Novel composite fire retardant module and preparation method thereof

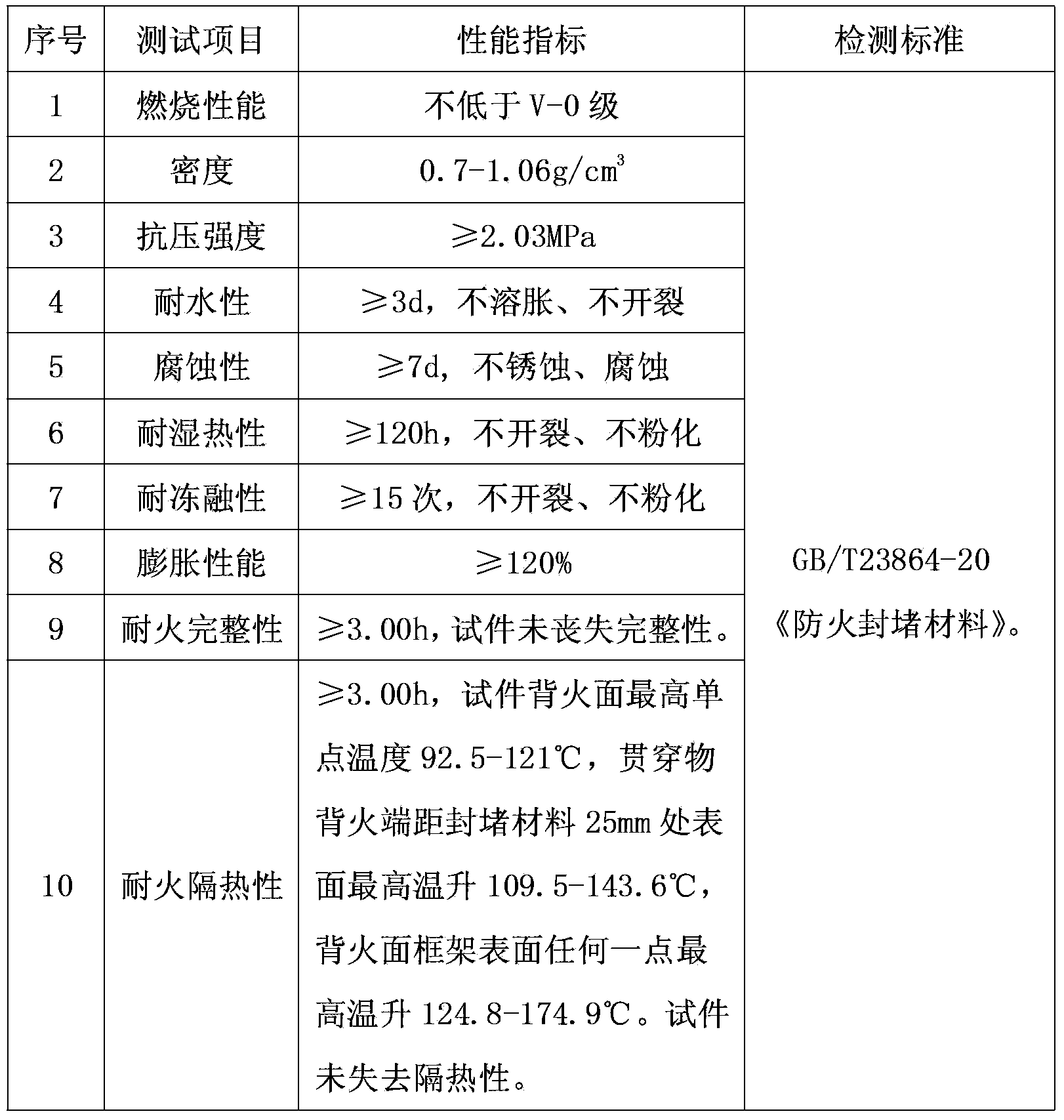

A new type of fire retardant technology, applied in the field of new composite fire retardant module and its preparation, fire retardant module and its preparation, can solve the problems of poor water resistance, poor fire resistance, waste of energy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

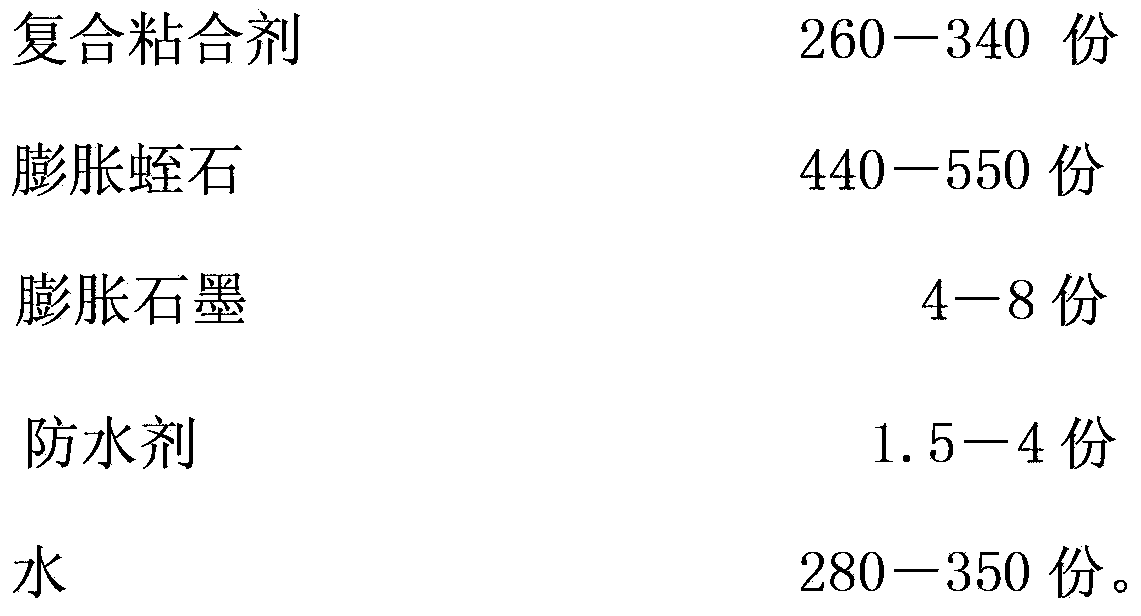

Method used

Image

Examples

Embodiment 1

[0013] A method for preparing a new type of composite fire retardant module, the preparation steps are as follows: (1) Firstly prepare a composite adhesive, 2 parts of latex powder, 2 parts of polyvinyl alcohol; 13 parts of kaolin, 2 parts of wet-process mica powder, P· Add 15 parts of O42.5 cement into a V-type forced mixer and stir evenly, the stirring speed is 8r / min, and the stirring time is 10min; (2) Add 300 parts of composite adhesive, 520 parts of expanded vermiculite and 6 parts of expanded graphite 3 parts, 3 parts of waterproofing agent and 330 parts of water are added to the high-efficiency plow mixer and stirred evenly, the stirring speed is 45r / min, and the stirring time is 10min; In the mould, perform hydraulic compression molding at a pressure of 20 MPa, hold the pressure for 8 seconds, and then demould and dry at room temperature for 7 days to obtain the composite fire retardant module.

Embodiment 2

[0015] A method for preparing a new type of composite fire-retardant module. The preparation steps are as follows: (1) First prepare a composite adhesive, 4 parts of polyvinyl alcohol; 14 parts of kaolin, 2 parts of bentonite, 2.5 parts of wet-process mica powder, P·O42 .5 Add 11 parts of cement to a V-type forced mixer and stir evenly, the stirring speed is 9r / min, and the stirring time is 10min; (2) Add 260 parts of composite adhesive, 550 parts of expanded vermiculite, and 8 parts of expanded graphite , 1.5 parts of waterproofing agent and 280 parts of water are added to the high-efficiency coulter mixer and stirred evenly, the stirring speed is 50r / min, and the stirring time is 10min; (3) Add the well-stirred mixture into the mold which is pre-coated with universal loose rust lubricant In the process, hydraulic press molding was carried out at a pressure of 20 MPa, the pressure was kept for 8 seconds, and then demolded and dried at room temperature for 7 days to obtain the ...

Embodiment 3

[0017] A method for preparing a new type of composite fire retardant module, the preparation steps are as follows: (1) Firstly prepare a composite adhesive, 1.5 parts of latex powder, 3 parts of polyvinyl alcohol; 12 parts of kaolin, 3 parts of bentonite, P·O42.5 Add 13 parts of cement into a V-type forced mixer and stir evenly, the stirring speed is 10r / min, and the stirring time is 10min; (2) Add 280 parts of composite adhesive, 470 parts of expanded vermiculite, 5 parts of expanded graphite, waterproof Add 2 parts of agent and 300 parts of water into the high-efficiency coulter mixer and stir evenly, the stirring speed is 55r / min, and the stirring time is 10min; (3) Add the well-stirred mixture into the mold pre-coated with universal loose rust lubricant, Perform hydraulic press molding at a pressure of 20 MPa, hold the pressure for 8 seconds, and then demould and dry at room temperature for 7 days to obtain the composite fire retardant module.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com