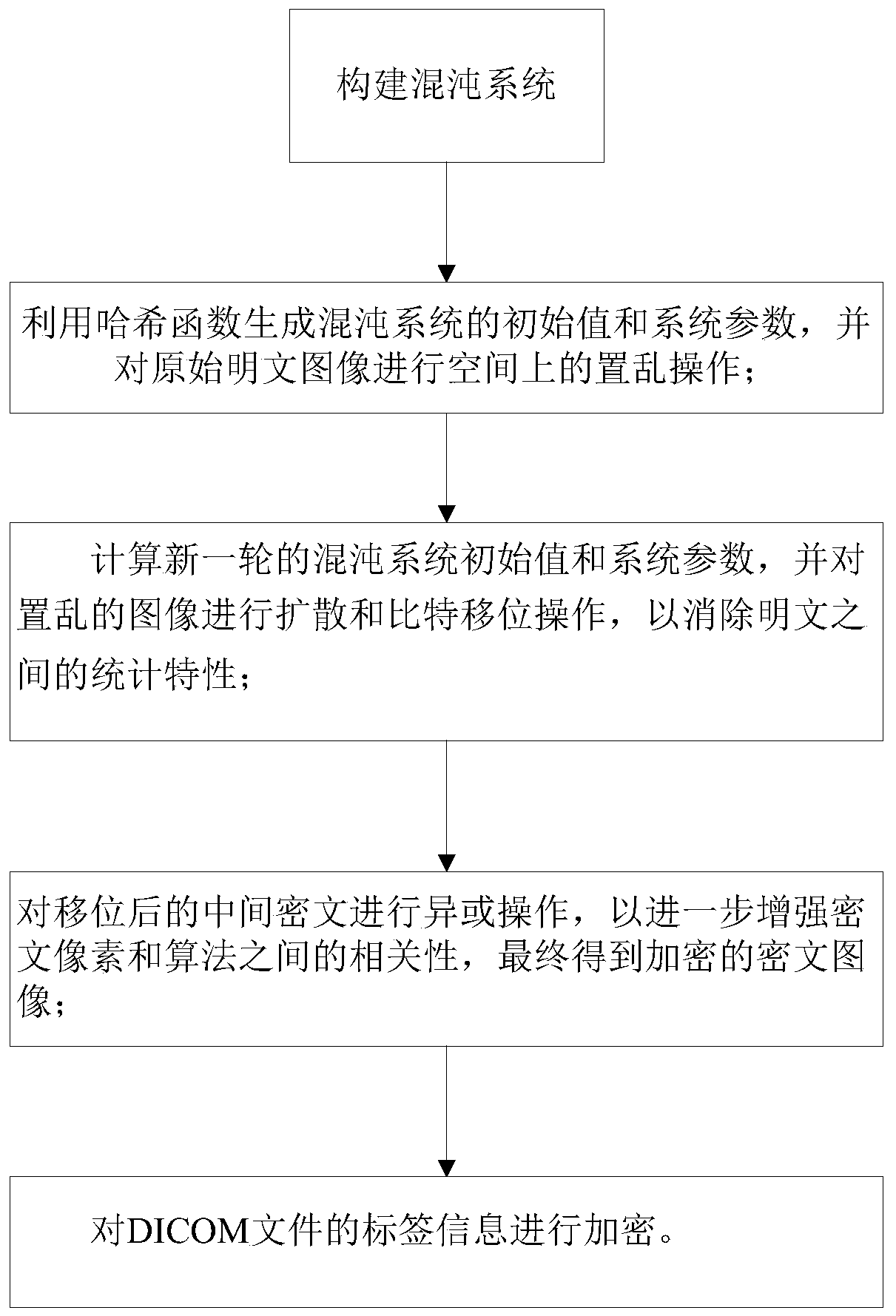

Medical image privacy protection method applied to DICOM format

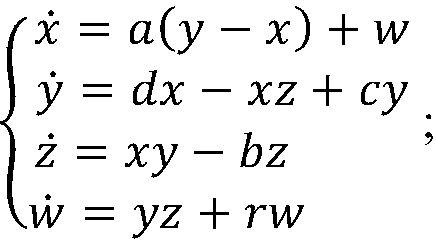

ActiveCN110535624AGood scrambling effectGood effectEncryption apparatus with shift registers/memoriesSecuring communication by chaotic signalsChaotic systemsPrivacy protection

The invention discloses a medical image privacy protection method applied to a DICOM format. The medical image privacy protection method comprises the following steps: firstly, constructing a chaoticsystem; generating an initial value and a system parameter of the chaotic system by using a hash function, and performing spatial scrambling operation on the original plaintext image; calculating a new round of chaotic system initial value and system parameters, and performing diffusion and bit shift operation on the scrambled image to eliminate statistical characteristics between plaintexts; performing XOR operation on the shifted intermediate ciphertext to further enhance the correlation between ciphertext pixels and an algorithm, and finally obtaining an encrypted ciphertext image; and finally, encrypting the tag information of the DICOM file. The method provided by the invention has very strong robustness for selecting plaintext attacks, key brute force attacks and differential analysis attacks.

Owner:HUBEI UNIV OF TECH

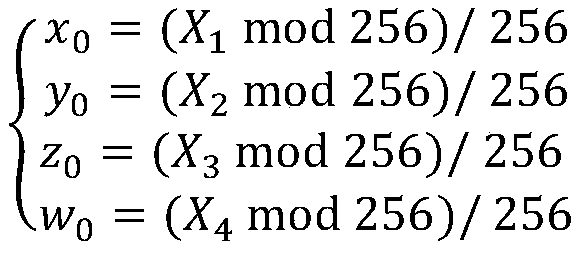

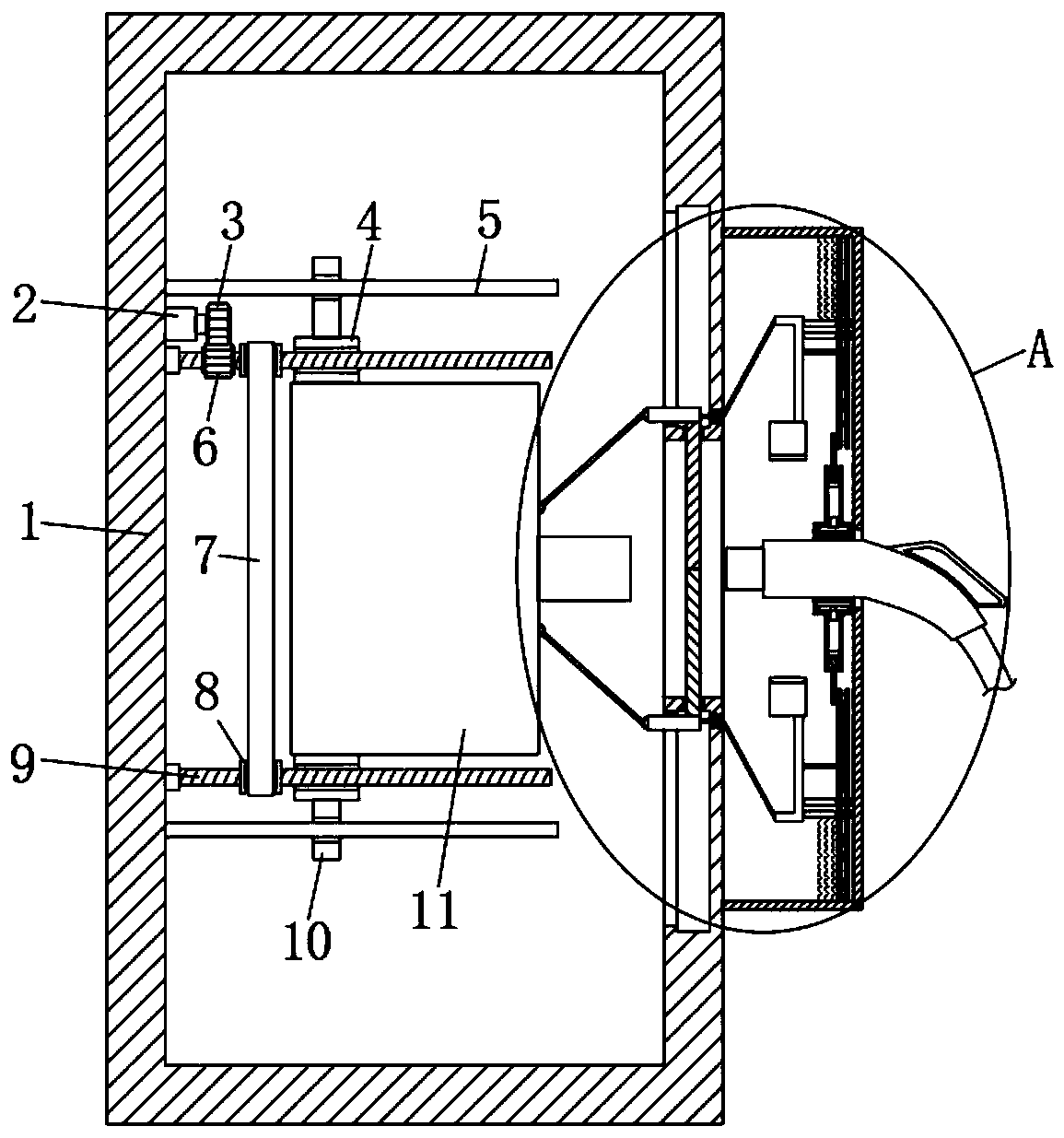

Charging device for new energy vehicle

ActiveCN110126654AEasy to reinforceRealize the initial limitCharging stationsElectric vehicle charging technologyNew energyAlternative fuel vehicle

The invention discloses a charging device for a new energy vehicle. The charging device for the new energy vehicle comprises a box body; a mounting cavity is formed in the box body; a charging power supply is arranged in the mounting cavity; a moving mechanism is connected between the charging power supply and the internal side wall of the mounting cavity; a first communication groove communicating with the mounting cavity is arranged in the side wall of the box body in a through manner; two sliding cavities which are arranged with one under the other one are symmetrically formed in the box body; the first communication groove is formed between the two sliding cavities; communication holes communicating with the sliding cavities are formed in the internal side walls of the upper and lowerends of first communication groove in a through manner; and two strip-shaped grooves communicating with the sliding cavities are formed in the internal side walls of the mounting cavities in a throughmanner. According to the charging device for the new energy vehicle, the structural design is reasonable; a user can be prevented from manually connecting a charging gun with the charging power supply; potential safety hazards are reduced; and moreover, stable connection between the charging gun and the charging power supply can be guaranteed; easy falling of the charging gun can be avoided; andnormal charging working can be guaranteed.

Owner:安徽省智慧交通科技有限责任公司

Decorative cement

The invention discloses a decorative cement. The cement is prepared form the following materials in parts by weight: 12 to 22 parts of Portland cement, 4 to 7 parts of tourmaline powder, 2 to 4 parts of N-acyl sarcosinate, 0.2 to 0.7 parts of fiberglass, 0.3 to 0.5 parts of calcium silicate hydrate, 0.2 to 0.7 parts of calcium chloride, 15 to 20 parts of EVA emulsion, 2 to 4 parts of neutralizer, 3 to 5 parts of preservative, 2 to 4 parts of ethanediol, 4 to 6 parts of isobutylene, 3 to 7 parts of kaolin, 6 to 9 parts of fiber, 15 to 23 parts of polyurethane rigid foam particle, 12 to 24 parts of aluminium silicate, 10 to 16 parts of melamine resin, 15 to 25 parts of resorcinol. The cement has the following beneficial effects: the decorative cement has good workabilities of easy-blending and no-bleeding; the cement will not loose and expand; and the corrosion resistance of the cement is improved.

Owner:青岛千帆高新技术有限公司

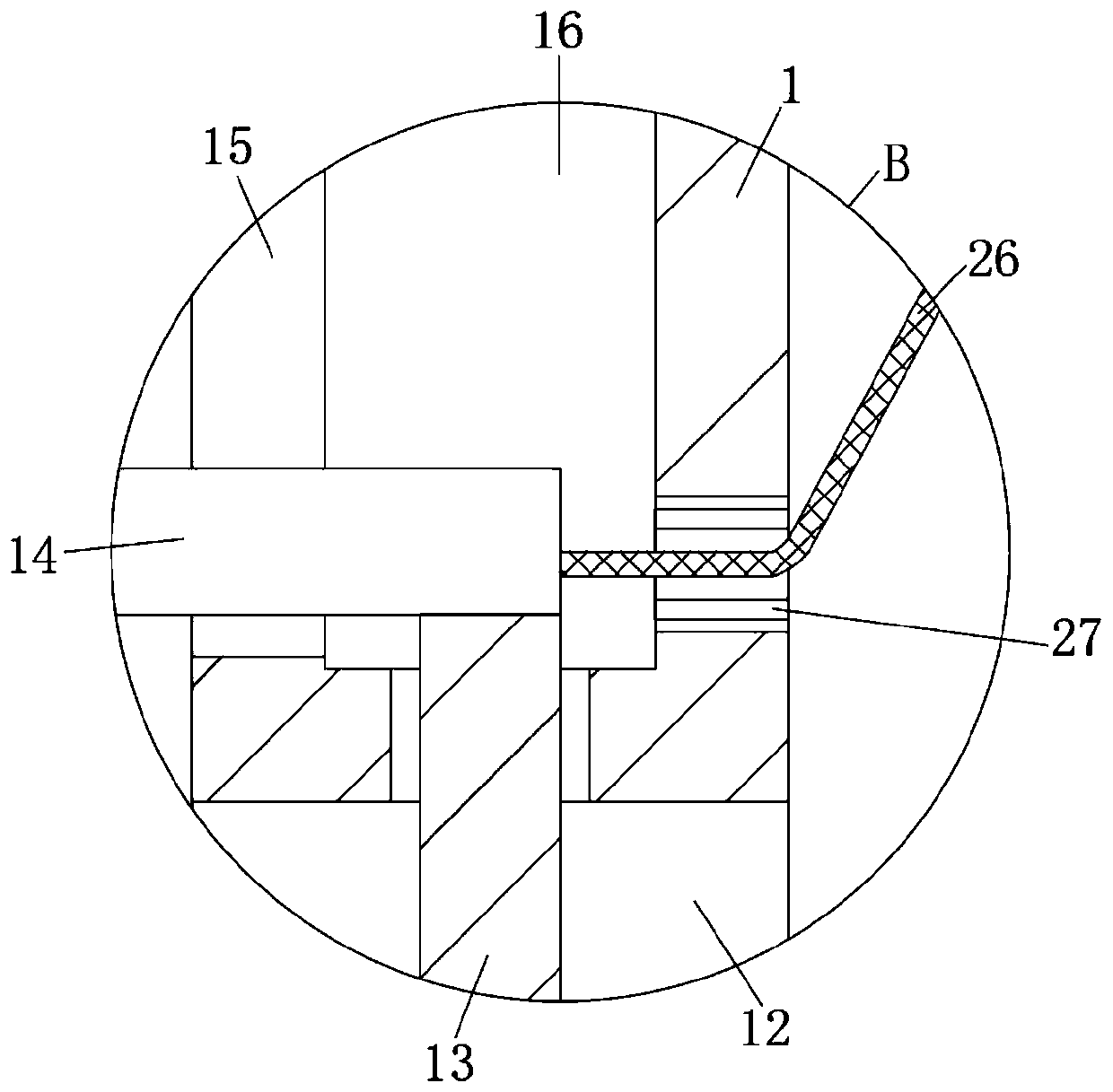

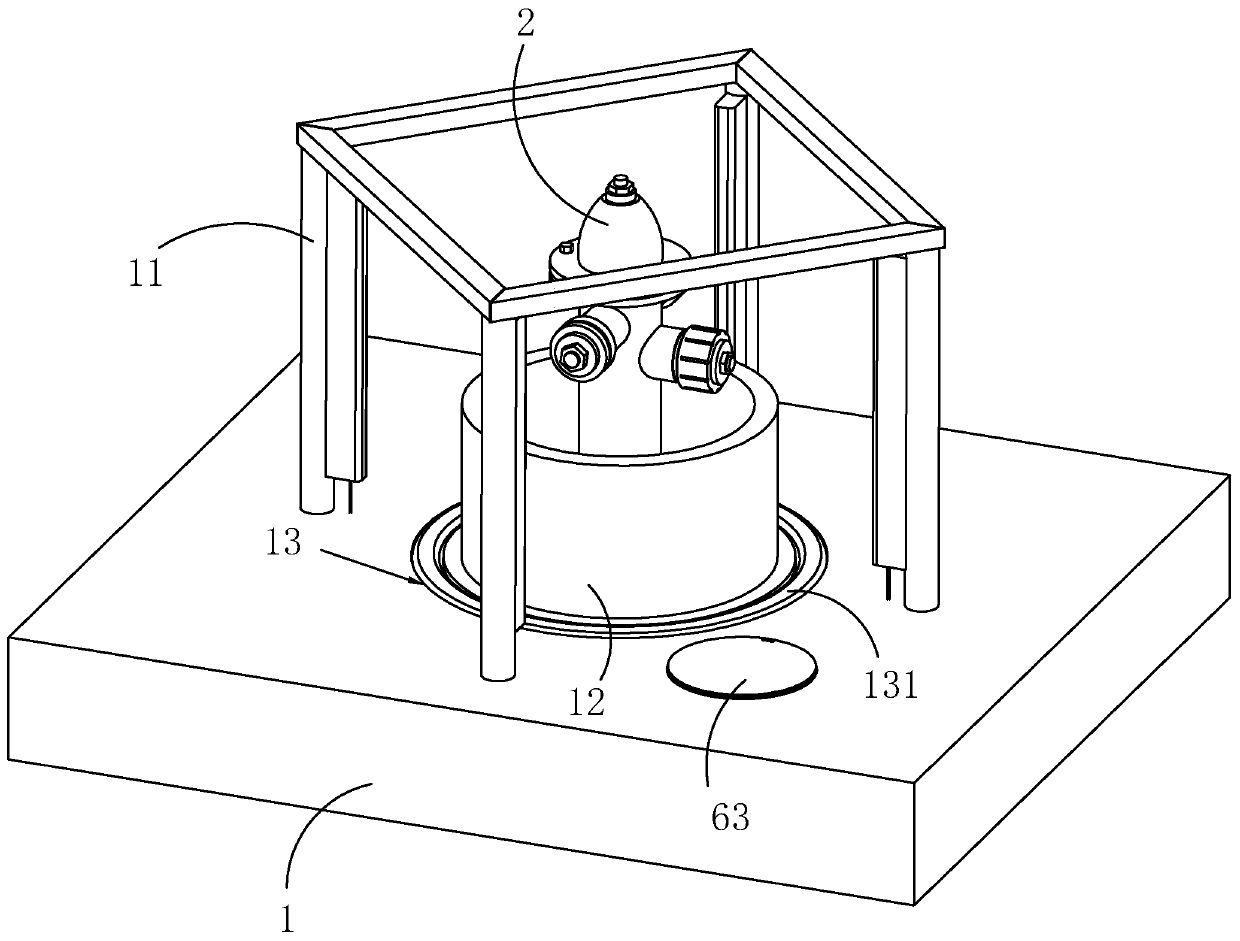

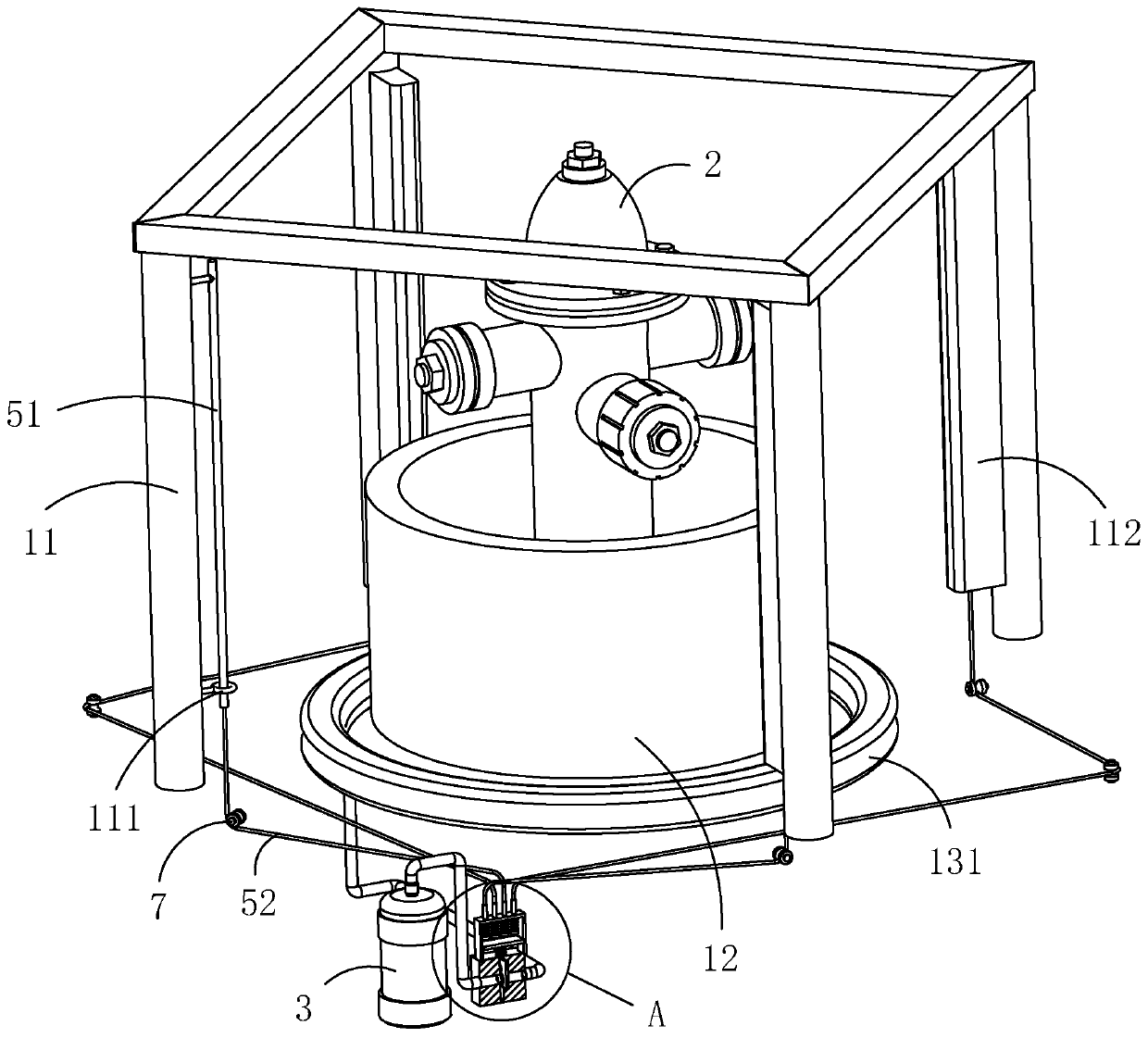

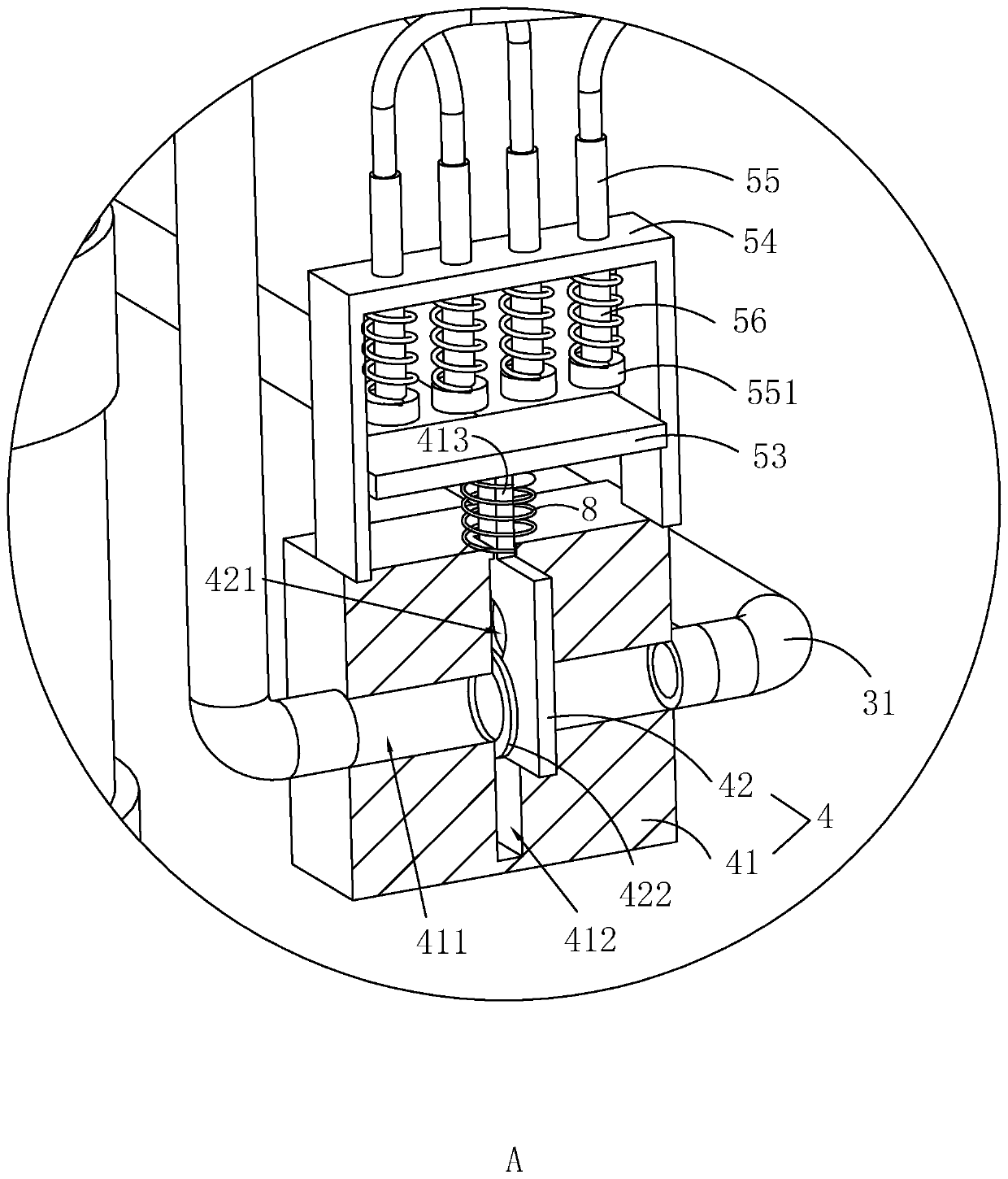

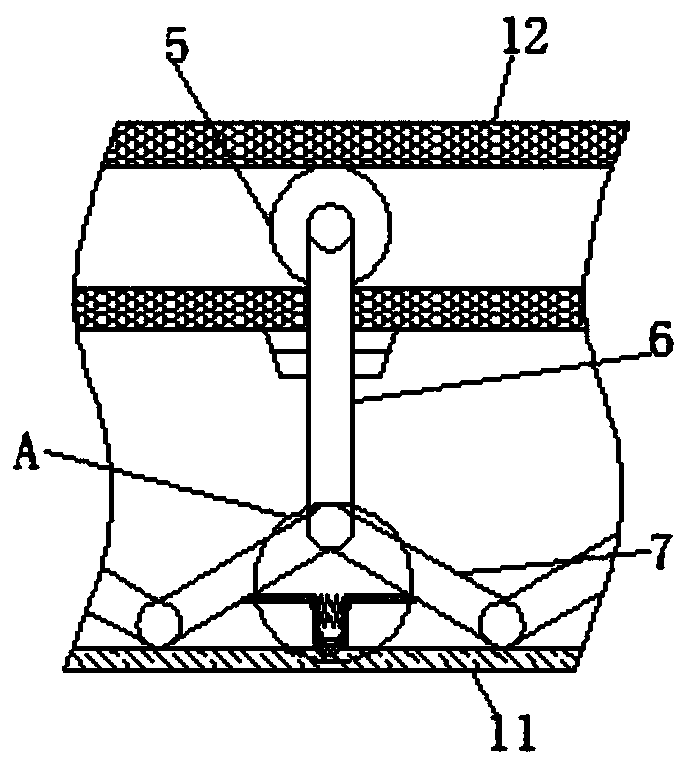

Outdoor anti-collision fire hydrant system

InactiveCN110130443ADisperse impactDispersion and weakening of impact forceDrawing-off water installationsRoadway safety arrangementsEngineeringHigh pressure

The invention relates to an outdoor anti-collision fire hydrant system, and belongs to the technical field of fire hydrants. The outdoor anti-collision fire hydrant system comprises a base and a firehydrant, wherein the fire hydrant is arranged on the base; anti-collision columns are fixedly arranged on the base; a retaining wall is fixedly arranged on the base; the retaining wall is positioned between the fire hydrant and the anti-collision columns; an annular accommodating groove is formed in the base; an air bag is arranged in the accommodating groove; a high-pressure air tank is arrangedin the base; the high-pressure air tank communicates with the air bag through a connecting pipe; and the connecting pipe is provided with a valve, and a driving assembly for driving a valve to open during anti-collision rod bending is arranged on the base. If a vehicle runs out of control and collides with the anti-collision columns, causing the anti-collision columns to bend or break, the drivingassembly opens the drive valve, at the moment, the air bag is rapidly filled with high-pressure air in the high-pressure air tank through the connecting pipe, the expansion of the air bag becomes larger and collide with the retaining wall, and the fire hydrant is wrapped in the air bag; and a buffering role is played, the impact force of the vehicle is effectively dispersed and weakened, the firehydrant is protected, and the fire hydrant is prevented from being hit and damaged by the vehicle.

Owner:四川安泰信建设集团有限公司

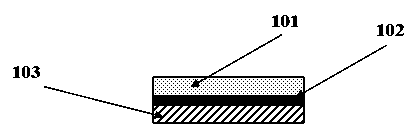

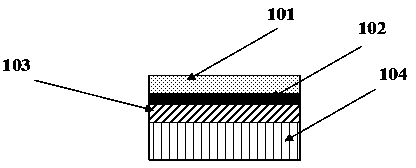

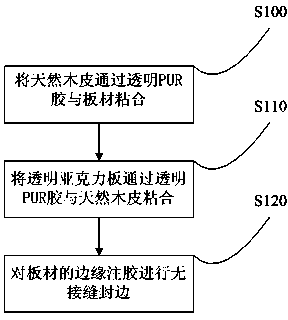

High-gloss natural veneer, board and rapid molding method of high-gloss surface thereof

InactiveCN103465316ASkip the painting processWon't swellLaminationLamination apparatusAdhesiveEngineering

The invention discloses a high-gloss natural veneer, a board and a rapid molding method of the high-gloss surface of the board. The high-gloss natural veneer comprises a transparent acrylic plate, a transparent polyurethane (PUR) adhesive layer and a natural veneer which are arranged in a stacking way, wherein the transparent acrylic plate is stuck with the natural veneer by the transparent PUR adhesive layer. The board comprises the high-gloss natural veneer, and the high-gloss natural veneer is stuck with the surface of the board. The rapid molding method of the high-gloss surface of the board comprises the steps of A1, enabling the natural veneer to be stuck with the board by transparent PUR adhesive; A2, enabling the transparent acrylic plate to be stuck with the natural veneer by the transparent PUR adhesive; A3, injecting glue into the edge of the board, and carrying out seamless edge banding. According to the high-gloss natural veneer, the board and the rapid molding method of the high-gloss surface of the board, the natural veneer is stuck on the surface of the board, and the transparent acrylic plate is stuck on the surface of the natural veneer by the transparent PUR adhesive, so that the coating process is completely omitted in the board processing process, the board is not needed to be repeatedly polished, the production process is environment-friendly, the labor is saved, and the production efficiency is improved.

Owner:吴乐平

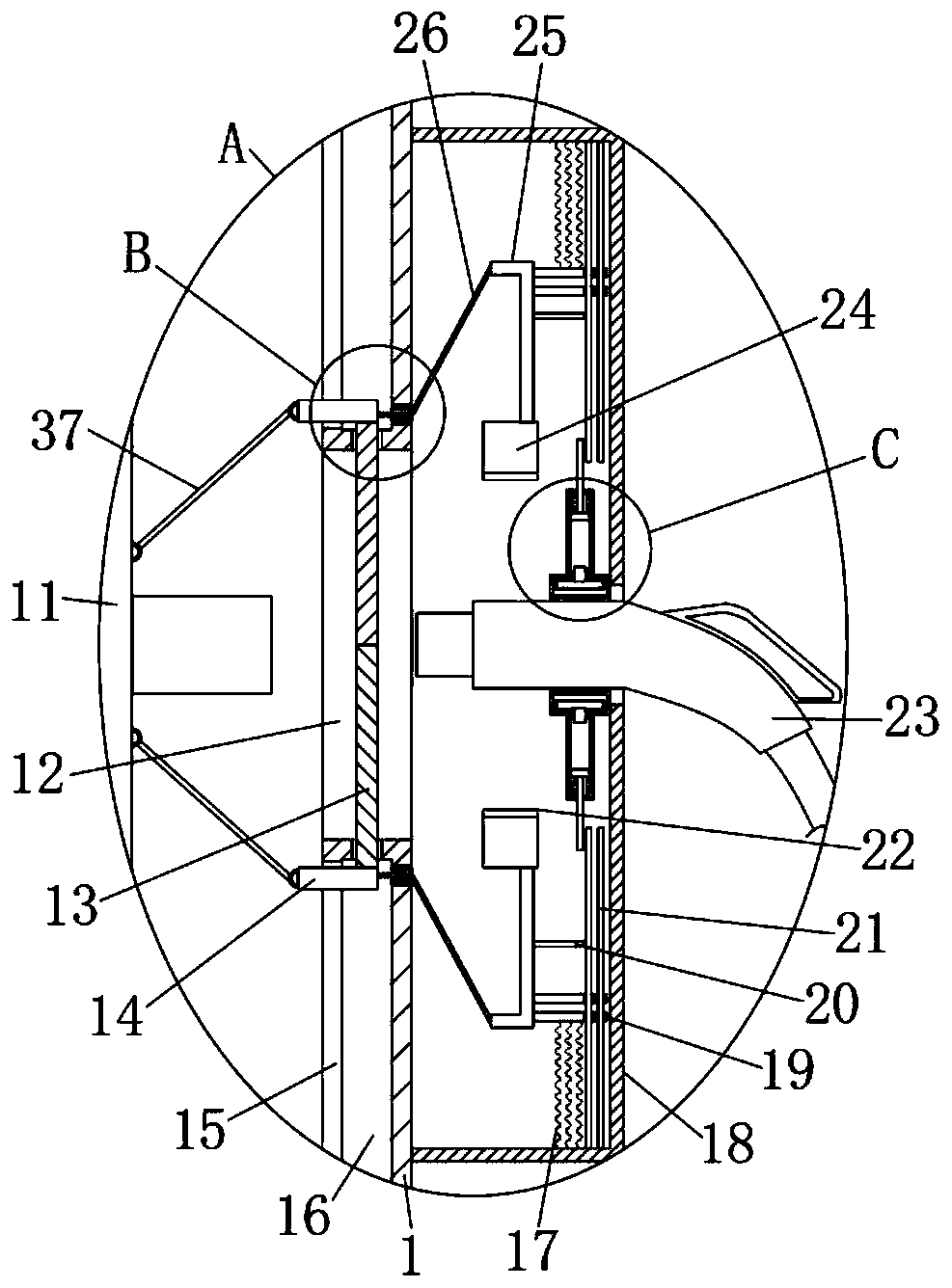

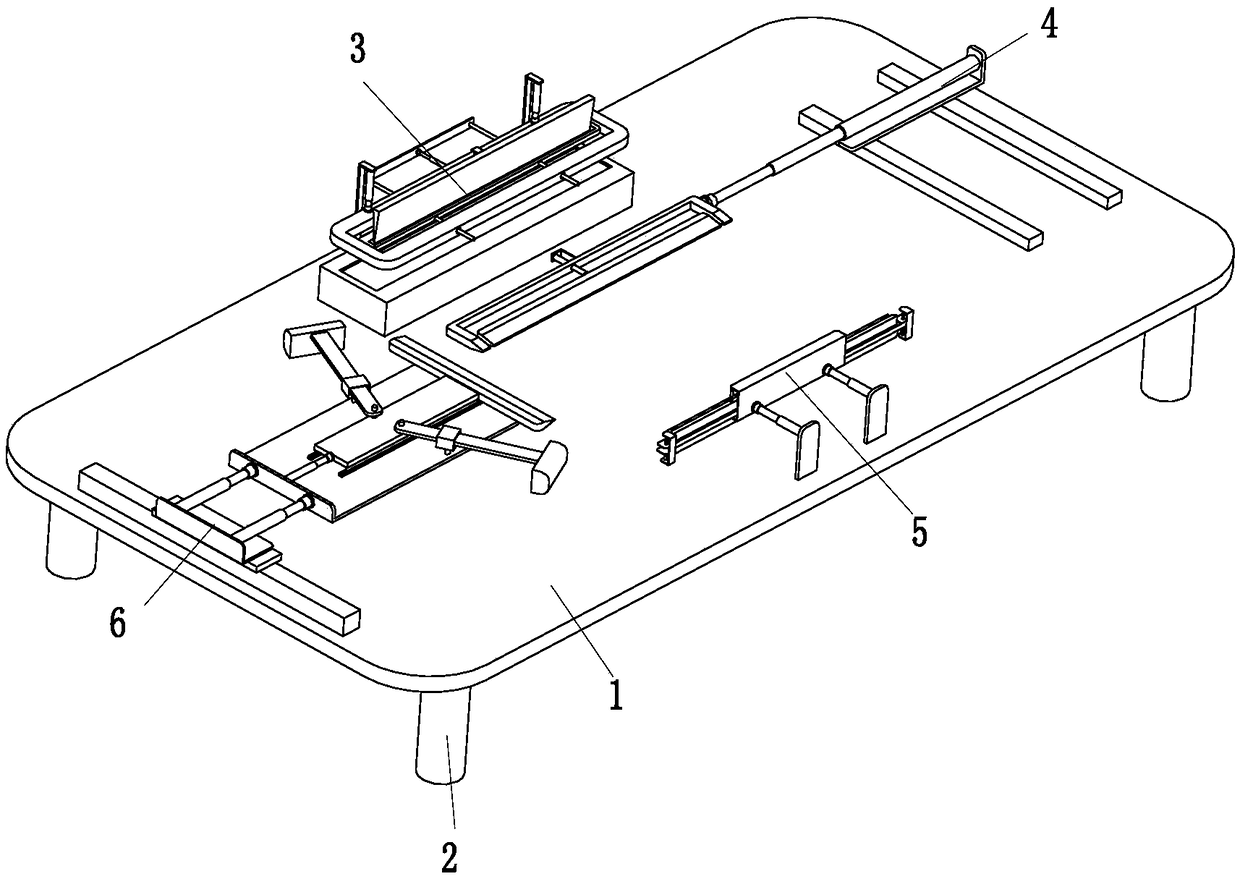

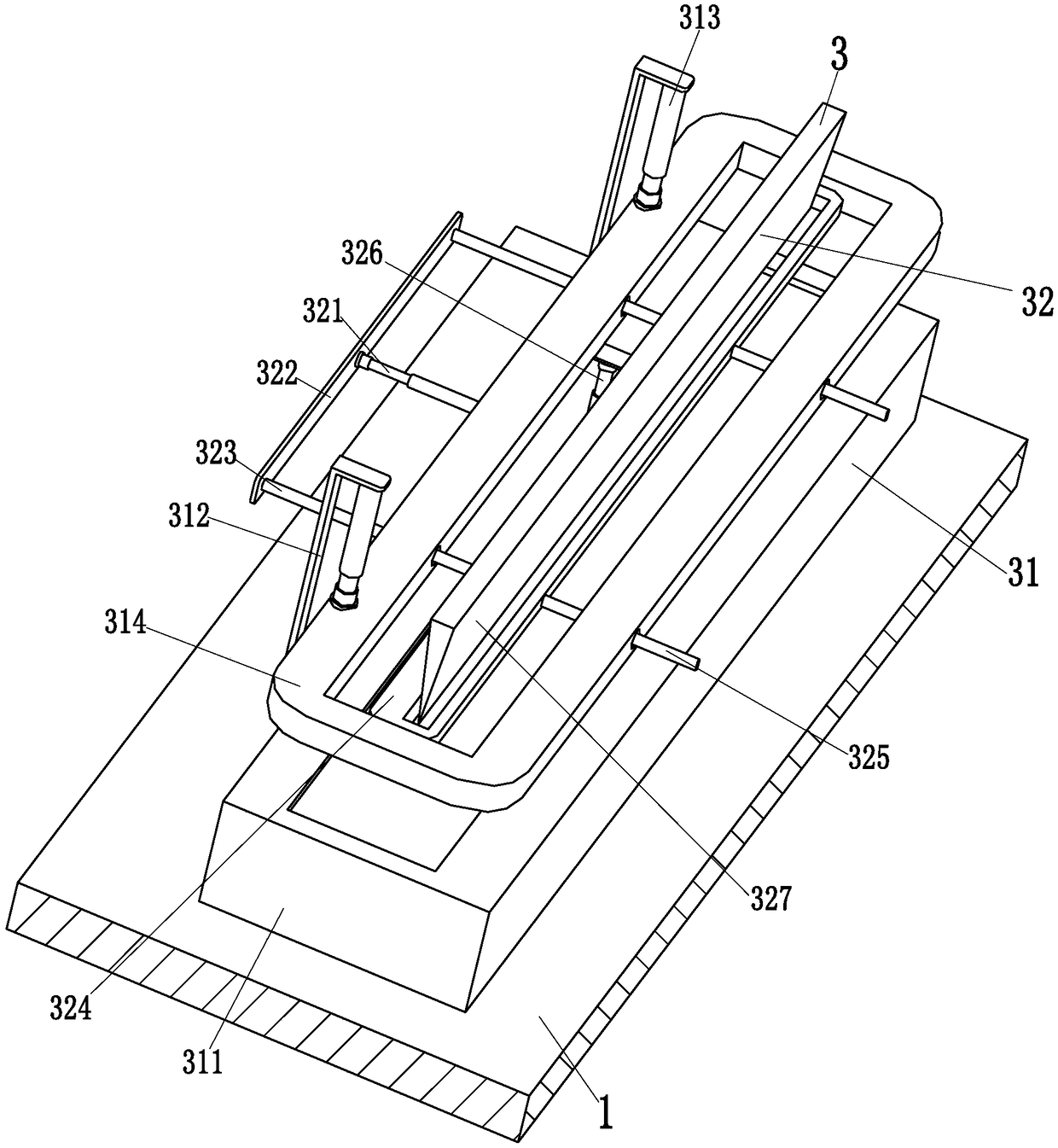

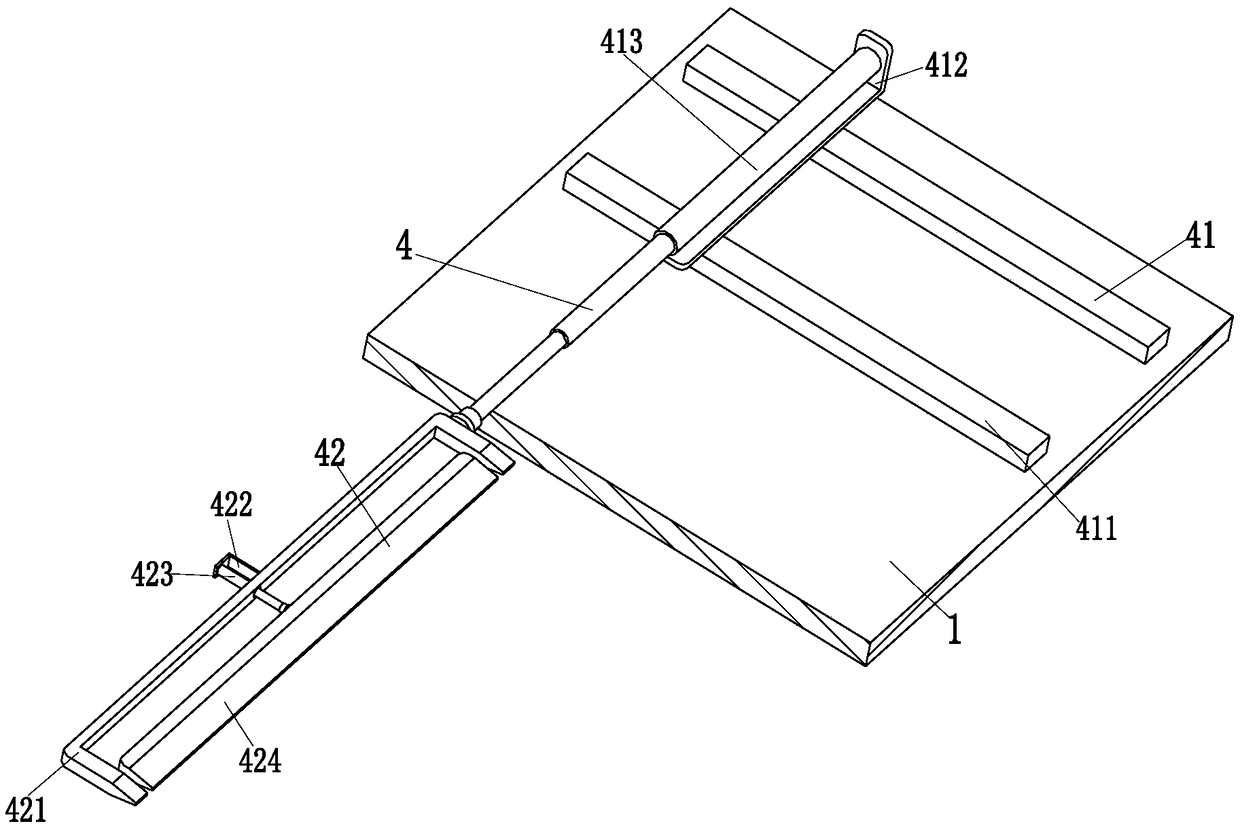

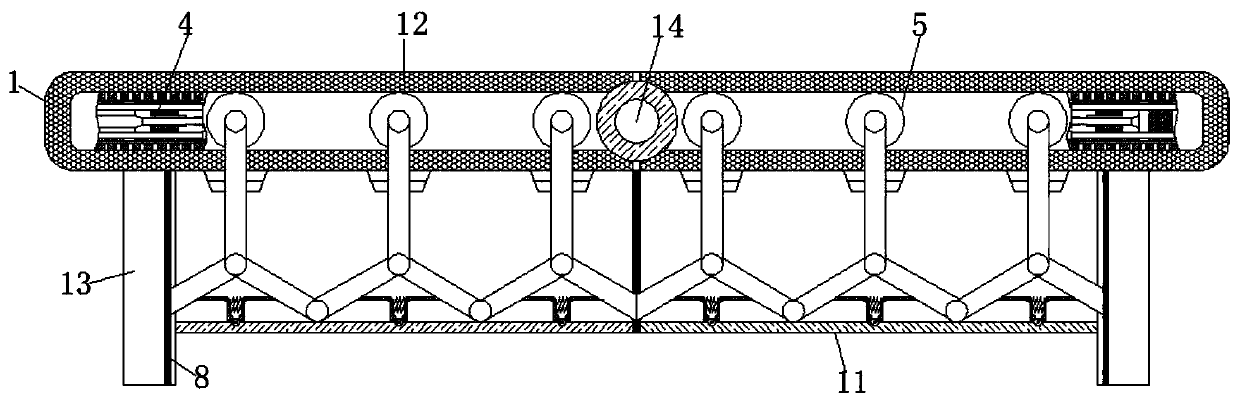

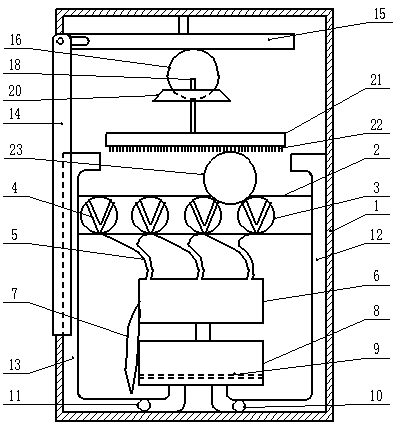

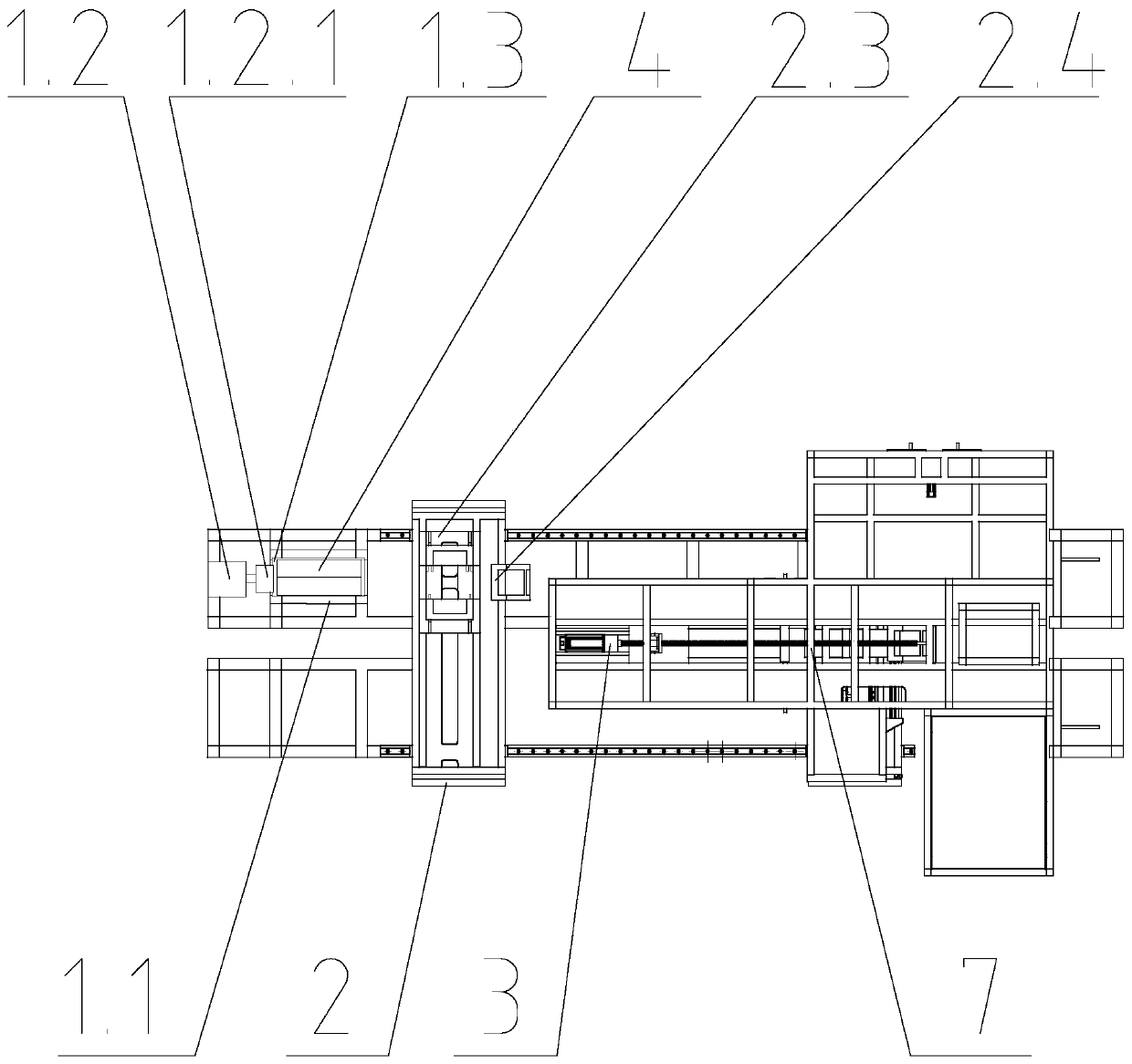

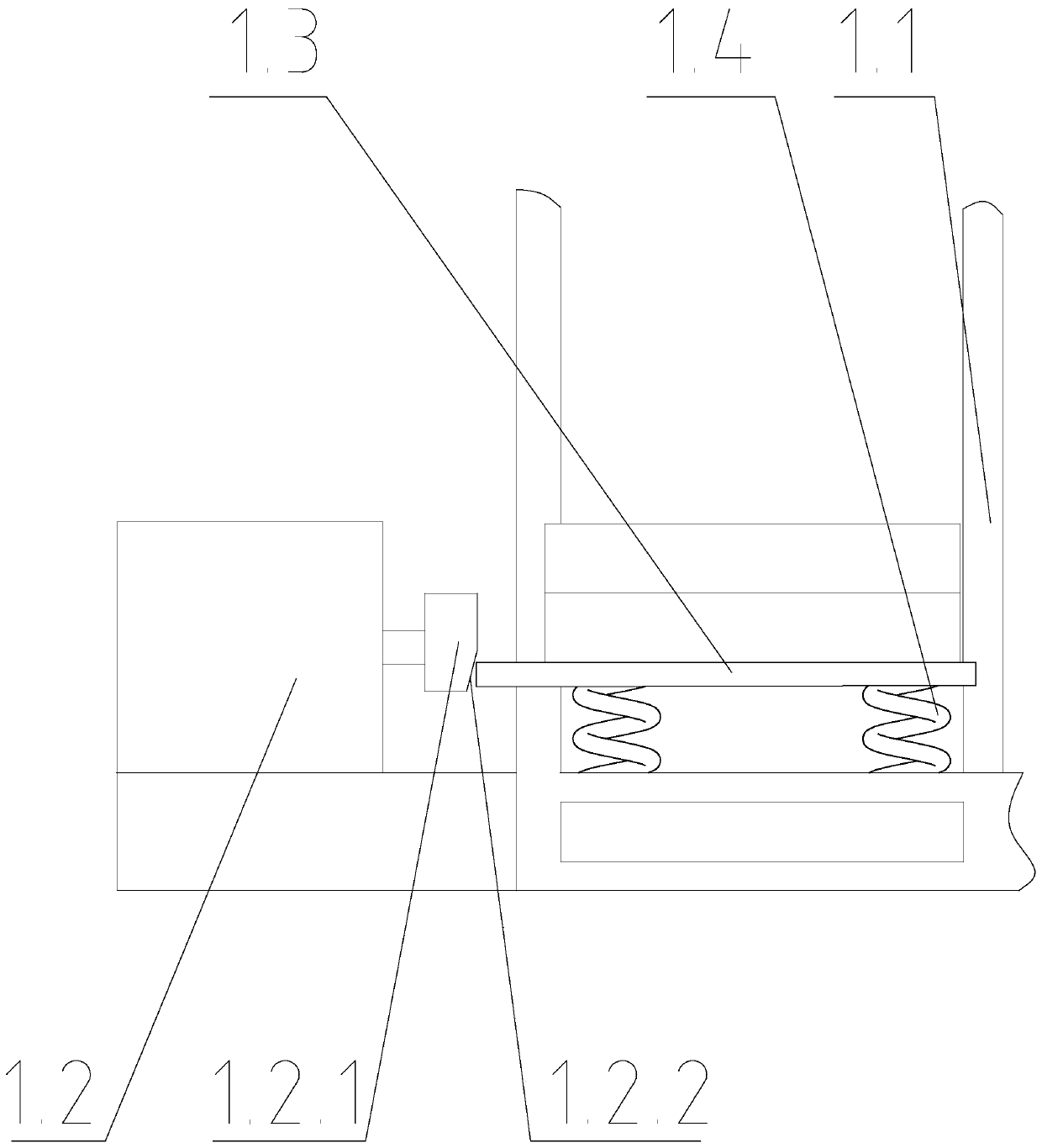

Woven bag automatic manufacturing equipment and manufacturing method thereof

ActiveCN108790282AWon't swellReduce stacking difficultyBag making operationsPaper-makingEngineeringTextile

The invention relates to woven bag automatic manufacturing equipment and a manufacturing method thereof. The woven bag automatic manufacturing equipment comprises a bottom plate, pillars, a press headdevice, a folding device, a pleating device and a leveling device; the pillars are evenly mounted at the lower end of the bottom plate, the press head device is mounted on the left side of the upperend of the bottom plate, the folding device is mounted on the rear side of the upper end of the bottom plate, and the pleating device is mounted on the right side of the upper end of the bottom plate;and the leveling device is mounted on the front side of the upper end of the bottom plate. The woven bag automatic manufacturing equipment can solve the difficult problems of long process time, highlabor intensity and low efficiency caused by the fact that in an existing woven bag manufacturing process, the woven cloth need to be fold manually and then stitched, the two end heads of the fold woven cloth are stitched, the extra rim charge is artificially trimmed to be not aligned, the folding crease is not clear due to the manual folding of the woven cloth and the manufactured woven bag is prone to inflating and not flat after being manufactured due to the operating problem, and the functions of automation trimming, pleating treatment and bag-in leveling of the woven bags are achieved.

Owner:昆明市华港塑业有限公司

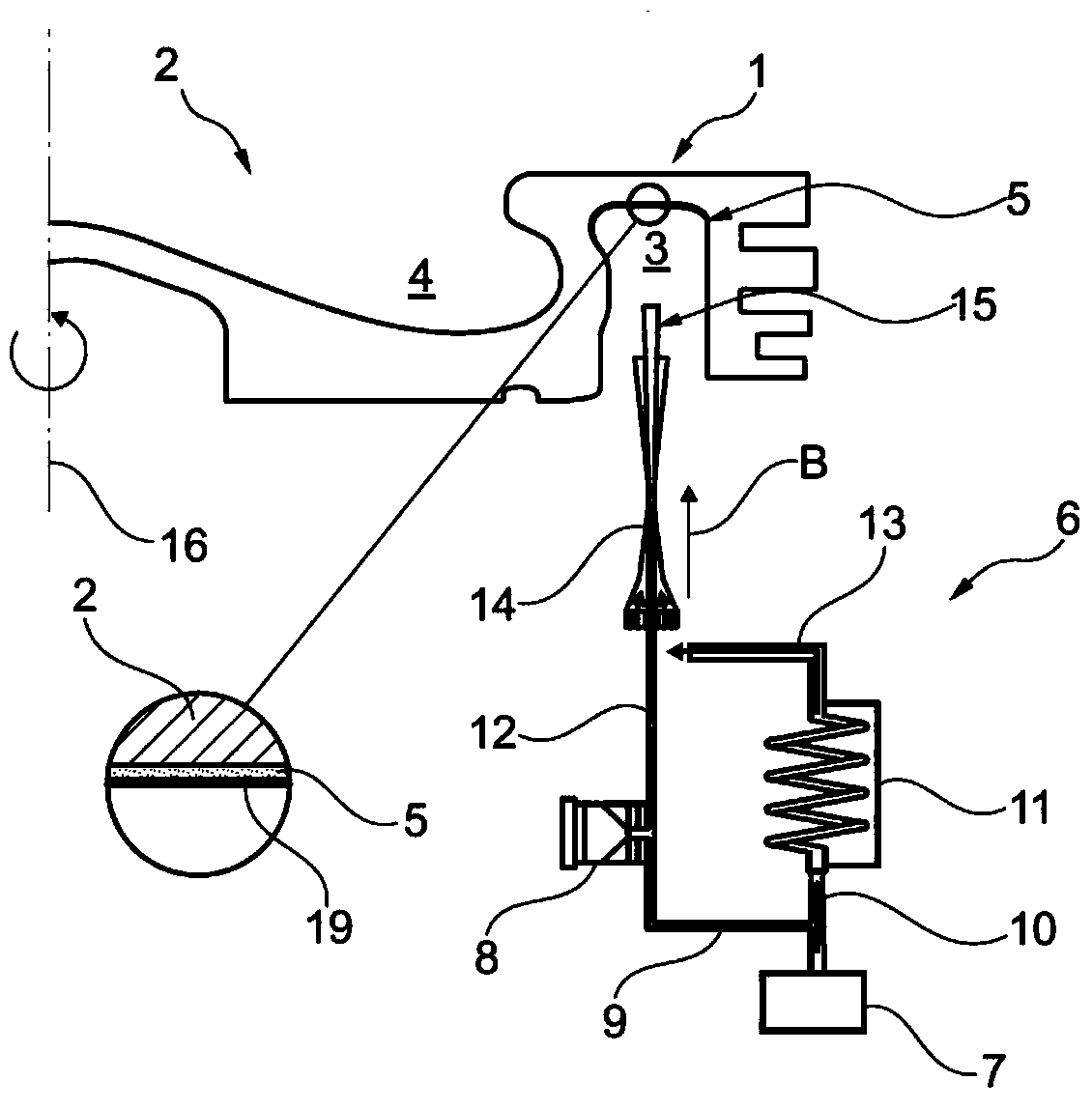

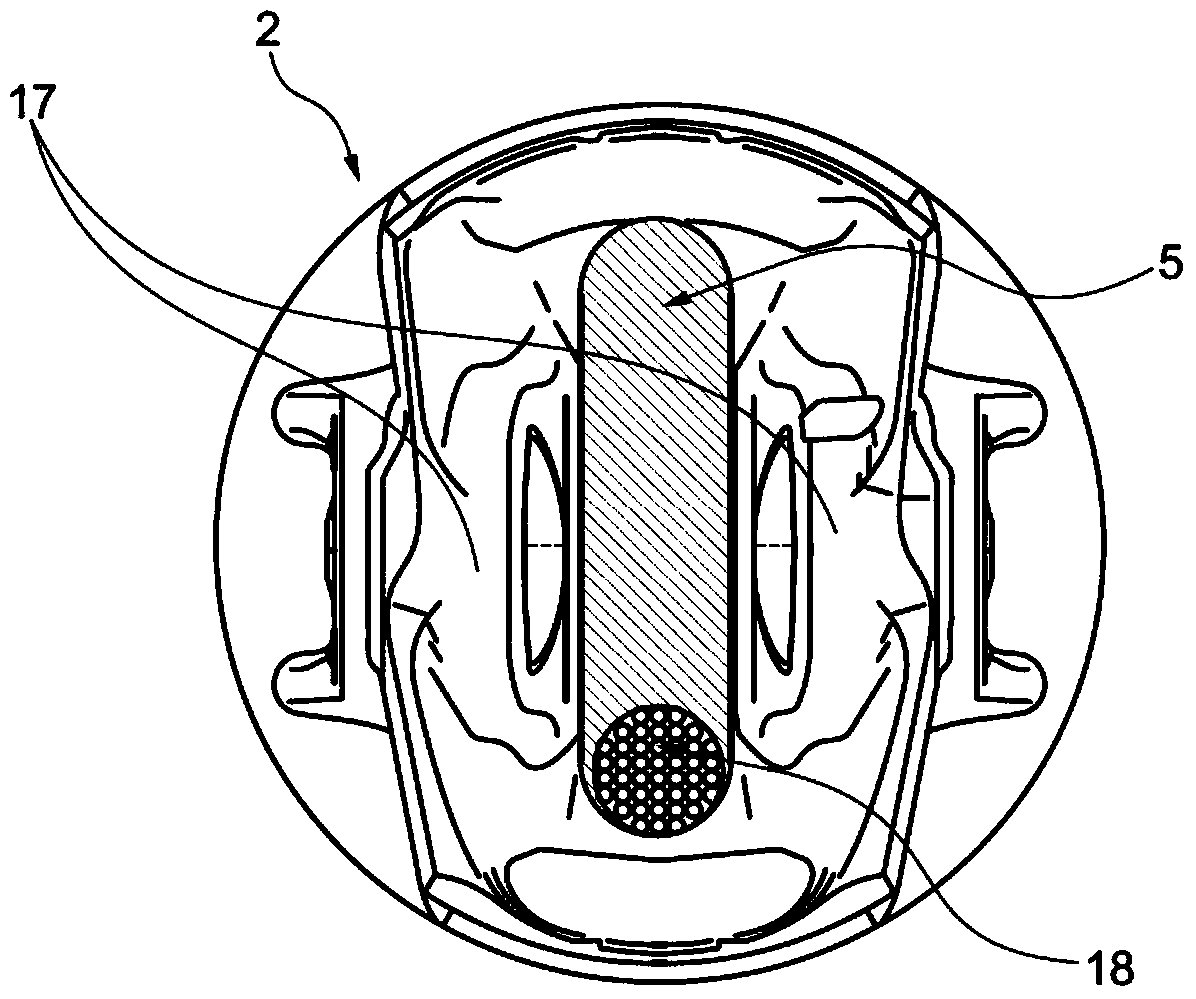

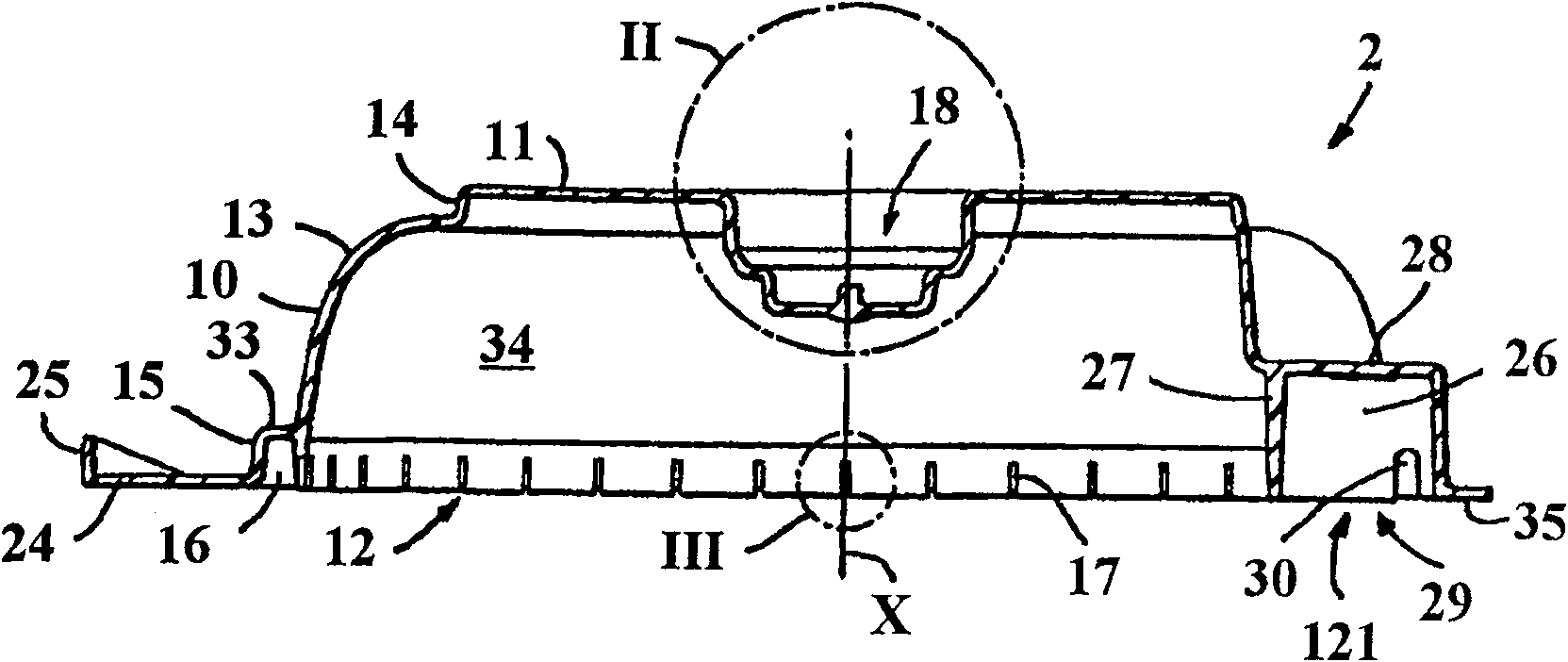

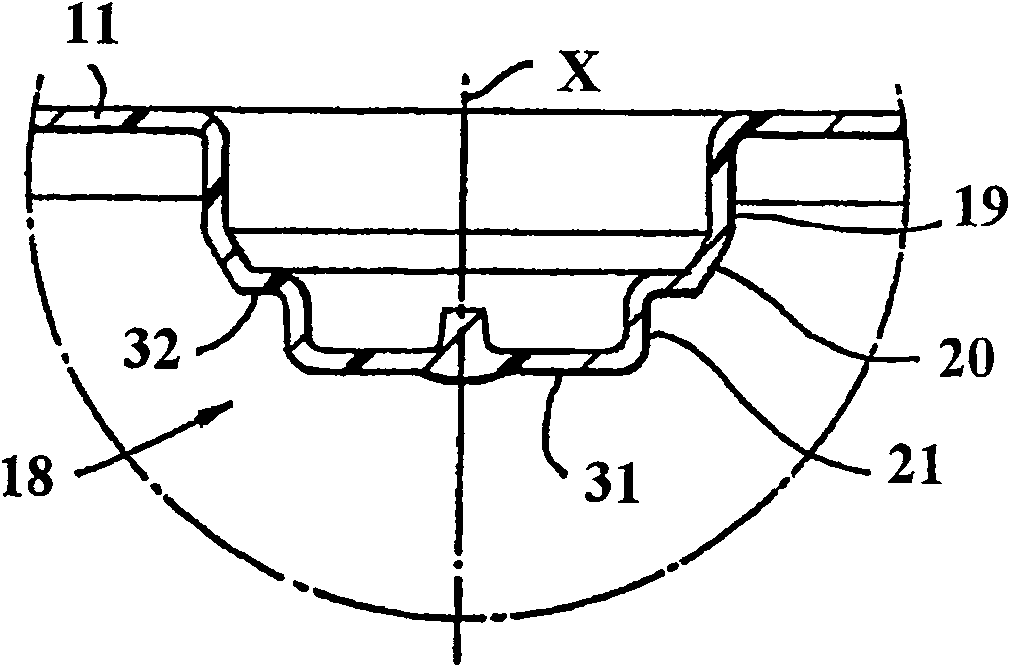

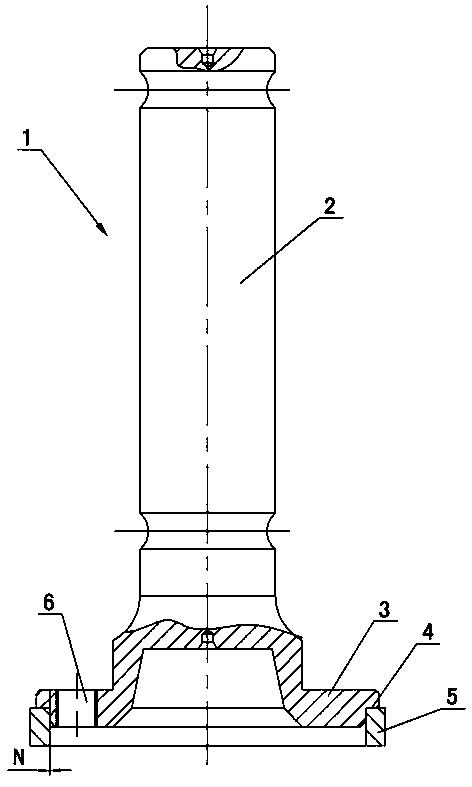

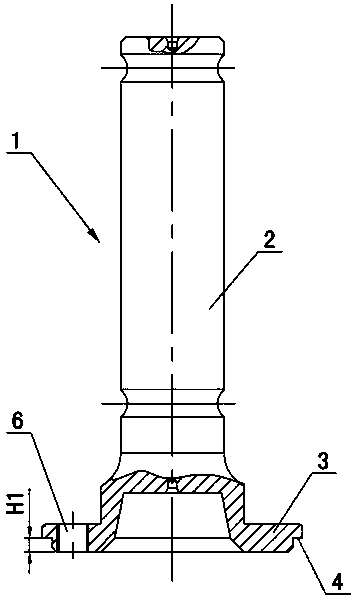

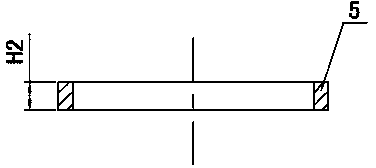

Piston

InactiveCN103890363AAvoid scorchingProcessing speedMolten spray coatingMachines/enginesProduction lineThermal spraying

The invention relates to a piston (2) for an internal combustion engine. It is essential to the invention that a region of the piston (2) on the crankshaft side is provided with a thermally conductive coating (5) that is sprayed on by means of a thermal spraying method. Thus, it is possible to economically apply the thermally conductive coating (5) within the production line.

Owner:MAHLE INT GMBH

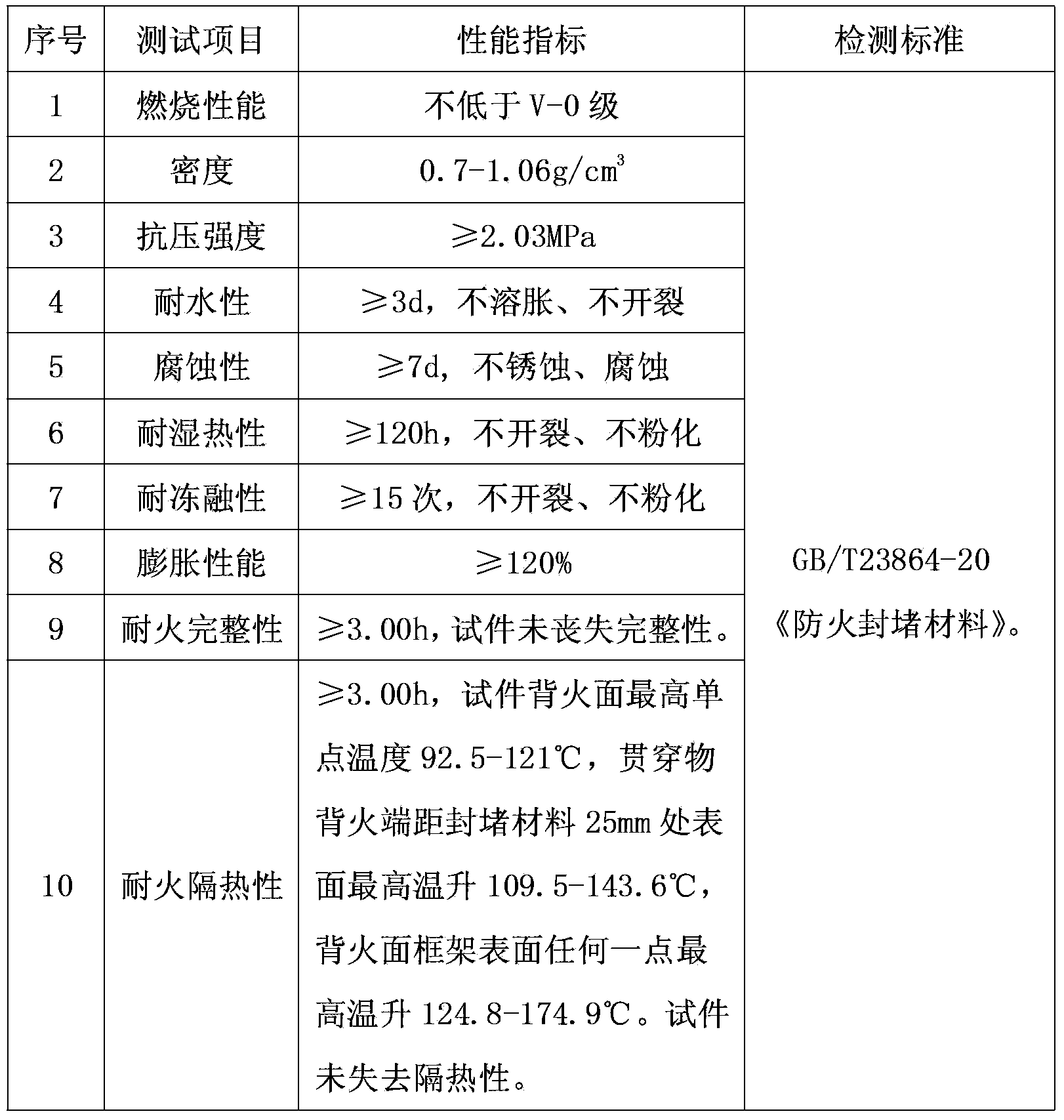

Novel composite fire retardant module and preparation method thereof

The invention discloses a novel composite fire retardant module and a preparation method thereof. The novel composite fire retardant module has good fire retardance and water resistance and is also simple in processing technology, convenient in construction and nontoxic and nonharmful to the environment.

Owner:HAILONG EMERSON ZHENJIANG ENERGY TECH

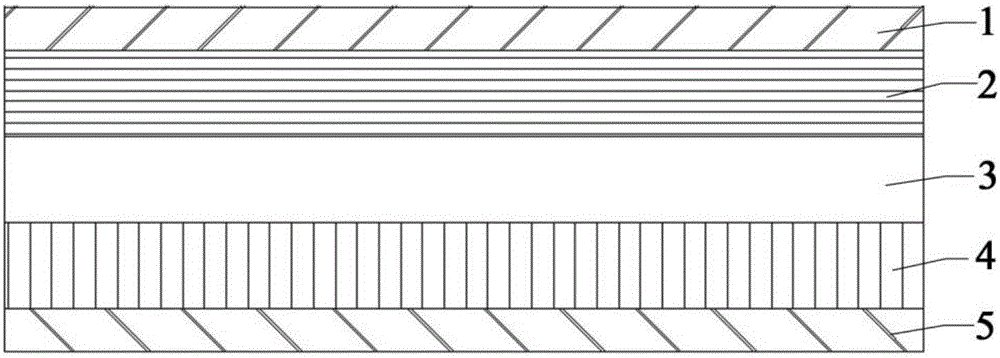

Flame retardant waterproof composite fiber floor

PendingCN106836711AReasonable compositionImprove flame retardant performanceSynthetic resin layered productsFlooring insulationsFire retardantMaterials science

The invention discloses a flame retardant waterproof composite fiber floor. The flame retardant waterproof composite fiber floor is sequentially composed of a flame retardant layer, a nylon layer, a floor core layer, a fiber layer and a waterproof layer from top to bottom. The flame retardant waterproof composite fiber floor is simple and reasonable in structure, easy to implement, low in production cost and high in strength. The surface of the flame-retardant waterproof composite fiber floor is flame retardant and the bottom of the flame retardant waterproof composite fiber floor is waterproof, thus the flame retardant waterproof composite fiber floor is high in security, durable and cost-effective.

Owner:SUZHOU XINENG ENVIRONMENTAL SCI & TECH CO LTD

Machine for the preparation of beverages

ActiveCN100515293CAvoid bar deviceIncreased easeCooking-vessel lids/coversBeverage vesselsEngineeringMechanical engineering

A closure mechanism for a beverage preparation machine (201) comprising a fixed lower part (255) and an upper part (256) rotatable relative to the lower part, the upper part being movable from an open position in which the upper part is disengaged from the lower part to In the closed position where the upper and lower parts are engaged, the closing mechanism also includes a clamp lever (280) operable to hold the upper part in the closed position, wherein the clamp lever includes a pivotable lever at a first pivot point (283). A first part (281) connected to the upper part (256), and a second part (282) having a first end pivotable around a second pivot point (285), the first part (281) The one end and the second end of the second member (282) are pivotally connected together at a third pivot point (286) such that the clamp bar has a first stable position and a second stable position, wherein the clamp bar During the operation of moving the upper part from the open position to the closed position, the clamp bar moves from the first stable position to the second stable position.

Owner:KONINK DOUWE EGBERTS BV

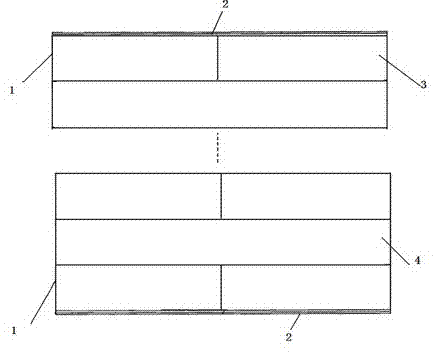

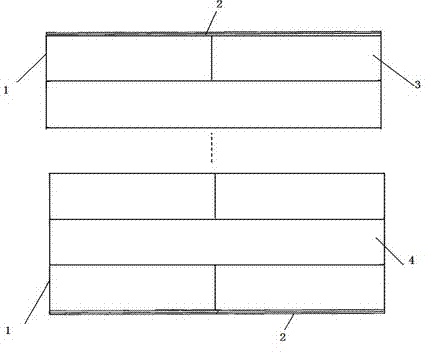

Method for manufacturing paint-free moisture-proof board

InactiveCN102225560AWill not deformWill not open glueSynthetic resin layered productsWood veneer joiningHardnessMelamine

The invention discloses a method for manufacturing a paint-free moisture-proof board. The method comprises the following steps of: 1, superposing boards made of a hard wood material in a longitudinal and transverse staggered mode to form a multilayer board, wherein the hard boards of even layers in the multilayer board are arranged transversely and the hard boards of odd layers are arranged longitudinally, or the hard boards of even layers in the multilayer board are arranged longitudinally and the hard boards of odd layers are arranged transversely, and the joints of the hard boards of the even layers and the odd layers are not on the same straight line and are staggered; and 2, sticking melamine impregnated paper to the front and the back of the multilayer board, and pressing. The paint-free moisture-proof board obtained in a longitudinal and transverse staggered superposition mode can well resist moisture, does not cause deformation, glue opening, expansion or peeling, and is suitable for moist environments; and because the melamine protective film is adopted on the surface of the produced moisture-proof board, the moisture-proof board is environmentally-friendly, high in hardness and paint-free.

Owner:上海荷雨木业有限公司

Shell and tube heat exchanger and using method thereof in mariculture

ActiveCN103245228AIncrease flow rateImprove heat transfer coefficientPisciculture and aquariaHeat exchanger casingsMariculturePlate heat exchanger

The invention discloses a shell and tube heat exchanger and a using method thereof in mariculture. The shell and tube heat exchanger comprises a shell tube and a plurality of heat exchange tubes. Shell tube flange roots, tube plates, tube boxes, end plates, transition tubes and gas-liquid conveying tubes are symmetrically arranged at two ends of the shell tube. The shell tube, the shell tube flange roots, the tube plates, the tube boxes and the end plates are connected in sequence. Two transition tubes are installed on the end plates, the gas-liquid conveying tubes are installed on every transition tube, inlaying concave parts are arranged on the inner sides of the tube boxes, flow equalizing plates are installed on the inlaying concave parts and are provided with a plurality of flow equalizing holes, and a plurality of baffling plates are installed on a pipe wall on the inner side of the shell tube. The shell and tube heat exchanger is simple and reasonable in structure and convenient to use, saves energy remarkably when applied to mariculture, and is good in heat exchange effect.

Owner:QINGDAO HONGYU ENVIRONMENTAL PROTECTION AIR CONDITIONING EQUIP

Transfer-type operating table capable of reducing self-weight pressure of patient

ActiveCN110393647AReduce self-weight pressureImprove fitDiagnosticsOperating tablesEngineeringOperating table

The invention relates to the technical field of operating tables, and discloses a transfer-type operating table capable of reducing self-weight pressure of a patient. The table comprises a bed body, an extrusion groove is fixedly connected to the interior of the bed body, a heating opening is formed in the surface of the extrusion groove, an airflow channel is fixedly connected to the interior ofthe extrusion groove, rollers are movably connected to the two sides of the airflow channel, connecting rods are movably connected to the surfaces of the rollers, one ends, far from the rollers, of the connecting rods are hinged to push rods, and one ends, far from the connecting rods, of the push rods are slidably connected to guide rails. Hips extrude a heat conduction bag, the heat conduction bag deforms to extrude the rollers, the rollers move downwards and push the connecting rods, the push rods are clamped by springs and limiting plates in connecting frames to move towards two sides, therollers adjacent to the push rods are pushed to move upwards, in other words, the rollers on the back of the patient move upwards, the back of the patient is supported, the body of the patient is well attached to the bed body, and therefore the effect of relieving the self-weight pressure of the patient is achieved.

Owner:HEBI CITY PEOPLES HOSPITAL

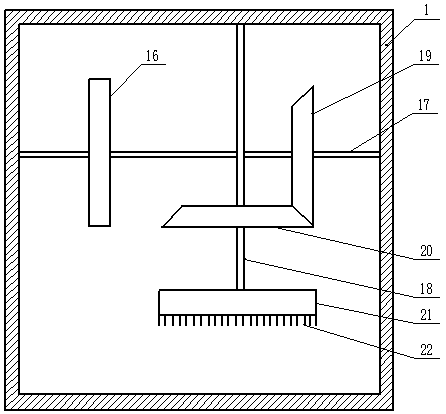

Automobile part cleaning device

ActiveCN107755312AFully contactedSave waterCleaning using toolsCleaning using liquidsEngineeringMechanical engineering

The invention relates to the technical field of automobile parts, in particular to an automobile part cleaning device. The automobile part cleaning device comprises a device frame, and a collecting pool and a water tank communicating with the collecting pool are arranged at the bottom of the device frame. A filter net is arranged in the water tank, a first water pipe and a second water pipe are arranged on the water tank, and the two water pipes are each provided with a water pump. A mounting frame is arranged in the middle of the device frame, and a roller set in which adjacent rollers do notmake contact with each other is arranged on the mounting frame. Branch pipes are arranged between the adjacent rollers, and each branch pipe communicates with the collecting pool. A through groove with openings of the two ends being upward is formed inside each roller. An air bag is arranged on the side wall of the collecting pool, and a vertical lever is rotatably connected on the position, on the same side with the air bag, of the device frame. The lower end of the lever is opposite to the air bag, and the upper end of the lever is provided with a rack. A gear is arranged on the lower portion of the rack in an engaged mode, and a first conical gear is arranged in the mode of being coaxial with the gear. The first conical gear is engaged with a second conical gear, and a cleaning brush is arranged on a shaft of the second conical gear. By adopting the technical scheme, parts can be overall cleaned.

Owner:重庆纵翼机械制造有限公司

Connecting coupling bearing of thermal insulating X-Ray tube

InactiveCN103939484ADoes not affect normal use accuracyFit closelyBearing coolingMachine maintenanceCoupling

The invention discloses a connecting coupling bearing of a thermal insulating X-Ray tube. The bearing comprises a connecting coupling bearing composed of a connecting flange and a shaft lever. The bearing is characterized in that a thermal insulating ceramic device is arranged at the contact surface between the connecting flange and a tungsten disc of a CT machine. The thermal insulating ceramic device is arranged at the contact surface between the connecting flange and the tungsten disc of the CT machine, so that when the CT machine works, the tungsten disc emits heat, the heat of the tungsten disc transmitted to the coupling bearing is reduced, and thus the heating of the coupling bearing is alleviated, and the heating expansion and cooling contraction coefficient of the coupling bearing is reduced; therefore, the transmission accuracy of the coupling bearing is guaranteed, the service life of the coupling bearing is prolonged and the machine maintenance cost is saved.

Owner:ZHEJIANG UTE BEARING

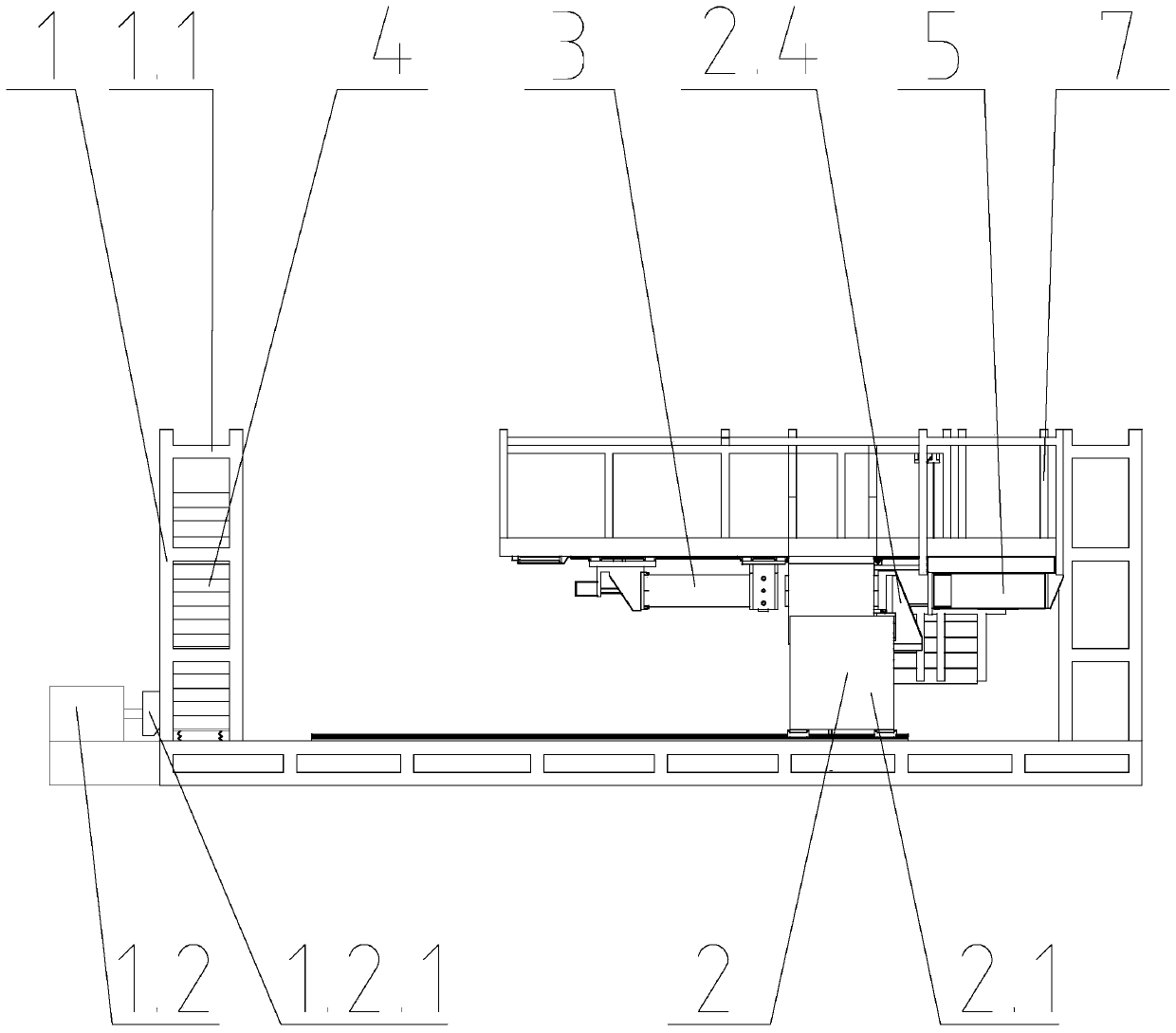

Automatic boxing device for film reel

Owner:宁波宇动机械科技有限公司

Golf tee and preparation method thereof

The invention belongs to the technical field of sports equipment, and particularly relates to a golf tee and a preparation method thereof. The golf tee is mainly prepared from gum-containing pine barks, elm barks and / or banyan barks and cassava, and extra binders are omitted. The preparation method includes the steps: firstly, collecting and crushing various raw materials; secondly, performing high-temperature treatment and extrusion to form the golf tee. The method is simple in preparation process and convenient in operation. The golf tee turns into soil particles within 2 minutes when touching water, the golf tee can be effectively combined with soil and can be absorbed by a lawn after degradation to generate fertilizers, the problems of foot and tire stabbing properties and difficulty in recovery of other tees are solved, a large number of manpower and material resources are saved, and environments are protected. Besides, the transverse pressure resistance of the golf tee is 3-5 kilograms, the vertical pressure resistance of the golf tee is 15-20 kilograms, the golf tee is broken once being hit, a golf club cannot be blocked, and technical indexes of the golf tee are variously demonstrated at home and abroad to prove that the golf club cannot be damaged, and accuracy is improved.

Owner:朱君

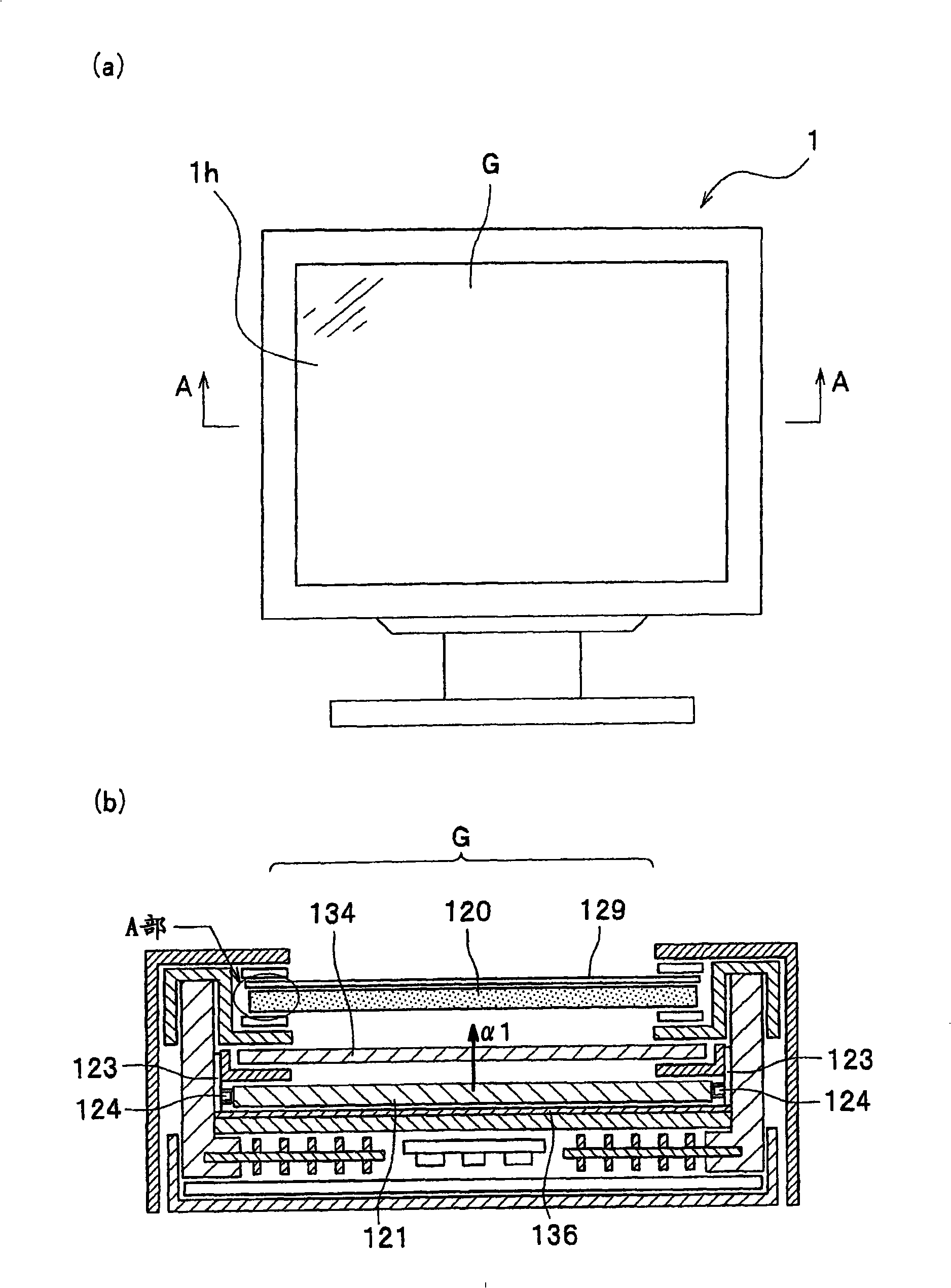

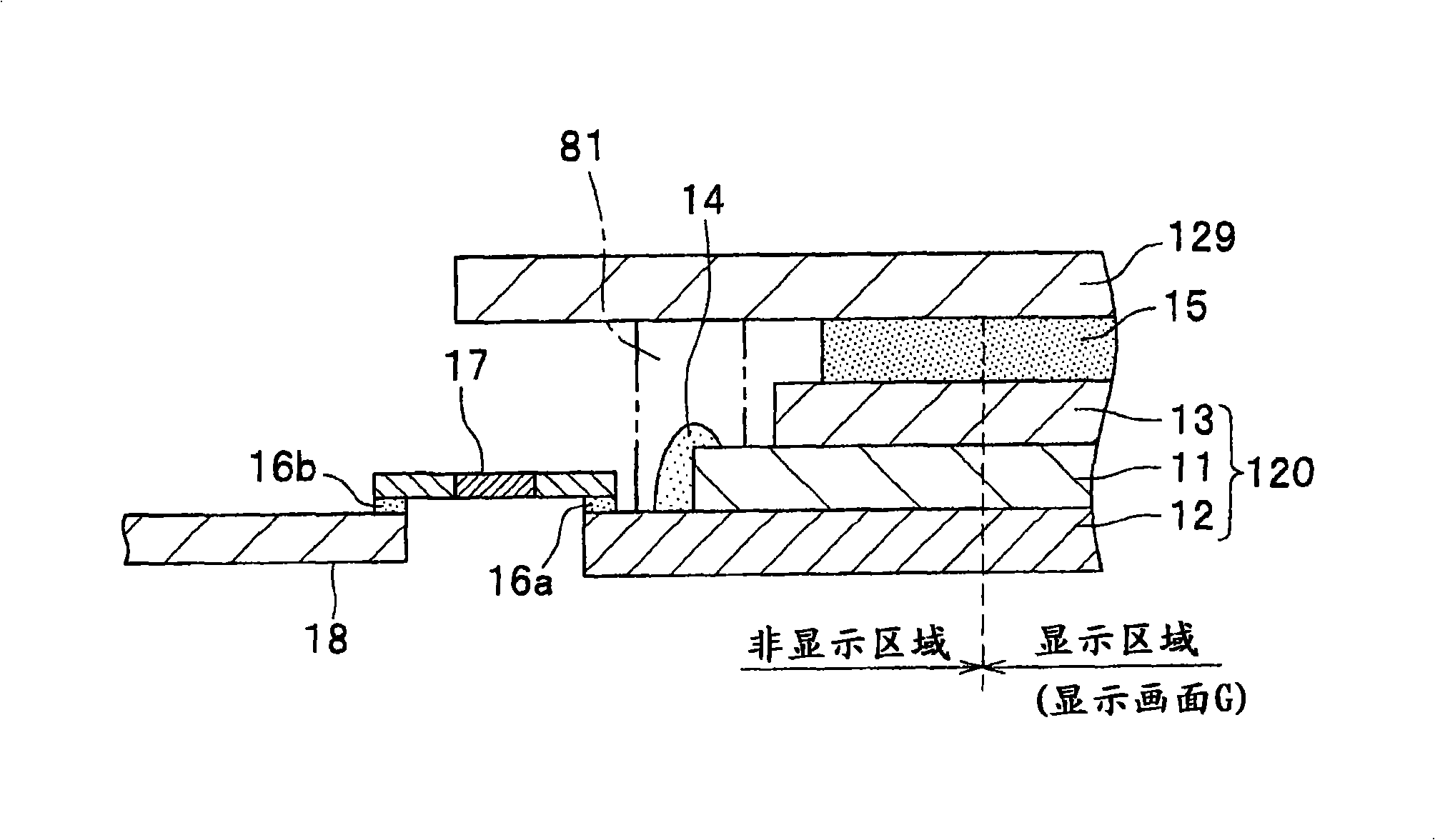

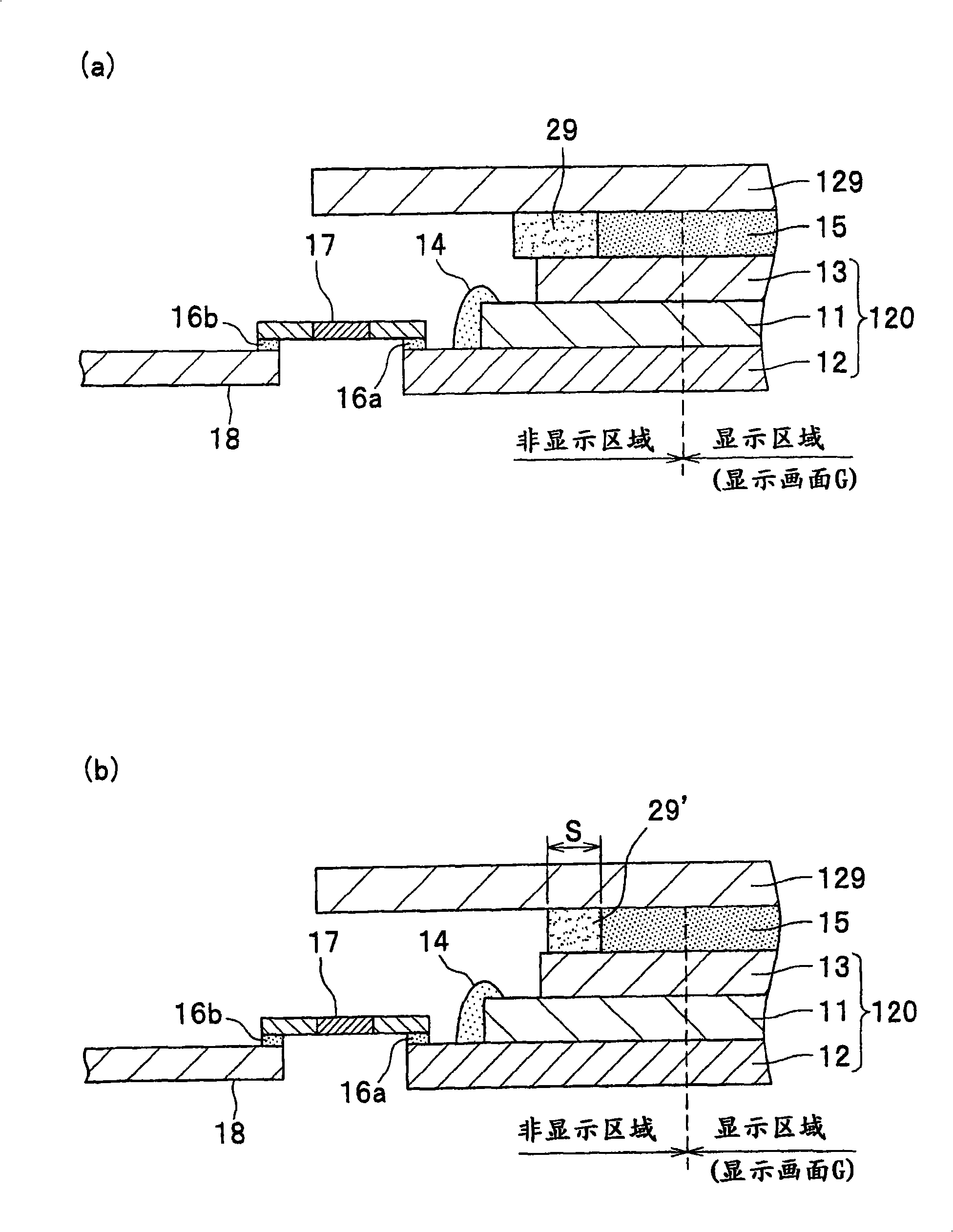

Image display device

ActiveCN101315482APrevent leakagePrevent infiltrationNon-linear opticsElastomerLiquid-crystal display

Owner:JAPAN DISPLAY INC +1

Multipurpose lightweight fireproof material

InactiveCN111777356AImprove flame retardant performanceImprove waterproof performanceCeramicwareEpoxyCalcium silicate

Owner:中南华兴科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com