Positive photosensitive resin composition

A technology of photosensitive resin and composition, applied in photosensitive material processing, optics, photomechanical equipment, etc., can solve the problems of low sensitivity, longer exposure time, and increased number of steppers, etc., and achieve the effect of high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example

[0067] Specific examples include 3,5-diamino-1-hydroxybenzene, 4,6-diamino-1,3-dihydroxybenzene, 3,3'-dihydroxy-4,4'-diaminobiphenyl, 4, 4'-dihydroxy-3,3'-diaminobiphenyl, 3,4-dihydroxy-3',4'-diaminobiphenyl, 2,2-bis(4-amino-3-hydroxyphenyl) Propane, bis(3-amino-4-hydroxyphenyl)sulfide, bis(3-amino-4-hydroxyphenyl)sulfone, bis(3-amino-4-hydroxyphenyl)methane, bis(4-amino-3 -Hydroxyphenyl)methane, 2,2-bis(4-amino-3-hydroxyphenyl)hexafluoropropane, 2,2-bis(3-amino-4-hydroxyphenyl)hexafluoropropane, 2-( 3-Hydroxy-4-aminophenyl)-2-(3-amino-4-hydroxyphenyl)hexafluoropropane, bis(3-amino-4-hydroxyphenyl)sulfone and bis(4-amino-3- hydroxyphenyl) sulfone. These phenolic diamines can be used individually or in combination of 2 or more types. Among the above-mentioned phenolic diamines, 2,2-bis(3-amino-4-hydroxyphenyl)hexafluoropropane, 3, 3'-dihydroxy-4,4'-diaminobiphenyl and bis(3-amino-4hydroxyphenyl)sulfone.

[0068] A particularly preferable example of the polycondensate A use...

Embodiment

[0148] Examples according to the embodiment of the present invention are explained in more detail by the following Reference Examples, Examples and Comparative Examples.

[0149] (Manufacture of polymer solution)

reference example 1

[0151] A detachable glass four-neck flask equipped with a stainless steel anchor stirrer is equipped with a Dean-Stark water trap and a nitrogen gas inlet pipe. Heat and stir in a silicone oil bath.

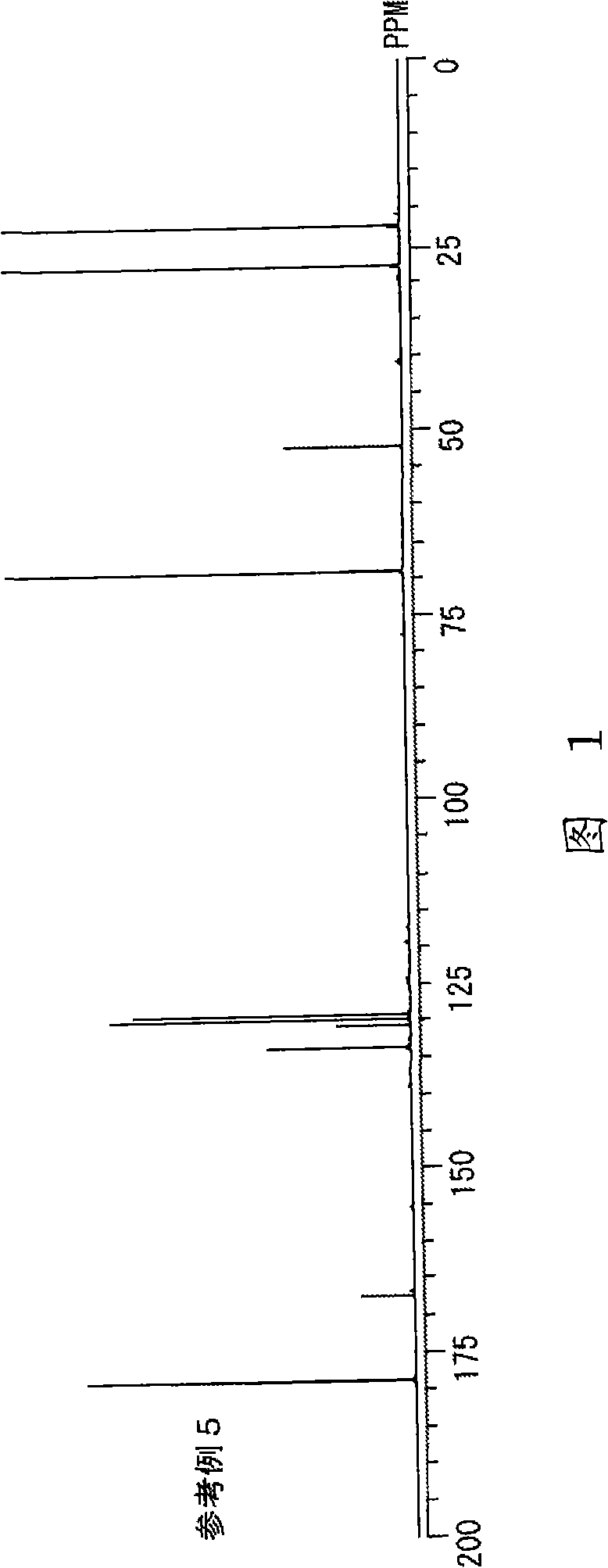

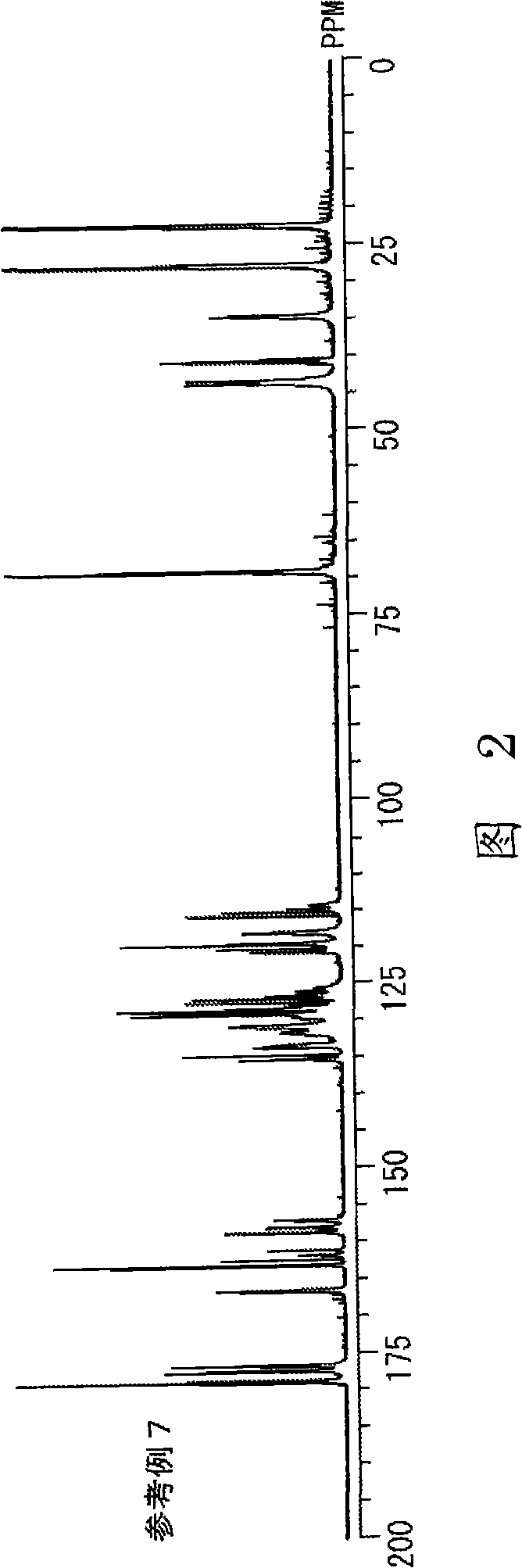

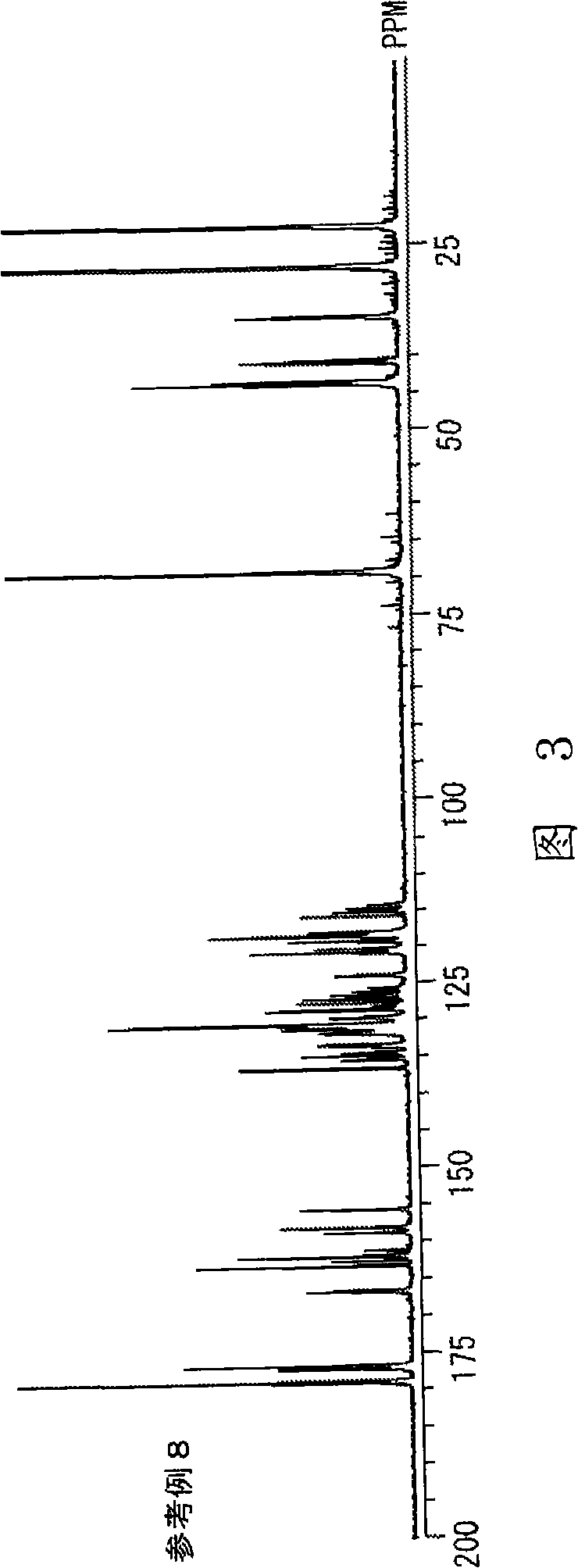

[0152] Add 26.66g (60mmol) 2,2-bis(3,4-dicarboxyphenyl)hexafluoropropane dianhydride (hereinafter referred to as "6FDA"), 10.8g (50mmol) 3,3'-dicarboxy-4,4 '-Diaminobiphenyl (hereinafter referred to as "HO-AB"), 0.6g (6mmol) γ-valerolactone, 1.8g (18mmol) pyridine, 150g N-methylpyrrolidone (hereinafter referred to as "NMP"), 30g toluene , the resulting mixture was heated and stirred at 180 rpm at a silicone oil bath temperature of 180° C. for 1 hour and 40 minutes while blowing nitrogen gas. During the reaction, distilled components of toluene and water (25 g of toluene, 3 g of water) were removed. A part of this solution was diluted with NMP, and the molecular weight of the polycondensate was measured by gel permeation chromatography (manufactured by Tosoh Corporation, TSK gel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com