Multilayer structure varying in three-dimentional structure by absorbing water and textile product

A composite fabric and water absorption technology, which is applied in the direction of layered products, clothing, underwear, etc., can solve the problem that composite fabric materials are rarely raised.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

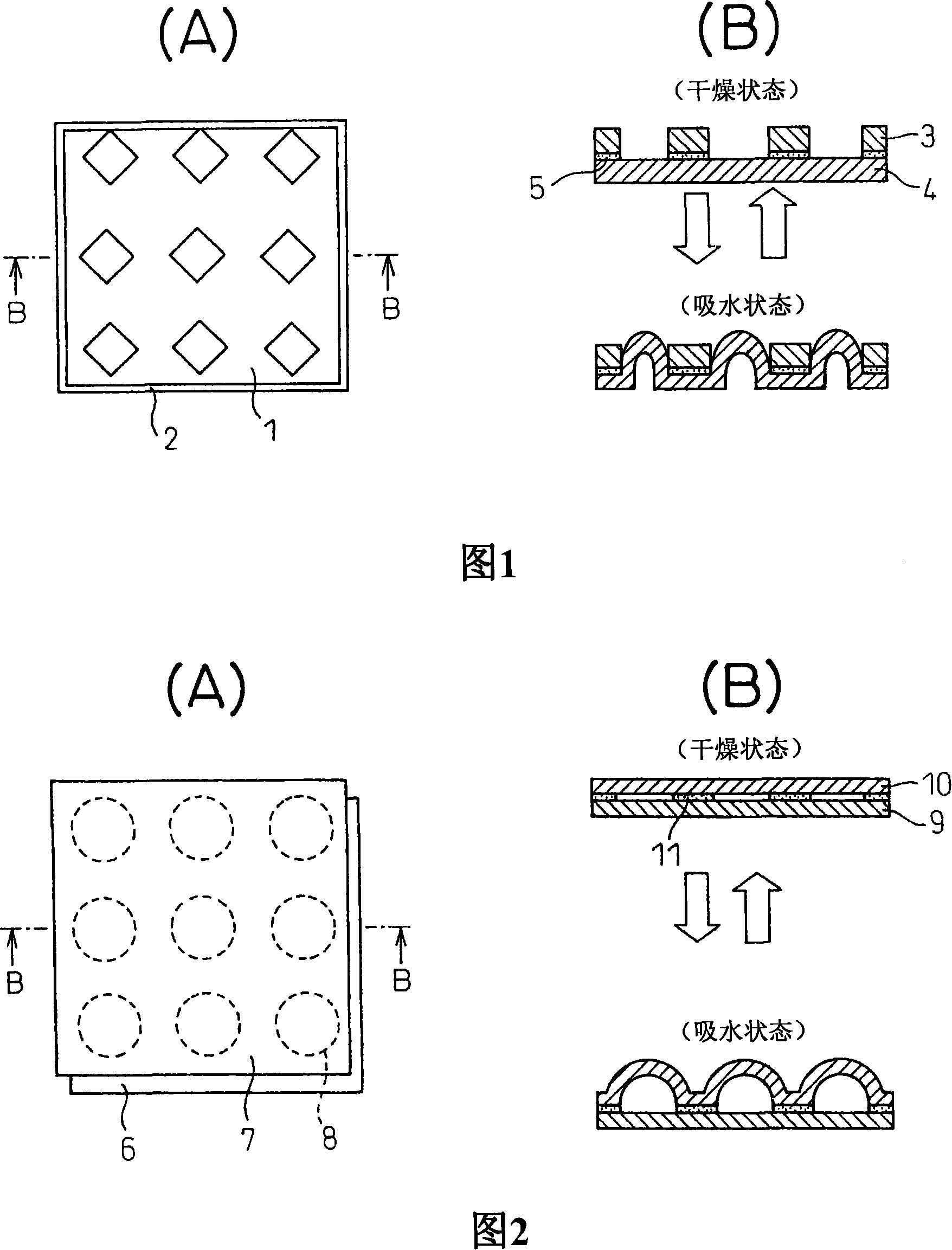

Embodiment 1

[0147] A polyether ester composed of 49.8 parts by weight of polybutylene terephthalate as a hard segment and 50.2 parts by weight of polyethylene glycol with a number average molecular weight of 4000 as a soft segment was melted at 230° C. The spinneret was extruded with a discharge rate of 3.05 g / min, and the polymer was pulled out at 705 m / min by 2 godet rolls, and wound at 750 m / min (winding stretch 1.06) to obtain 44 decitex / 1 silk elastic water absorption / high self-extensibility thread. The water-absorbing self-extensible yarn had a swelling rate in the fiber axis direction of 10% and a boiling water shrinkage rate of 8% when absorbing water.

[0148] In addition, a common polyethylene terephthalate multifilament (84 dtex / 24 filaments) with a boiling water shrinkage rate of 10% and a water expansion rate of 1% or less was prepared as a low water absorption / self-extensibility of silk strips.

[0149] Then, using a 28-gauge single circular knitting machine, while pul...

Embodiment 2

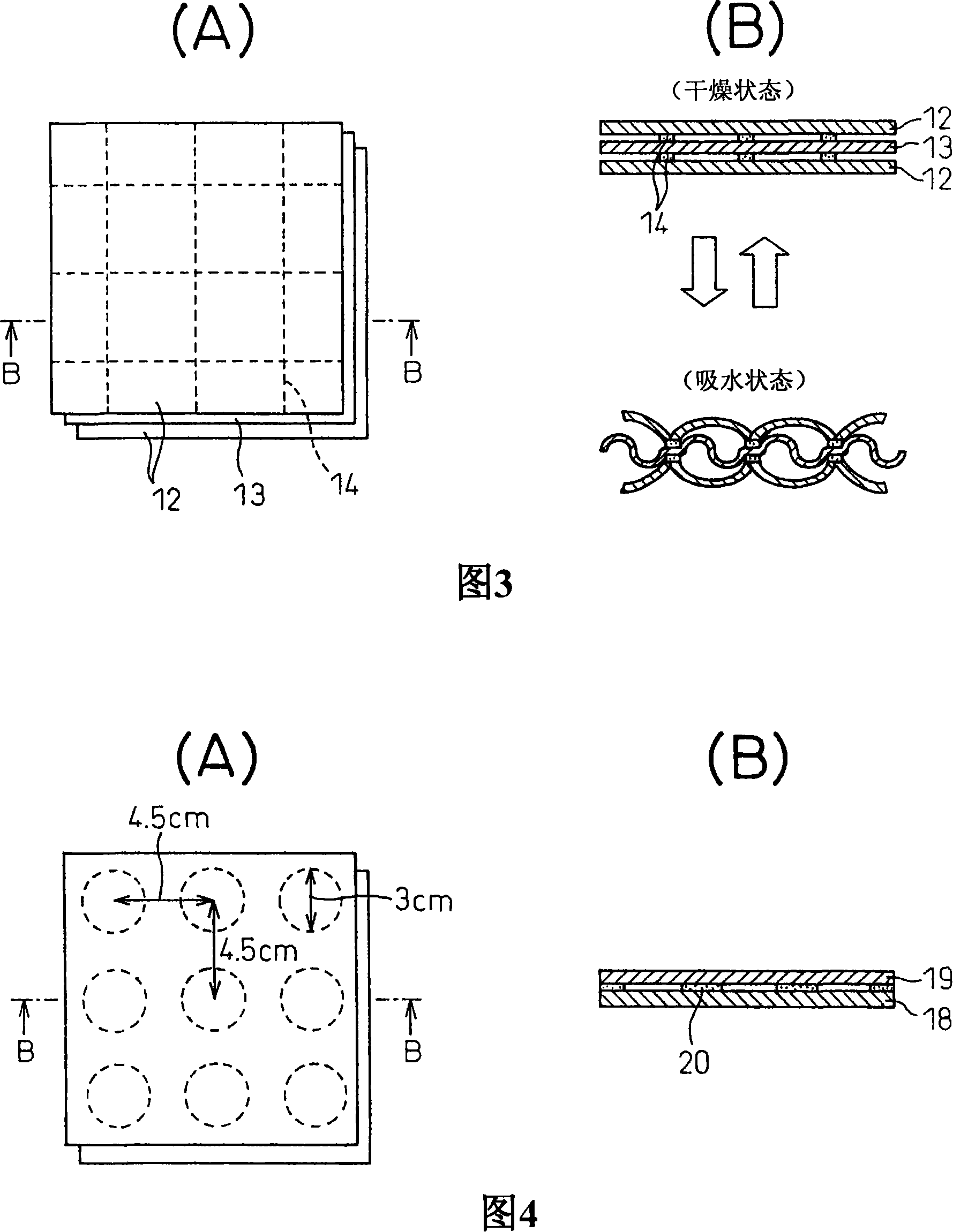

[0157] With a 36-gauge Tricot knitting machine, the polyester monofilament (22 dtex 1 filament) is fully threaded in the rear reed, and the same thread as the rear reed is fully threaded in the middle reed, at the rear: 10-12, before: In the 12-10 double-bar warp flat weave, under the knitting condition that the number of courses on the machine is 100 courses / inch, try to produce knitted fabrics. The knitted fabric is dyed under the processing conditions of the conventional method to complete the processing. The resulting knitted fabric had a dimensional change rate of 0.0% vertically and 0.0% horizontally and a thickness change rate of 0.1% or less during drying and water absorption, and the knitted fabric was used as an area change limiting member. On the other hand, the jersey fabric used as the water-absorbent knitted fabric in Example 1 was used as the water-absorbent knitted fabric.

[0158] Then, the above-mentioned area change limiting member 18 and the water-absorben...

Embodiment 3

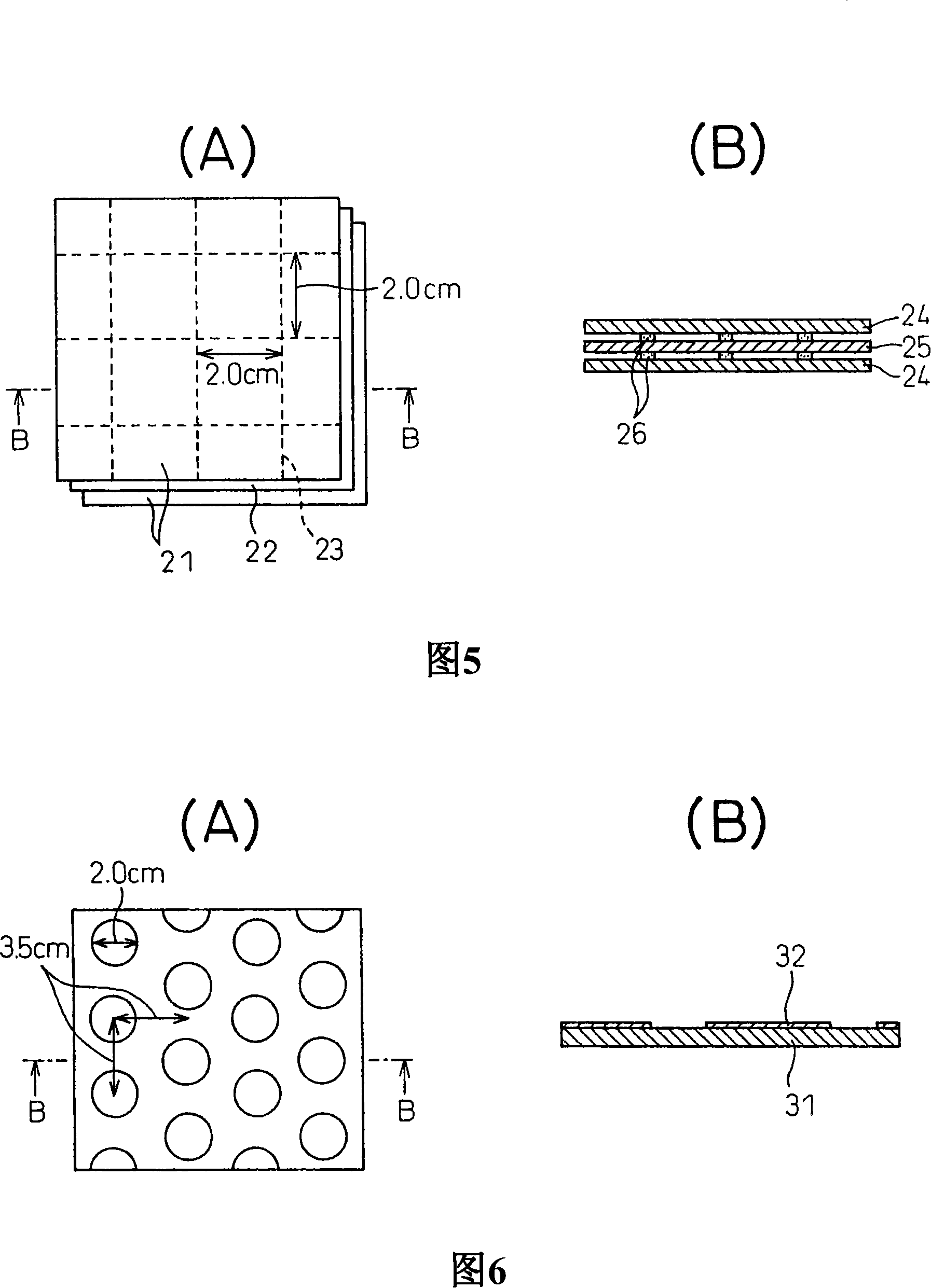

[0161] Using the water-absorbent knitted fabric and the area change limiting member used in Example 2, the water-absorbent knitted fabric 22, 25 is bonded in three layers with the adhesive part 26 in the middle layer to form the area change limiting member 21, 24. In this case, the three-layer structure of the reversed two-layer structure was bonded in a square pattern with a grid width of 3 mm and a grid size of 2 cm square (see FIG. 5 ).

[0162] The evaluation results of the obtained three-layer structure are shown in Table 1. By absorbing water, the three-layer non-adhesive part floated three-dimensionally (the part in the grid), and as a result, the thickness changed by 120%, and the air permeability was also improved by 50%. A composite fabric material that realizes the object of the present invention, that is, a three-dimensional structural change by absorbing water, is a satisfactory result.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com