High-efficiency production process of EPS (Expandable polystyrene) foam product

A production process and high-efficiency technology, applied in the field of foam processing, can solve the problems of long drying time and unsatisfactory drying, and achieve the effects of improving cooling efficiency, shortening drying time, and shortening drying time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

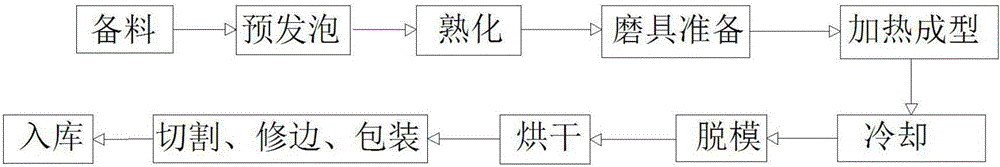

[0030] like Figures 1 to 4 As shown, the present embodiment proposes a production process of high-efficiency EPS foam products, including the following steps:

[0031] 1) Prepare materials, according to the technical requirements of EPS foam products, select the appropriate specifications and models of EPS raw materials;

[0032] 2) Pre-foaming, choose a suitable EPS pre-expansion machine, turn on the EPS pre-expansion machine to preheat, raise the temperature of the foaming device to 70-75 degrees and keep it for 3-5 minutes, put the EPS raw materials into the hopper of the EPS pre-expansion machine , feed the material after preheating, and adjust to the optimum temperature, then feed steam and compressed air, and effectively control uniform foaming at the same time, to obtain EPS beads with a density that meets the requirements. The density can be adjusted from adjusting temperature, feeding The speed and the height of the bead overflow port are realized. Among them, the p...

Embodiment 2

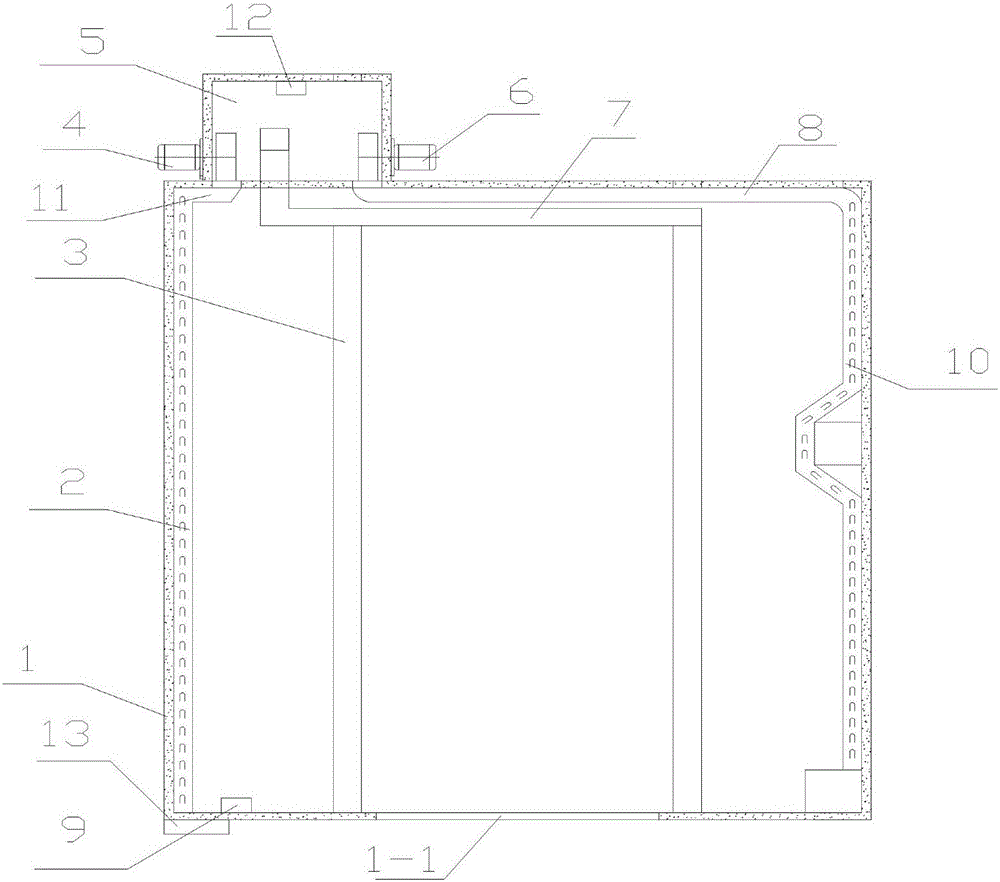

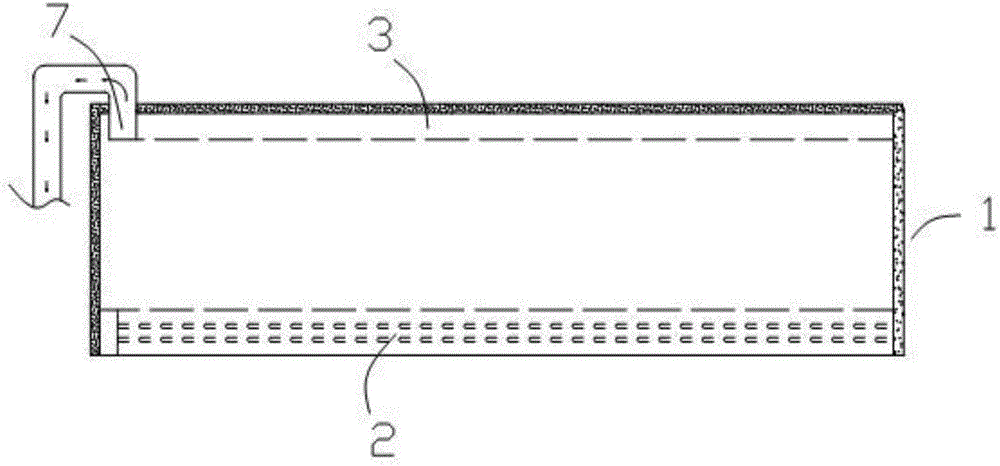

[0043] The drying room used in the embodiment 1 comprises a drying room body 1 and a combustion chamber 5 arranged on the outside of the drying room body 1, and a hot air system and a return air system which are all communicated with the combustion chamber 5 are arranged in the drying room body 1;

[0044] The hot air system includes a left hot air exhaust pipe 2 and a right hot air exhaust pipe 10, the left hot air exhaust pipe 2 and the right hot air exhaust pipe 10 are located in the drying room body, and are respectively located on the left and right side walls of the drying room body 1 At the bottom of the bottom, the air inlets of the left hot blast exhaust pipe 2 and the right hot blast exhaust pipe 10 are respectively connected by the pipeline A11 and the pipeline B8, and the pipeline A11 and the pipeline B8 all pass through the wall of the drying room body 1 to communicate with the combustion chamber 5, and the pipeline A11 A circulating fan A4 and a circulating fan B6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com