Piston

A technique for pistons and heat-conducting coatings, applied in the direction of pistons, pressure inorganic powder coating, superimposed layer coating, etc., can solve the problems of uneven heat distribution and difficulties in the upper structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

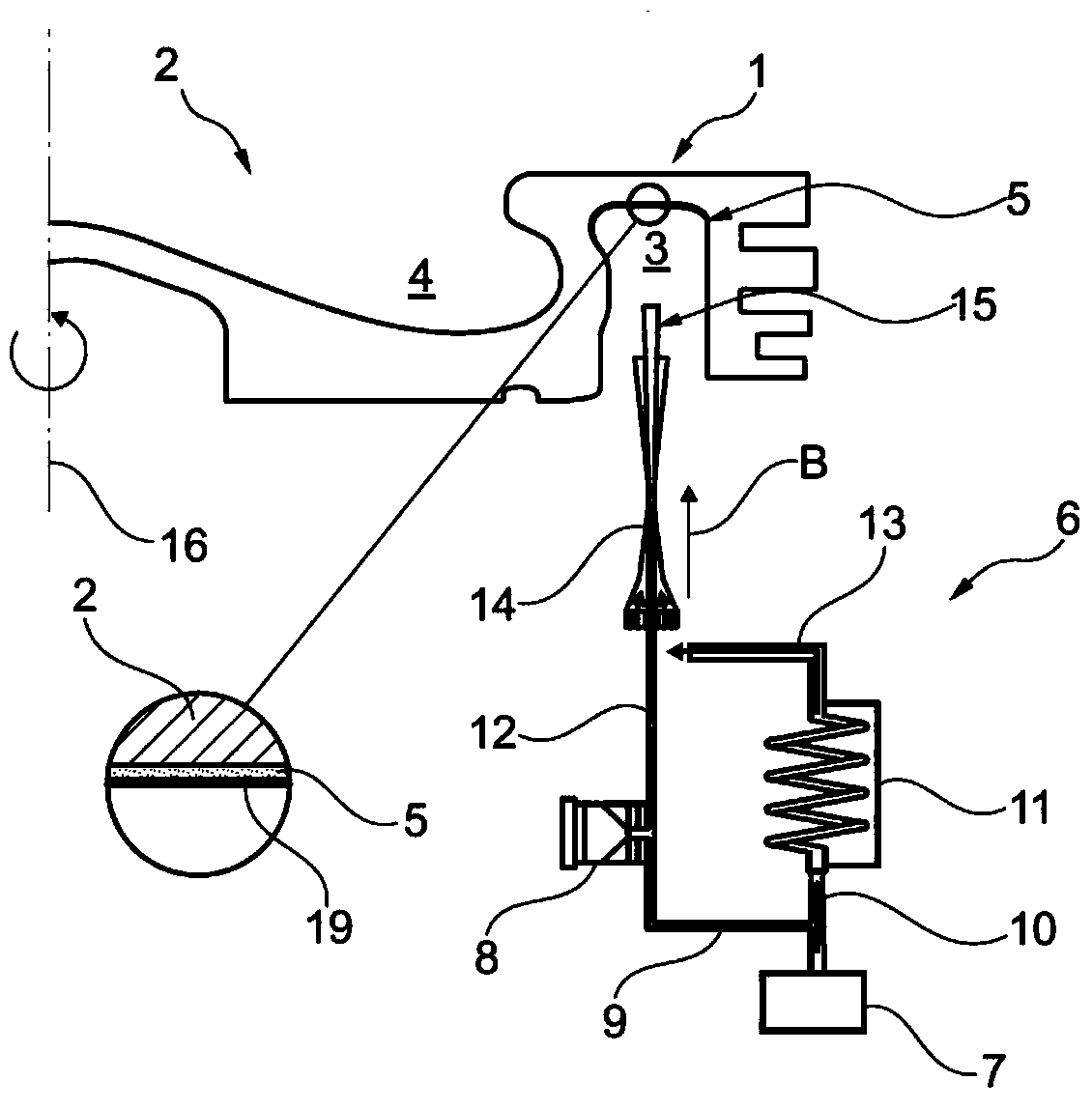

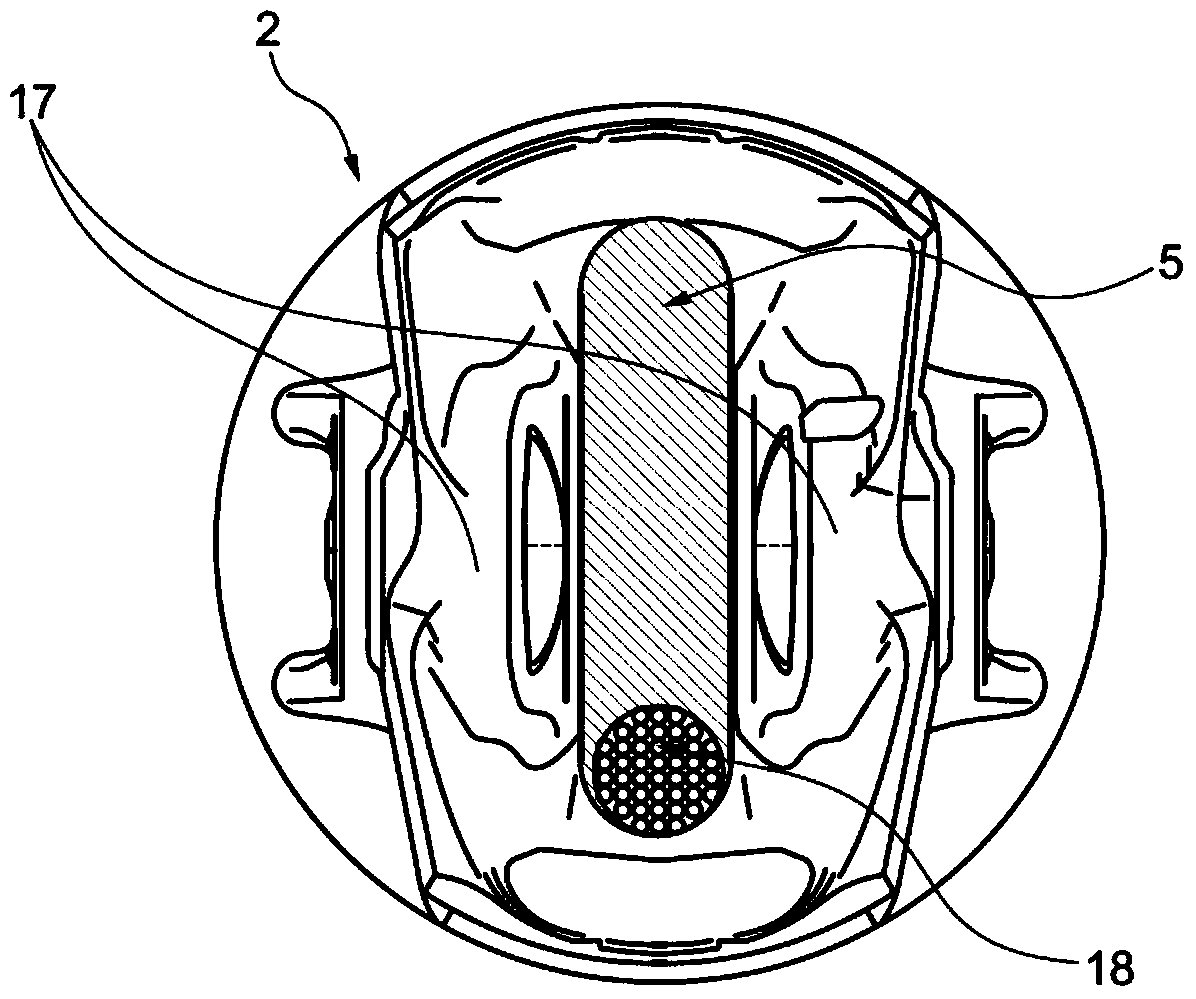

[0017] figure 1 A superstructure 1 of a piston 2 is shown, wherein cooling ducts 3 are arranged in the piston superstructure 1 . In the exemplary embodiment shown in the figures, a cooling duct 3 facing the combustion chamber 4 is arranged on the crankshaft-side piston 2 which has a heat-conducting coating 5 applied thereto by thermal spraying. One can consider melt spraying, arc spraying, plasma spraying, flame spraying, detonation spraying, laser spraying or cold gas spraying, all of which are thermal spraying methods. In particular, the last-mentioned cold-air spraying has high processing speeds and can thus be carried out very economically on production lines.

[0018] The piston 2 can be a composite material piston or a monolithic piston, or even an iron material, preferably stainless steel. The heat-conducting coating 5 applied by thermal spraying, preferably cold-air spraying, can comprise aluminum, silver and / or copper. As far as thermal conductivity is concerned, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum granularity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com