Patents

Literature

100results about How to "Less sticky" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

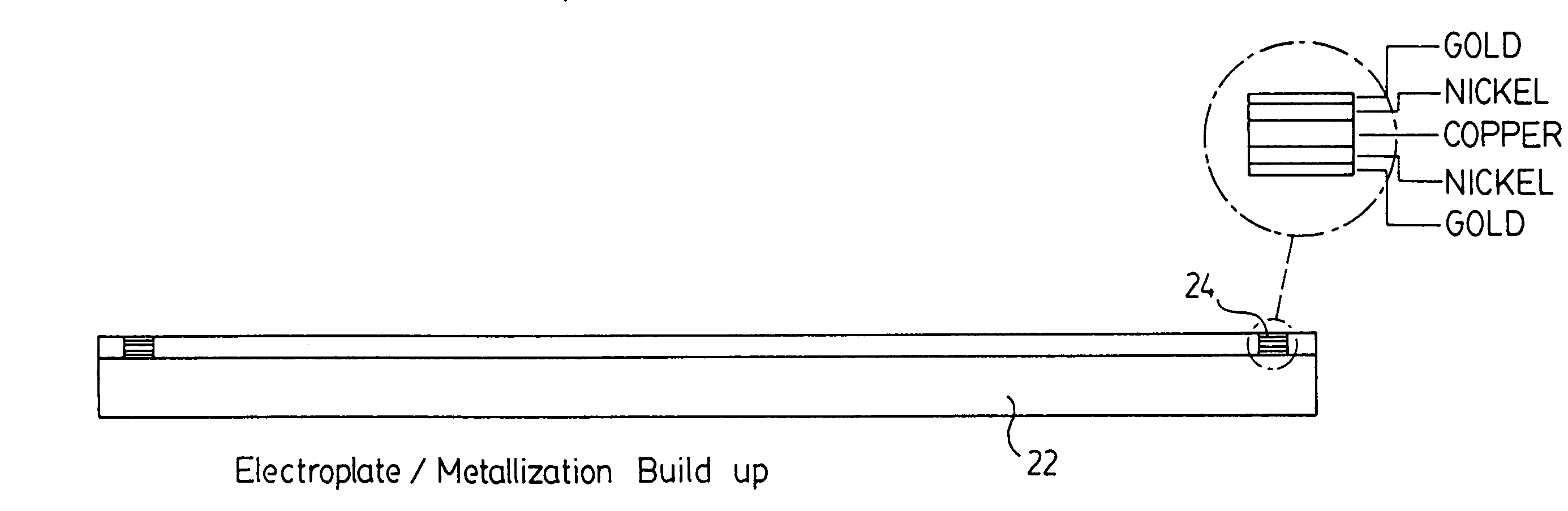

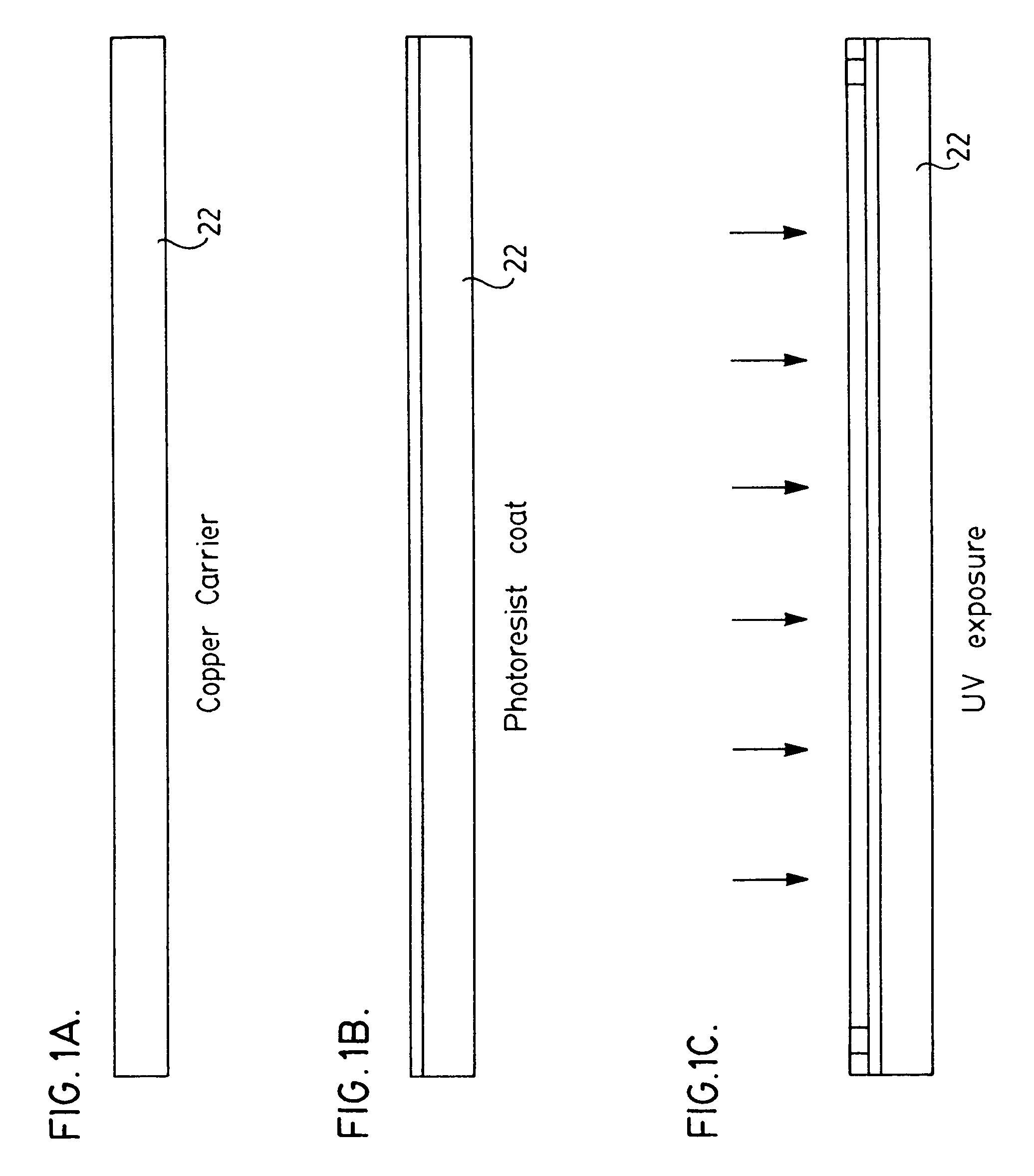

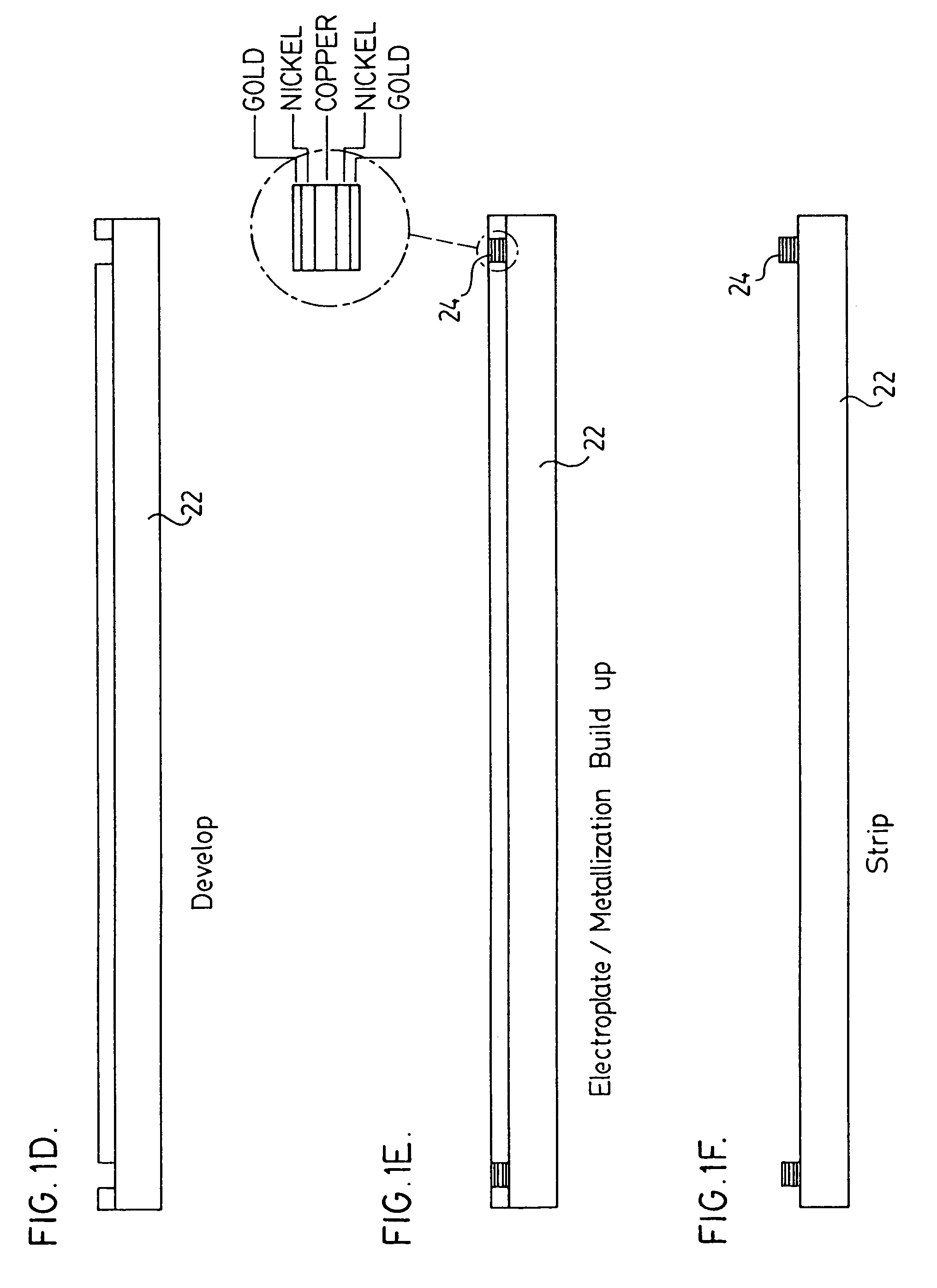

Thin array plastic package without die attach pad and process for fabricating the same

ActiveUS7358119B2Low profileAssembly is smallSemiconductor/solid-state device detailsSolid-state devicesContact padThinned array

Owner:UTAC HEADQUARTERS PTE LTD

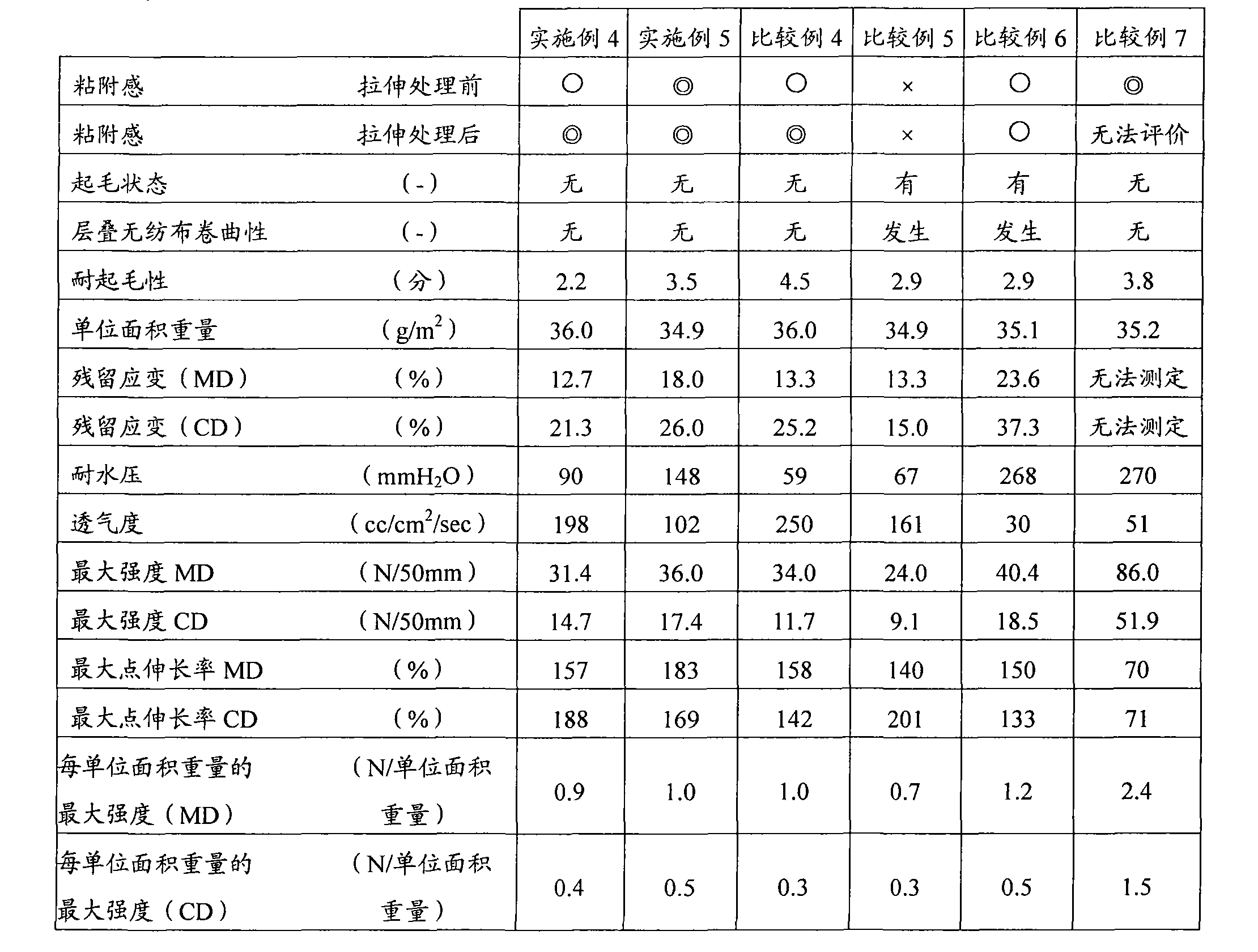

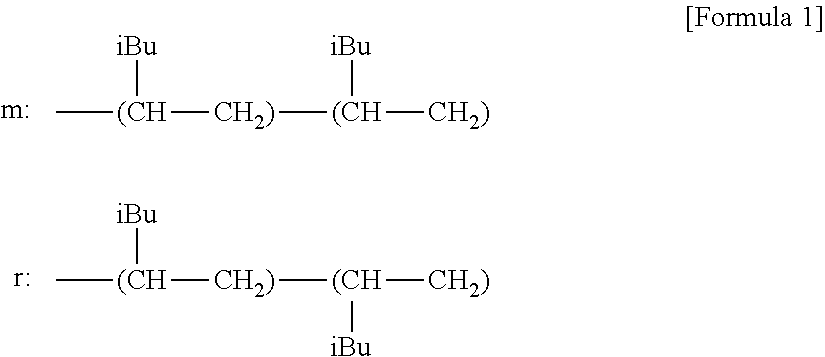

Stretch nonwoven fabric and method for production thereof

ActiveUS20060141883A1Feel goodNarrow distributionWoven fabricsNon-woven fabricsPolymer scienceThermoplastic polyurethane

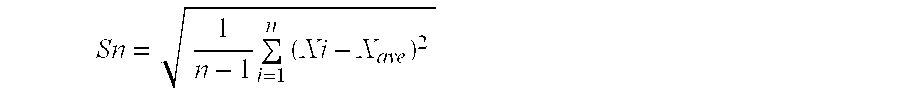

A spunbonded elastic nonwoven fabric according to the invention comprises fibers formed from a polymer comprising a thermoplastic polyurethane elastomer, wherein the thermoplastic polyurethane elastomer has a solidifying point of 65° C. or above as measured by a differential scanning calorimeter (DSC) and contains 3.00×106 or less polar-solvent-insoluble particles per g as counted on a particle size distribution analyzer, which is based on an electrical sensing zone method, equipped with an aperture tube having an orifice of 100 μm in diameter, and wherein the fibers have diameters such that the standard deviation of fiber diameters (Sn) divided by the average fiber diameter (Xave) (Sn / Xave) gives a value of 0.15 or less.

Owner:MITSUI CHEM INC

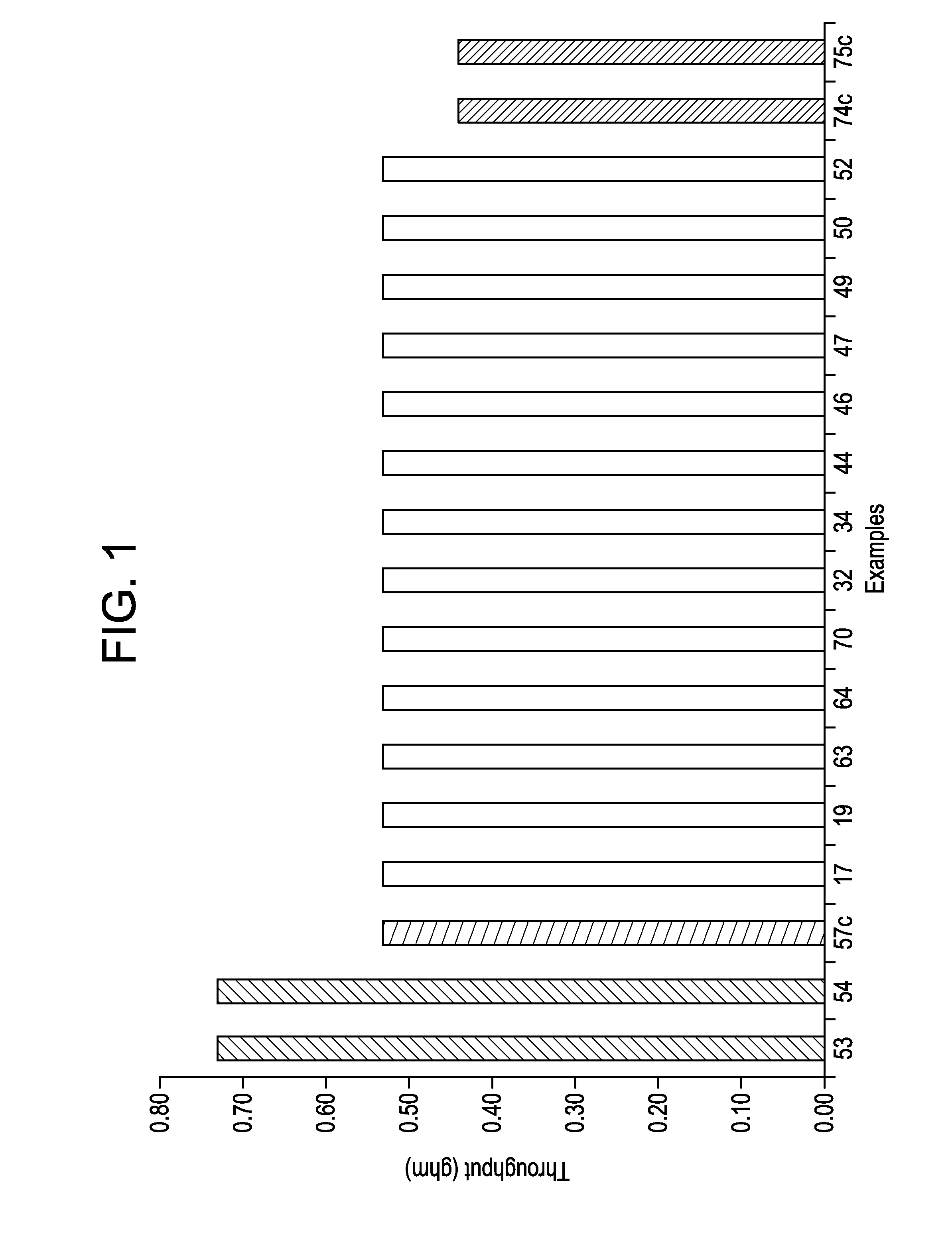

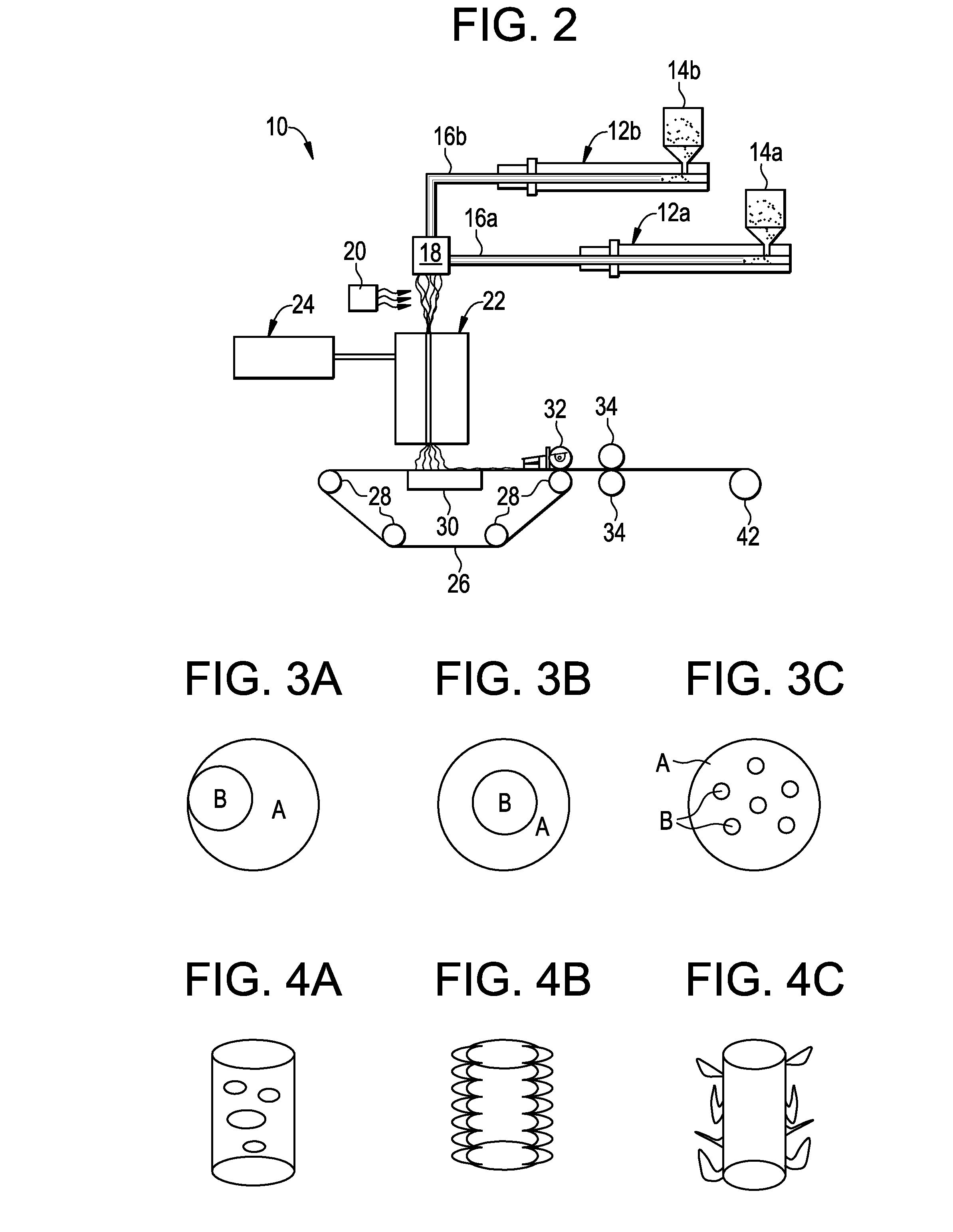

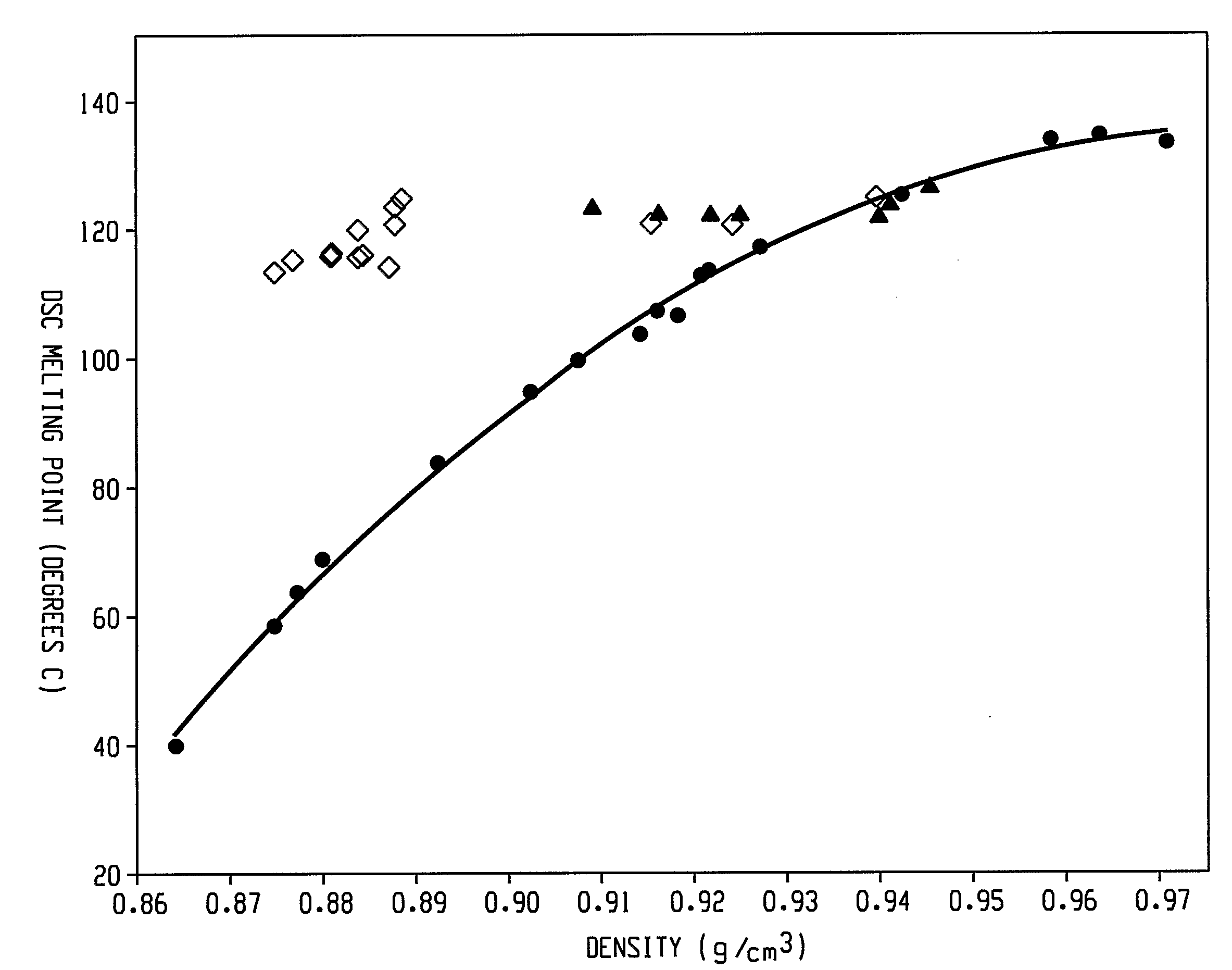

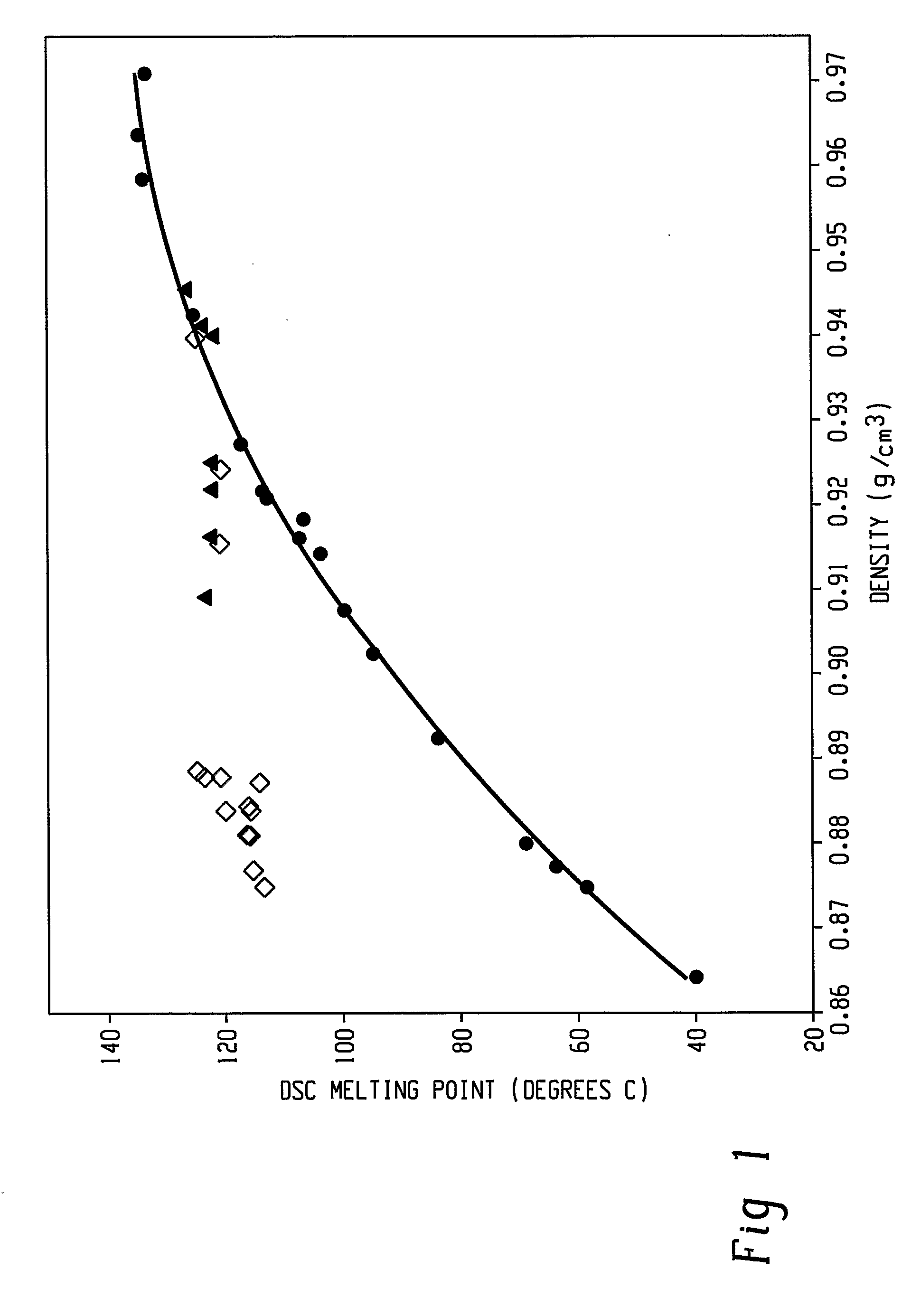

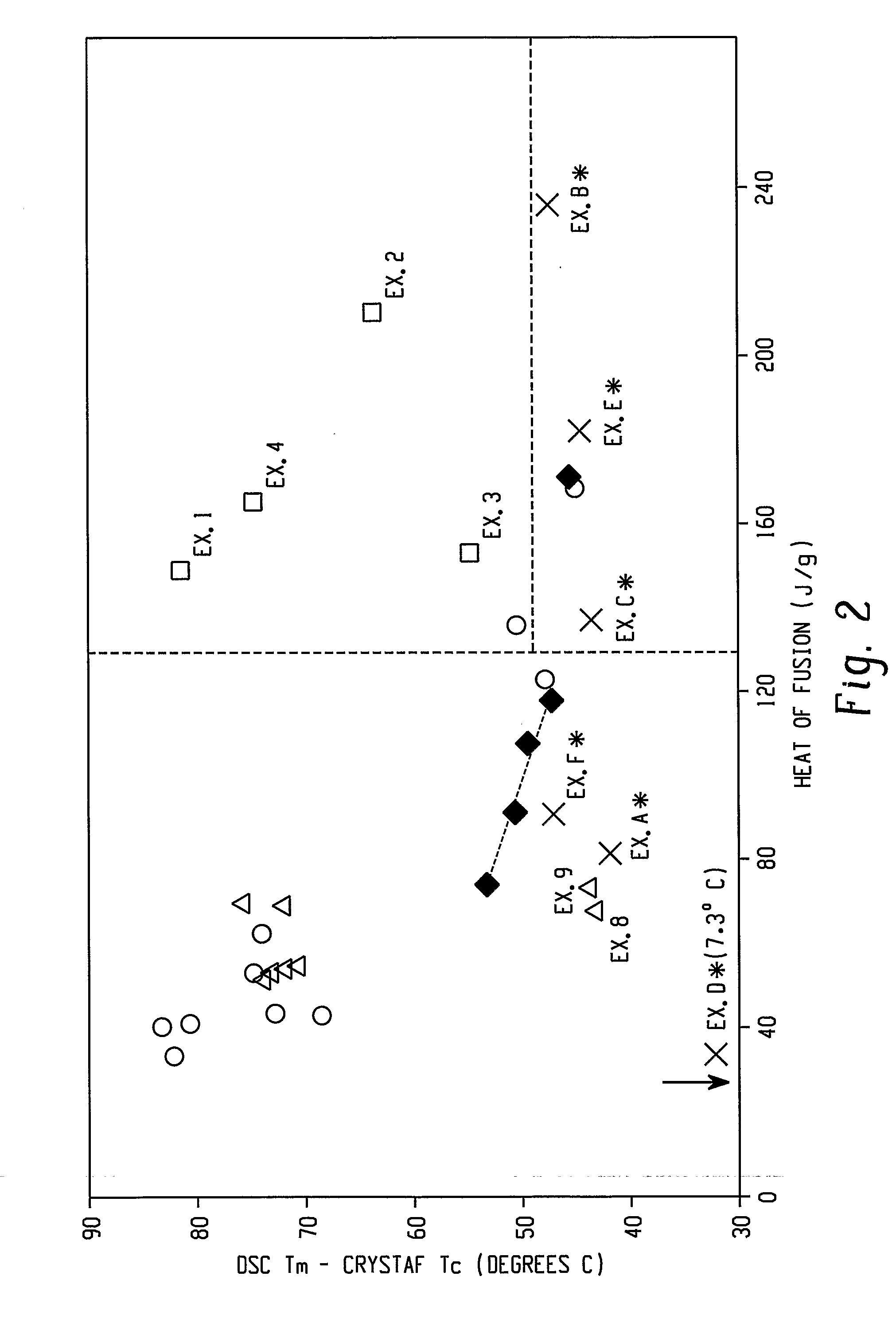

Fibers made from copolymers of ethylene/α-olefins

ActiveUS7947367B2Increase speedReduce the temperatureSynthetic resin layered productsMonocomponent synthetic polymer artificial filamentFiberAlpha-olefin

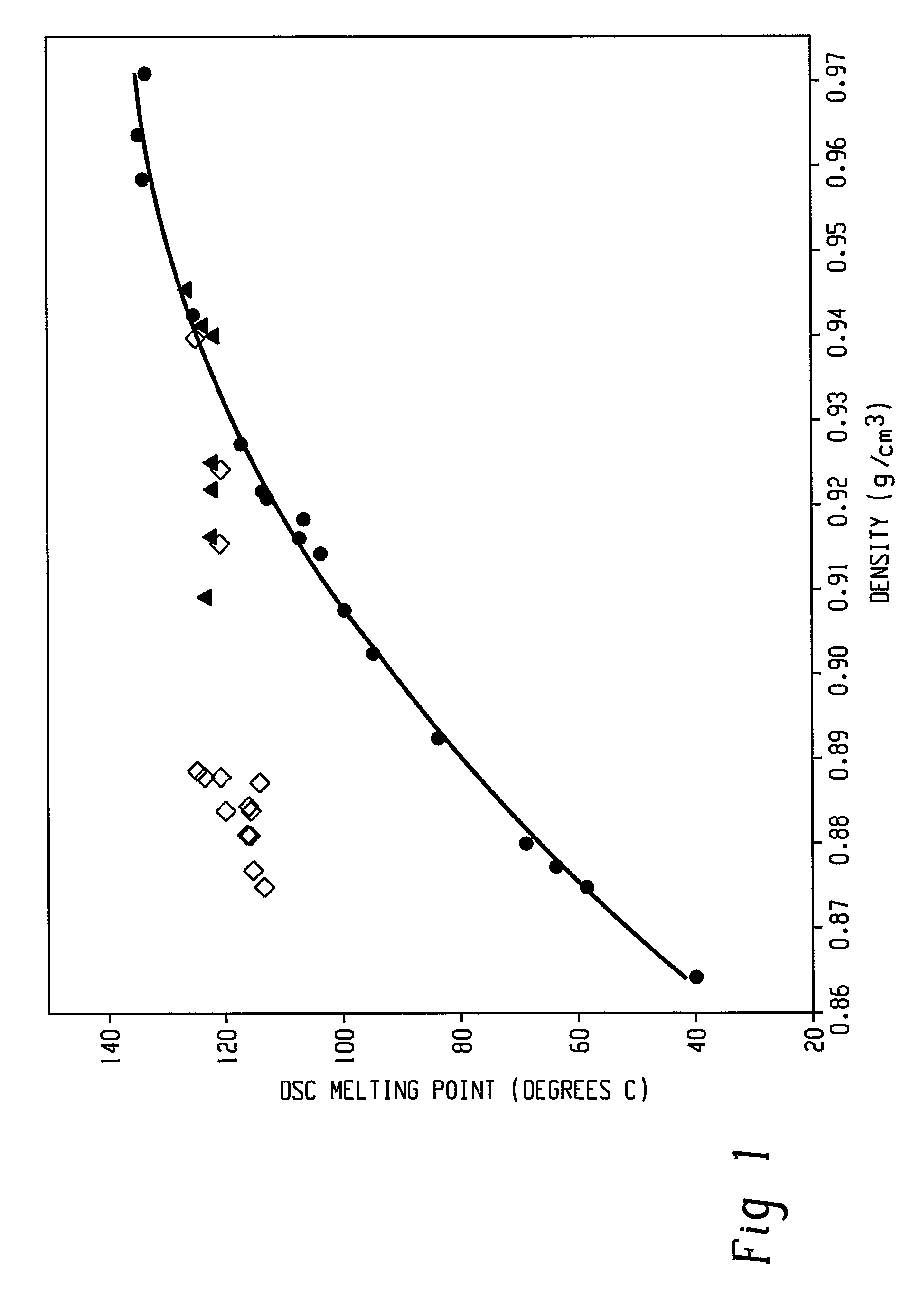

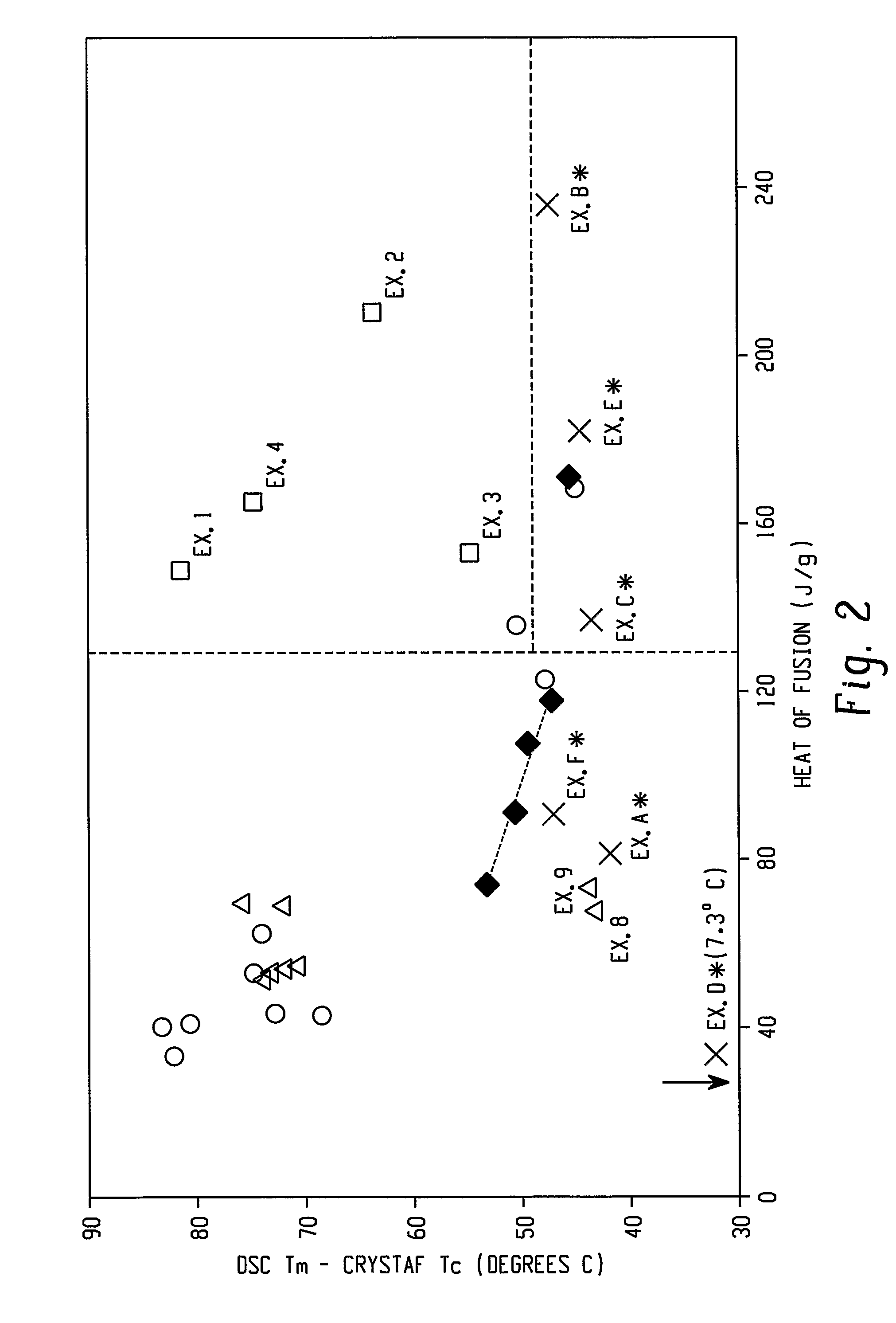

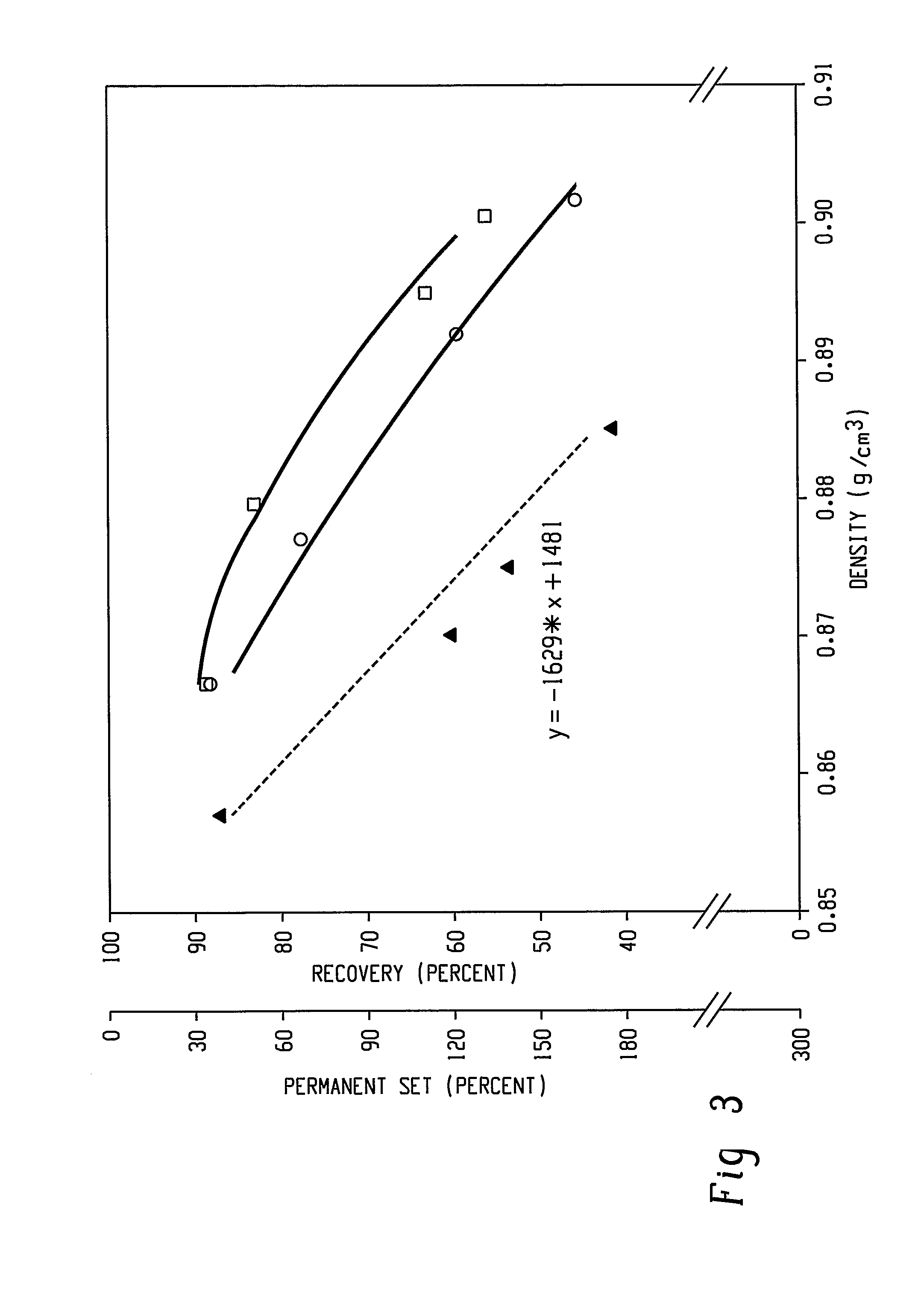

A fiber is obtainable from or comprises an ethylene / α-olefin interpolymer characterized by an elastic recovery, Re, in percent at 300 percent strain and (1) cycle and a density, d, in grams / cubic centimeter, wherein the elastic recovery and the density satisfy the following relationship: Re>1481−1629(d). Such interpolymer can also be characterized by other properties. The fibers made therefrom have a relatively high elastic recovery and a relatively low coefficient of friction. The fibers can be cross-linked, if desired. Woven or non-woven fabrics can be made from such fibers.

Owner:DOW GLOBAL TECH LLC

FIBERS AND FABRICS MADE FROM ETHYLENE/alpha-OLEFIN INTERPOLYMERS

InactiveUS20110003524A1Impart strengthIncrease speedLayered productsFilament/thread formingFiberAlpha-olefin

A bicomponent fiber is obtainable from or comprises an ethylene / α-olefin interpolymer characterized by an elastic recovery, Re, in percent at 300 percent strain and 1 cycle and a density, d, in grams / cubic centimeter, wherein the elastic recovery and the density satisfy the following relationship: Re>1481−1629(d). Such interpolymer can also be characterized by other properties. The fibers made therefrom have a relatively high elastic recovery and a relatively low coefficient of friction. The fibers can be cross-linked, if desired. Woven or non-woven fabrics, such as spunbond, melt blown and spun-laced fabrics or webs can be made from such fibers.

Owner:DOW GLOBAL TECH LLC

Fibers Made from Copolymers of Ethylene/Alpha-Olefins

ActiveUS20090042472A1Increase speedReduce the temperatureSynthetic resin layered productsCeramic shaping apparatusFiberVolumetric Mass Density

A fiber is obtainable from or comprises an ethylene / α-olefin interpolymer characterized by an elastic recovery, Re, in percent at 300 percent strain and (1) cycle and a density, d, in grams / cubic centimeter, wherein the elastic recovery and the density satisfy the following relationship: Re>1481−1629(d). Such interpolymer can also be characterized by other properties. The fibers made therefrom have a relatively high elastic recovery and a relatively low coefficient of friction. The fibers can be cross-linked, if desired. Woven or non-woven fabrics can be made from such fibers.

Owner:DOW GLOBAL TECH LLC

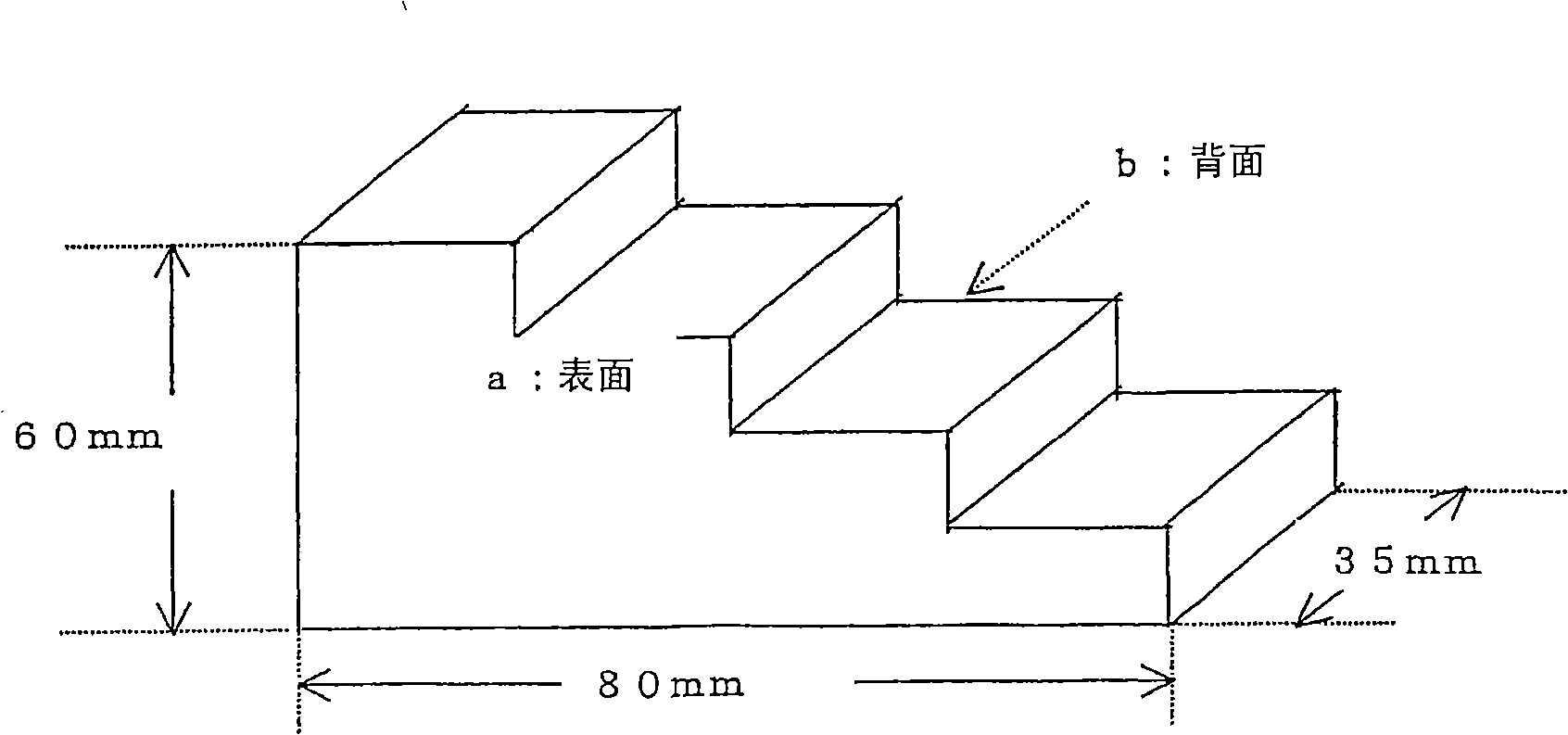

Non-woven fabric laminate and method for production thereof

ActiveCN101432478AImprove flexibilityGood flexibilityLayered productsNon-woven fabricsFiberThermoplastic elastomer

Disclosed is a non-woven fabric laminate which is excellent in shrink properties, flexibility, water-resistance, anti-fuzz properties and anti-curl properties and shows less stickiness. The non-woven fabric laminate comprises at least one meltblown non-woven fabric layer and a mixed spunbonded non-woven fabric layer laminated on the both sides of the meltblown non-woven fabric layer, wherein the mixed spunbonded non-woven fabric layer comprises a long fiber compose of a thermoplastic elastomer (A) and a long fiber composed of a thermoplastic resin (B) which is different from the thermoplastic elastomer (A) at a ratio of [10-90 wt%]:[90-10 wt%] (provided that the sum total of the components (A) and (B) is 100% by weight).

Owner:MITSUI CHEM INC

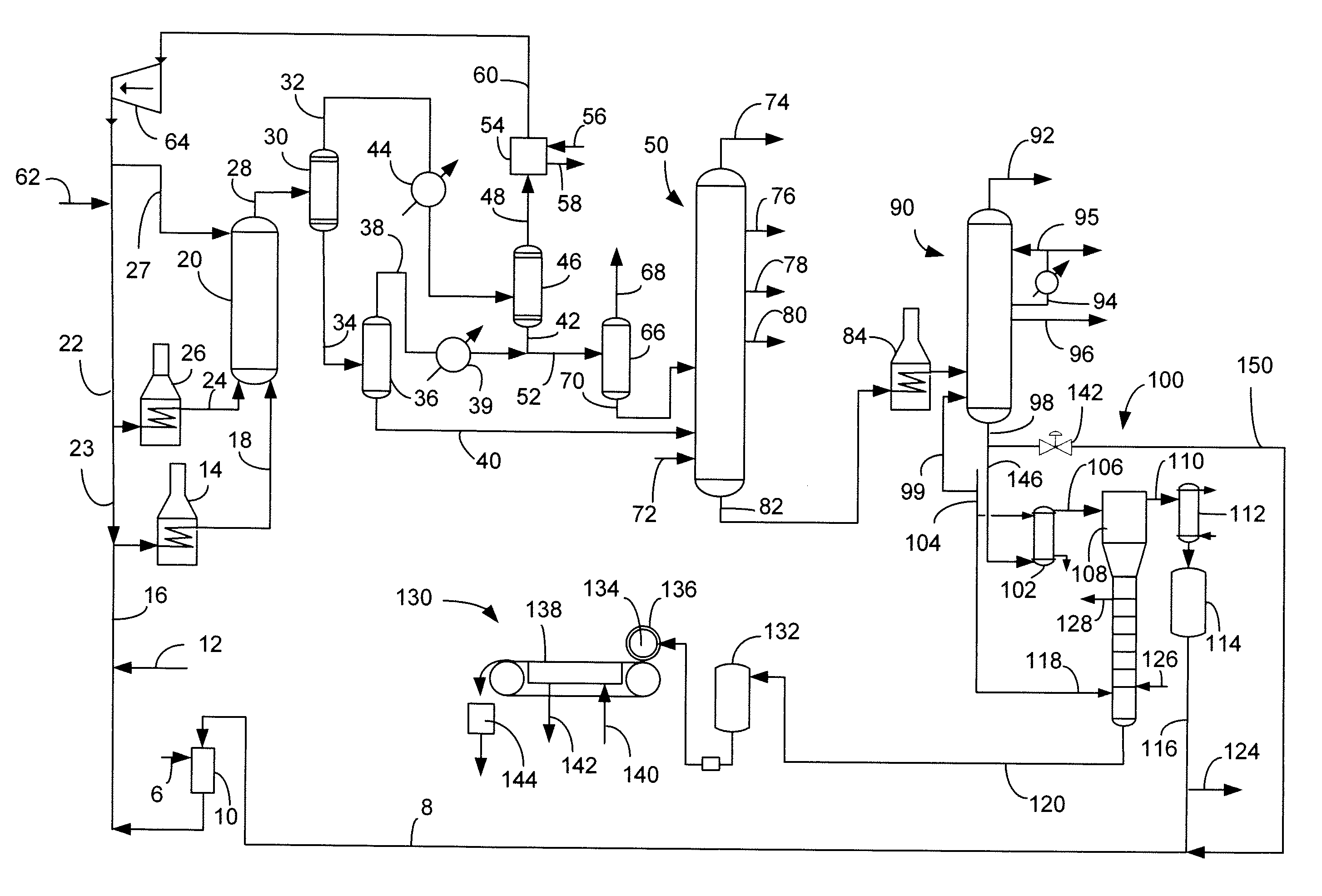

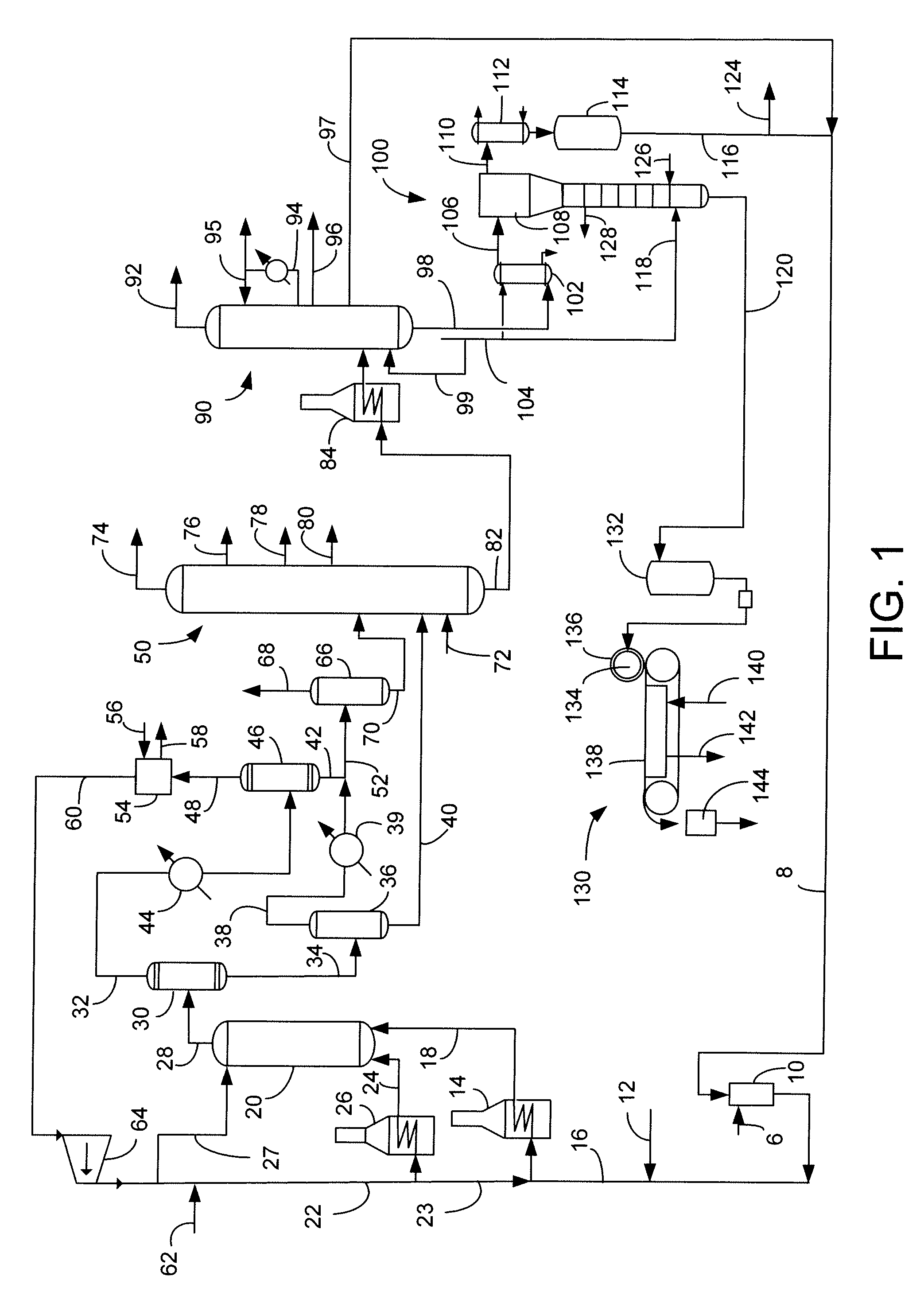

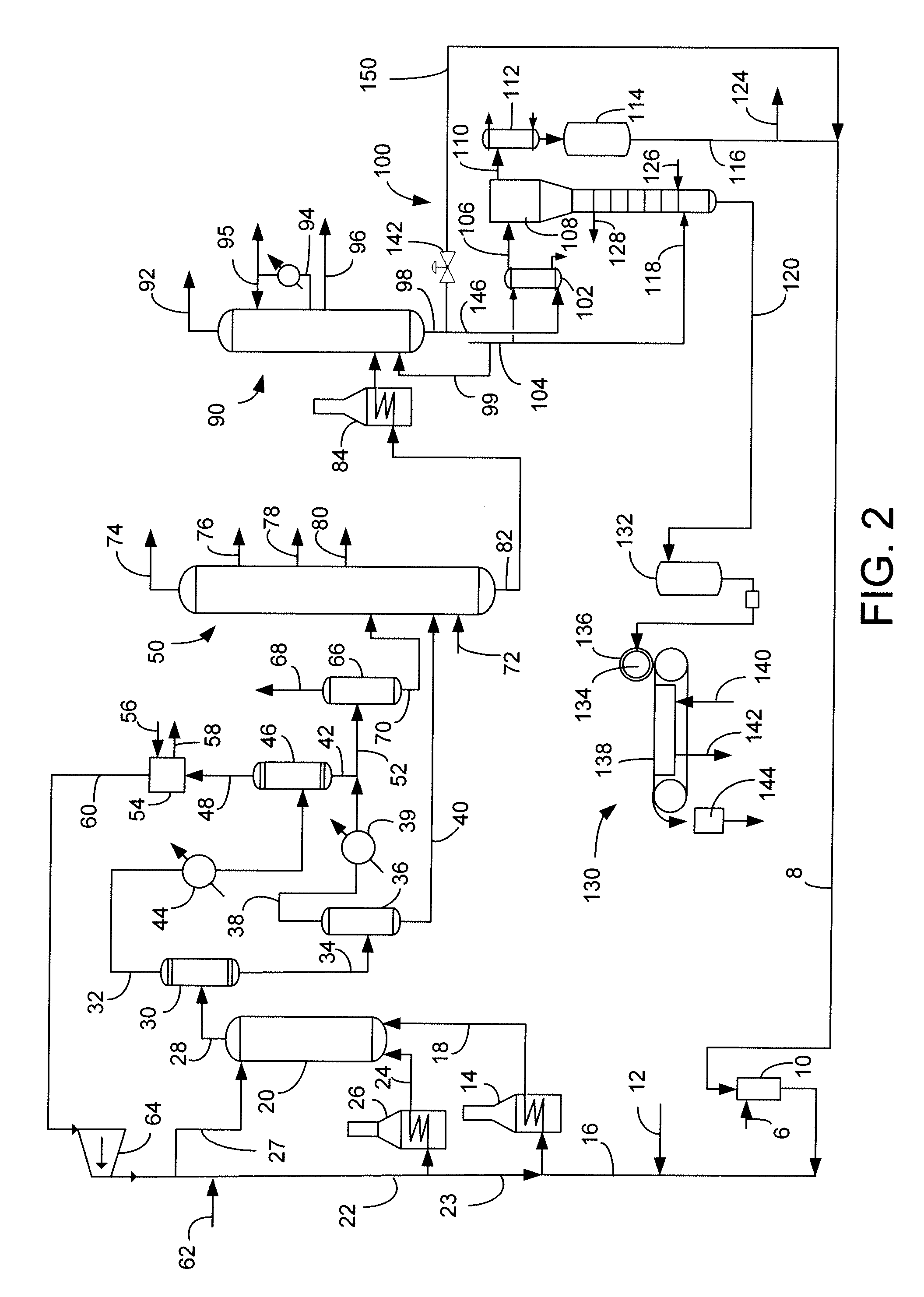

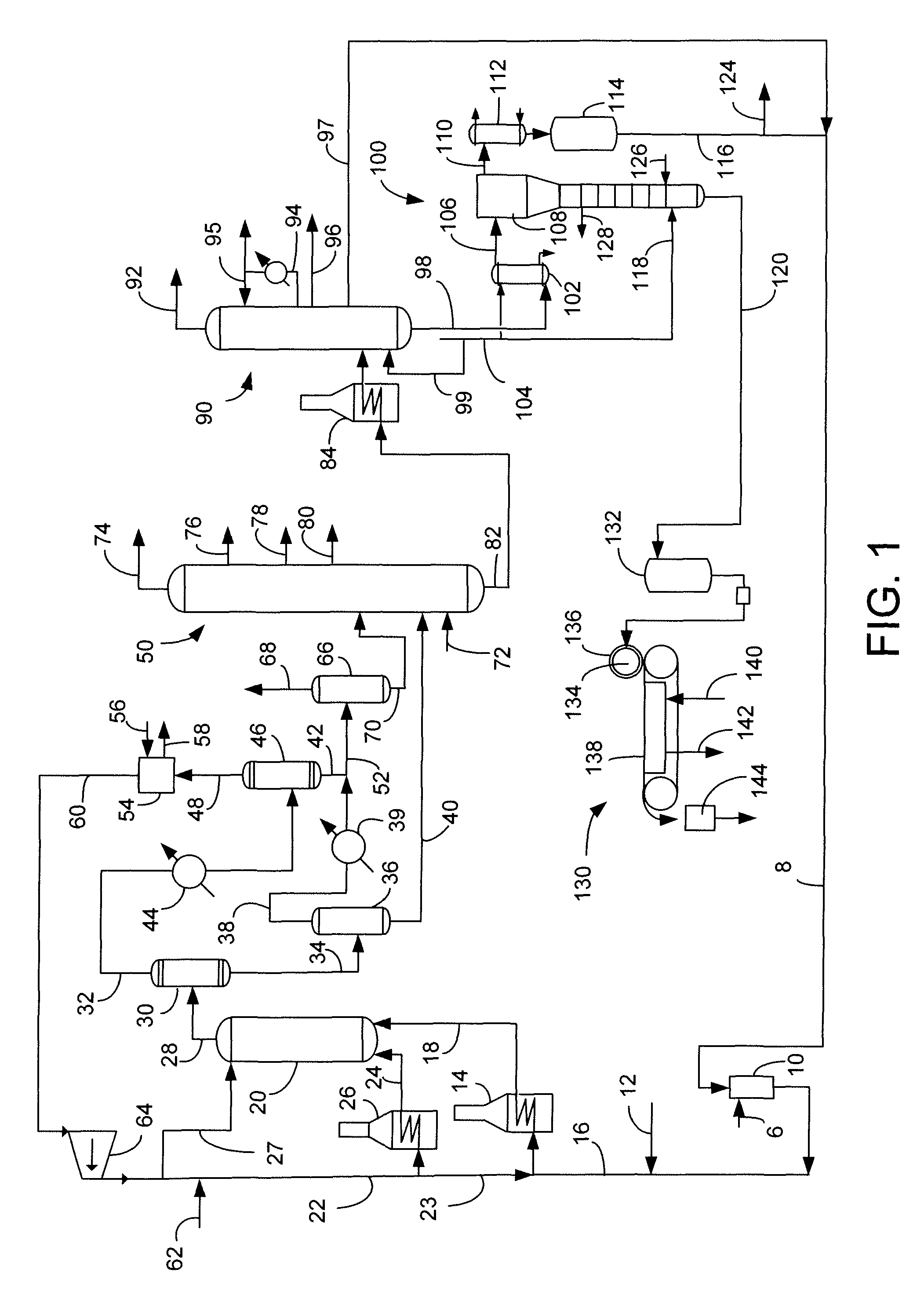

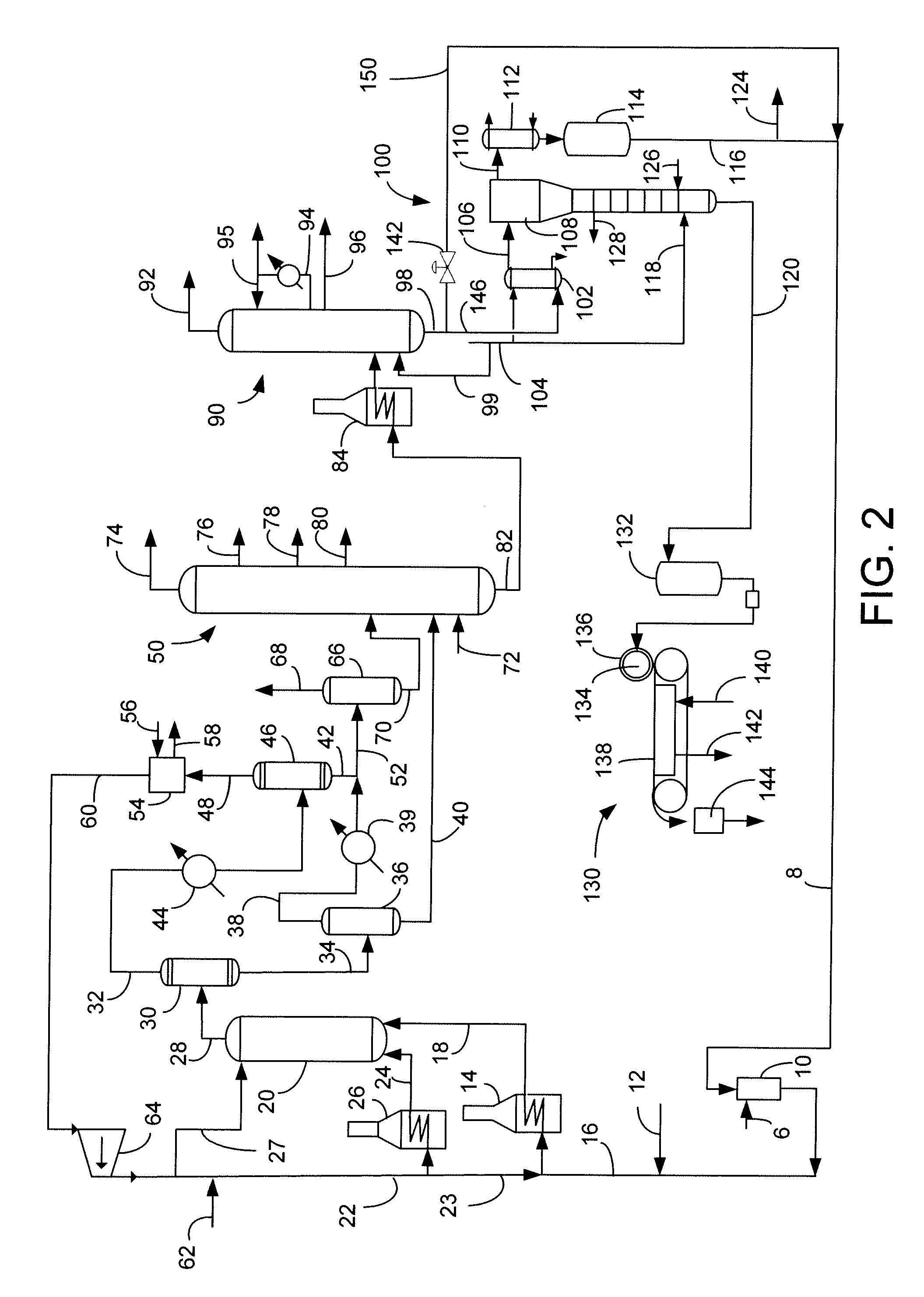

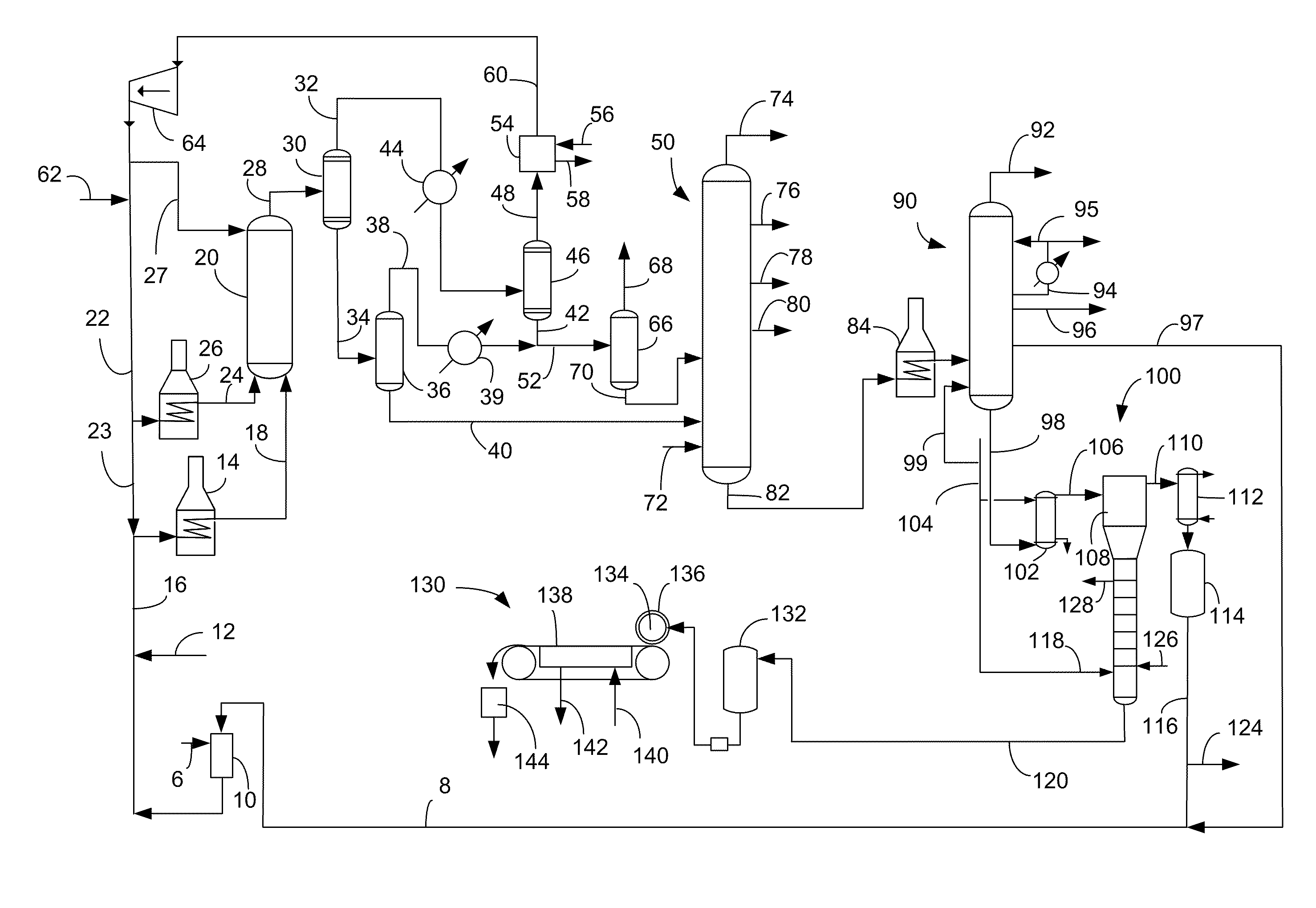

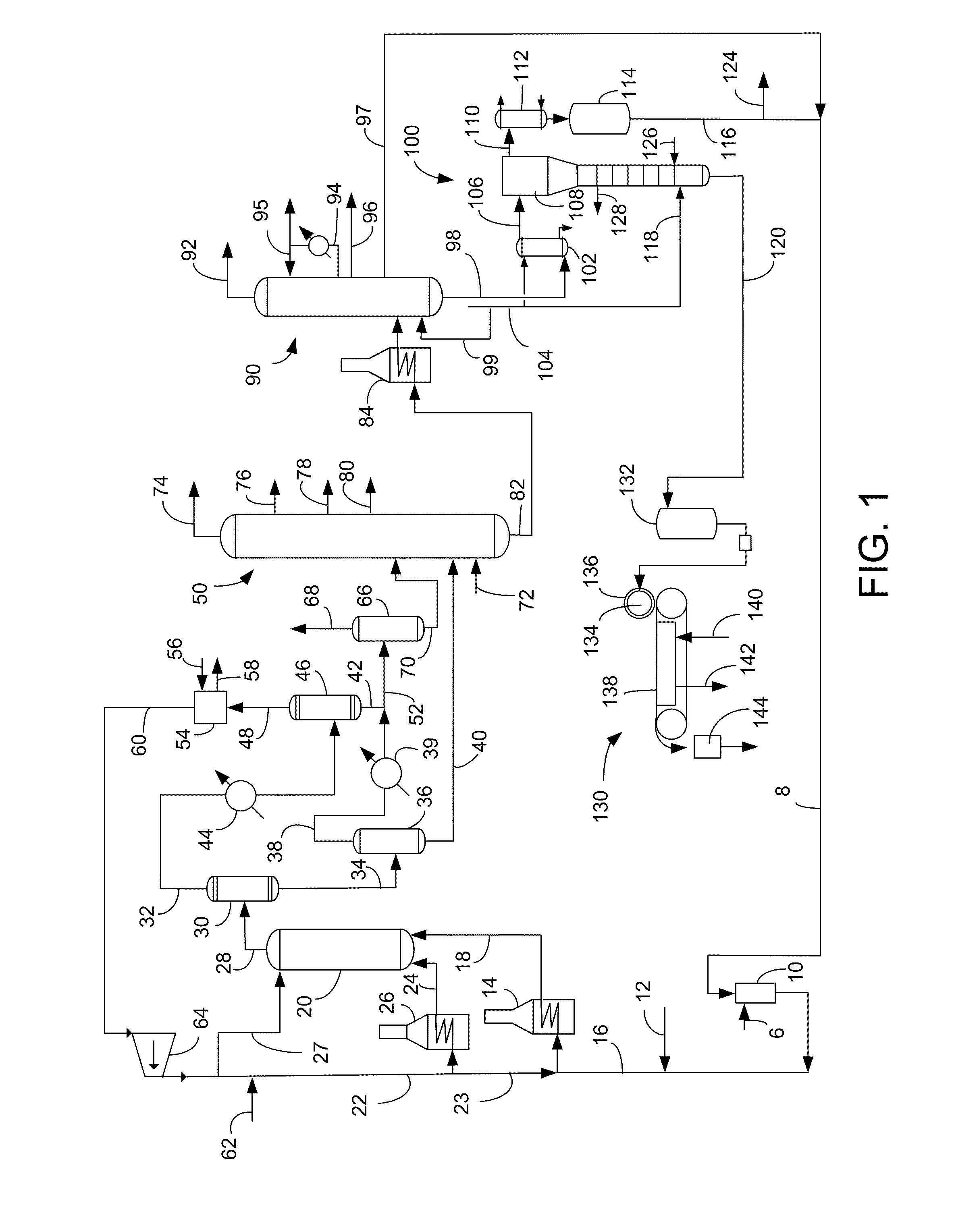

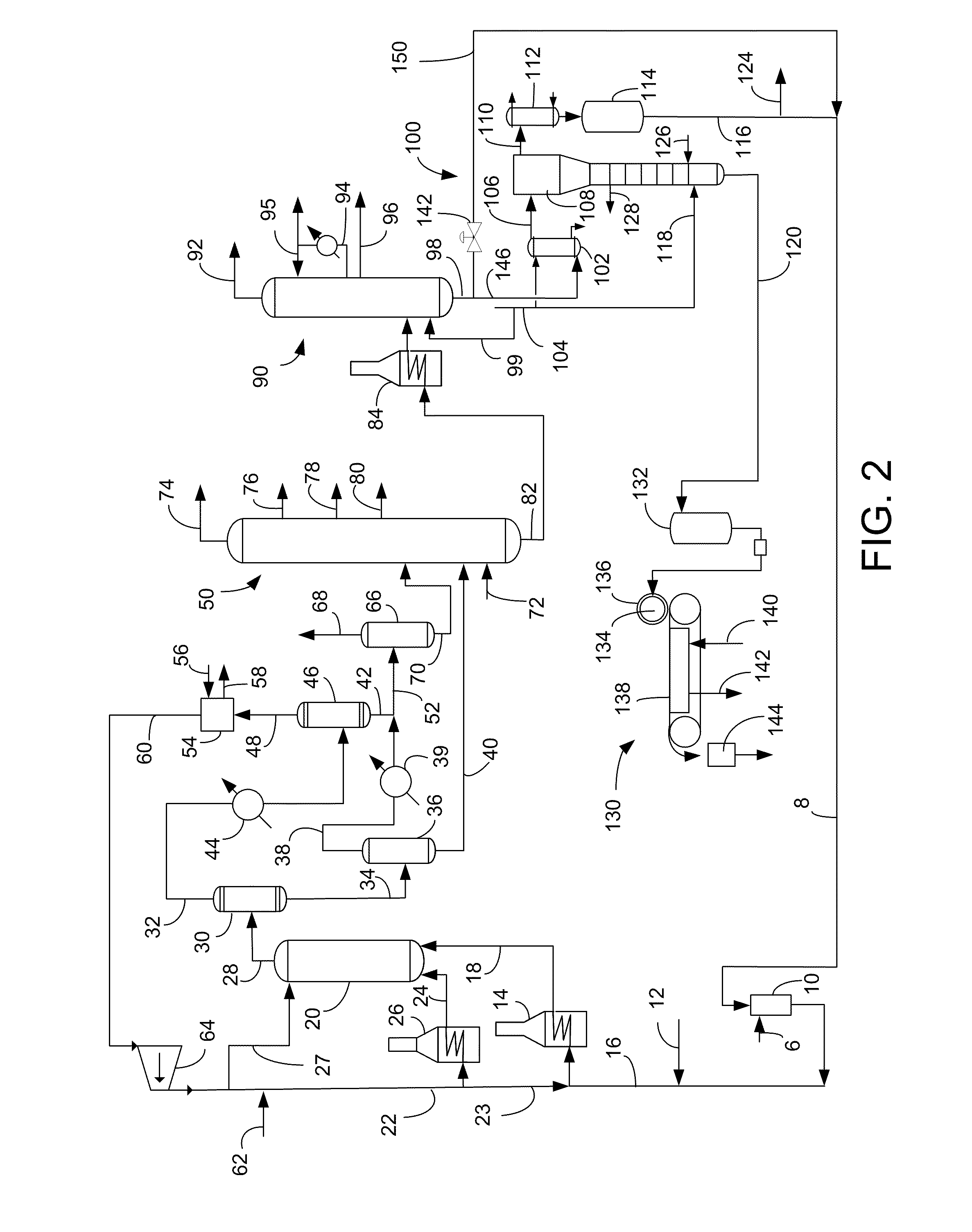

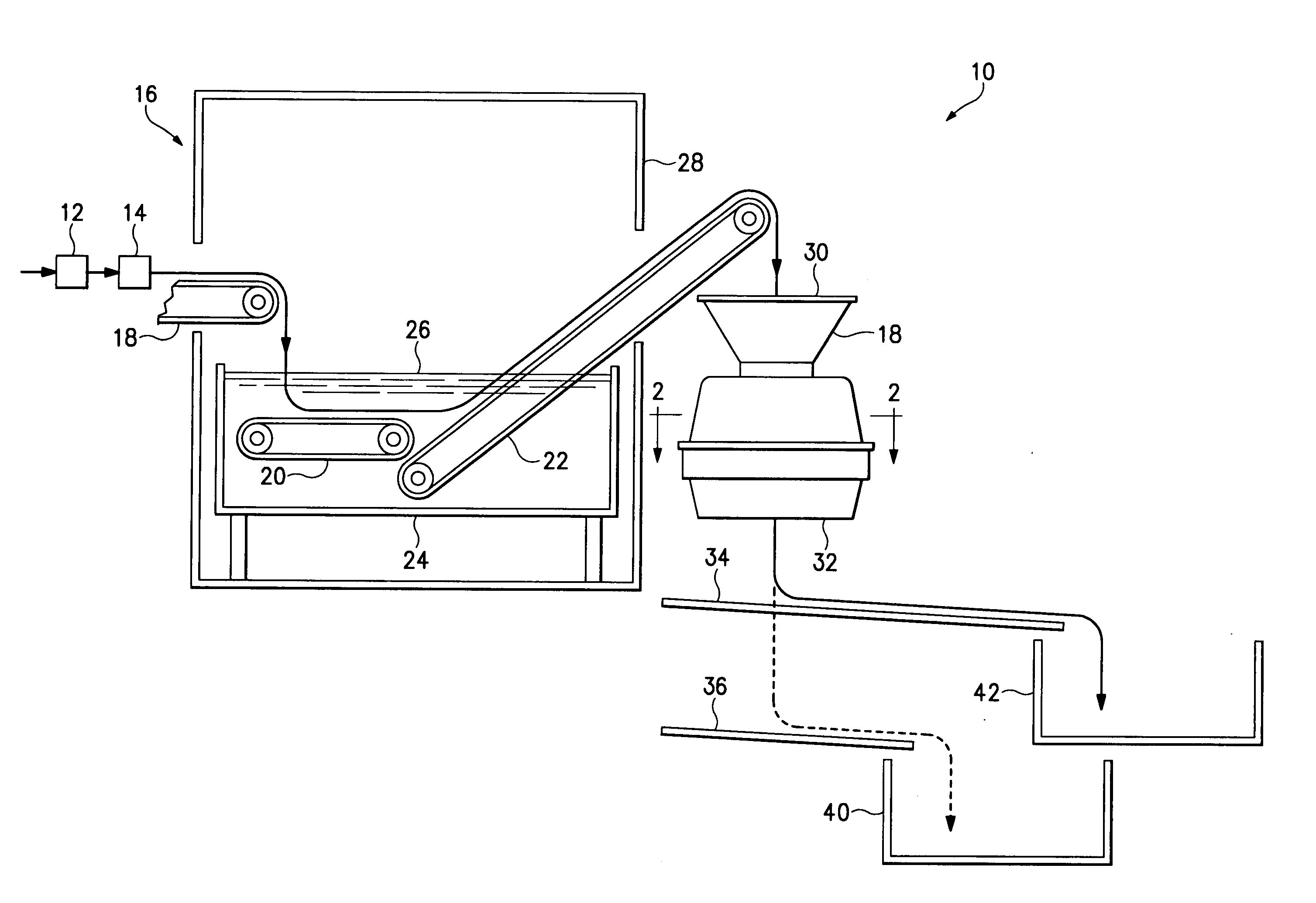

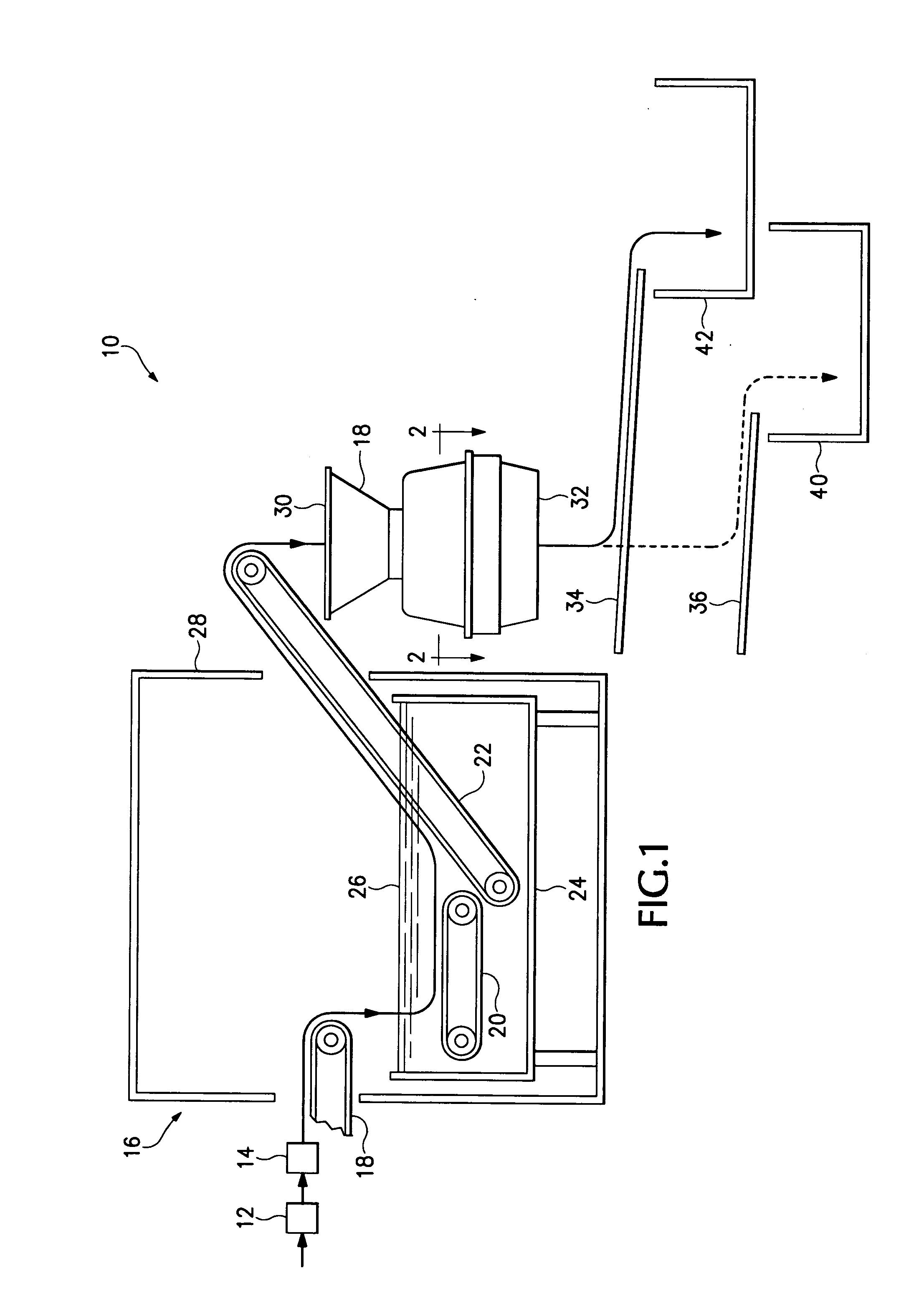

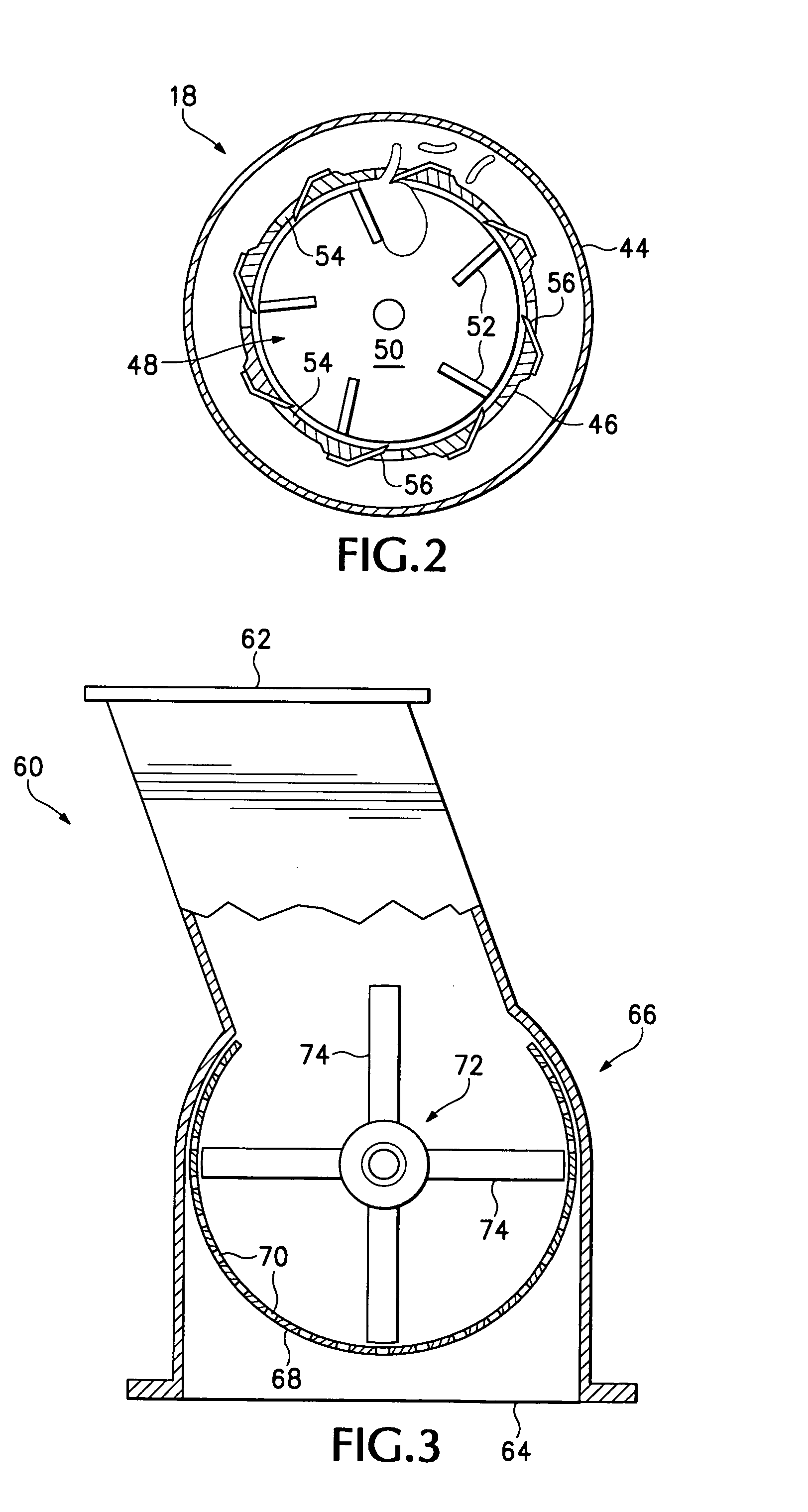

Process for Separating Pitch from Slurry Hydrocracked Vacuum Gas Oil

InactiveUS20100326887A1Easy to manageLess stickyWorking-up pitch/asphalt/bitumen by distillationHydrocarbon oil crackingParticulatesSlurry

A process is disclosed for converting heavy hydrocarbon feed into lighter hydrocarbon products. The heavy hydrocarbon feed is slurried with a particulate solid material to form a heavy hydrocarbon slurry and hydrocracked in a slurry hydrocracking unit to produce vacuum gas oil (VGO) and pitch. A first vacuum column separates VGO from pitch, and a second vacuum column further separates VGO from pitch. As much as 15 wt-% of VGO can be recovered by the second vacuum column and recycled to the slurry hydrocracking unit. A pitch composition is obtained which can be made into particles and transported without sticking together.

Owner:UOP LLC

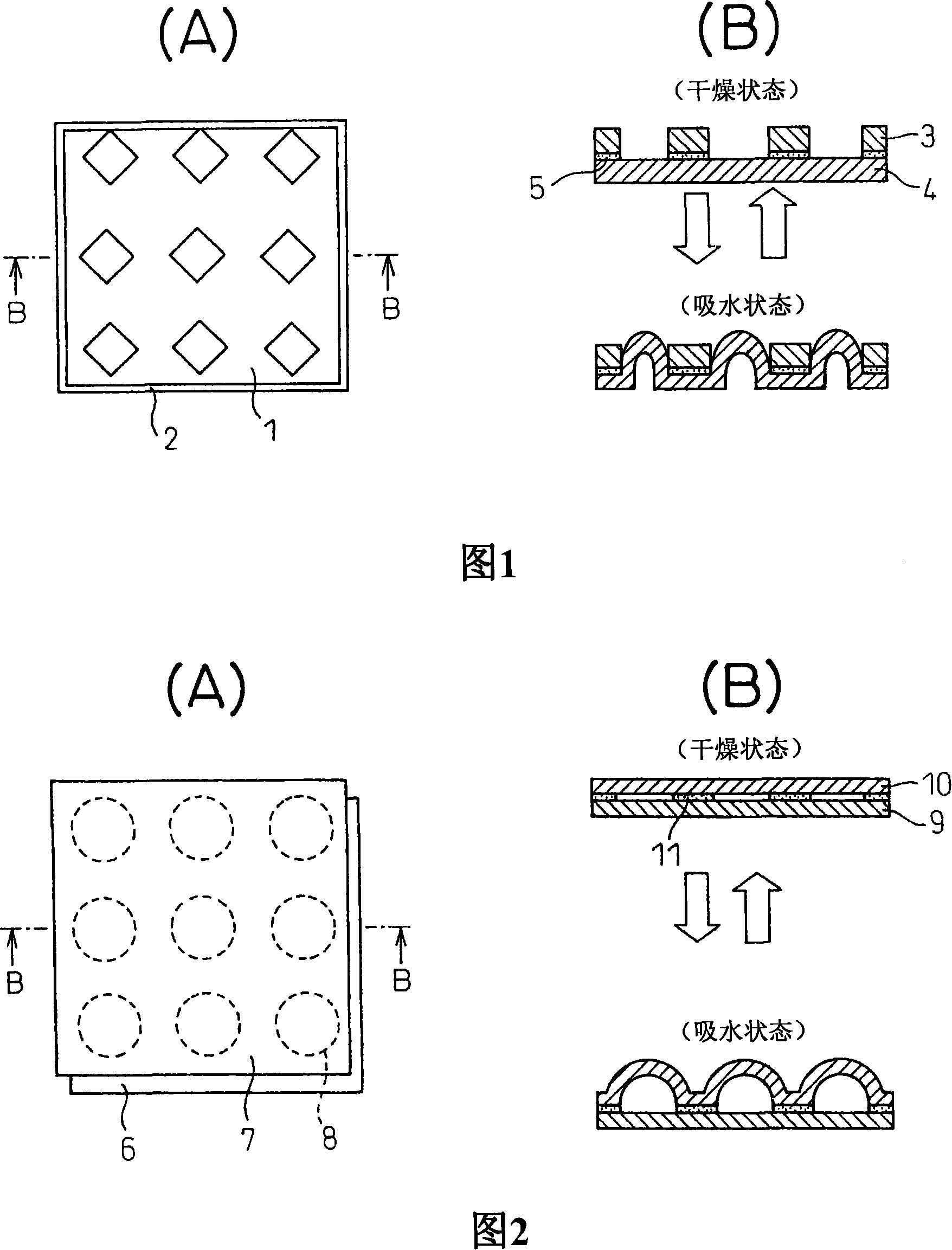

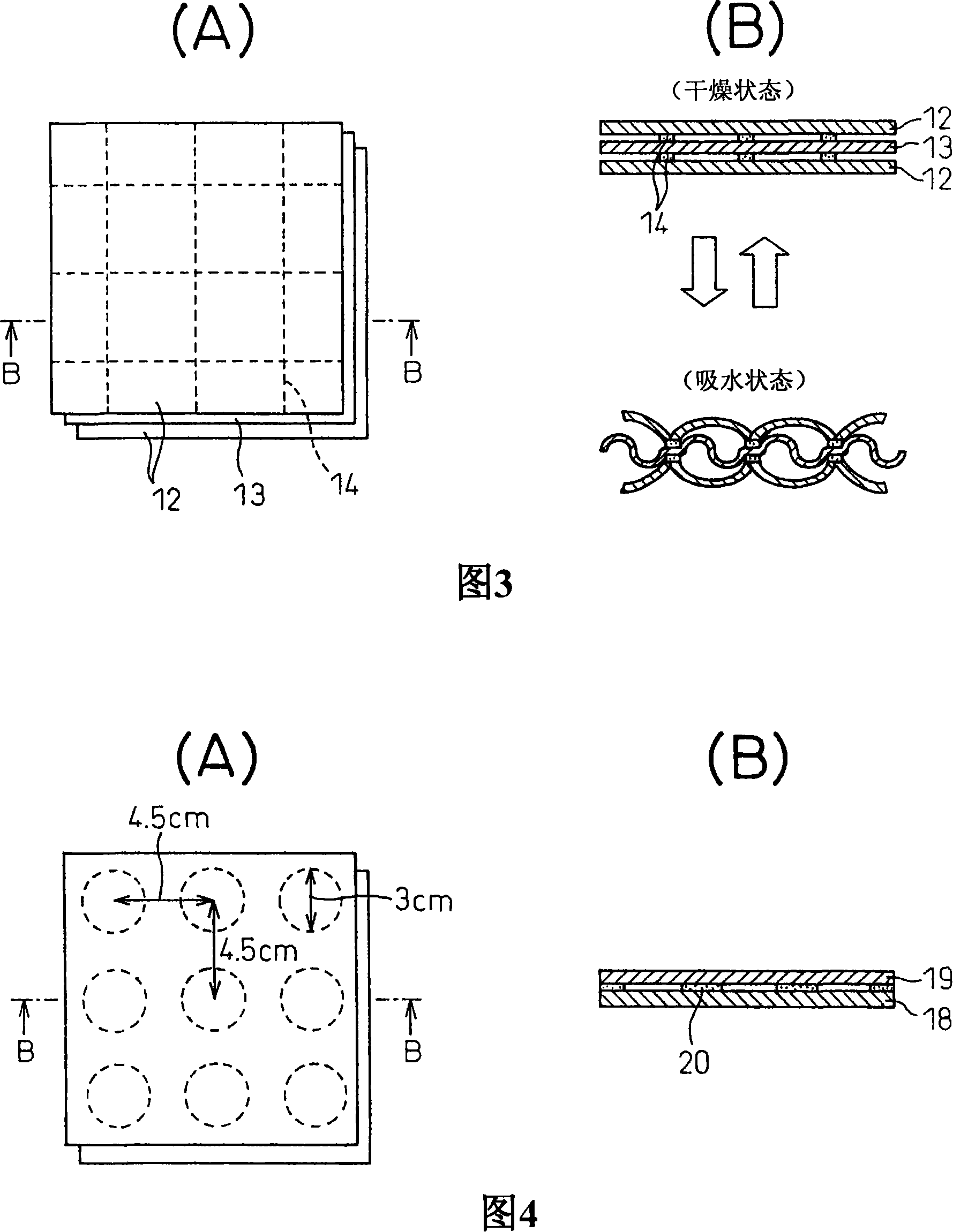

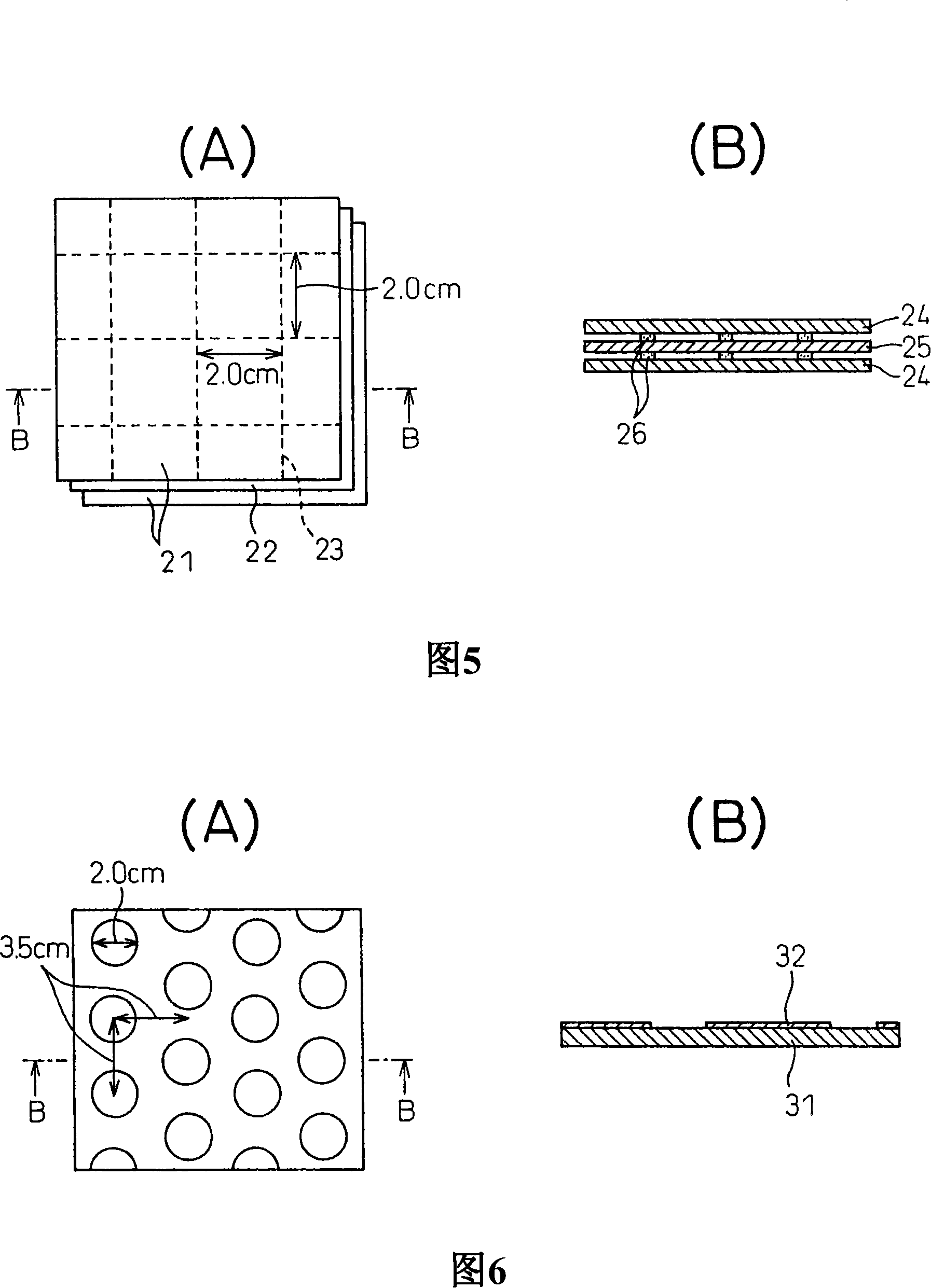

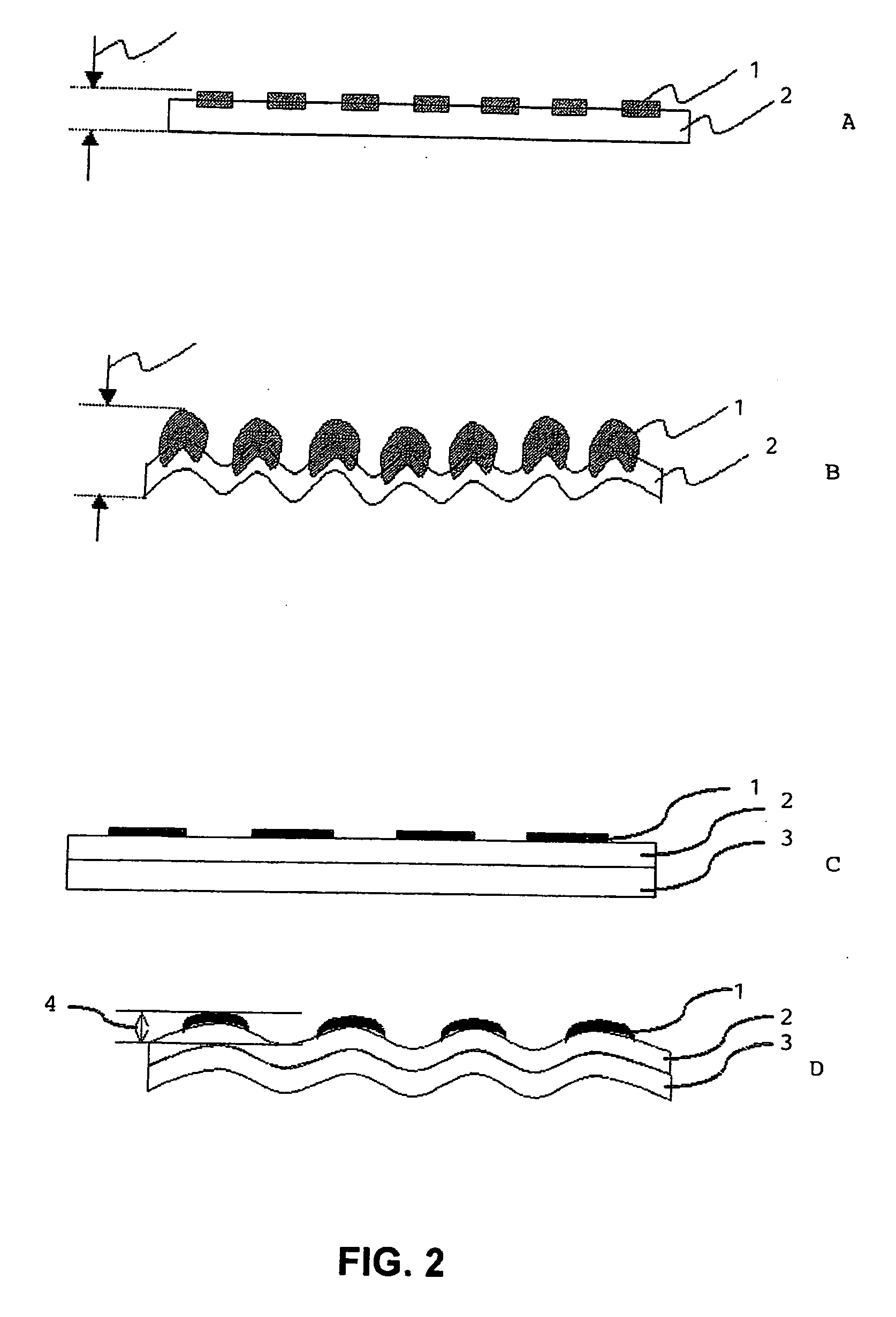

Multilayer structure varying in three-dimentional structure by absorbing water and textile product

InactiveCN101128313AIncreasing the thicknessImprove breathabilityLayered productsUndergarmentsResin coatingEngineering

A composite fabric material which comprises: a water-absorbing woven / knit fabric which, upon water absorption, increases in area and thickness or in area or thickness by at least 10% as compared with that in a dry state; a woven / knit fabric, nonwoven fabric, resin film, or resin coating layer which undergoes substantially no change in area and thickness upon water absorption as compared with that in a dry state; and a means of inhibiting an areal change with water absorption, the means being bonded to or fixed by stitching to at least one side of the water-absorbing woven / knit fabric so as to cover part of the surface and leave exposed regions independent of one another or to cover the whole surface, and the means inhibiting that part of the water-absorbing woven / knit fabric to which the means is bonded or fixed by stitching from changing in area upon water absorption. In the water-absorbing woven / knit fabric, the regions independent of one another increase in area and thickness or in area or thickness upon water absorption. As a result, the composite fabric material undergoes a three-dimensional structural change.

Owner:TEJIN FIBERS LTD

Process for separating pitch from slurry hydrocracked vacuum gas oil

InactiveUS8540870B2Easy to manageLess stickyWorking-up pitch/asphalt/bitumen by distillationWorking-up pitch/asphalt/bitumen by solidifying/disintegratingParticulatesSlurry

A process is disclosed for converting heavy hydrocarbon feed into lighter hydrocarbon products. The heavy hydrocarbon feed is slurried with a particulate solid material to form a heavy hydrocarbon slurry and hydrocracked in a slurry hydrocracking unit to produce vacuum gas oil (VGO) and pitch. A first vacuum column separates VGO from pitch, and a second vacuum column further separates VGO from pitch. As much as 15 wt-% of VGO can be recovered by the second vacuum column and recycled to the slurry hydrocracking unit. A pitch composition is obtained which can be made into particles and transported without sticking together.

Owner:UOP LLC

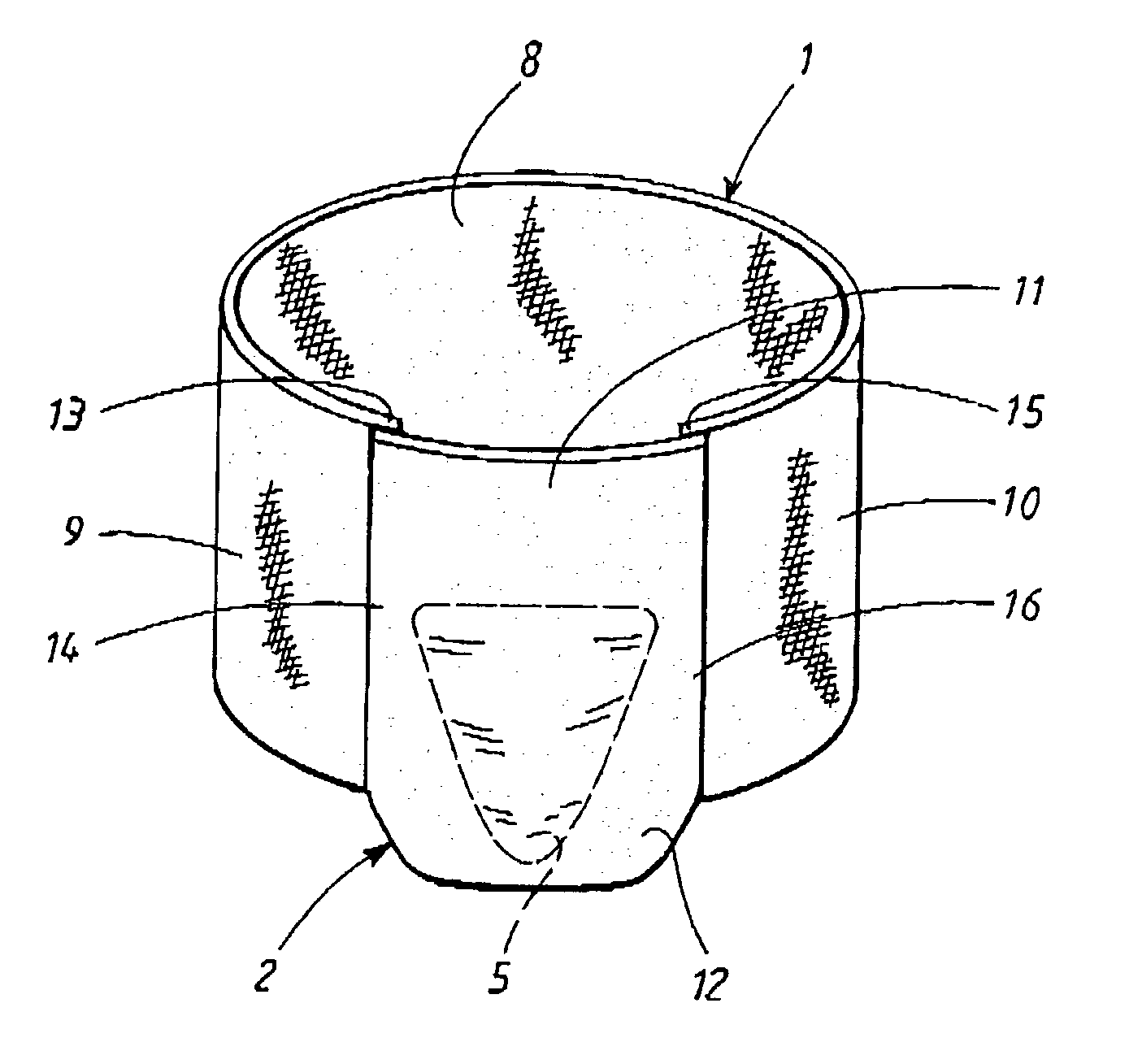

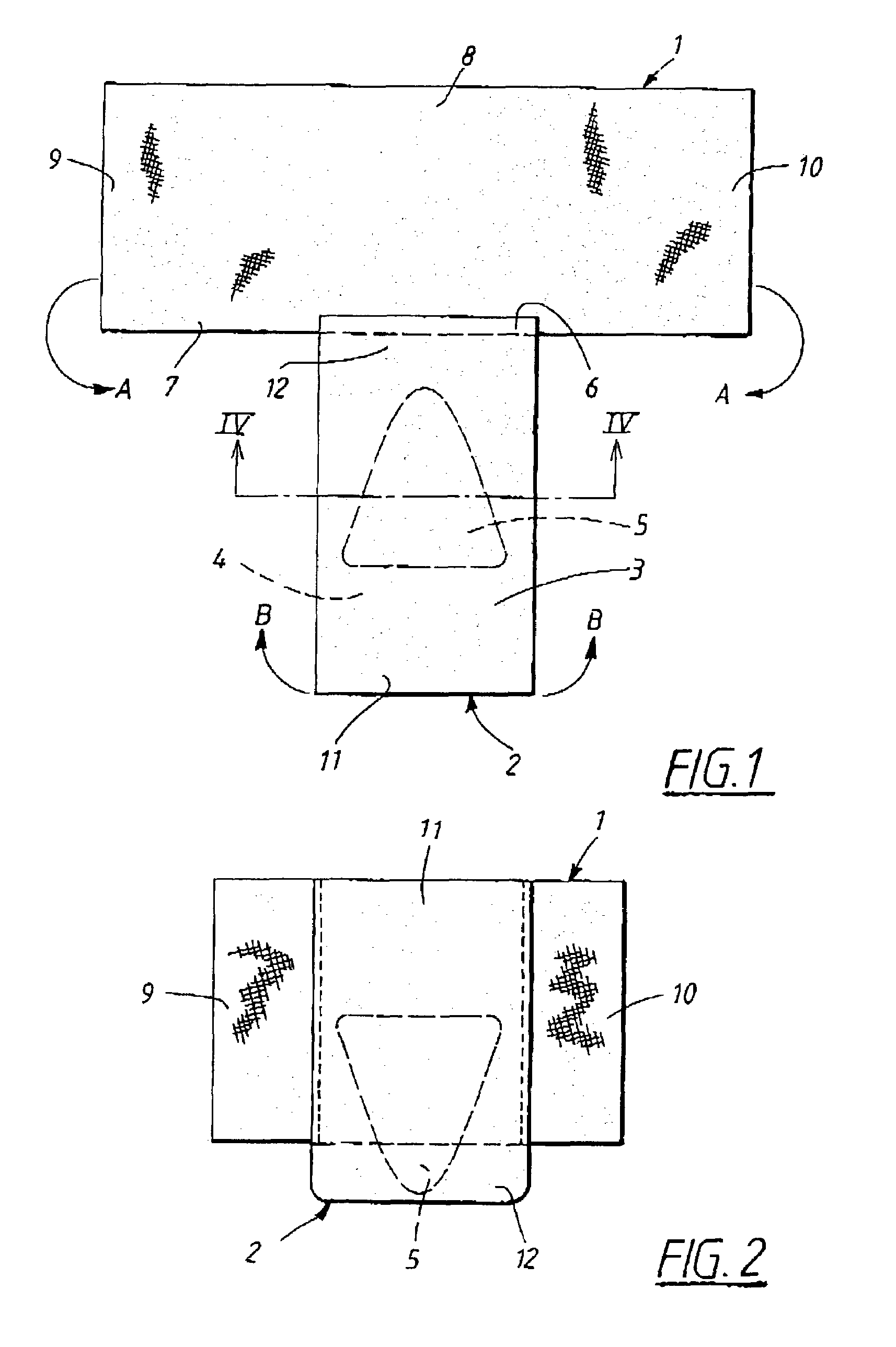

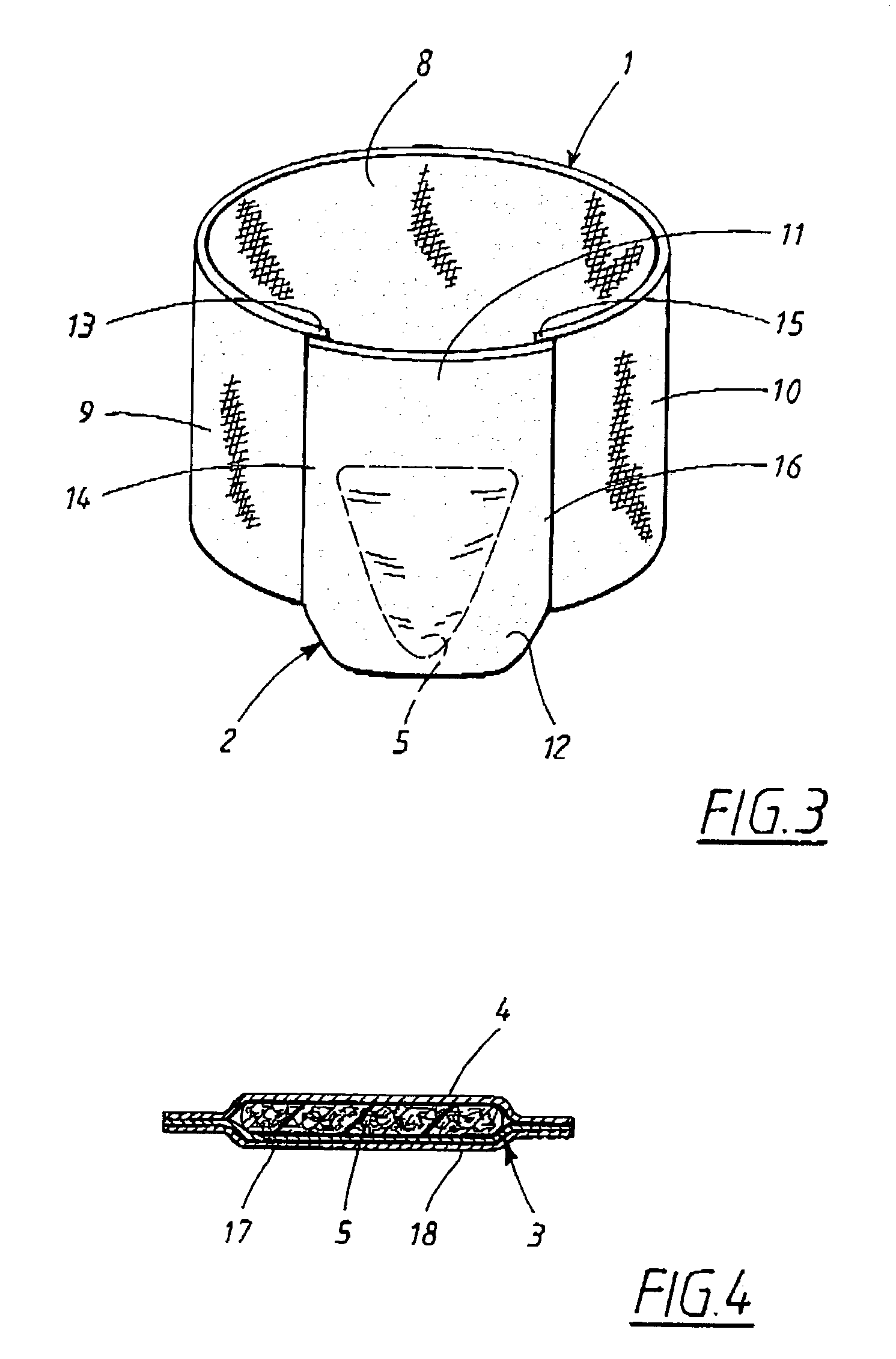

Absorbent article with two-piece construction and method of making the same

An absorbent article of pants shape includes an elastic waist portion, an absorbent element (5), and a liquid-impermeable outer layer (3). The elastic waist portion is made from an elastic first piece (1) which is rectangular and is intended to form the rear portion (8) and side portions (9, 10) of the article. A second piece (2) forms the front portion (11) and crotch portion (12) of the pants-like article. The second piece (2) is elongate, and the width thereof is, at least in the crotch portion (12), smaller than the length of the first piece (1). The absorbent element (5) is in its entirety arranged on the second piece (2).

Owner:SCA HYGIENE PROD AB

Irrigating and lavage compositions

Irrigants to be used with vibratory scaling apparatus and lavage are provided. The irrigants of the invention are characterized in that they contain medicaments for the treatment of conditions in the mouth and have a viscosity and deliquescence adapted to substantially optimize the efficiency of the apparatus. The irrigants are formulated so that they have minimal stickiness on drying, minimal foaming and do not gum-up the apparatus in which they are used. Also provided is a method for treating dental diseases comprising applying the irrigants of the invention through a vibratory scaring apparatus to substantially optimize the efficiency of said apparatus and to substantially optimize destruction and removal of infectious bacteria using said apparatus and the removal or inactivation of endotoxins derived from bacteria or the host.

Owner:DENTSPLY RES DEVMENT

High amylose dog chew formulation

InactiveUS7722911B2Resist formationReducing of choking and intestinal blockageBaking mixturesFrozen sweetsThermoplasticPlasticizer

Owner:B&S PLASTICS

Metal polish liquid, and prepartion method

InactiveCN101092540AImprove concentrationFast polishing ratePolishing compositions with abrasivesGranularityMetal

This invention relates to a metal polishing solution, which is composed of: abrasive material 10-50 wt. %, surfactant 0.1-1 wt. %, pH regulator 1-5 wt. %, chelating agent 0.1-1 wt. %, and deionized water as balance. The granularity of the abrasive material is 15-100 nm. The pH value of the metal polishing solution is 8-12. The metal polishing solution is prepared by: filtering and purifying the above components of the metal polishing solution, introducing the components into a container through a mass flowmeter under negative pressure in a class 1000 clean room, and stirring uniformly. The metal polishing solution has such advantages as high polishing speed, high smoothness, small diameters, and little damage to wafer surface, wasy cleaning, no toxicity, no odor, no corrosion, simple process and easy operation.

Owner:天津晶岭电子材料科技有限公司

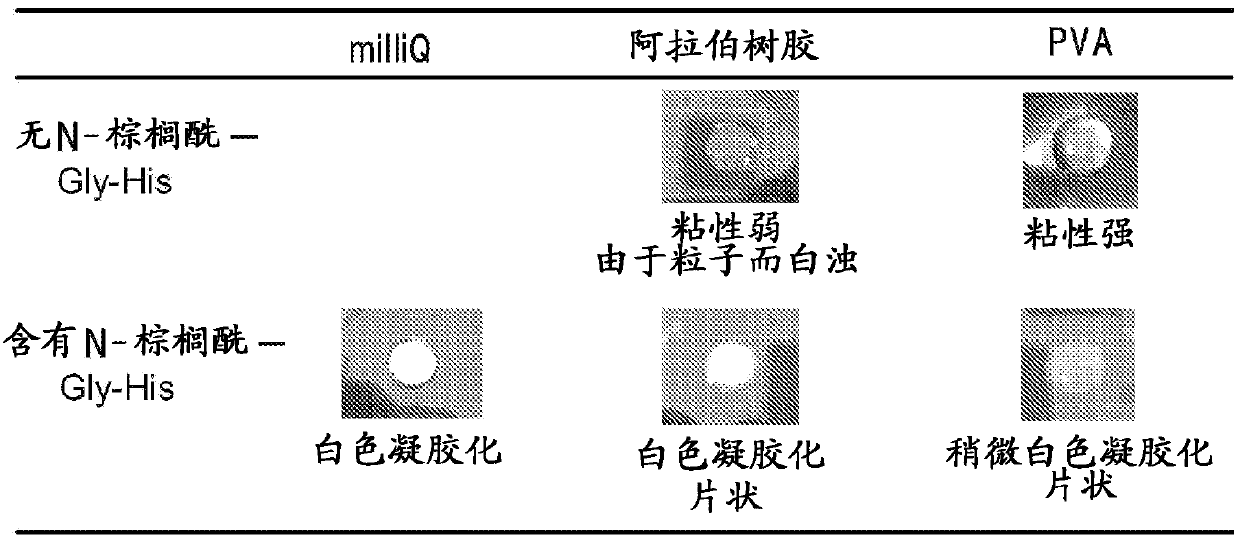

Gel sheet comprising lipidic peptide type gelling agent and polymeric compound

ActiveCN103313732AImprove adaptabilityImprove securityCosmetic preparationsToilet preparationsHuman skinMedicine

Owner:NISSAN CHEM CORP +1

High amylose dog chew formulation

InactiveUS20080063775A1Easy to processResist formationBaking mixturesFrozen sweetsThermoplasticPlasticizer

The invention provide methods and materials for producing nutritious pet chews comprising an edible thermoplastic comprising from 45 to 80 wt. % starch selected from one or more potato and non-potato starches wherein said starch comprises at least 28% amylose as determined by size exclusion chromatography if less than 50% of said starch is potato starch or at least 20% amylose as determined by size exclusion chromatography if greater than or equal to 50% of said starch is potato starch; from 5 to 25 wt. % plasticizer; 2% to 15 wt % of a humectant and from 5 to 25 wt. % water.

Owner:B&S PLASTICS

Polishing liquid for germanium wafer and preparation method thereof

InactiveCN101081965AImprove concentrationFast polishing ratePolishing compositions with abrasivesSURFACTANT BLENDIon

The germanium wafer polishing fluid consists of abradant 10.0-50.0 wt%, surfactant 0.1-1.0 wt%, pH value regulator 1.0-5.0 wt%, chelating agent 0.1-1.0 wt% and deionized water for the rest; and has pH 8-12, and grain size of 15-100 nm. It is prepared through filtering all the ingredients, and mixing via stirring under the action of negative pressure in a clean condition. The germanium wafer polishing fluid has the advantages of high polishing speed, high polished flatness, small grain size causing less surface damage of wafer, simple preparation process and easy use.

Owner:天津晶岭电子材料科技有限公司

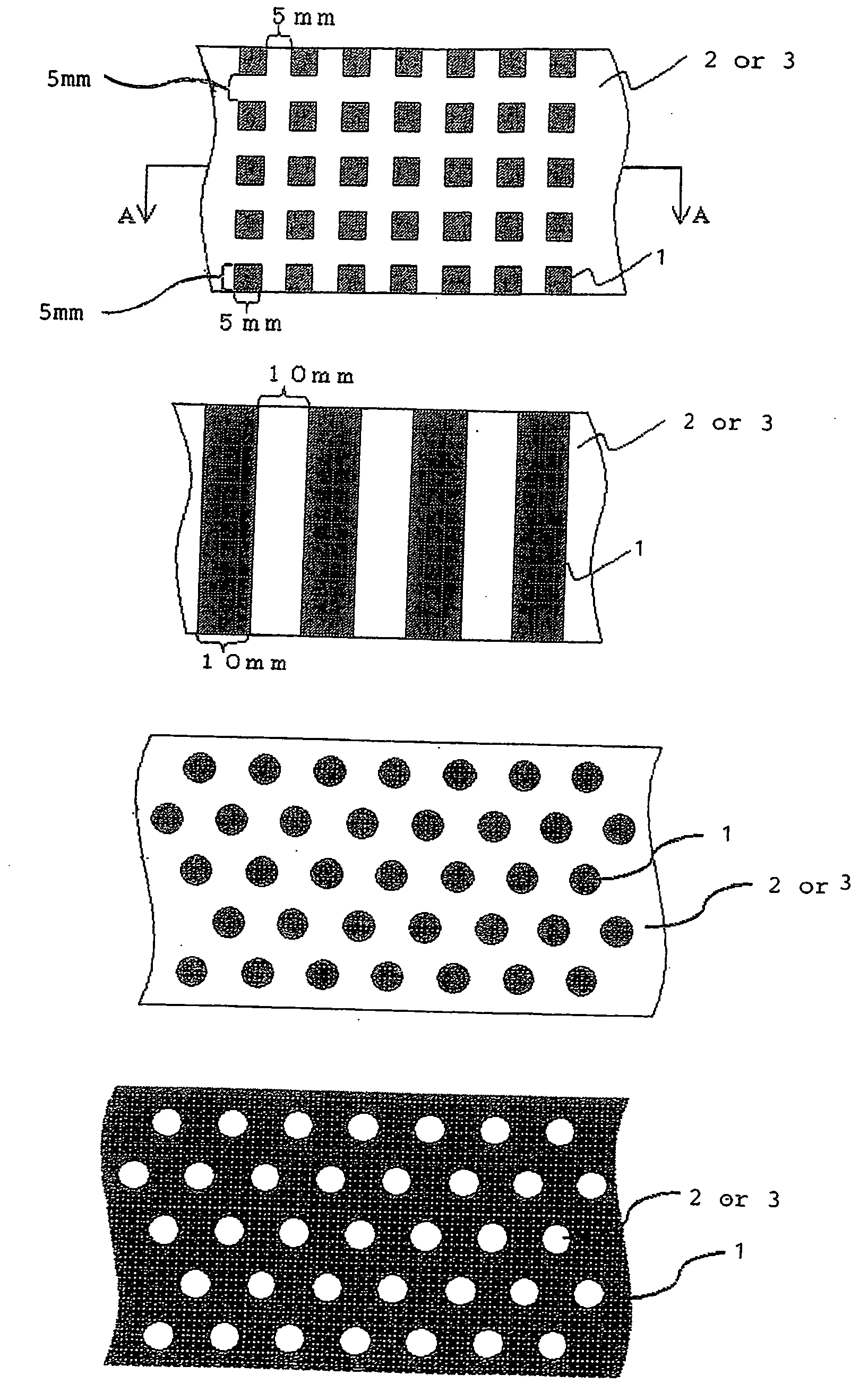

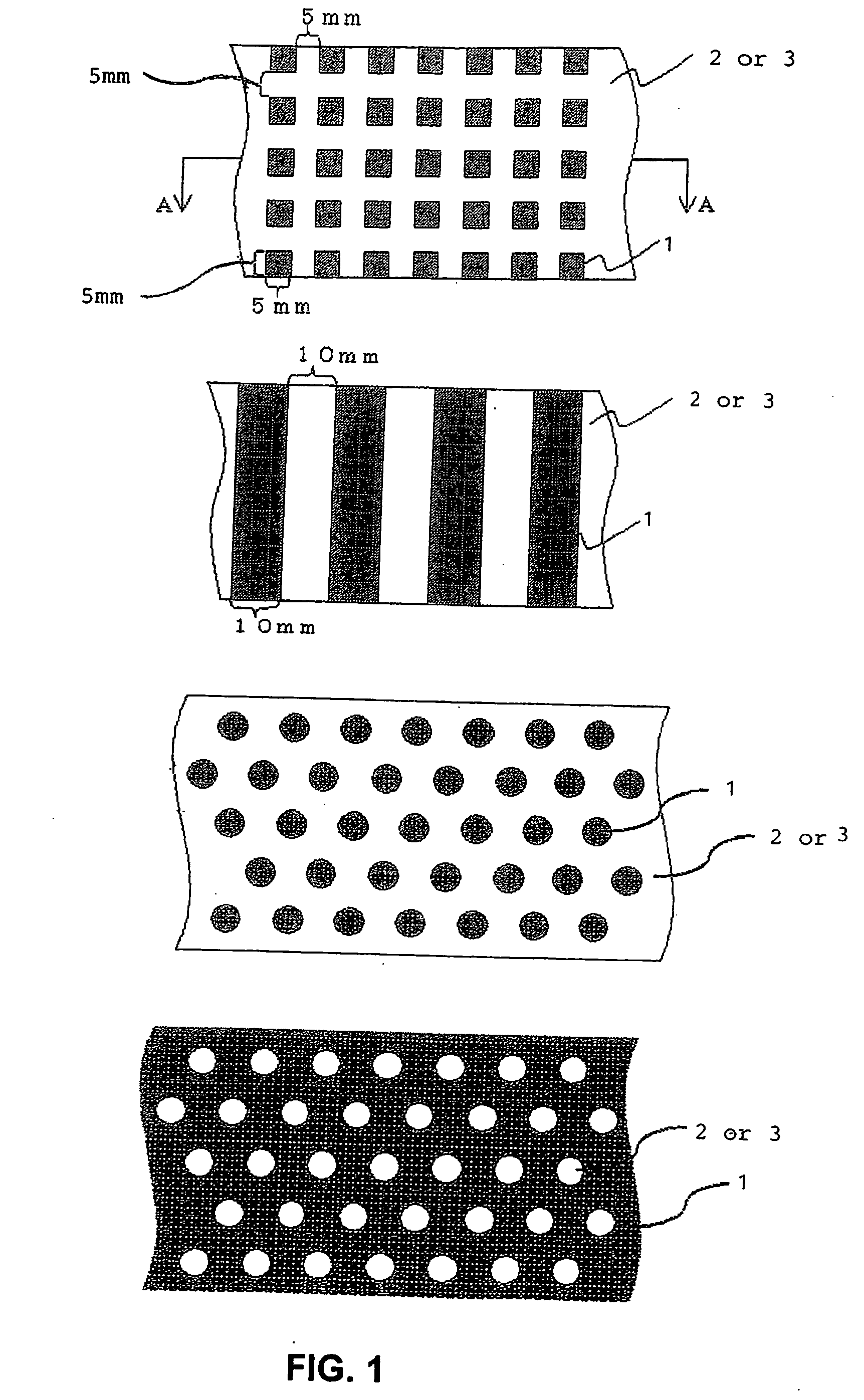

Shape changeable textile fabric

InactiveUS20090276936A1Less stickySuperior feelingFibre treatmentSynthetic resin layered productsEngineeringTextile

A waterproof layer is formed as necessary on one or both surfaces of a textile fabric and as an outermost layer there is formed a water-swelling layer comprising a water-insoluble water-swelling resin applied in a pattern form.

Owner:SEIREN CO LTD

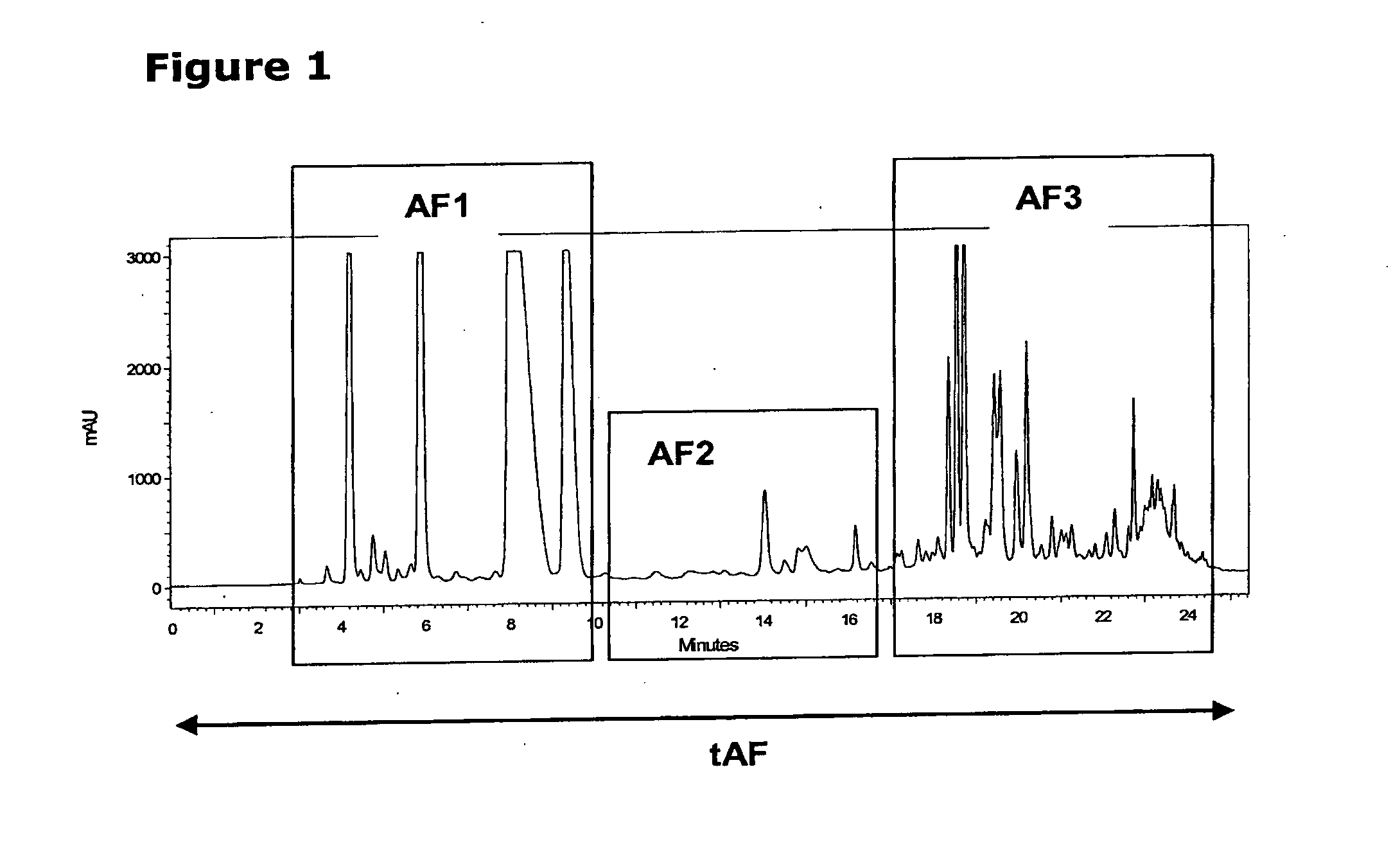

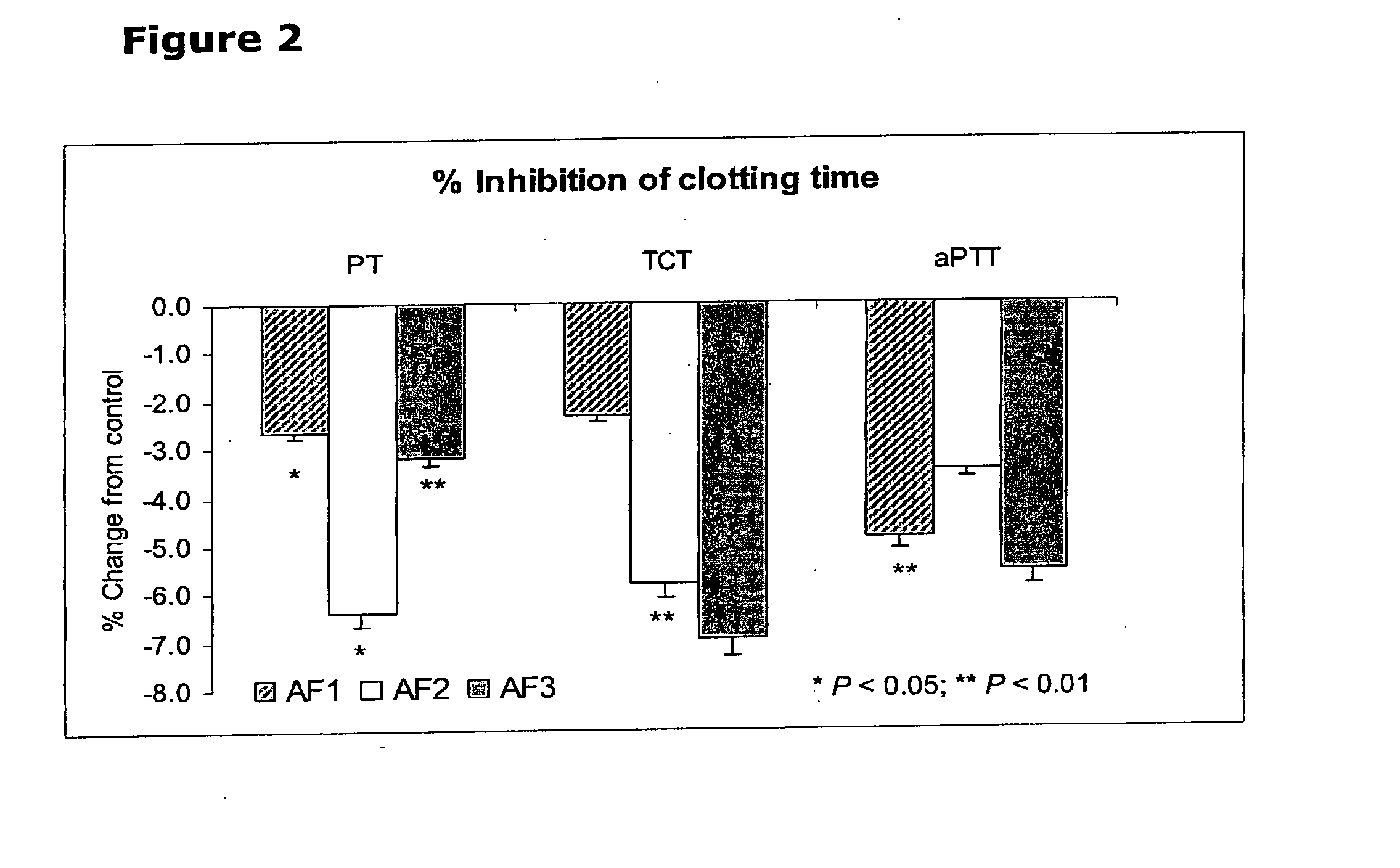

Therapeutic uses of tomato extracts

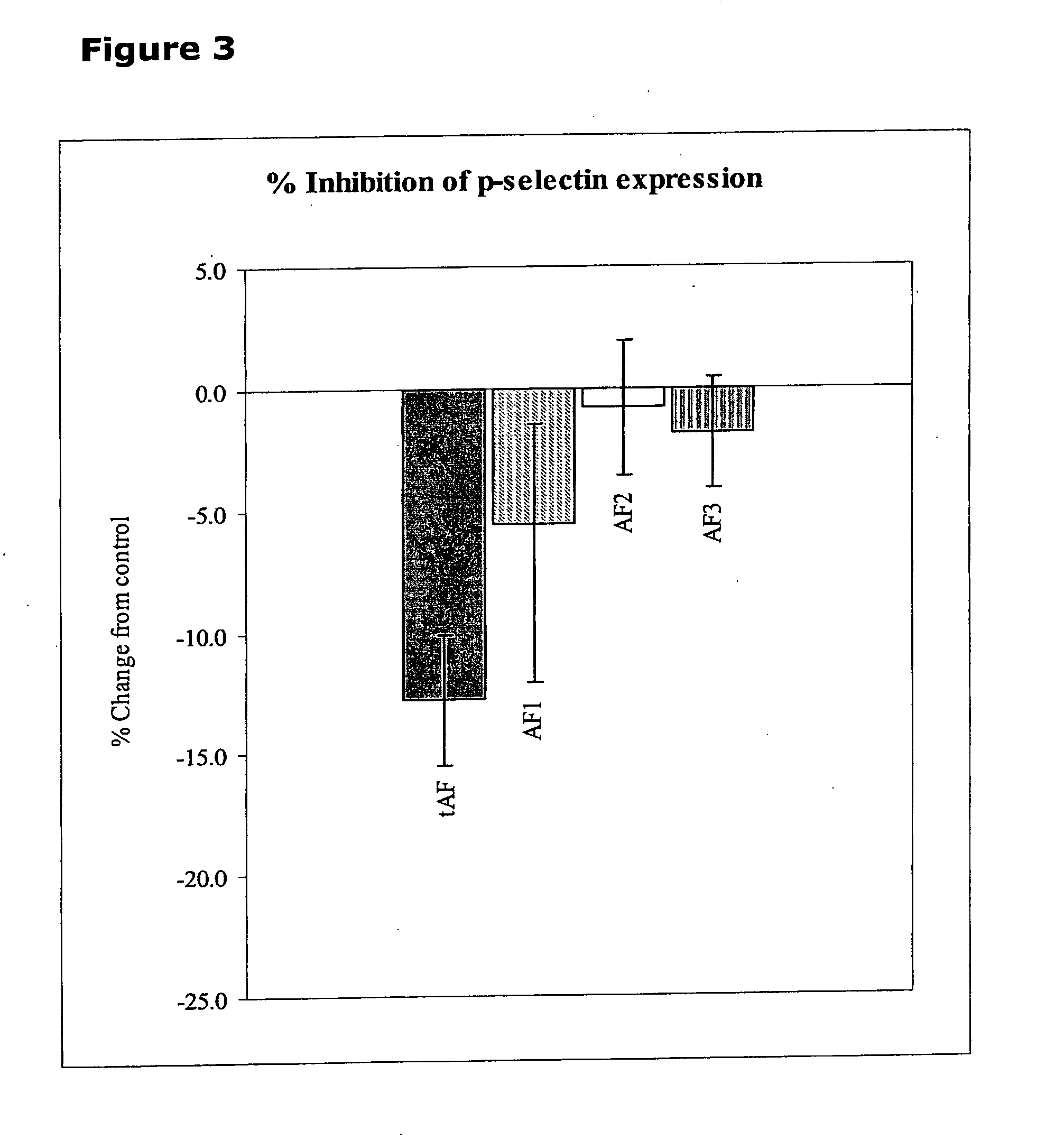

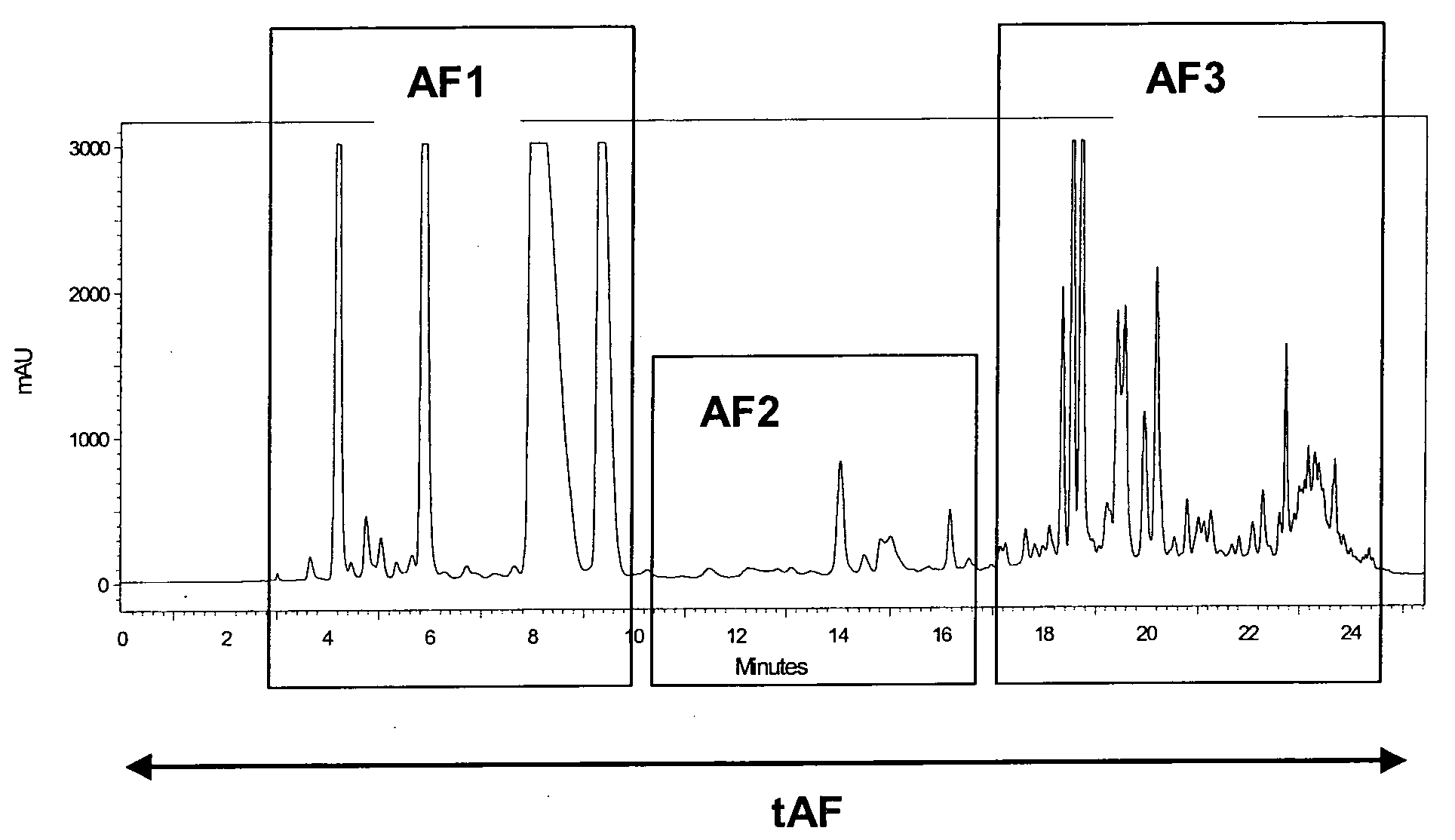

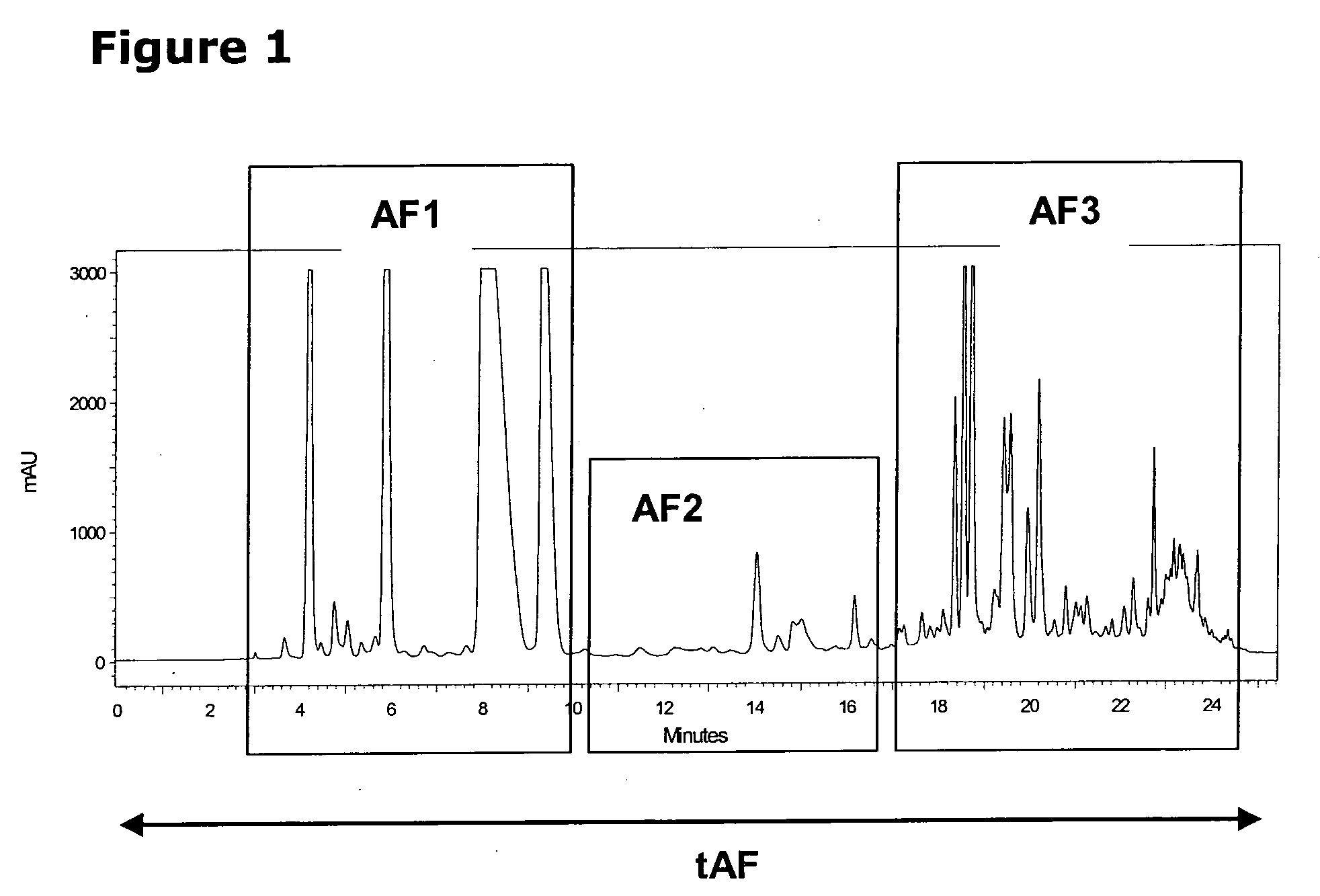

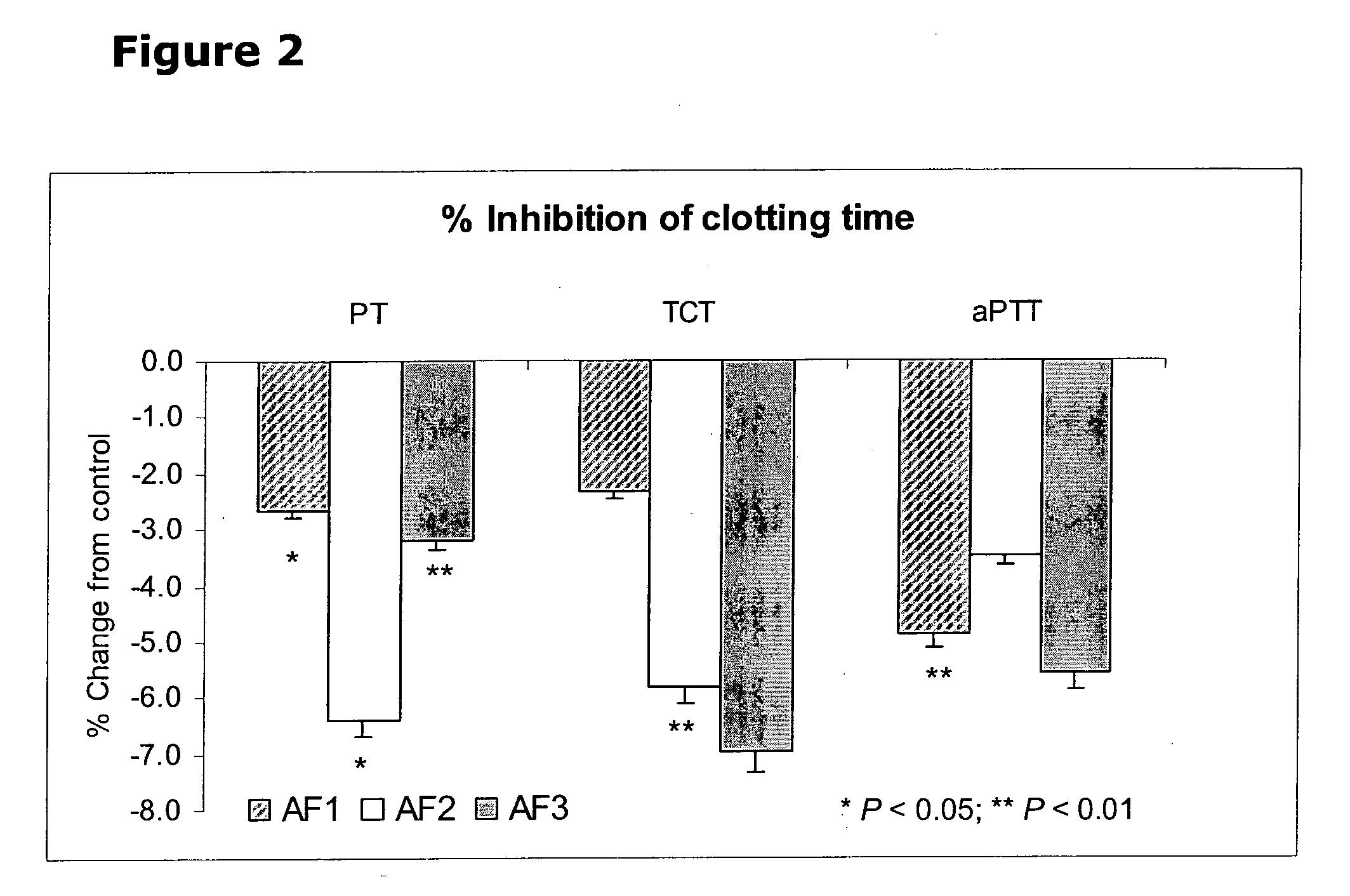

InactiveUS20120321732A1Preventing initiationShorten clotting timeBiocideAnimal repellantsVeinPhysiology

The present invention relates to tomato extracts or an active fraction thereof for use in preventing or inhibiting the initiation of venous thrombosis and fibrin clot formation in a vein.

Owner:PROVEXIS NATURAL PROD

Therapeutic uses of tomato extracts

InactiveUS20090123584A1Reduce in vitro clotting timePreventing initiationBiocideAnimal repellantsVeinPhysiology

The present invention relates to tomato extracts or an active fraction thereof for use in preventing or inhibiting the initiation of venous thrombosis and fibrin clot formation in a vein.

Owner:PROVEXIS NATURAL PROD

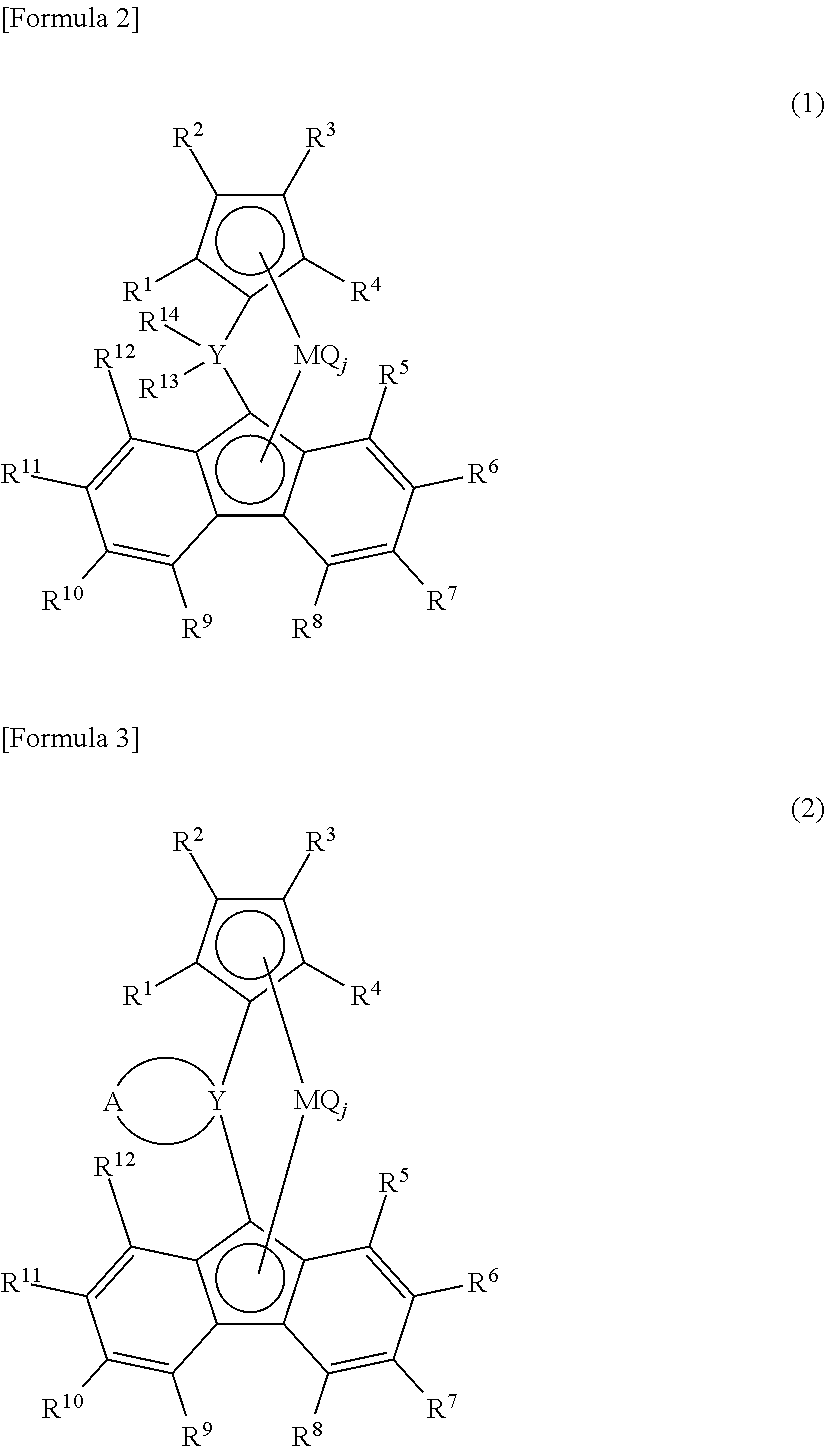

4-methyl-1-pentene polymer, resin composition containing 4-methyl-1-pentene polymer, masterbatch thereof, and formed product thereof

ActiveUS20110165416A1Excellent mold releasabilityExcellent blocking resistanceFilm/foil adhesivesSynthetic resin layered productsMasterbatchSolvent

[Object] To provide a resin composition with excellent mold releasability and blocking resistance.[Solution] A resin composition containing a 4-methyl-1-pentene polymer includes 0.01 to 10 parts by mass of a 4-methyl-1-pentene polymer (B) per 100 parts by mass of at least one resin (A) selected from the group consisting of thermoplastic resins and thermosetting resins, wherein the 4-methyl-1-pentene polymer (B) has (B1) an intrinsic viscosity [η] of 0.01 or more but less than 0.50 dl / g measured at 135° C. in a decalin solvent.

Owner:MITSUI CHEM INC

Lost-wax composition for precision casting and method for making pattern for precision casting

InactiveCN101538383ALow shrinkageHigh hardnessFoundry mouldsFoundry coresPolymer scienceEthylene Homopolymers

Disclosed is a polyethylene wax defined by the features (i) to (iv): (i) said polyethylene wax is an ethylene homopolymer or a copolymer of ethylene and an alpha-olefin of 3 to 20 carbon atoms, (ii) a ratio (Mw / Mn) of the weight-average molecular weight (Mw) to the number-average molecular weight (Mn), as measured by GPC, is in the range of 1.7 to 4.0, (iii) the softening point is not higher than 125 DEG C., and (iv) the penetration hardness is not more than 15 dmm. Also disclosed are a lost wax composition for precision casting, which comprises the polyethylene wax, and a method for forming a model for precision casting, which uses the lost wax composition for precision casting.

Owner:MITSUI CHEM INC

Thermoplastic elastomeric resin composition and a process for the preparation thereof

The invention provides a process for the preparation of a thermoplastic elastomeric resin composition comprising (a) 100 parts by weight of a block copolymer consisting of at least two polymeric blocks (A) composed of a vinyl aromatic compound and at least one polymeric block (B) composed of a conjugated diene compound, or a hydrogenated block copolymer, (b) 20 to 300 parts by weight of a non-aromatic softening agent for rubber, (c) 1 to 100 parts by weight of a peroxide-crosslinking type olefinic resin or a copolymeric rubber containing said resin, and (d) 10 to 150 parts by weight of a peroxide-decomposition type olefinic resin or a copolymer containing said resin, characterized in that the process comprises a step of heat-processing component (a), component (b), at least a part of component (c) and a part of component (d) in the presence of an organic peroxide to cause crosslinking, and a subsequent step of blending these with the remaining part of component (d) and, if any, the remaining part of component (c). The obtained composition is soft and good in rubber properties, mechanical strength and processability, and is less sticky.

Owner:RIKEN TECHNOS CORP

Pitch composition

ActiveUS8231775B2Easy to manageLess stickyWorking-up pitch/asphalt/bitumenWorking-up tarParticulatesSlurry

A process and apparatus is disclosed for converting heavy hydrocarbon feed into lighter hydrocarbon products. The heavy hydrocarbon feed is slurried with a particulate solid material to form a heavy hydrocarbon slurry and hydrocracked in a slurry hydrocracking unit to produce vacuum gas oil (VGO) and pitch. A first vacuum column separates VGO from pitch, and a second vacuum column further separates VGO from pitch. As much as 15 wt-% of VGO can be recovered by the second vacuum column and recycled to the slurry hydrocracking unit. A pitch composition is obtained which can be made into particles and transported without sticking together.

Owner:UOP LLC

Fruit breaking method and apparatus

ActiveUS20080166468A1Promote growthReduce moisture contentMilk preservationFood shapingSugarLiquid nitrogen

Methods and apparatus for producing pieces of sweetened, dried fruit. Methods as described in the present disclosure generally include supercooling sweetened, dried fruit having a moisture content between 8% and 18%, and then breaking the supercooled fruit into pieces having an appropriate size distribution. Supercooling the fruit may be accomplished by immersing or otherwise exposing the fruit to a supercooling substance such as liquid nitrogen, liquid oxygen, or solid carbon dioxide. Breaking the fruit may be accomplished, for example, by rapidly vibrating the supercooled fruit on a screen, or by passing the supercooled fruit through a cutting device such as a centrifugal slicer, among others. A system for producing pieces of sweetened, dried fruit may include apparatus for drying the fruit, infusing it with sugar or otherwise sweetening it, immersing or otherwise exposing the fruit to a supercooled substance, and / or breaking the fruit through vibration, cutting, or the like.

Owner:MEDURI FARMS

MODIFIED PROPYLENE-(a-OLEFIN) COPOLYMER, METHOD FOR PRODUCING SAME, COATING MATERIAL COMPRISING SAME, RESIN COMPOSITION FOR MOLDING USE, AND HOT-MELT COMPOSITION

The purpose of the present invention is to provide a polar-group-containing propylene-type wax having excellent properties including a low melting point. A modified propylene-(α-olefin) copolymer (A) according to the present invention is produced by grafting at least one compound selected from an unsaturated carboxylic acid, a derivative of the unsaturated carboxylic acid and an unsaturated sulfonic acid salt onto a propylene-(α-olefin) copolymer (A1) and has an acid value of 1 to 100 KOHmg / g, wherein the propylene-(α-olefin) copolymer (A1) comprises 60 to 95 mol % of a propylene-derived constituent unit (a) and 5 to 40 mol % of a constituent unit (b) derived from an α-olefin having 4 or more carbon atoms, and satisfies the specific requirements (i) to (iii).

Owner:MITSUI CHEM INC

Coated dried fruit and methods

ActiveUS8999413B2Inhibition of agglomerationReduced tendency to blockingAnimal feeding stuffFood coatingDried fruitsDried fruit

Owner:GENERAL MILLS INC

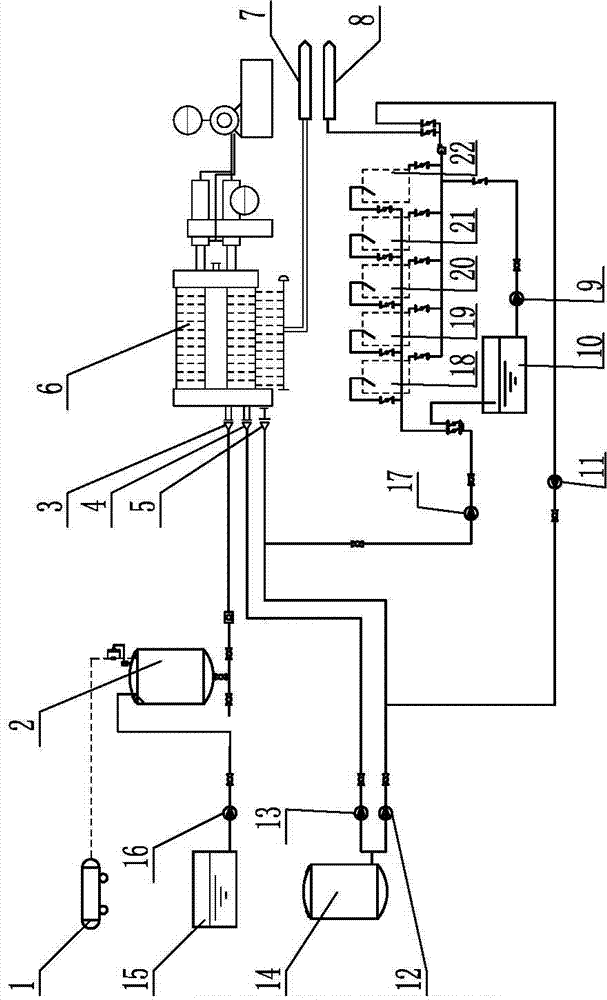

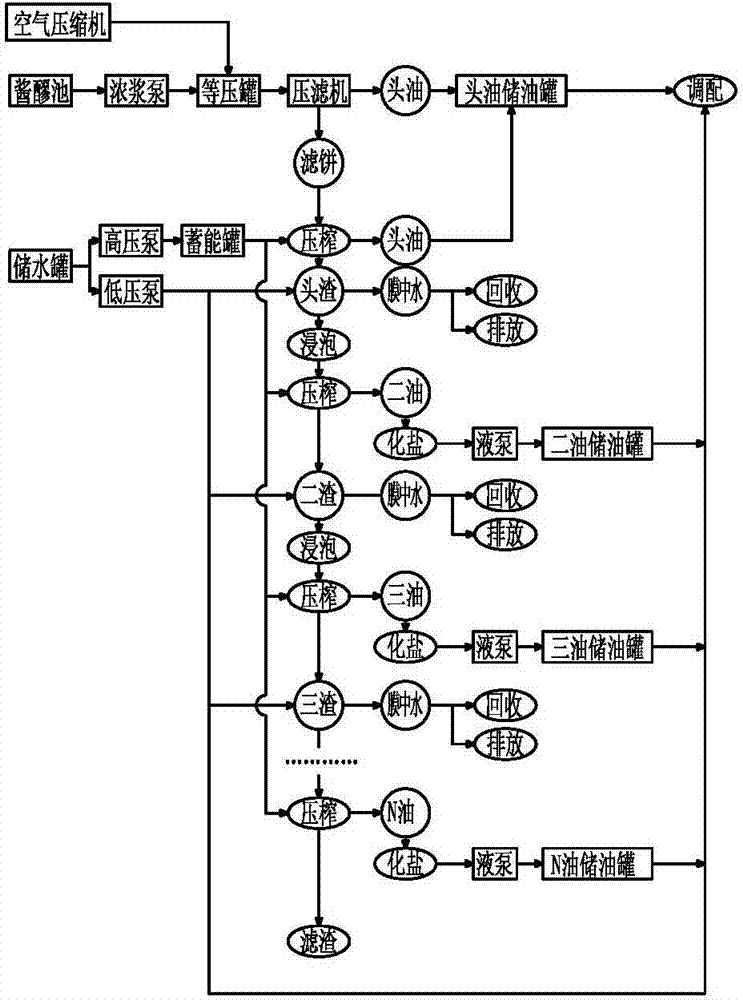

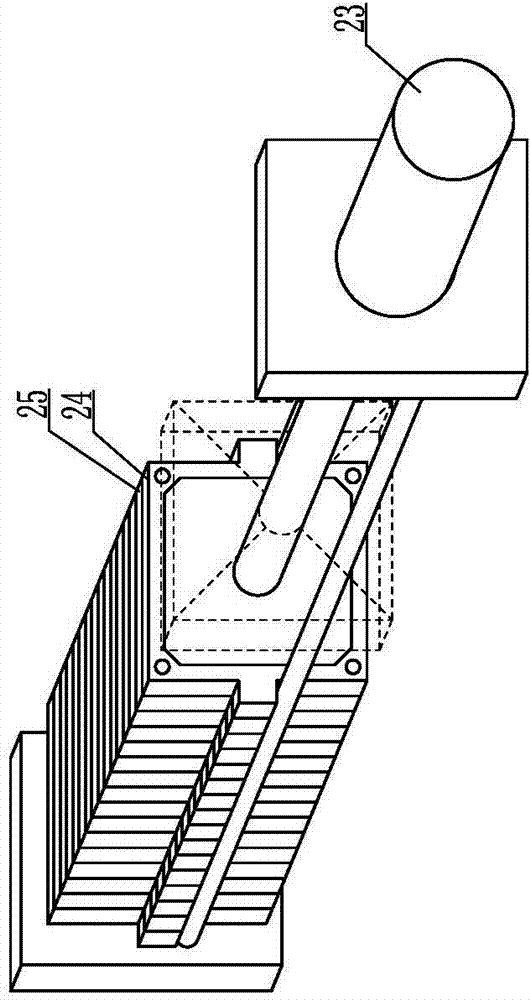

Squeezing system and squeezing process for high-salt liquid sauce

ActiveCN104757502ALess stickyReduce particle damage and other phenomenaFood preparationWater storageWater storage tank

The invention provides a squeezing system and squeezing process for a high-salt liquid sauce, belonging to the field of squeezing of sauces. The squeezing system is characterized by comprising a sauce mash squeezing system, a pneumatic system and a water-circulating pipe system, wherein the sauce mash squeezing system is connected with a feed inlet of an isobaric tank through an underflow pump, a discharge outlet of the isobaric tank is connected with a feed inlet of a membrane plate-type filter press, discharge outlets of the membrane plate-type filter press are separately connected with a salt dissolving pond and an oil storage tank, the salt dissolving pond is connected with the oil storage tank through a material pump, an air compressor of the pneumatic system is connected with the air inlet of the isobaric tank, water storage tanks of the water-circulating pipe system are separately connected with a high-pressure pump and a low-pressure pump, the high-pressure pump is connected with a membrane plate water filling port of the membrane plate-type filter press, and the low-pressure pump is connected with the discharge outlet of the membrane plate-type filter press. The squeezing system provided by the invention needs low investment; the squeezing process is excellent; high production efficiency and high crude oil removal quality are obtained; and labor intensity of workers is low.

Owner:山东玉兔食品股份有限公司

Sealing material, process for production of the material, and gasket using the material

InactiveUS20100105797A1Good durabilityLow moisture permeabilityOther chemical processesChemistryLiquid resin

A sealing material which comprises (A) an unsaturated group-containing ester-type urethane oligomer which is an energy ray-curable liquid resin and (B) a compound having at least one carbodiimide group in the molecule in an amount of 0.01 to 10 parts by mass based on 100 parts by mass of the component (A) and which is excellent in moist heat durability, can retain low moisture permeability, is excellent in adhesion to a material to be jointed and can form a highly precise extrusion shape; a process for production of a scaling material excellent in long-term storage stability; a scaling material produced by the process; a gasket using a sealing material having the above-mentioned properties. A cured product of the sealing material has a reduced surface adhesion property, enables the easy removal of an HDD cover, and consequently is improved in durability against an external force produced at the time of reuse.

Owner:BRIDGESTONE CORP

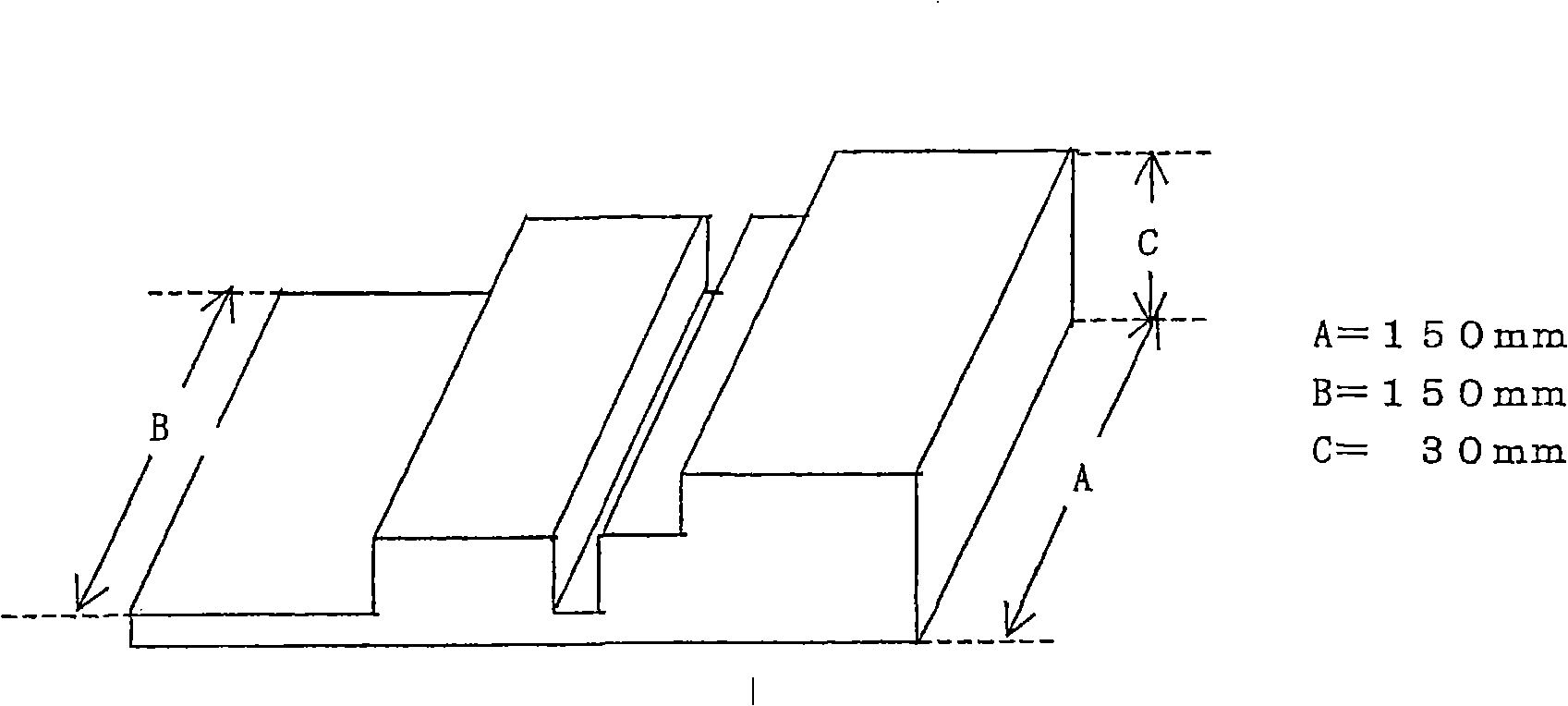

Mixed-fiber nonwoven fabric laminate

InactiveUS20100093244A1Excellent strechability and flexibility and touchLess stickyPersonal careLayered productsPolymer chemistryNonwoven fabric

An object of the present invention is to develop a mixed-fiber nonwoven fabric laminate being excellent in strechability, flexibility, touch feeling, and formability and being less sticky.The mixed-fiber nonwoven fabric laminate of the present invention comprising at least two mixed-fiber spunbonded nonwoven fabric layers whose fiber mixing ratios of long fibers of a thermoplastic elastomer (A) and long fibers of a thermoplastic resin (B) are different from each other can be suitably used not only in sanitary materials but in medical materials, hygienic materials, industrial materials, and so on. Specific examples of the sanitary materials include absorptive articles such as disposable diapers and sanitary napkins. In a spreading-type disposable diaper or a pants-type disposable diaper, the laminate can be suitably used in portions such as a top sheet, a back sheet, a waistband (extension tape, side flap), a fastening tape, a three-dimensional gather, leg cuffs, and side panels of the pants-type disposable diaper.

Owner:MITSUI CHEM INC

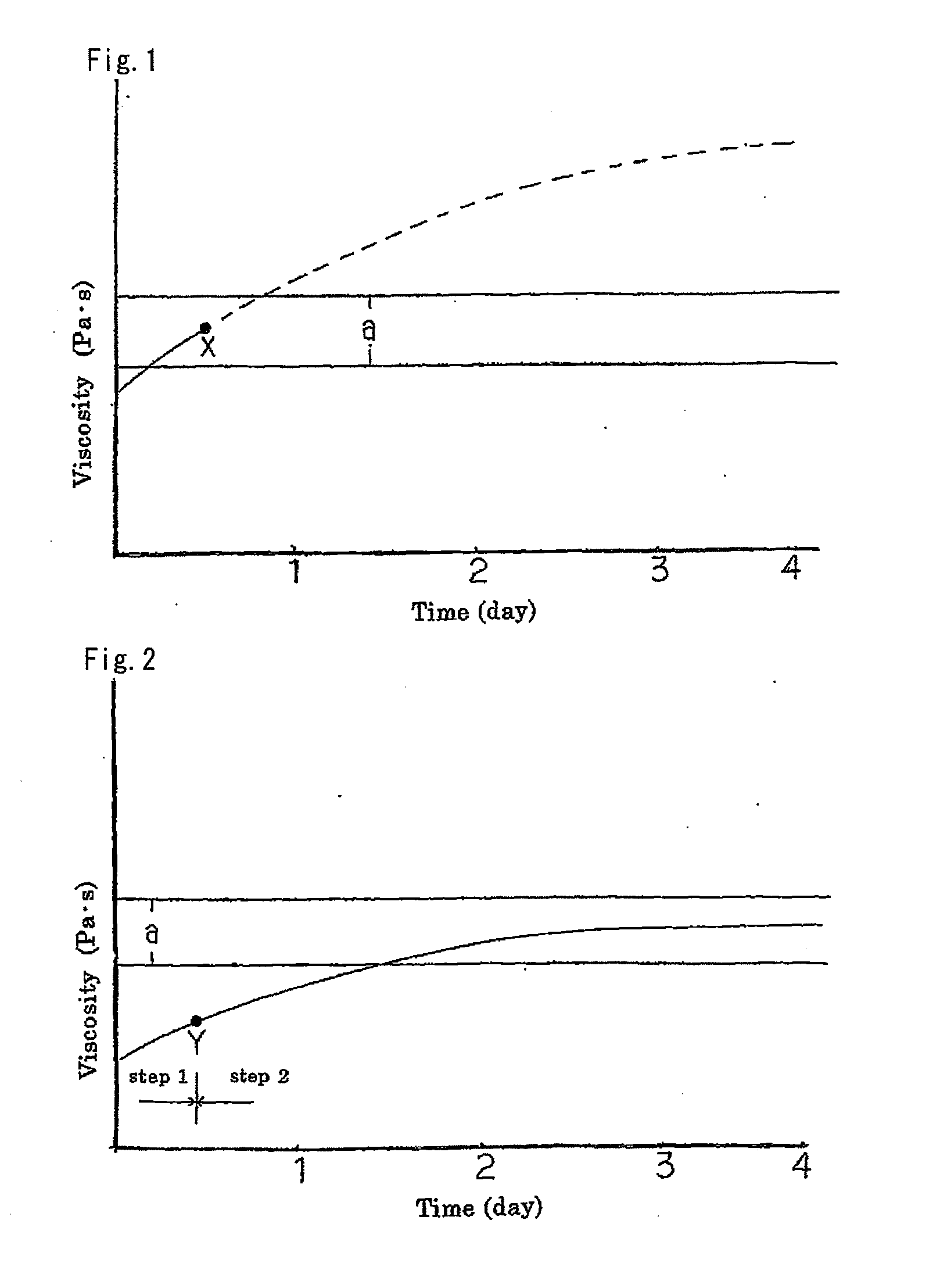

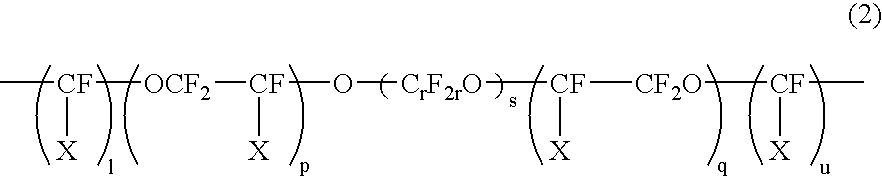

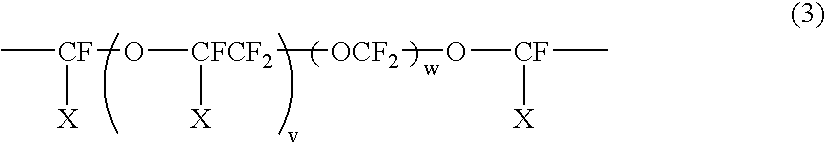

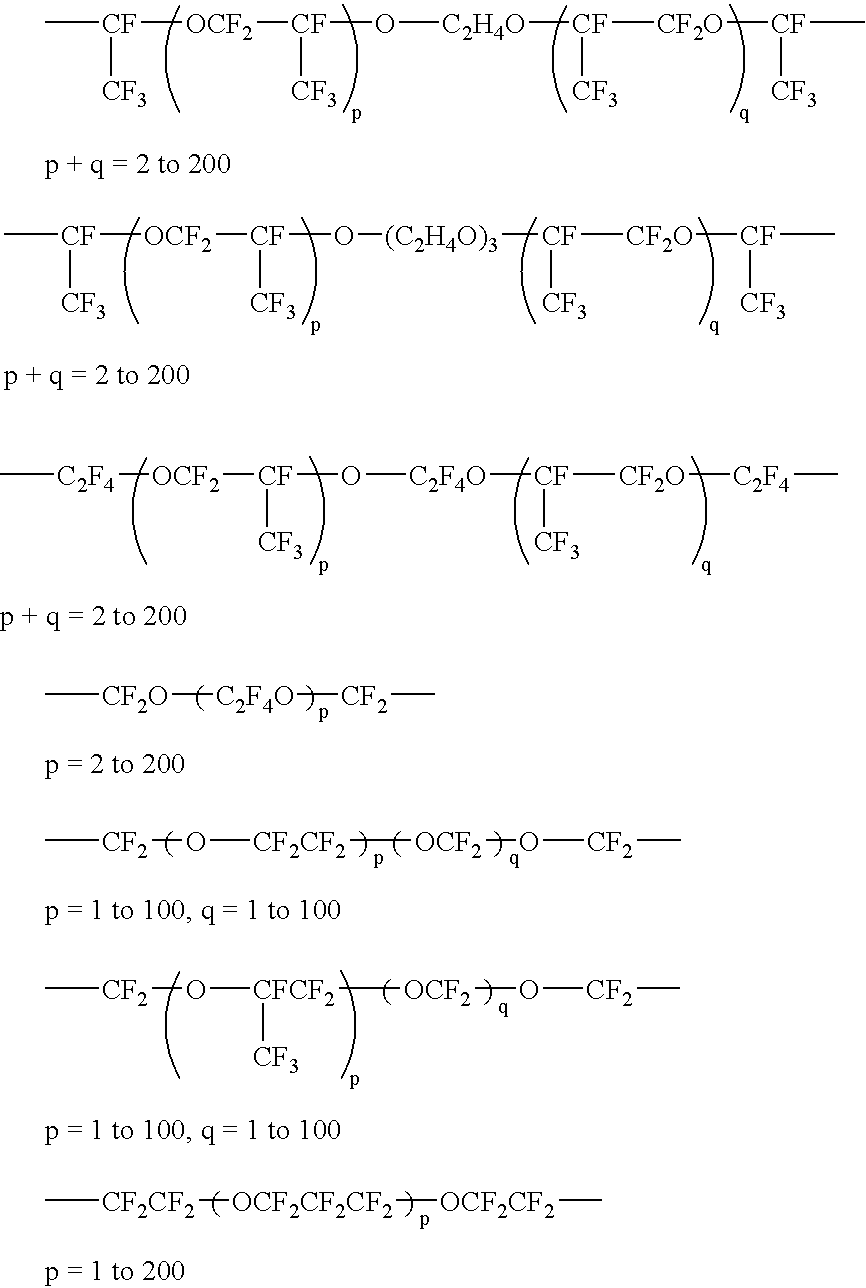

Fluororubber compositions and articles thereof

ActiveUS7087673B2Good chemical resistanceImprove heat resistanceEngine sealsFibre treatmentOxidePolymer

A crosslinkable fluororubber composition comprising (A) a polymer of the formula: Z-(Rf-Q)n—Rf-Z wherein n is an integer of at least 1, Rf is a divalent perfluoroalkylene or perfluorooxyalkylene radical, Q is a divalent organic radical, and Z is a monovalent organic radical, having a viscosity of at least 1,000 Pa·s at 25° C., (B) a reinforcing filler, and (C) a peroxide crosslinking agent is effectively roll milled and experiences minimal changes of viscosity after milling. Molded parts can be produced on a mass scale.

Owner:SHIN ETSU CHEM IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com