Method for preventing fireproof material of rotary kiln from falling down

A refractory material and rotary kiln technology, which is applied in the field of chain grate rotary kiln, can solve the problems of refractory material damage, peeling of the working layer, easy damage of refractory material, etc., and achieve the effect of eliminating thermal stress, reducing production cost and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

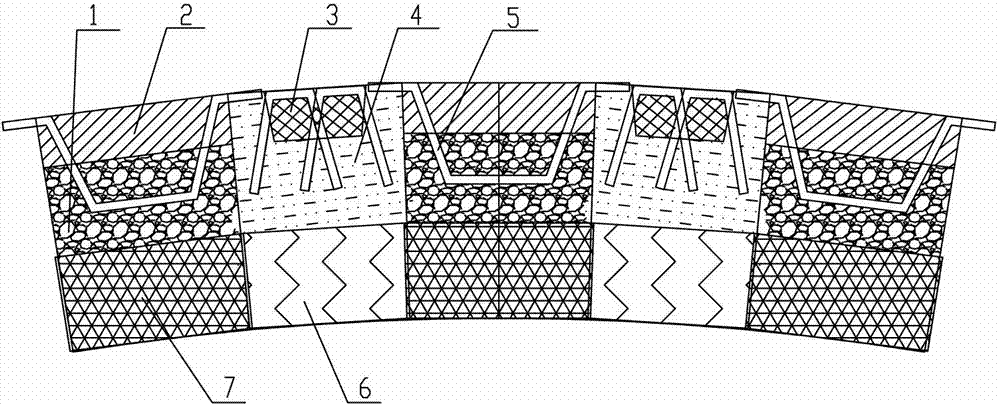

[0019] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

[0020] like figure 1 As shown, the method for preventing the refractory material of the rotary kiln from falling off of the present invention comprises the following steps:

[0021] The annular refractory protective layer composed of the prefabricated brick belt, the pouring belt 4 and the kiln body anchoring nail 5 alternately arranged with the prefabricated brick belt, the inner surface of the annular refractory protective layer is the low temperature zone on the kiln head side and the kiln tail side, The middle is the high temperature zone, the prefabricated brick belt is made of prefabricated bricks, the prefabricated bricks and the pouring belt are close to the kiln body anchoring nail side is the non-working area, and the inner side of the rotary kiln is the working area, which is characterized in that Specific steps are as follows:

[0022] 1) Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com