Method for manufacturing paint-free moisture-proof board

A technology for moisture-proof boards and wood boards, which is applied in the joining of wooden veneers, chemical instruments and methods, and manufacturing tools, etc., can solve the problems of insufficient moisture-proof effect and environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

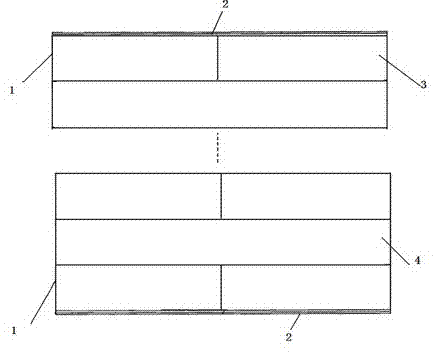

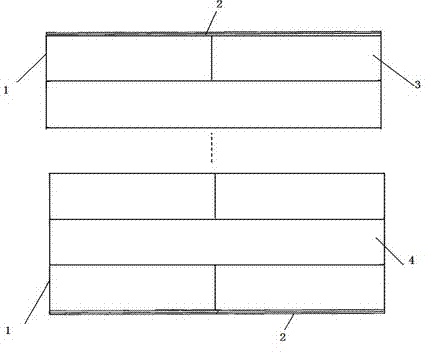

[0018] Step 1: Selection of multi-layer boards. The core of the multi-layer boards is made of 1.5-2.2 cm eucalyptus wood single layer, which is stacked vertically and horizontally to make 11-13 odd-numbered layers. It is required that the middle single layer has no overlapping, No faults, no gaps, etc. The production process of multi-layer boards can basically follow the general practice in the market. In the multi-layer board, the even-numbered hard wood boards are arranged horizontally, and the odd-numbered hard wood boards are arranged vertically. The joints between the hard planks in the even-numbered and odd-numbered layers are not on one straight line, but in a staggered manner.

[0019] Step 2: Attach melamine-impregnated film paper on both sides of the front side of the multi-layer board, and put it into the multi-layer press horizontally with the multi-layer board. Through the different surface treatments of the steel plates on the press, the market is divided into: ...

Embodiment 2

[0021] Step 1: Selection of multi-layer boards. The core of the multi-layer boards is made of 1.5-2.2 cm eucalyptus wood single layer, which is stacked vertically and horizontally to make 11-13 odd-numbered layers. It is required that the middle single layer has no overlapping, No faults, no gaps, etc. The production process of multi-layer boards can basically follow the general practice in the market. In the multi-layer board, the hard wood boards of even layers are arranged horizontally, and the hard wood boards of odd layers are arranged vertically; or the hard wood boards of even layers are arranged vertically, and the hard wood boards of odd layers are arranged horizontally; The joints between the rigid planks are not in a straight line, but in a staggered manner.

[0022] Step 2: Attach melamine-impregnated film paper on both sides of the front side of the multi-layer board, and put it into the multi-layer press horizontally with the multi-layer board. Through the diffe...

Embodiment 3

[0024] Step 1: Selection of multi-layer boards. The core of multi-layer boards is made of a single layer of 1.5-2.2cm miscellaneous wood (such as pine miscellaneous wood, etc.). It is required that the middle single layer has no overlapping, no faults, no empty seams, etc. The production process of multi-layer boards can basically follow the general practice in the market. In the multi-layer board, the hard wood boards of even layers are arranged horizontally, and the hard wood boards of odd layers are arranged vertically; or the hard wood boards of even layers are arranged vertically, and the hard wood boards of odd layers are arranged horizontally; The joints between the rigid planks are not in a straight line, but in a staggered manner.

[0025] Step 2: Attach melamine-impregnated film paper on both sides of the front side of the multi-layer board, and put it into the multi-layer press horizontally with the multi-layer board. Through the different surface treatments of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com