Squeezing system and squeezing process for high-salt liquid sauce

A technology of high-salt dilute soy sauce and pneumatic system, applied in application, food preparation, food science, etc., can solve the problems of low juice yield, high production cost, high labor intensity, etc., achieve streamlined production process, high yield, Squeeze smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Combine below Attached picture The present invention is further described in detail with specific embodiments.

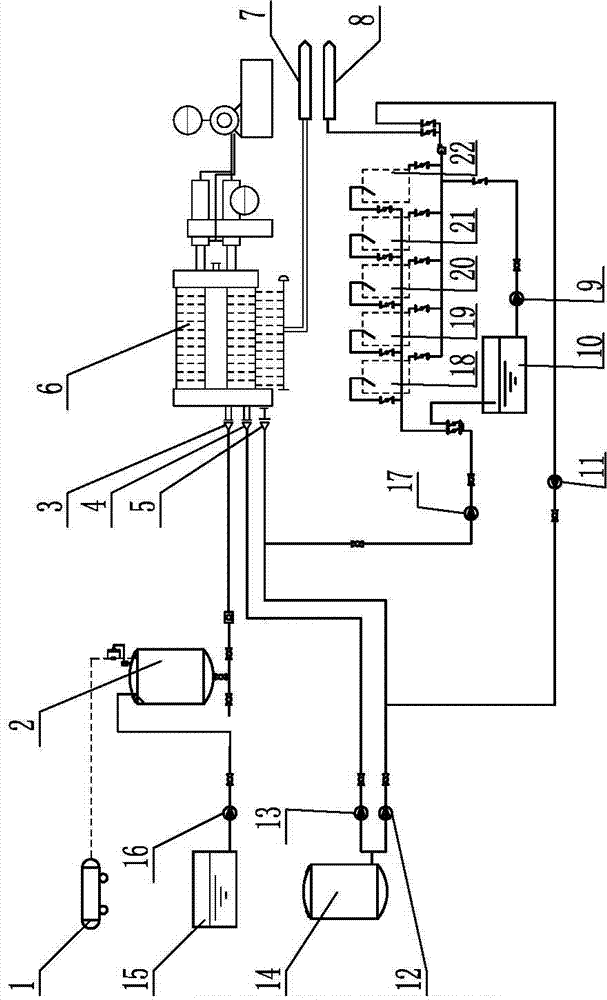

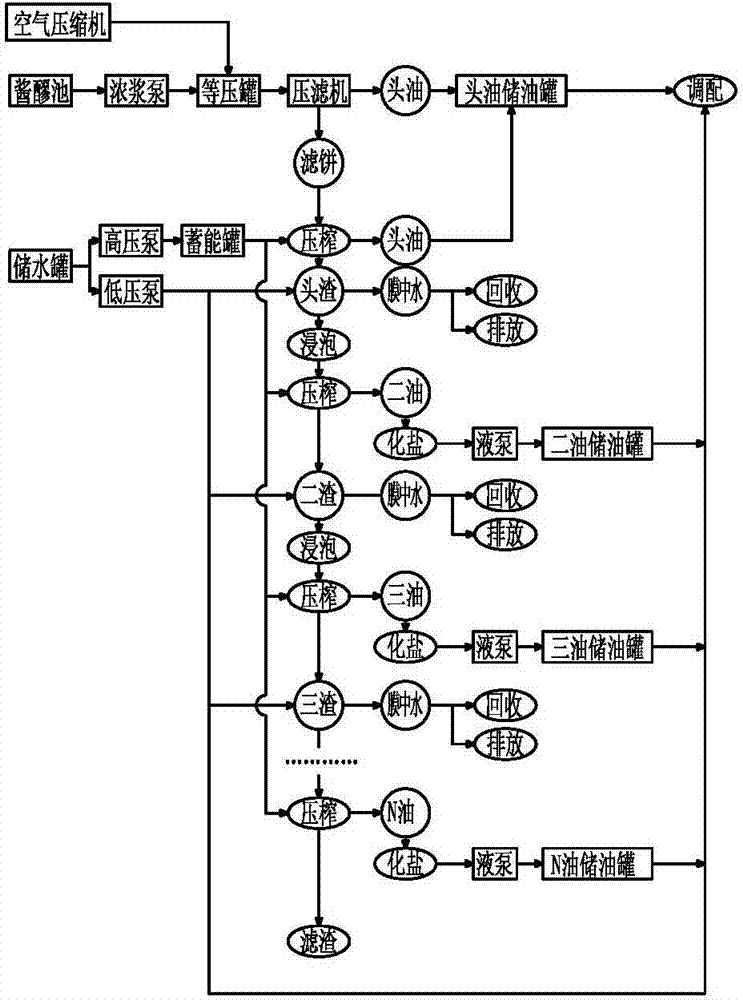

[0039] Such as figure 1 As shown, the high-salt dilute soy sauce press system of the present invention includes a moromi press system, a pneumatic system and a water circulation pipe system.

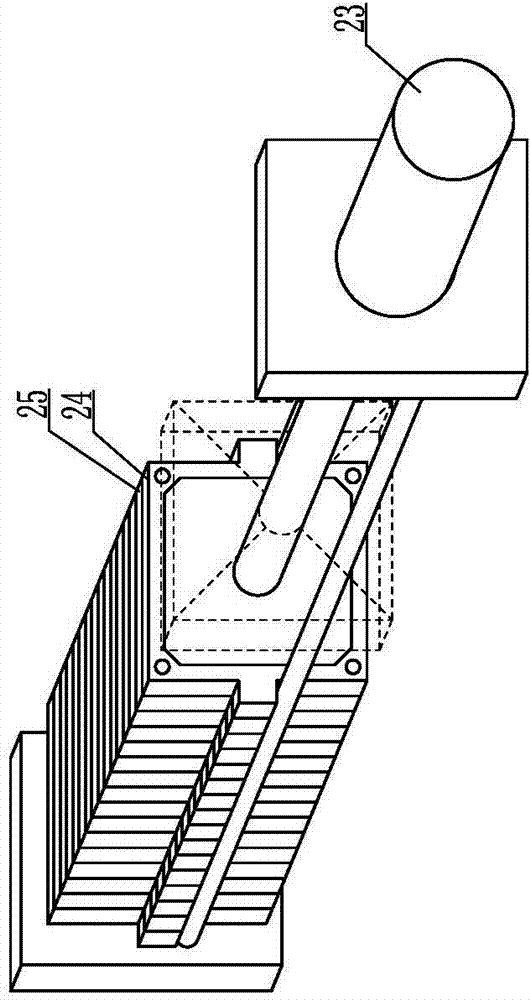

[0040]The mash pressing system includes a mash tank, a thick slurry pump, an equal pressure tank 2, a diaphragm plate type plate and frame filter press 6, a salt tank and an oil storage tank. The isobaric tank 2 includes a feed inlet, a feed outlet and an air inlet. The diaphragm plate filter press includes a feed port 3 , a discharge port 5 and a diaphragm plate water injection port 4 . The sauce mash tank is connected to the feed port of the isobaric tank 2 through the thick slurry pump, the discharge port of the isobaric tank 2 is connected to the feed port 3 of the diaphragm plate type plate and frame filter press 6, and the discharge port 5 of the diaphragm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com